Fixed Vs Floating Stripper Plate: The Die Decision That Makes Or Breaks Your Tooling

The Critical Stripper Plate Decision Every Die Designer Must Master

Imagine running a high-volume stamping operation when suddenly your parts start sticking to punches, edges show unexpected burrs, and your maintenance team scrambles to diagnose the problem. What went wrong? In many cases, the root cause traces back to a fundamental choice made during die design: selecting the wrong stripper plate type for the application.

Whether you're engineering progressive dies for automotive components or designing tooling for precision electronics, understanding the fixed vs floating stripper plate decision is essential. This choice directly impacts part quality, tool longevity, and your bottom line.

Why Your Stripper Plate Choice Defines Die Performance

So, what is a stripper plate exactly? It's the component responsible for removing the workpiece material from the punch after each stroke. Proper stripper plate ejection ensures clean part separation, prevents slug pulling, and maintains consistent cycle times. When you select the right configuration, your die runs smoothly. Choose incorrectly, and you'll face a cascade of production headaches.

The stripper plate does more than simply strip material—it guides punches, controls material movement, and influences overall die stability. This makes your selection between fixed and floating designs a cornerstone decision that ripples through every aspect of die performance.

The Hidden Cost of Wrong Stripper Selection

Selecting an inappropriate stripper plate type creates consequences that extend far beyond the initial tooling investment:

- Part damage: Scratches, deformation, and dimensional inconsistencies from improper stripping force

- Accelerated tool wear: Misaligned punches and excessive friction shorten component life

- Unplanned downtime: Frequent adjustments and emergency repairs disrupt production schedules

- Increased scrap rates: Poor ejection leads to rejected parts and wasted material

Setting the Stage for Precision Stamping Success

Here's the challenge many die designers face: information about stripper plate selection is scattered across technical manuals, supplier catalogs, and tribal knowledge passed between engineers. No single resource consolidates this critical comparison with clear, actionable decision criteria—until now.

This guide provides a comprehensive evaluation of fixed versus floating stripper plates, complete with structured selection frameworks and practical recommendations. You'll discover exactly when each type excels, understand the trade-offs involved, and gain confidence in making this crucial tooling decision for your specific applications.

Evaluation Criteria for Stripper Plate Selection

Before diving into the specifics of fixed and floating stripper plates, you need a clear framework for making this decision. Without defined criteria, comparing these two options becomes guesswork rather than engineering. Let's establish the evaluation methodology that professionals use when selecting the right stripper plate configuration for stripper plate molds and die applications.

Five Factors That Determine Stripper Plate Success

When engineers assess what is a stripper plate best suited for their application, they consistently return to five critical dimensions. Each factor carries different weight depending on your specific production requirements:

- Stripping force requirements: The force needed to separate material from punches typically ranges from 10-25% of the punching force. Applications with higher stripping demands require more robust plate designs capable of consistent pressure delivery.

- Material thickness compatibility: Thin gauge materials behave differently than thick stock during stripping. Your plate selection must accommodate the specific thickness range you'll process, as mismatches cause part damage or incomplete ejection.

- Production volume considerations: High-volume operations demand stripper plates that maintain performance across millions of cycles. Lower volume runs may tolerate simpler configurations that require more frequent adjustment.

- Maintenance requirements: Some stripper plate designs need regular spring replacement, lubrication, or realignment. Understanding these ongoing demands helps you calculate true operating costs.

- Cost-effectiveness: Initial purchase price tells only part of the story. Factor in installation complexity, downtime for adjustments, component replacement frequency, and impact on part quality when evaluating total cost of ownership.

How We Evaluated Each Stripper Type

Throughout this comparison, we'll assess fixed and floating stripper plates against each criterion above. You'll see clear breakdowns of where each type excels and where limitations emerge. This structured approach eliminates subjective preference and grounds your decision in measurable performance factors.

The Selection Framework Professionals Use

Experienced die designers don't choose stripper plates based on habit or supplier recommendations alone. They match application requirements to plate capabilities systematically. As you move through the detailed comparisons ahead, keep these evaluation dimensions in mind—they'll guide you toward the configuration that delivers optimal performance for your specific stamping challenges.

Fixed Stripper Plates for Stability and Cost Efficiency

Now that you understand the evaluation framework, let's examine our first contender in the fixed vs floating stripper plate comparison. Fixed stripper plates represent the foundational approach to part ejection—a design philosophy that prioritizes simplicity, rigidity, and consistent performance for specific application ranges.

When your stamping operation demands predictable behavior and budget-conscious tooling, fixed strippers often emerge as the smart choice. But understanding exactly how they work—and where they excel—separates successful die designs from problematic ones.

