Laser Metal Cutting Decoded: From Wattage Selection To ROI Mastery

What Makes Laser Metal Cutting a Manufacturing Game-Changer

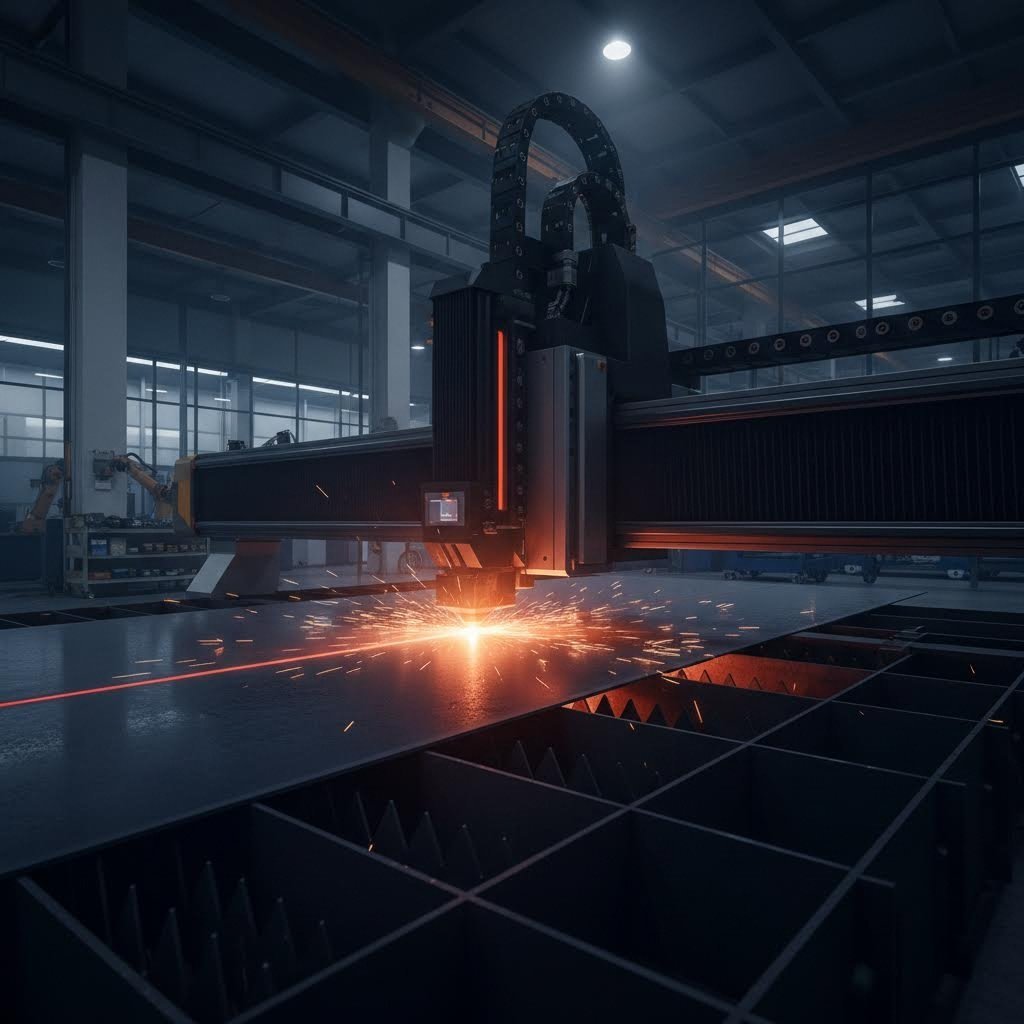

Imagine directing a beam of light so powerful it can slice through steel like a hot knife through butter. That's essentially what laser metal cutting accomplishes—transforming raw sheets of metal into precision components with tolerances as tight as ±0.1mm. This thermal separation process uses a highly focused beam of coherent light to melt, burn, or vaporize metal along a predetermined path, creating cuts that traditional methods simply cannot match.

How Focused Light Transforms Raw Metal

At its core, metal laser cutting relies on a fascinating principle: Light Amplification by Stimulated Emission of Radiation. When this concentrated energy beam strikes a metal surface, three critical stages unfold in rapid succession. First, the material absorbs the laser's photonic energy. Next, this absorbed energy converts to heat, pushing temperatures past the metal's melting or vaporization point. Finally, the molten or vaporized material gets expelled from the cut zone by high-pressure assist gases.

The magic happens at the focal point. A laser metal cutting machine concentrates its beam to an intense spot typically measuring just 0.1-0.3mm in diameter. This creates power densities exceeding 1 MW/cm²—enough to transform solid metal into liquid or vapor within milliseconds. Whether you're working on laser cutting of metal sheets for automotive panels or crafting intricate aerospace brackets, this precision remains remarkably consistent.

The Science Behind Precision Metal Fabrication

What makes a metal cutting laser truly revolutionary isn't just raw power—it's control. Modern systems combine fiber optics or mirrors to guide the beam, focusing lenses to concentrate energy, and CNC motion systems that follow digital design paths with micron-level accuracy. The result? A cutter machine metal fabricators trust for everything from prototypes to production runs numbering in the thousands.

Laser cutting represents the elegant application of fundamental physics to industrial manufacturing—transforming light into precise, controllable thermal energy to shape our material world with unprecedented accuracy.

This technology has revolutionized manufacturing across industries because it delivers what others cannot: non-contact cutting that applies zero mechanical force to materials, cutting speeds reaching up to 100m/min on thin sheets, and smooth edges that often eliminate secondary processing entirely. From hobbyists crafting custom signage to industrial facilities producing medical implants and electronic components, this precision-first approach continues reshaping what's possible in metal fabrication.

Fiber Laser vs CO2 Technology for Metal Applications

So you understand how laser metal cutting works—but which laser type should power your operations? This question trips up countless buyers because both fiber lasers and CO2 laser cutting machines have passionate advocates. The truth? Each technology excels in specific scenarios, and understanding these differences can save you thousands in operating costs while maximizing your cutting quality.