How Fixed Strippers Deliver Consistent Performance

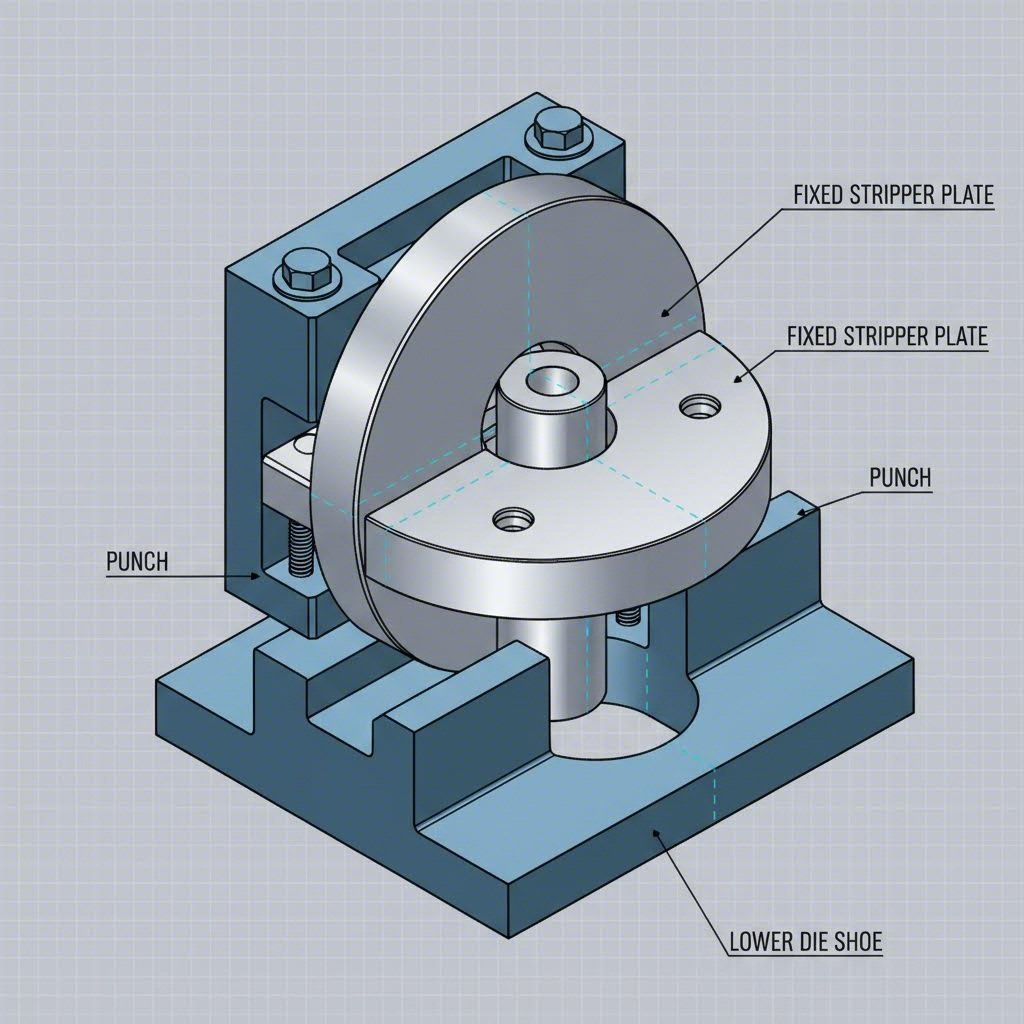

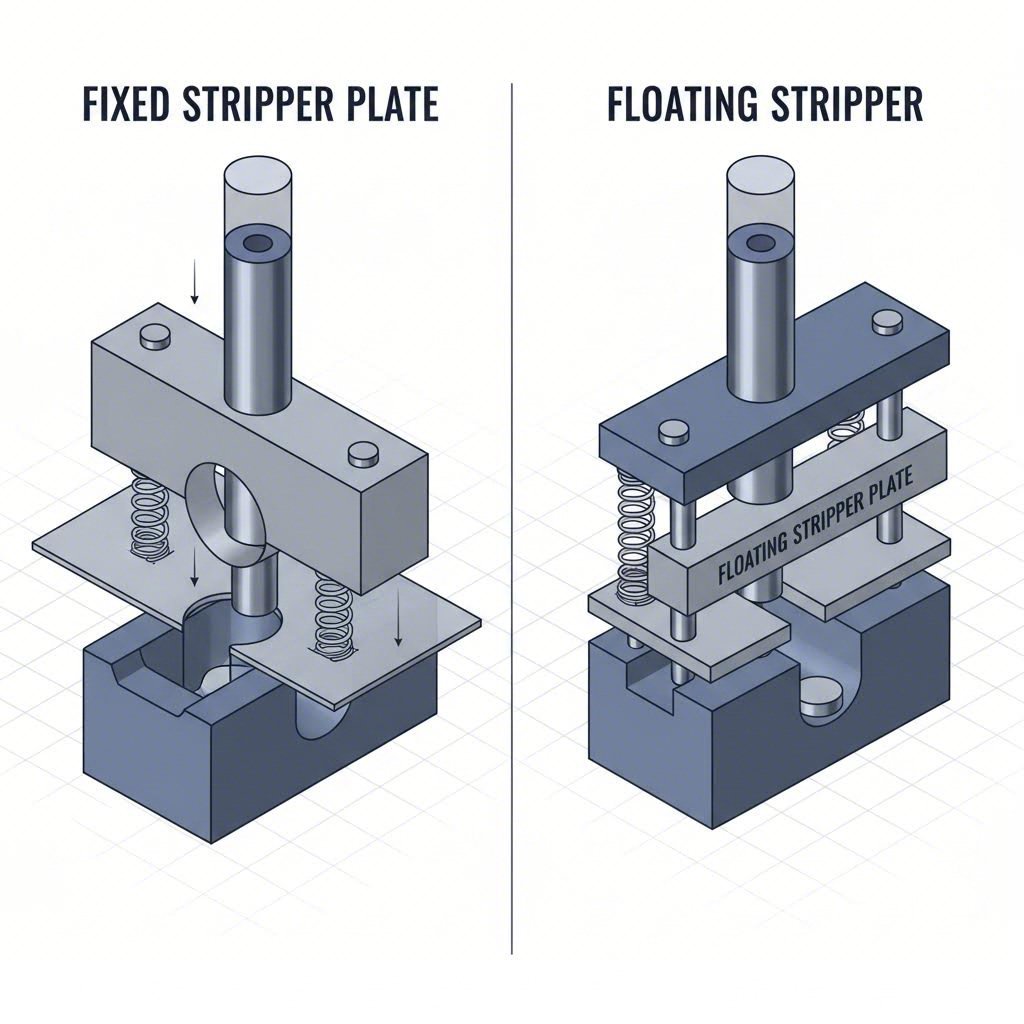

Fixed stripper plates mount rigidly to the die shoe or punch holder assembly, maintaining a constant position relative to the die components throughout the press stroke. Unlike their spring-loaded counterparts, these plates don't move independently—they rely on the press stroke itself to separate material from punches.

This rigid mounting design creates several performance characteristics you'll notice immediately:

- Punch guidance: The plate provides a stable reference surface that guides pilot punches for fixing to stripper plates, maintaining alignment throughout high-speed operations

- Consistent clearances: Without spring deflection variables, the gap between punch and stripper remains constant, ensuring uniform stripping action

- Vibration resistance: The solid connection to the die structure dampens operational vibration that could affect part quality

When working with straight pilot punches for stripper plates, the fixed configuration ensures these critical alignment components remain precisely positioned. This stability proves especially valuable in progressive die applications where cumulative misalignment could compound across multiple stations.

Ideal Applications for Fixed Stripper Plates

Fixed strippers shine brightest in applications matching their inherent strengths. Consider this design when your project involves:

- Thin gauge materials: Stock under 1.5mm thickness typically strips cleanly without requiring the controlled pressure that floating designs provide

- High-speed stamping: Operations exceeding 400 strokes per minute benefit from the reduced moving parts and consistent behavior

- Precision electronics components: Lead frames, connector terminals, and micro-stamped parts demand the stability fixed plates deliver

- Thin gauge automotive components: Brackets, clips, and small structural elements from thin steel or aluminum stock

- Simple blanking operations: Single-station dies with straightforward geometry where material behavior is predictable

The key pattern here? Fixed stripper plates excel when material thickness falls within a manageable range and punch-to-material interaction remains predictable. They're particularly effective when the stripper plate rubs top surface contact is minimal and controlled.

Fixed Stripper Pros and Cons Breakdown

Every tooling decision involves trade-offs. Here's an honest assessment of what fixed stripper plates bring to your die design:

Pros

- Lower initial cost: Simpler construction translates to reduced manufacturing expense—often 20-30% less than equivalent floating designs

- Simpler design and installation: Fewer components mean faster setup, easier troubleshooting, and reduced assembly errors

- Minimal maintenance requirements: No springs to fatigue, no adjustment mechanisms to calibrate, no moving parts to lubricate

- Excellent thin stock performance: Delivers reliable stripping for materials where controlled force isn't critical

- Longer service life: With fewer wear components, properly designed fixed plates often outlast floating alternatives

- Consistent cycle-to-cycle behavior: Eliminates variables introduced by spring degradation or adjustment drift

Cons

- Limited material thickness range: Struggles with thicker stock where controlled stripping pressure becomes necessary

- Less forgiving of punch misalignment: Without spring compliance, minor misalignment transmits directly to punch and die components

- No pre-stripping capability: Cannot hold material before punch engagement, limiting applications in complex forming operations

- Reduced adaptability: Difficult to fine-tune stripping behavior after die construction is complete

- Material springback challenges: Thicker materials may deflect punches without the counterforce floating designs provide

Fixed stripper plates represent the 80/20 solution in die design—handling 80% of applications at a fraction of the complexity. The key is recognizing when your application falls within that majority.

When specifying fixed stripper plates, material selection matters significantly. Tool steels like D2 offer excellent wear resistance for high-volume applications, while OHNS (oil-hardening non-shrinking steel) provides a cost-effective alternative for moderate production runs. Hardness typically ranges from 58-62 HRC for the stripper surface, ensuring durability without excessive brittleness.

Understanding these characteristics positions you to make an informed choice—or to recognize when your application demands the additional capabilities that floating stripper plates provide.

Floating Stripper Plates for Maximum Versatility

What happens when your application exceeds the comfortable limits of fixed stripper plates? When material thickness increases, part geometry becomes complex, or precision requirements tighten, you'll need a more sophisticated solution. Enter floating stripper plates—the spring-actuated workhorses that handle demanding stamping applications where fixed alternatives fall short.

Floating strippers represent the premium tier in the fixed vs floating stripper plate comparison, offering controlled force delivery and adaptability that transforms challenging die operations into reliable production processes.