Fiber Lasers and Their Metal-Cutting Dominance

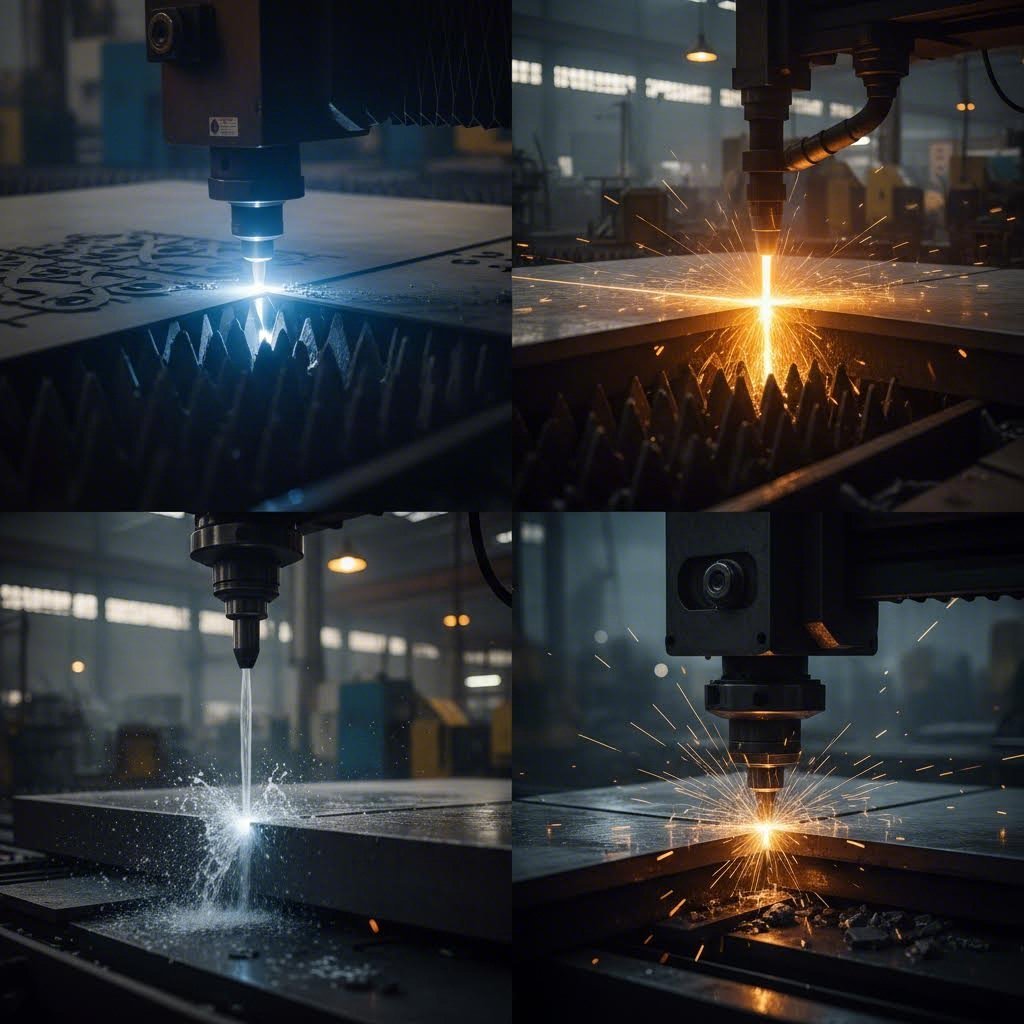

Fiber laser cutting has transformed the metalworking industry in just 15 years, rapidly overtaking CO2 systems for most metal applications. Here's why: a fiber laser cutting machine generates its beam through optical fibers doped with rare-earth elements, producing light at a wavelength of 1.064 micrometers. This shorter wavelength gets absorbed more efficiently by metals, translating directly into faster cuts and lower energy consumption.

When you're laser cutting steel, aluminum, or stainless steel under 10mm thick, fiber technology delivers unmatched performance. The focused beam creates a spot size as small as 0.1mm, enabling cutting speeds up to 20 meters per minute on thin sheets. For reflective materials like brass and copper—notorious for causing problems with other laser types—a fiber laser engraver for metal handles them effortlessly without the back-reflection issues that can damage CO2 systems.

The efficiency numbers tell a compelling story. Fiber lasers convert approximately 35% of electrical energy into laser light, compared to just 10-20% for CO2 alternatives. This means a 2kW fibre laser can match the cutting performance of a higher-powered CO2 unit while consuming significantly less electricity. Add in the 100,000-hour lifespan of fiber laser sources versus 20,000-30,000 hours for CO2 tubes, and the long-term cost advantages become substantial.

Where CO2 Lasers Still Excel

Don't dismiss machine laser CO2 technology entirely—it maintains clear advantages in specific applications. Operating at a wavelength of 10.6 micrometers, CO2 lasers interact differently with materials, producing smoother edge finishes on thicker metals where edge quality matters more than speed.

CO2 systems truly shine when cutting non-metallic materials alongside metals. If your shop processes wood, acrylic, textiles, or plastics in addition to steel, a CO2 laser cutting machine offers versatility that fiber simply cannot match. The longer wavelength gets absorbed efficiently by organic materials, creating clean cuts without charring or excessive heat-affected zones.