Spring-Loaded Precision for Demanding Applications

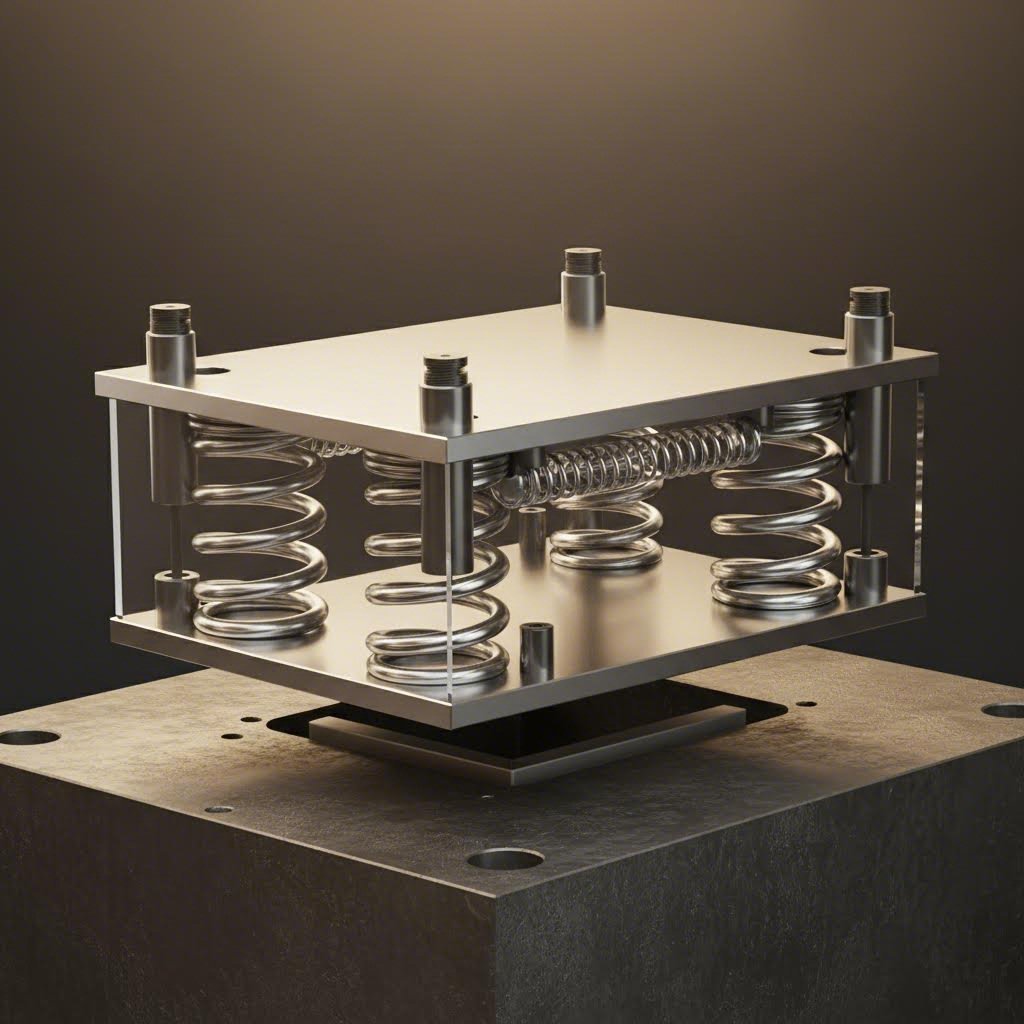

Unlike their rigid counterparts, floating stripper plates mount on springs or other elastic elements that allow independent vertical movement. This seemingly simple difference fundamentally changes how the stripper interacts with your workpiece material.

Here's how the spring-actuated design works in practice:

- Pre-engagement contact: As the press descends, the floating plate contacts and holds the material before punches engage—stabilizing the workpiece for cleaner cuts

- Controlled pressure during piercing: Springs compress as punches penetrate, maintaining consistent downward force on the material throughout the cutting stroke

- Active stripping on return: During the upstroke, spring force actively pushes material off the punches rather than relying solely on gravity and friction

- Automatic wear compensation: The spring-loaded design accommodates minor punch wear without requiring die adjustment

Stripper plate spring retainers play a critical role in this system, securing the springs in position while allowing proper compression travel. These components must withstand millions of cycles without loosening or failing—making quality retainer selection essential for long-term reliability.

The magic happens in that controlled pressure delivery. Where fixed plates offer a single, static relationship with the material, floating designs create a dynamic interaction that adapts to material variations, punch conditions, and operational demands.

When Floating Strippers Outperform Fixed Alternatives

Certain applications practically demand floating stripper plates. If your project matches any of these scenarios, the additional investment typically pays dividends in quality and productivity:

- Thick material processing: Stock exceeding 1.5mm thickness requires the controlled force that prevents material lifting and ensures complete punch penetration

- Progressive die operations: Multi-station dies benefit from the material control floating plates provide, maintaining registration across sequential operations

- Slug pulling prevention: The active downward pressure during stripping dramatically reduces the tendency for slugs to pull back through the die

- High-precision part positioning: Adjustable stripper plates allow fine-tuning of material hold-down for applications with tight positional tolerances

- Variable material conditions: When processing materials with thickness variations or different hardness lots, spring compliance accommodates these changes

- Complex part geometries: Parts with formed features, drawn areas, or intricate perimeter shapes benefit from controlled material handling

Consider molding stripper plates in injection mold applications—they serve a similar function, using spring force to eject parts cleanly from complex cavity geometries. The underlying principle translates directly to metal stamping: controlled force application solves problems that rigid systems cannot address.

Floating Stripper Advantages and Limitations

Making an informed decision requires honest evaluation of both strengths and constraints. Floating stripper plates offer compelling advantages—but they're not without trade-offs.

Pros

- Superior part control: Material remains firmly positioned throughout the punch stroke, eliminating shifting that causes dimensional variation

- Handles thicker materials effectively: Spring force counteracts material springback and lifting forces that overwhelm fixed plates

- Reduces slug pulling significantly: Active stripping pressure keeps slugs in the die opening rather than pulling back with the punch

- Accommodates punch wear: As cutting edges dull, spring compliance maintains effective stripping without immediate adjustment

- Adjustable force delivery: Spring preload and selection allow tuning stripping force to specific application requirements

- Protects punches from damage: Controlled material engagement reduces side loading that can break or chip cutting edges

- Improves edge quality: Proper material hold-down minimizes burr formation and distortion around pierced features

Cons

- Higher initial cost: Springs, retainers, and precision machining requirements increase upfront tooling investment

- Spring maintenance required: Compression springs fatigue over time, requiring periodic inspection and replacement

- More complex setup: Proper spring preload and travel adjustment demands skilled die setters and more setup time

- Additional wear points: Spring pockets, guide pins, and retainer surfaces introduce components that require monitoring

- Potential for inconsistency: Worn or mismatched springs can create uneven stripping force across the plate surface

- Increased die height: Spring travel requirements add to overall die stack height, potentially limiting press compatibility

Proper spring selection is critical to floating stripper plate success. Springs must deliver adequate force throughout their working range while surviving millions of compression cycles—a balance that requires careful engineering rather than arbitrary specification.

When specifying floating stripper plates, spring force calculations deserve particular attention. The stripping force must overcome material grip on the punch plus any vacuum effects, while remaining gentle enough to avoid part deformation. This calculation depends on material type, thickness, punch perimeter, and cutting clearance—variables unique to each application. Rather than applying generic formulas, consult with experienced die engineers or spring manufacturers who can evaluate your specific requirements.

The adjustability that floating plates offer proves especially valuable during die tryout and production optimization. If stripping performance isn't quite right, you can modify spring preload or swap spring rates without major die modifications—flexibility that fixed plates simply cannot match.

With both fixed and floating options now thoroughly examined, you're ready to explore how advanced engineering capabilities elevate stripper plate performance even further.

Precision-Engineered Stripper Solutions for Automotive Excellence

You've now seen how fixed stripper plates deliver cost efficiency for thin materials and how floating designs handle demanding thick-stock applications. But what happens when your project requires the best of both worlds? When automotive OEMs demand zero-defect parts, when tolerances tighten to micron levels, and when production volumes climb into the millions—standard approaches reach their limits.

This is where precision-engineered stripper plate solutions enter the picture. Modern die engineering combines advanced simulation technology, certified manufacturing processes, and expert design methodology to create stripper systems optimized for specific application requirements. Whether you need an injection mold stripper plate for plastic components or a stamping die stripper for metal parts, the engineering principles that drive excellence remain consistent.

Engineering Excellence in Modern Stripper Plate Design

What separates adequate stripper plate performance from exceptional results? The answer lies in understanding that every application presents unique demands. Material properties vary between suppliers. Part geometries create localized stress concentrations. Production rates influence thermal behavior. Expert engineering accounts for these variables through systematic analysis rather than generic specifications.

Consider what is a stripper plate in injection molding contexts—it must withstand thermal cycling, resist wear from filled polymers, and deliver consistent ejection force across the part surface. Metal stamping stripper plates face different challenges: high-frequency impact loading, abrasive material contact, and precise alignment requirements. Professional die engineering addresses these application-specific demands through:

- Material selection optimization: Matching tool steel grades to specific wear patterns, load conditions, and surface finish requirements

- Geometric analysis: Evaluating stripping force distribution across complex part perimeters to prevent localized overload

- Thermal management: Accounting for heat generation during high-speed operations that affects clearances and material behavior

- Integration planning: Designing stripper systems that work harmoniously with other die components for optimal overall performance

The injection mold design stripper plate approach offers valuable lessons for stamping applications. Mold designers routinely use simulation tools to predict ejection behavior before cutting steel—a methodology that progressive stamping die engineers increasingly adopt for complex stripper plate challenges.

How CAE Simulation Optimizes Stripper Performance

Sounds complex? It doesn't have to be. Computer-Aided Engineering simulation transforms stripper plate optimization from guesswork into science. Before manufacturing begins, engineers can virtually test different configurations, predict potential problems, and refine designs for optimal performance.

CAE simulation addresses critical questions that traditional methods cannot answer reliably:

- Force distribution mapping: Visualizing how stripping forces distribute across the plate surface reveals areas needing reinforcement or relief

- Deflection analysis: Predicting plate deflection under load identifies designs that maintain critical clearances throughout the press stroke

- Spring rate optimization: For floating designs, simulation helps specify spring combinations that deliver consistent force across the working range

- Wear prediction: Identifying high-wear zones guides surface treatment decisions and maintenance planning

- Thermal effects modeling: Understanding temperature-induced dimensional changes prevents clearance problems during production

Companies like Shaoyi leverage advanced CAE simulation to optimize stripper plate designs before committing to tooling manufacture. This approach catches potential issues early—when changes cost pennies rather than dollars—and accelerates the path from concept to production-ready tooling.

The simulation-driven methodology proves especially valuable when evaluating the fixed vs floating stripper plate decision. Rather than relying solely on experience-based rules, engineers can model both configurations for a specific application and compare predicted performance objectively. Sometimes the analysis reveals that a well-designed fixed plate handles an application traditionally assigned to floating designs—or vice versa.

Precision Manufacturing for Defect-Free Results

Even the most sophisticated design delivers nothing without precision manufacturing to bring it to life. Automotive applications particularly demand manufacturing capabilities that consistently produce tooling meeting tight specifications. This is where certifications like IATF 16949 become meaningful rather than merely decorative.

IATF 16949 certification indicates a quality management system specifically designed for automotive supply chain requirements. For stripper plate manufacturing, this translates to:

- Documented process controls: Every manufacturing step follows verified procedures that ensure repeatability

- Measurement system validation: Inspection equipment undergoes regular calibration and capability verification

- Traceability: Material certifications and processing records link finished components back to source materials

- Continuous improvement: Systematic analysis of quality data drives ongoing process refinement

When stripper plate precision directly impacts part quality—and automotive OEMs trace defects back through the supply chain—these manufacturing controls become essential rather than optional. A silver plate stripper finish, for example, requires consistent surface preparation and plating thickness control that only disciplined manufacturing processes can deliver.

The difference between acceptable and exceptional stripper plate performance often comes down to manufacturing precision—the ability to consistently produce components that match design intent within microns rather than tenths.