For metal thicknesses exceeding 20mm, CO2 lasers often deliver superior results. The gas-assisted cutting process distributes heat more evenly through thick sections, reducing the likelihood of rough edges or incomplete penetration that can plague fiber systems pushing their thickness limits.

| Comparison Factor | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1.064 micrometers | 10.6 micrometers |

| Optimal Metal Types | Steel, stainless steel, aluminum, brass, copper (including reflective metals) | Steel, stainless steel; struggles with reflective metals |

| Thickness Capability | Up to 25mm (optimal under 10mm) | Up to 40mm+ (excels on thick materials) |

| Energy Efficiency | ~35% conversion rate | ~10-20% conversion rate |

| Operating Costs | Lower electricity consumption, minimal consumables | Higher power requirements, gas consumption costs |

| Maintenance Requirements | Minimal—no optical alignment, sealed components | Regular mirror alignment, tube replacement every 20,000-30,000 hours |

| Cutting Speed (thin materials) | Up to 20 meters/minute | Significantly slower on metals |

| Lifespan | Up to 100,000 hours | 20,000-30,000 hours |

Metal-Specific Performance Breakdown

Choosing between these technologies becomes clearer when you examine performance on specific metals:

- Mild Steel: Fiber lasers cut thin mild steel at blistering speeds with clean edges. CO2 handles thicker sections (15mm+) with better edge quality but slower processing.

- Stainless Steel: Fiber laser cutting produces burr-free finishes up to 10mm thickness. Both technologies perform well, but fiber wins on speed and operating cost.

- Aluminum: Fiber dominates here—the shorter wavelength handles aluminum's reflectivity without beam damage. CO2 systems require specialized coatings and careful parameter tuning.

- Brass and Copper: Only fiber lasers safely cut these highly reflective materials. CO2 systems risk back-reflection that can destroy internal components.

When should you choose each? Fiber laser cutting makes sense when processing primarily metals under 15mm, when cutting reflective materials, when electricity costs matter, or when high-volume production demands maximum speed. CO2 remains the better choice for mixed-material shops, thick metal cutting above 20mm, or applications where edge smoothness on organics matters more than processing speed.

Understanding these distinctions positions you to select equipment that matches your actual production needs—but power requirements add another critical dimension to this decision.

Power and Wattage Requirements for Different Metals

You've selected your laser type—now comes the question that makes or breaks your cutting results: How much power do you actually need? Getting wattage wrong means either underpowered cuts that leave rough edges and dross, or overspending on capacity you'll never use. A laser cutting machine for metal performs optimally only when power matches your material requirements precisely.

Power Requirements by Metal Type and Thickness

Think of laser wattage like engine horsepower—more power enables faster speeds and thicker material handling, but efficiency matters just as much as raw capability. According to industry research, the relationship between laser power and cutting thickness follows predictable patterns, though material properties create important variations.

The fundamental equation is straightforward: higher wattage equals thicker cutting capacity and faster processing speeds. A fiber laser machine rated at 1.5kW can slice through 6mm mild steel efficiently, while a 6kW industrial laser cutting machine handles sections up to 25mm. But here's what most guides miss—optimal performance occurs well within maximum capacity, not at the limits.

Material reflectivity and thermal conductivity dramatically affect power requirements. Aluminum and copper demand higher wattage relative to their thickness because they reflect significant laser energy and conduct heat away from the cut zone rapidly. A laser cutting machine aluminum applications require typically needs 30-50% more power than steel of equivalent thickness.

| Metal Type | Thickness Range | Minimum Wattage | Optimal Wattage | Expected Cutting Speed | Tolerance Achievable |

|---|---|---|---|---|---|

| Mild Steel | 1-6mm | 1.5kW | 2-3kW | 8-20 m/min | ±0.1mm |

| Mild Steel | 6-12mm | 3kW | 4-6kW | 2-8 m/min | ±0.15mm |

| Mild Steel | 12-25mm | 4kW | 6kW | 0.5-2 m/min | ±0.2mm |

| Stainless Steel | 1-6mm | 1.5kW | 2-4kW | 6-15 m/min | ±0.1mm |

| Stainless Steel | 6-12mm | 3kW | 4-6kW | 1.5-6 m/min | ±0.15mm |

| Stainless Steel | 12-20mm | 4kW | 6kW | 0.3-1.5 m/min | ±0.2mm |

| Aluminum | 1-4mm | 1.5kW | 2-3kW | 5-12 m/min | ±0.1mm |

| Aluminum | 4-8mm | 2kW | 3-4kW | 2-5 m/min | ±0.15mm |

| Aluminum | 8-12mm | 3kW | 4-6kW | 0.8-2 m/min | ±0.2mm |

| Brass | 1-4mm | 1.5kW | 2-3kW | 4-10 m/min | ±0.1mm |

| Brass | 4-8mm | 2kW | 3-4kW | 1-4 m/min | ±0.15mm |

| Copper | 1-3mm | 1.5kW | 2-3kW | 3-8 m/min | ±0.1mm |

| Copper | 3-6mm | 2kW | 3-4kW | 0.8-3 m/min | ±0.15mm |

Matching Laser Wattage to Your Cutting Needs

Sounds complex? Here's the practical approach: identify your thickest regular cutting requirement, then select a metal cutting machine with optimal—not minimum—wattage for that thickness. Operating at 70-80% of maximum capacity extends consumable life, improves edge quality, and provides headroom for occasional thicker jobs.

A laser cutter for steel applications illustrates this perfectly. While a 1.5kW system can technically cut 6mm mild steel, you'll achieve faster speeds, cleaner edges, and less dross with a 3kW unit running at moderate power settings. The recommended power range of 1.5-6kW for mild steel up to 25mm thickness gives you flexibility to scale operations without equipment replacement.

For precision applications like laser cut aluminum components or decorative brass work, consider how assist gases interact with your power selection. Nitrogen cutting produces oxide-free edges essential for welding or painting but requires higher power settings than oxygen-assisted cuts. A laser marking machine for metal uses far lower wattages—typically 20-50W—because it only needs to affect surface layers rather than penetrating material completely.

- Light fabrication shops (1-6mm steel focus): 2-3kW provides excellent versatility

- General metal fabrication (mixed materials to 12mm): 4-6kW handles most requirements

- Heavy industrial cutting (thick sections, high volume): 6kW+ delivers maximum productivity

- Reflective metals priority (aluminum, brass, copper): Add 30-50% to steel-based calculations

Understanding power requirements positions you to evaluate equipment intelligently—but wattage alone doesn't determine whether laser cutting suits your application. How does this technology compare to alternatives like plasma, waterjet, or EDM when your project demands a specific outcome?