Professional die engineering services combine these capabilities—CAE simulation, certified manufacturing, and application expertise—to deliver stripper plate solutions optimized for specific requirements. Shaoyi's engineering team exemplifies this integrated approach, offering rapid prototyping in as little as 5 days and achieving a 93% first-pass approval rate through their simulation-driven design methodology. Their comprehensive mold design and fabrication capabilities serve demanding automotive applications where both fixed and floating stripper designs require expert engineering to meet OEM standards.

Key benefits of partnering with precision die engineering specialists include:

- Rapid prototyping capabilities: Accelerate development timelines with quick-turn tooling for validation testing

- High first-pass approval rates: Simulation-validated designs reduce tryout iterations and speed production launch

- OEM-standard tooling: Meet the documentation, quality, and traceability requirements that automotive customers demand

- Application-specific optimization: Benefit from engineering expertise that matches stripper plate designs to your unique requirements

Whether your application calls for a silver plate stripper surface treatment for corrosion resistance or specialized hardening for abrasive materials, precision engineering ensures the finished tooling performs as intended from first article through end of production life.

With engineering excellence establishing the foundation for optimal stripper plate performance, let's examine the essential components and accessories that complete the system.

Essential Stripper Plate Components and Accessories

Your stripper plate selection—whether fixed or floating—represents only part of the complete system. The components surrounding that plate dramatically influence overall die performance, tool life, and part quality. Pilot punches, spring retainers, and stripper bolts work together with your chosen plate design to create a reliable stripping system.

Think of it this way: even the finest floating stripper plate underperforms when paired with inadequate pilot punches or improperly specified springs. Understanding these supporting components helps you build complete systems rather than isolated solutions.

Pilot Punch Selection for Stripper Plate Systems

Pilot punches serve a critical function that extends beyond simple hole-making. These precision components maintain strip registration throughout progressive die operations, ensuring each station engages the workpiece in exactly the right position. When selecting carbide pilot punches for fixing to stripper plates, you're investing in alignment accuracy that compounds across every die station.

Straight pilot punches for stripper plates must meet demanding requirements:

- Concentricity: The pilot diameter must run true to the shank within microns to prevent cumulative positioning errors

- Surface finish: Smooth pilot surfaces reduce friction during strip advancement and minimize wear on pilot holes

- Hardness: The pilot tip must resist wear from repeated material contact while maintaining dimensional stability

- Length precision: Proper pilot engagement depth ensures the strip locates before cutting punches contact the material

The relationship between pilot punch engagement and stripper plate type deserves careful attention. In fixed stripper designs, pilots must fully engage the strip before cutting punches break through the plate surface. Floating strippers offer more flexibility—the spring-loaded plate holds material while pilots locate, creating a controlled engagement sequence that reduces the risk of mislocation.

Critical Components That Enhance Stripper Performance

Beyond pilot punches, several component categories influence how well your stripper plate system performs over production life:

- Spring retainer options: These components secure compression springs in floating stripper applications. Quality retainers maintain spring position throughout millions of cycles, preventing the loosening or misalignment that causes uneven stripping force. Consider shoulder-style retainers for positive spring location or socket-head designs for easy adjustment access.

- Stripper bolt configurations: The bolts connecting floating plates to die components must balance strength with adjustability. Fine-thread designs allow precise preload control, while standard threads offer easier replacement. Bolt material selection—from standard alloy steel to premium grades—affects fatigue life under cyclic loading.

- Guide pin and bushing systems: Proper plate guidance prevents the lateral movement that causes punch stripper plate rubs top surface contact issues. Precision-ground guide pins paired with quality bushings maintain alignment even as wear accumulates.

- Keeper plates and backing blocks: These support components distribute stripping forces across the plate surface, preventing localized deflection that affects part quality.

Punch movement distance—the stroke length through which punches travel beyond the stripper plate—influences component selection significantly. Longer punch travel requires more robust pilot guidance and greater spring travel capacity in floating designs. When the punch stripper plate rubs top surface during misalignment, both components suffer accelerated wear.

Carbide vs Standard Pilot Punches Compared

One of the most impactful component decisions involves pilot punch material selection. The choice between carbide and standard tool steel pilots affects tool life, maintenance intervals, and long-term operating costs.

| Characteristic | Carbide Straight Pilot Punches | Standard Tool Steel Pilots |

|---|---|---|

| Wear Resistance | Exceptional—maintains diameter through millions of cycles | Good—gradual wear requires periodic replacement |

| Initial Cost | 3-5x higher than standard alternatives | Lower upfront investment |

| Best Applications | High-volume production, abrasive materials, tight tolerances | Moderate volumes, non-abrasive materials, standard tolerances |

| Breakage Risk | Higher brittleness requires careful handling | More forgiving of impact and misalignment |

| Regrind Potential | Limited—typically replaced rather than reground | Multiple regrinds extend useful life |

Carbide straight pilot punches for fixing to stripper plates deliver compelling advantages in demanding applications. When processing abrasive materials like stainless steel or silicon steel, carbide pilots maintain their precision diameter far longer than standard alternatives. For operations running three shifts with minimal planned downtime, the reduced replacement frequency often justifies the higher initial investment.

However, carbide's brittleness demands respect. Improper handling during die setup, accidental impact, or severe misalignment can fracture carbide pilots instantly—whereas tool steel alternatives might survive the same abuse with only surface damage. This characteristic influences not just material selection but also stripper plate type selection: the controlled engagement sequence of floating strippers reduces the impact loading that threatens carbide components.

Component-level decisions compound across your die system. Investing in premium carbide pilot punches for fixing to stripper plates while neglecting spring retainer quality creates a system limited by its weakest element.

When specifying pilot punches and accessories for your stripper plate system, consider the complete operating environment. Match component quality levels across the system, select materials appropriate for your production volumes, and ensure all elements work harmoniously with your chosen fixed or floating plate design.

Stripper Bars and Rings as Alternative Solutions

So far, we've focused on the fixed vs floating stripper plate decision—but what if a plate isn't the right answer at all? Sometimes the best solution isn't choosing between fixed and floating designs. It's stepping back and recognizing that stripper bars or ring strippers might serve your application more effectively.

These alternative stripping methods occupy important niches in die design. Understanding when each approach excels helps you avoid over-engineering simple applications while ensuring complex dies receive appropriate solutions.

When Stripper Bars Outperform Plates

Imagine a straightforward blanking operation—a single punch producing simple round or rectangular parts from sheet stock. Does this application really need a full plate stripper with all its associated complexity and cost? Often, the answer is no.

Stripper bars offer a streamlined alternative for simpler die configurations. These narrow strips of hardened tool steel mount across the die opening, contacting the workpiece on either side of the punch. As the press returns, the bars hold the material while the punch withdraws.

Consider stripper bars when your application involves:

- Simple blanking dies: Single-station operations with straightforward part geometries benefit from the reduced complexity

- Large punch footprints: When stripper plates wider than available stock would be required, bars spanning the die opening provide a practical solution

- Quick-change tooling: Bars allow faster punch access for replacement or sharpening compared to removing full plates

- Limited die height: The minimal vertical profile of bars conserves shut height in press-constrained applications

- Cost-sensitive projects: Bars require less material and machining than full plates, reducing tooling investment

The trade-off? Stripper bars provide less material control than plates. They contact the workpiece only along narrow lines rather than across the full surface. For thin materials or operations where part flatness isn't critical, this limitation rarely matters. For applications demanding precise material hold-down, full plate strippers remain the better choice.

Ring Strippers for Specialized Applications

What about round punches operating in isolation? Ring strippers—also called stripper rings or collar strippers—wrap concentrically around individual punches, providing localized stripping force exactly where needed.

This plate stripper alternative shines in specific scenarios:

- Single-punch piercing operations: When one round hole dominates the die function, a ring stripper delivers efficient stripping without full plate overhead

- Turret punch tooling: Individual punch stations benefit from self-contained stripping systems that travel with each tool

- Large-diameter punches: Massive round punches generate significant stripping forces concentrated in a small area—rings handle these loads efficiently

- Retrofit applications: Adding stripping capability to existing dies often proves easier with rings than installing full plate systems

- Spring-loaded variations: Ring strippers can incorporate individual springs for floating-style behavior on a per-punch basis

Ring strippers typically mount in the stripper plate mould or holder with a slight interference fit or set screws. The ring's inner diameter provides punch guidance while its lower face contacts the workpiece during stripping. This dual function—guidance plus stripping—makes rings particularly valuable for long, slender punches prone to deflection.

Choosing Between Plates, Bars, and Rings

How do you determine which stripping method suits your application? The decision flows from die complexity, part geometry, and production requirements:

| Stripping Method | Best Applications | Key Advantages | Primary Limitations |

|---|---|---|---|

| Stripper Plates (Fixed/Floating) | Progressive dies, complex geometries, precision parts | Full material control, punch guidance, versatility | Higher cost, more complex design |

| Stripper Bars | Simple blanking, large parts, quick-change dies | Lower cost, easy punch access, minimal height | Limited material hold-down, less precise |

| Ring Strippers | Round punches, turret tooling, retrofit applications | Concentrated force, punch guidance, modular design | Round punches only, individual setup required |

When evaluating your options, ask these guiding questions:

- How many punches require stripping? Multiple punches in close proximity favor plates; isolated punches may suit bars or rings

- What part geometry am I producing? Complex perimeters need plates; simple shapes work with bars or rings

- How critical is material flatness? Demanding flatness requirements push toward full plate strippers

- What's my budget constraint? Limited budgets may favor simpler bar solutions for appropriate applications

- How often will I change punches? Frequent changes favor bars or rings for easier access

The best stripping solution matches the application's actual requirements—not the most sophisticated option available. Simple blanking dies with stripper plates are over-engineered; progressive dies with only stripper bars are under-designed.

Many production dies combine these methods strategically. A progressive die might use a floating stripper plate across most stations while incorporating ring strippers for isolated large-diameter punches that generate exceptional stripping forces. This hybrid approach optimizes each station's stripping system for its specific demands.

With alternative stripping solutions now understood, you're ready for the comprehensive head-to-head comparison that brings all these options together in a unified selection framework.

Complete Fixed vs Floating Stripper Plate Comparison

You've explored fixed stripper plates, floating designs, precision-engineered solutions, and alternative stripping methods. Now it's time to bring everything together in the comprehensive comparison you've been waiting for—the side-by-side analysis that consolidates all the critical factors into actionable decision-making guidance.

This isn't about declaring a universal winner. Instead, you'll gain a clear framework for matching each stripper plate type to specific application requirements. The right choice depends entirely on your unique production demands, material characteristics, and performance priorities.