Laser Cutting vs Plasma Waterjet and EDM Methods

You've got the power requirements figured out—but here's a question that separates smart buyers from frustrated ones: Is laser cutting actually the right choice for your application? Sometimes it isn't. Understanding when alternatives like plasma, waterjet, or EDM outperform laser technology saves you from expensive mistakes and positions you to select the optimal process for each job.

Laser Cutting Precision Advantages Over Plasma

When precision matters most, sheet metal laser cutting delivers results that plasma simply cannot match. According to industry comparisons, laser cutting achieves tolerances of ±0.001" (±0.025mm) or better on thin materials, while plasma cutting hovers around ±0.030" to ±0.060"—roughly 30 to 60 times less precise.

Why such a dramatic difference? Plasma cutting uses ionized gas heated to 20,000-50,000 degrees to melt through metal. This near-supersonic jet of plasma creates significant heat-affected zones and rough edges that often require secondary processing. A laser sheet metal cutter, by contrast, focuses energy into a spot as small as 0.1mm, minimizing thermal distortion and producing edges clean enough for immediate welding or painting.

Speed comparisons favor laser technology for thin materials as well. CNC laser cutting processes thin sheets at velocities plasma cannot approach, with feed rates reaching 100 m/min on lightweight gauges. However, plasma gains ground as thickness increases—it handles sections up to 6" of aluminum where laser machines reach their practical limits around 1" (25mm) of steel.

The cost equation also differs significantly. Plasma equipment costs less upfront, and the process requires no expensive assist gases beyond shop air for many applications. But when you factor in secondary finishing operations, material waste from wider kerfs, and the labor required to clean plasma-cut edges, laser cut sheet metal often delivers lower total cost per part despite higher hourly operating rates.

When Waterjet or EDM Outperforms Laser

Here's what most laser advocates won't tell you: for certain applications, waterjet and EDM aren't just alternatives—they're definitively superior choices. Understanding these scenarios prevents you from forcing laser technology into jobs where it underperforms.

Waterjet cutting uses cold supersonic abrasive erosion, creating zero heat-affected zone. This matters enormously for heat-sensitive materials or applications where metallurgical properties must remain unchanged. According to cutting process comparisons, waterjet machines can slice through 4" (100mm) of steel—four times the thickness most laser systems handle effectively. They also cut virtually anything: glass, ceramic tile, marble, granite, and composite materials that would damage or reflect laser beams.

Wire EDM (Electrical Discharge Machining) occupies the extreme precision end of the spectrum. With tolerances reaching ±0.0001" (±0.025mm)—ten times tighter than laser cutting—and surface finishes of Ra 0.8μm versus laser's Ra 12μm, EDM excels for precision fits and sliding surfaces. Cost analysis reveals laser cutting runs approximately $28/hour compared to EDM's $85/hour, but when your part demands mirror-like finishes or extreme accuracy, EDM remains irreplaceable.

| Comparison Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Wire EDM |

|---|---|---|---|---|

| Precision Tolerance | ±0.001" (±0.025mm) | ±0.030" to ±0.060" | ±0.003" (±0.1mm) | ±0.0001" (±0.025mm) |

| Material Thickness Range | Up to 1" (25mm) steel | Up to 6" aluminum | Up to 4" (100mm) steel | Over 12" (30cm) reported |

| Heat-Affected Zone | Minimal (<0.25mm with proper settings) | Significant HAZ and distortion | None—cold cutting process | Some HAZ from electrical discharge |

| Operating Cost per Hour | ~$28/hour | Lower than laser | Moderate ($30,000+ equipment) | ~$85/hour |

| Edge Quality | Excellent (Ra 12μm) | Fair—often requires finishing | Good—minimal burr | Excellent (Ra 0.8μm) |

| Ideal Use Cases | Thin to medium metals, high-volume production, intricate designs | Thick conductive metals, budget-conscious operations | Thick materials, heat-sensitive parts, non-metals | Extreme precision, hardened materials, mirror finishes |

When NOT to Use Laser Cutting

Making informed decisions means knowing when to choose alternatives. Consider these specific scenarios where laser technology isn't your best option:

- Choose Plasma When: Cutting electrically conductive metals over 1" thick, budget constraints limit equipment investment, edge quality requirements are moderate, or you need faster processing on thick sections where laser speeds drop significantly.

- Choose Waterjet When: Processing heat-sensitive materials where metallurgical changes are unacceptable, cutting non-metals like stone, glass, or composites, working with reflective materials that challenge even fiber lasers, or cutting thick sections (2-4") where laser power requirements become impractical.

- Choose EDM When: Tolerances tighter than ±0.1mm are mandatory, surface finish below Ra 1μm is required, cutting hardened materials over 45 HRC, or precision fits for sliding applications demand mirror-quality edges.

- Choose CNC Milling When: Parts require 3D profiling or variable-depth features, extremely tight tolerances on specific features matter more than cutting speed, or material removal rather than separation is the primary goal.

The laser for cutting machine applications excels in a sweet spot: thin to medium-thickness metals requiring high precision, fast processing, and minimal post-processing. Outside this range, forcing laser technology creates quality problems, slow production rates, or both.

According to manufacturing analysis, laser cutting provides processing speeds 10x faster than bandsaws and 50-100 times faster than wire cutting for appropriate applications. A 12kW oxygen-assisted laser cuts 40mm steel at speeds no other precision method approaches. But those same sources note limitations: most systems sit under 6kW, restricting practical thickness to around 12mm—and harmful fumes from certain materials require controlled atmosphere processing.

Understanding these trade-offs positions you to match technology to requirements rather than forcing square pegs into round holes. But once you've confirmed laser cutting fits your application, how do you select between hobbyist-grade desktop units and industrial production systems?

Choosing Equipment for Small Shops vs Industrial Production

You've confirmed laser cutting fits your application—now comes a decision that shapes your entire operation: What scale of equipment makes sense for your specific situation? The gap between a desktop laser engraver and an industrial laser cutter isn't just about size or price. It's about matching capabilities to your production reality, workspace constraints, and growth trajectory.

Desktop and Small Shop Laser Cutting Solutions

Starting small doesn't mean starting weak. Today's metal laser cutter options for home workshops and small businesses deliver capabilities that would have required industrial facilities just a decade ago. According to industry analysis, machines like the OMTech 50W Fiber Laser Engraver (around $2,730) offer high-quality metal engraving capabilities in a compact footprint that fits most garage or basement workshops.

But here's what catches many first-time buyers off guard: a metal laser cutting machine for home use typically excels at engraving and marking rather than through-cutting thicker metals. Most desktop fiber systems under $5,000 handle marking, thin sheet cutting (under 1mm), and detailed engraving work. For actual metal cutting capability, you'll need to step up to units in the $15,000-$20,000 range—like the Blue Elephant ELECNC-1325FL mentioned in small business equipment guides.

When evaluating a cnc laser cutter for your small shop, consider these critical factors:

- Work Area Dimensions: Desktop units typically offer 300×200mm to 600×400mm cutting areas. Before purchasing, measure your largest regular workpiece—not your dream project—and add 20% margin for material positioning.

- Power Limitations: Most affordable desktop units range from 20W to 50W, suitable for marking and engraving. Actual metal cutting starts around 500W+ for thin materials, with 1.5kW+ needed for general fabrication.

- Space Requirements: Budget minimum 2×3 meters floor space including operator access, ventilation ducting, and material staging. Ceiling height matters too—fume extraction systems need vertical clearance.

- Entry-Level Investment: Expect $2,500-$5,000 for quality marking/engraving units, $15,000-$25,000 for legitimate metal cutting capability. Factor in another 15-20% for ventilation, safety equipment, and initial consumables.

- Electrical Requirements: Desktop units run on standard 110V/220V circuits. Higher-powered cutting systems may require dedicated 30A or higher circuits—check before you buy.

- Cooling Systems: Air-cooled units simplify setup for beginners. Water-cooled systems offer better performance but add maintenance complexity and space requirements.

The laser cutting machine price for small business applications varies dramatically based on actual cutting versus marking capability. A $3,000 desktop system might produce beautiful engravings but struggle to cut 0.5mm steel cleanly. Understanding this distinction prevents disappointment and wasted investment.

Industrial-Scale Production Capabilities

When production volume exceeds what a desktop system handles—or when cutting thickness requirements push beyond hobby-grade limits—industrial equipment becomes essential. A cnc fiber laser cutting machine designed for production environments operates in an entirely different category, with capabilities that justify investment often exceeding $100,000.

According to manufacturing automation research, modern industrial laser cutting machines no longer function as standalone tools. They integrate into fully automated production lines with automatic loading/unloading systems, dual-exchange platforms that enable near-continuous operation, and sophisticated software that optimizes cutting paths and material utilization.

What separates industrial-grade cnc laser cutting machine systems from their smaller counterparts:

- Work Area Standards: Industrial formats typically start at 1300×2500mm (1325) and scale to 1500×3000mm (3015) or larger. The 3015 format dominates metal fabrication because it matches standard sheet sizes, minimizing waste.

- Power Range: Production systems commonly run 3kW to 12kW+, enabling thick material cutting at speeds that justify the equipment investment. Higher power translates directly to throughput capacity.

- Automation Integration: Robotic loading/unloading eliminates manual material handling bottlenecks. Dual-exchange platforms allow material preparation while cutting continues, maximizing spindle utilization above 85%.

- Production Volume Capacity: Industrial systems handle continuous multi-shift operation with duty cycles approaching 24/7. Reliability engineering ensures uptime that smaller units cannot match.

- Precision Under Load: Heavy-duty frames, precision linear guides, and temperature-stable construction maintain cutting accuracy even during extended production runs—critical for IATF 16949 or similar quality certification requirements.

- Software Sophistication: Nesting optimization, production scheduling, and ERP integration streamline operations from order entry through shipping.

Understanding the Power-Speed-Quality Relationship

Regardless of scale, one fundamental equation governs your cutting results: the relationship between laser power, cutting speed, and edge quality. Getting this balance wrong creates either slow production (too little power, too slow speed) or poor quality (too much speed for available power).

For hobbyists and small shop operators, this means accepting realistic limits. A 1.5kW system cutting 6mm steel at optimal speed produces clean edges. Push that same system to 8mm, and cutting speed drops dramatically while edge quality suffers—you're asking the machine to exceed its efficient operating envelope.

Industrial users face the same physics but have more headroom. A 6kW cnc laser system handles the same 6mm steel at three to four times the speed, or tackles 15mm material at speeds the smaller unit achieves on thin sheets. The difference translates directly to parts per hour and cost per cut.

Edge quality follows predictable patterns across both scales:

- Thin materials (under 3mm): Higher speeds generally improve edge quality by reducing heat input and minimizing dross formation.

- Medium thickness (3-10mm): Optimal speed balances heat input against material removal. Too fast creates rough edges; too slow causes excessive heat-affected zones.

- Thick sections (10mm+): Speed drops significantly, and edge quality becomes more dependent on assist gas selection, focus position, and nozzle standoff than raw power.

According to equipment sizing research, many buyers fall into a "one-machine-for-all" trap—purchasing equipment based on occasional maximum requirements rather than regular production needs. The smarter approach? Match your primary workload to equipment that handles it at 70-80% capacity, with occasional thick-material jobs outsourced to specialty shops until volume justifies upgrading.

Whether you're setting up a garage workshop or planning a production facility, equipment selection determines your operational ceiling. But initial purchase price tells only part of the story—understanding total cost of ownership reveals whether your investment actually makes financial sense.

Total Cost of Ownership and ROI Analysis

You've selected your equipment scale—but here's where most buyers stumble: focusing on purchase price while ignoring the expenses that accumulate over years of operation. A laser cutter for metal represents a long-term production asset, not a one-time purchase. According to industry analysis, what looks inexpensive upfront can become costly over time when you factor in energy consumption, maintenance demands, and productivity limitations.