Fixed vs Floating Head-to-Head Comparison

When evaluating the fixed vs floating stripper plate decision, six dimensions matter most. The following comparison table presents all three solution tiers—precision-engineered, floating, and fixed—across these critical performance factors:

| Evaluation Factor | Precision-Engineered Solutions | Floating Stripper Plates | Fixed Stripper Plates |

|---|---|---|---|

| Stripping Force Capability | Optimized through CAE simulation for exact application requirements; handles 10-25% of punch force with precision calibration | Adjustable via spring selection; typically handles higher stripping forces effectively | Limited to forces manageable through rigid mounting; best for lower-force applications |

| Material Thickness Range | Full spectrum capability—thin to thick materials with application-specific optimization | Excels with materials over 1.5mm; handles thick stock requiring controlled pressure | Optimal for thin gauge materials under 1.5mm; struggles with thicker stock |

| Maintenance Requirements | Predictive maintenance enabled through simulation data; optimized service intervals | Regular spring inspection and replacement; periodic adjustment required | Minimal maintenance; fewer wear components to monitor or replace |

| Initial Cost | Premium investment; highest upfront cost offset by performance optimization | Moderate to high; 20-40% more than fixed alternatives | Lowest initial investment; economical for appropriate applications |

| Best Applications | Automotive OEM requirements, zero-defect production, complex progressive dies | Thick materials, progressive dies, slug pulling prevention, precision positioning | Thin gauge stamping, high-speed operations, simple blanking, electronics components |

| Production Volume Suitability | High-volume manufacturing with demanding quality requirements; millions of cycles | Medium to high volumes; spring replacement adds periodic maintenance windows | All volumes; particularly cost-effective for high-speed, high-volume thin material runs |

Notice how each option occupies a distinct performance envelope. Precision-engineered solutions deliver maximum capability but require corresponding investment. Floating designs balance versatility with manageable complexity. Fixed plates offer simplicity and economy for applications matching their strengths.

Selection Matrix by Application Type

Beyond the general comparison, specific application scenarios point toward clear recommendations. Use this matrix to match your project characteristics with the most suitable stripper plate approach:

| Application Scenario | Recommended Solution | Reasoning |

|---|---|---|

| Automotive structural components with IATF requirements | Precision-Engineered | OEM traceability demands, zero-defect expectations, and complex geometries justify premium tooling |

| Progressive dies with 5+ stations | Floating or Precision-Engineered | Material control across multiple operations prevents cumulative positioning errors |

| Thick steel blanking (over 2mm) | Floating | Spring force counteracts material springback; prevents slug pulling |

| High-speed connector terminal stamping | Fixed | Thin materials and extreme speeds favor rigid stability over spring compliance |

| Prototype and low-volume production | Fixed | Lower investment appropriate when tooling may change before high-volume launch |

| Heated plate stripper applications | Precision-Engineered | Thermal management requires simulation-driven design to maintain clearances |

| Molding stripper plates proto mold development | Floating or Precision-Engineered | Adjustability accommodates design iterations; controlled ejection protects part surfaces |

| Simple round blanking operations | Fixed (or Ring Strippers) | Straightforward geometry doesn't justify floating complexity |

When your application spans multiple categories—say, a progressive die processing thin materials at high speed—weigh the factors accordingly. The dominant requirement typically drives the selection, with secondary factors confirming or adjusting the initial direction.

Cost and Performance Trade-offs Revealed

Initial purchase price tells only a fraction of the total cost story. Smart tooling decisions account for the complete economic picture across the production lifecycle:

- Upfront investment: Fixed plates cost 20-30% less than floating alternatives; precision-engineered solutions command premium pricing

- Setup time: Fixed plates install quickly with minimal adjustment; floating designs require spring preload calibration; precision solutions include optimized setup procedures

- Maintenance frequency: Springs in floating systems require inspection every 500,000-1,000,000 cycles; fixed plates may run maintenance-free for years

- Downtime costs: A stripper-related stoppage costs production time regardless of initial tooling investment—choosing the wrong type creates ongoing expense

- Scrap reduction: Proper stripper selection directly impacts first-pass yield; premium solutions often pay for themselves through reduced reject rates

- Tool life impact: Appropriate stripping force extends punch and die life; mismatched systems accelerate wear across all cutting components

Consider the molding stripper plates u tube ejection approach used in some injection mold applications—the initial complexity investment enables consistent part quality that reduces secondary operations and customer returns. The same principle applies to stamping: investing appropriately in stripper plate systems often delivers positive ROI through downstream quality improvements.

The most expensive stripper plate is the wrong one—regardless of its purchase price. A low-cost fixed plate causing 2% additional scrap on a million-piece run creates far greater expense than a premium floating system delivering consistent quality.

When calculating ROI for stripper plate investments, include these often-overlooked factors:

- Engineering time: Complex applications may require multiple tryout iterations with simpler strippers—time that precision-engineered solutions eliminate

- Opportunity cost: Delayed production launch while troubleshooting stripper problems costs market position and customer confidence

- Cascade effects: Stripper-induced part damage can cause downstream assembly problems, warranty claims, and reputation impact

- Flexibility value: Floating strippers' adjustability accommodates material lot variations and punch wear without die modifications

For high-stakes applications—automotive safety components, medical devices, aerospace parts—the performance assurance of precision-engineered or properly specified floating systems typically justifies their premium. For commodity parts with forgiving tolerances, fixed strippers deliver cost-effective results.

Armed with this comprehensive comparison framework, you're ready to translate analysis into action with specific recommendations tailored to common production scenarios.

Final Recommendations for Your Stripper Plate Selection

You've navigated the technical details, evaluated the trade-offs, and explored the full spectrum of stripping solutions. Now comes the moment that matters most—translating all that knowledge into confident action for your specific application. Whether you're designing a new progressive die, troubleshooting an existing stamping operation, or planning a high-volume production launch, these prioritized recommendations guide you toward the right stripper plate decision.

Remember: the goal isn't finding the "best" stripper plate in absolute terms. It's matching your unique application requirements to the solution that delivers optimal performance, reliability, and value for your specific situation.

Your Stripper Plate Selection Roadmap

After analyzing countless applications and evaluating the fixed vs floating stripper plate decision from every angle, clear patterns emerge. These prioritized recommendations reflect the decision-making process that experienced die engineers follow:

- For automotive precision stamping requiring IATF compliance: Partner