Breaking Down True Operating Expenses

Think of total cost of ownership like an iceberg—the fiber laser cutting machine price visible above the waterline represents only a fraction of your actual investment. The real financial picture emerges when you examine every cost category across a 5-10 year operating horizon.

| Cost Category | Entry-Level Systems ($15,000-$40,000) | Mid-Range Systems ($40,000-$70,000) | Industrial Systems ($70,000+) |

|---|---|---|---|

| Initial Equipment Investment | $15,000-$40,000 | $40,000-$70,000 | $70,000-$120,000+ |

| Installation & Training | $1,000-$3,000 (basic setup) | $3,000-$8,000 (infrastructure modifications) | $10,000-$25,000 (specialized labor, facility prep) |

| Consumables (Annual) | $500-$1,500 | $1,500-$4,000 | $4,000-$10,000 |

| Electricity (Annual at full operation) | $2,000-$4,000 | $4,000-$8,000 | $8,000-$15,000+ |

| Maintenance (Annual) | $200-$600 | $600-$2,000 | $2,000-$5,000 |

| Expected Lifespan | 8-12 years | 10-15 years | 15-20+ years |

According to cost analysis research, a 3000W fiber laser machine consumes approximately 8.5kW/h at full power. When you're shopping for a laser engraver for sale, that electricity figure might seem abstract—but multiply it across 2,000 annual operating hours, and you're looking at $2,000-$4,000 in power costs alone, depending on your local rates.

Assist gas consumption adds another significant expense most buyers underestimate. Nitrogen costs approximately $320 per canister and lasts 12-16 hours of continuous cutting. Oxygen runs around $15 per bottle per hour. For shops processing thin materials primarily, an air compressor alternative (3kW laser requires 15kW compressor; 6kW requires 22kW compressor) dramatically reduces ongoing gas expenses.

Maintenance Schedules and Consumable Replacement

Here's what separates profitable operations from money pits: disciplined maintenance that prevents small issues from escalating into production-stopping failures. A fiber laser engraver or cutting system requires attention across multiple intervals:

- Daily Tasks: Inspect lens and nozzle before each run. Check protective lens for contamination or damage. Protective lens replacement costs just $2-$5 per lens but neglecting this check risks damage to far more expensive components.

- Weekly Requirements: Clean optical components, verify gas pressure settings, and check coolant levels. Inspect cutting bed for debris accumulation that could affect material positioning.

- Monthly Duties: Replace water in the chiller system. Clean the laser table and remove cutting scrap. Inspect exhaust system and air filters if equipped. Nozzle replacement as needed ($2-$5 each for 3kW heads).

- Quarterly Checks: Verify motion system calibration. Inspect drive belts and linear guides for wear. Clean and lubricate all moving components per manufacturer specifications.

- Semi-Annual Requirements: Refill lubrication system oil. Replace air/gas filters ($2,000-$4,000 depending on system). Maintain dust collector filters ($800-$2,000). Air compressor service if applicable.

- Annual Inspection: Professional service check including laser source output verification, alignment confirmation, and complete system calibration.

Ceramic body components cost around $5/piece and typically last several months without damage. The fiber laser marking machine components like focusing and collimating lenses last considerably longer—replacement becomes necessary only when damage occurs, often from neglecting protective lens checks.

Calculating Your Laser Cutting ROI

The ROI formula itself is straightforward: ROI (%) = [(Net Profit from Investment - Cost of Investment) / Cost of Investment] × 100. But according to ROI assessment research, most businesses achieve full payback within 18-24 months when they account for productivity gains, material savings, and labor efficiency improvements.

What drives that return? Three primary factors compound across your ownership period:

- Production Speed Impact: Fiber laser cutting processes materials up to three times faster than traditional methods, with speeds reaching 20 meters per minute on thin sheets. This translates to 200-400% increased production capacity without adding labor.

- Material Savings: The narrow kerf width of 0.1-0.2mm combined with advanced nesting software reduces material waste by up to 20%. Smart optimization enables 80%+ material utilization rates.

- Labor Cost Reduction: Automated systems require minimal operator intervention. Eliminated secondary finishing processes—edges come off the machine ready for welding or painting—save significant labor hours per part.

For a medium-scale operation, monthly savings typically break down as follows: energy savings of $800-$1,200 versus less efficient alternatives, maintenance cost reductions of $400-$600 compared to CO2 systems, and additional revenue capacity of $3,000-$5,000 from increased throughput.

Environmental and Infrastructure Considerations

Laser cutting charges extend beyond direct operating costs to essential infrastructure investments. Fume extraction isn't optional—metal vaporization creates particulates and gases that pose health risks and can damage optical components. Budget $2,000-$10,000 for adequate extraction systems depending on production volume and local regulatory requirements.

Energy efficiency comparisons favor fiber technology decisively. Fiber lasers achieve approximately 35% electrical-to-optical conversion efficiency versus 10-20% for CO2 alternatives. According to operating cost analysis, CO2 lasers consume roughly $20 per operating hour while fiber systems run at approximately $4 per hour—a difference that compounds dramatically over years of production.

When evaluating laser cutting charges for your operation, remember that low-cost machines often depreciate more rapidly and have weaker secondary market demand. Higher-quality systems retain value longer and provide flexibility for future upgrades or resale. The question isn't "How much does this machine cost to buy?" but rather "How much does it cost to own, operate, and rely on over time?"

Understanding total ownership costs positions you to evaluate investments realistically—but even the best equipment produces disappointing results when cutting problems go undiagnosed. Knowing how to troubleshoot common defects transforms frustration into systematic problem-solving.

Troubleshooting Common Cutting Defects and Solutions

Even the best laser that cuts metal produces frustrating results when parameters drift or conditions change. The difference between profitable operations and quality nightmares often comes down to one skill: systematic troubleshooting. Rather than guessing at solutions, understanding the relationship between defect symptoms, root causes, and targeted fixes transforms random adjustments into predictable problem resolution.

Diagnosing Dross and Burr Formation Issues

When you're laser cutting metal sheet and find rough edges or solidified material clinging to the bottom of cuts, you're facing the most common defects in metal fabrication: dross and burrs. According to quality control research, these issues stem from an imbalance between cutting speed, laser power, and assist gas parameters.

Dross forms when molten material doesn't get expelled cleanly from the cut zone—it resolidifies on the bottom surface instead. Burrs appear as rough, raised edges when the laser doesn't complete a clean separation. Both indicate your metal laser cutting machine parameters need adjustment, but the specific corrections differ.

For dross elimination, start by increasing assist gas pressure in 0.1 bar increments. If the focus position sits below the material surface, raise it incrementally. When cutting speed is too fast for your power level, the laser doesn't fully melt through the material—slow down by 5-10% and observe results. For burrs specifically, the opposite often applies: cutting too slowly or with excessive power causes heat buildup that creates rough edges. Increase speed while maintaining adequate penetration.

Solving Heat-Affected Zone Problems

Excessive heat-affected zones (HAZ) compromise material properties around your cuts, causing discoloration, warping, or metallurgical changes that affect downstream processes like welding or bending. According to troubleshooting guides, the primary culprit is a laser moving too slowly or running at excessive power for the material thickness.

Finding the best laser for cutting your specific materials means optimizing the power-speed balance. Increase cutting speed while maintaining enough power for clean penetration—this reduces heat input per unit length. Adequate air assist or nitrogen flow cools the cutting zone and blows debris away before it can re-ignite. For reflective materials like aluminum, nitrogen cutting eliminates oxidation while reducing thermal damage.

| Problem Type | Likely Causes | Specific Solutions |

|---|---|---|

| Dross (bottom adhesion) | Focus too low; gas pressure insufficient; cutting speed too high; impure assist gas | Raise focus position; increase gas pressure by 0.1 bar increments; reduce speed 5-10%; verify gas purity (99.6%+ for nitrogen) |

| Burrs (rough raised edges) | Speed too slow; power too high; focus above surface; improper material preparation | Increase cutting speed; reduce power; lower focus position; clean material surface before cutting |

| Incomplete cuts | Insufficient power; excessive speed; low gas pressure; contaminated lens | Increase power 5-10%; reduce speed; increase assist gas pressure; clean or replace protective lens |

| Excessive heat-affected zone | Speed too slow; power too high; inadequate cooling; improper gas selection | Increase speed while maintaining penetration; reduce power; improve air assist flow; switch to nitrogen for sensitive materials |

| Rough/wavy cut surface | Gas pressure too high; damaged nozzle; contaminated lens; material quality issues | Reduce gas pressure 0.1-0.2 bar; replace nozzle; clean optics; verify material consistency |

Preventive Measures and Quality Control Checkpoints

Systematic prevention beats reactive troubleshooting every time. Implementing these quality control practices catches problems before they affect production:

- Pre-Cut Verification: Inspect protective lens before each run—a $2 lens check prevents damage to components costing hundreds. Verify nozzle centering and condition.

- Material Preparation: Clean surfaces remove coatings, oils, or contaminants that cause inconsistent cutting. Verify thickness consistency across the sheet.

- Parameter Documentation: Record optimal settings for each material-thickness combination. Reference these baselines when troubleshooting drift.

- Regular Calibration: Check focus alignment weekly. Verify gas pressure gauges monthly. Perform full optical path inspection quarterly.

- Cut Quality Sampling: Test cuts on scrap material when switching materials or after any maintenance. Verify edge quality before committing to production runs.

According to defect analysis research, maintaining nitrogen purity above 99.6% prevents the blue or purple discoloration common in stainless steel cutting. Impure oxygen similarly causes slag adhesion and reduced cutting speeds—verify gas quality when performance degrades without other apparent causes.

For metal laser engraving machine applications, similar principles apply at lower power levels. Focus position becomes even more critical when working at shallow depths, and material surface preparation directly affects marking consistency and contrast.

Mastering troubleshooting transforms your fiber laser engraving machine or cutting system from a temperamental tool into a reliable production asset. But systematic problem-solving represents just one piece of the decision-making puzzle—knowing how to evaluate your overall manufacturing strategy positions you to leverage laser cutting capabilities most effectively.

Making the Right Laser Metal Cutting Decision

You've absorbed the technical details—wattage requirements, technology comparisons, cost frameworks, and troubleshooting strategies. Now comes the moment that transforms knowledge into action: synthesizing everything into a decision that fits your specific situation. Whether you're evaluating your first laser metal cutter or upgrading an existing metal cutting laser machine, the path forward requires matching capabilities to your actual production reality.

Building Your Metal Cutting Capability Roadmap

Before contacting vendors or comparing quotes, step back and assess where you stand. According to industry buying guides, the most successful equipment decisions start with honest self-evaluation rather than chasing specifications. Your roadmap begins with these fundamental questions:

- Material Profile: What metals do you cut most frequently? What thickness ranges dominate your production? A cnc laser optimized for thin stainless differs dramatically from one built for thick mild steel.

- Volume Requirements: Are you running prototypes and short runs, or does your operation demand continuous multi-shift production? This determines whether a laser cnc machine with basic automation suffices or whether integrated loading systems become essential.

- Precision Standards: Do your parts require tolerances of ±0.1mm or is ±0.25mm acceptable? Tighter tolerances demand higher-quality motion systems and more rigorous maintenance protocols.

- Technology Selection: Based on your material mix, does fiber laser technology cover your needs, or do certain applications still favor CO2 or alternative methods like waterjet?

- Power Sizing: Match your thickest regular cutting requirement to optimal—not maximum—wattage. Operating at 70-80% capacity extends consumable life and improves edge quality.

- Total Cost Perspective: Look beyond purchase price to electricity consumption, consumables, maintenance schedules, and expected lifespan. A fiber laser cutter with higher upfront cost often delivers lower total ownership expense.

- Support Infrastructure: Verify local service availability before committing. As equipment analysts note, a machine waiting for service—regardless of its specifications—generates zero revenue.

This framework applies whether you're shopping for a desktop laser metal engraver or specifying an industrial laser cut machine for high-volume production. The technology scales, but the decision logic remains consistent.

Partnering with Precision Manufacturing Experts

Here's what many buyers overlook: laser cutting rarely exists in isolation. Most fabricated parts require additional operations—forming, stamping, welding, assembly—before they're production-ready. Building manufacturing capability means considering how laser cutting integrates with your complete workflow.

For automotive and precision component applications, this integration becomes critical. Consider how Shaoyi (Ningbo) Metal Technology exemplifies the kind of comprehensive manufacturing partner that complements laser cutting capabilities. Their IATF 16949-certified metal stamping and precision assemblies address what happens after laser cutting: forming complex geometries, joining components, and delivering finished assemblies ready for installation.

What makes such partnerships valuable? Several capabilities stand out:

- Rapid Prototyping Speed: When you need design validation before committing to production tooling, 5-day turnaround capabilities accelerate your development cycle dramatically. This matters whether you're iterating laser-cut brackets or stamped chassis components.

- Design for Manufacturability Support: Comprehensive DFM analysis catches potential problems before they become expensive corrections. A 12-hour quote turnaround means you can evaluate multiple design approaches quickly.

- Quality Certification: IATF 16949 certification—the automotive industry's quality management standard—ensures consistent processes for chassis, suspension, and structural components where failure isn't an option.

- Production Scalability: Moving from prototype validation to automated mass production requires partners who handle both ends of the volume spectrum without quality degradation.

According to fabrication partner research, the strongest manufacturing relationships provide engineering consultation, prototype testing, and material recommendations—not just machine time. This support reduces risk, shortens lead times, and ensures smooth production for complex assemblies.

Your Next Steps by Stage

Where you go from here depends on where you stand today:

If you're researching your first laser cutting investment: Request test cuts from multiple vendors using your actual production parts. Measure accuracy, examine edge quality, and time the complete process. Visit existing users in your region and ask candid questions about reliability and service experience.

If you're upgrading existing capabilities: Conduct honest capacity analysis. Are you bottlenecked by cutting speed, thickness capability, or material handling? Target upgrades to your actual constraint rather than chasing specifications that look impressive but don't address your production reality.

If you're outsourcing laser cutting currently: Calculate your true outsourcing costs including shipping, lead times, and quality coordination. Compare against in-house equipment ownership costs over 5-7 years. The break-even point often arrives sooner than expected for consistent volumes.

If you need precision manufacturing beyond cutting: Explore partnerships with integrated manufacturers who can handle stamping, forming, and assembly alongside your laser-cut components. For automotive applications, resources like Shaoyi's automotive stamping capabilities illustrate how comprehensive manufacturing support streamlines complex component production.

The journey from understanding laser metal cutting technology to implementing it profitably requires both knowledge and action. You now have the framework—wattage selection, technology comparison, cost analysis, troubleshooting capability, and decision criteria. The next step belongs to you: applying this understanding to your specific manufacturing challenges and building the cutting capability your operation demands.

Frequently Asked Questions About Laser Metal Cutting

1. Is laser cutting metal expensive?

Laser cutting costs depend on material type, thickness, and cutting speed. Hourly rates typically range from $60-$150, with fiber lasers operating at approximately $28/hour compared to alternative methods. While initial equipment investment ranges from $15,000 for entry-level systems to $120,000+ for industrial machines, fiber lasers achieve 35% energy efficiency versus 10-20% for CO2 systems, significantly reducing long-term operating costs. When factoring in eliminated secondary finishing, material savings from narrow kerf widths, and increased production speed, many businesses achieve full ROI within 18-24 months.

2. How thick of steel can a 1000W laser cut?

A 1000W fiber laser typically cuts up to 5mm stainless steel and approximately 6mm mild steel effectively. However, optimal performance occurs at 70-80% of maximum capacity—meaning a 1000W system delivers best edge quality on materials 3-4mm thick. For thicker materials, power requirements increase significantly: 2000W handles 8-10mm, 3000W manages 12mm, and 6kW+ systems tackle sections up to 25mm. Material reflectivity also matters—aluminum and copper require 30-50% more power than steel of equivalent thickness.

3. What is the difference between fiber laser and CO2 laser cutting?

Fiber lasers operate at 1.064 micrometers wavelength with 35% energy efficiency, excelling at cutting metals under 15mm—especially reflective materials like aluminum, brass, and copper. They offer 100,000-hour source lifespan and minimal maintenance. CO2 lasers use 10.6 micrometers wavelength with 10-20% efficiency, delivering superior results on thick metals exceeding 20mm and non-metallic materials like wood, acrylic, and textiles. CO2 tubes require replacement every 20,000-30,000 hours. Choose fiber for metal-focused operations and CO2 for mixed-material versatility.

4. Can I use a desktop laser cutter to cut metal at home?

Desktop fiber lasers under $5,000 excel at metal marking and engraving but typically cannot through-cut metals thicker than 1mm. Legitimate metal cutting capability starts around $15,000-$25,000 for systems with 500W+ power. Key considerations include work area (typically 300x200mm to 600x400mm), electrical requirements, ventilation for fume extraction, and space needs of minimum 2x3 meters. For hobbyists cutting thin sheets occasionally, outsourcing to services like OSH Cut or SendCutSend often proves more cost-effective than equipment ownership.

5. When should I choose waterjet or plasma cutting instead of laser?

Choose plasma when cutting electrically conductive metals over 25mm thick on a budget—plasma handles up to 6 inches of aluminum where lasers max out around 25mm steel. Select waterjet for heat-sensitive applications requiring zero heat-affected zone, non-metals like stone or glass, or thick sections up to 100mm. Waterjet uses cold abrasive erosion, preserving metallurgical properties critical for aerospace or medical components. Wire EDM suits extreme precision needs (±0.0001 inches) and mirror-finish requirements, though at $85/hour versus laser's $28/hour.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —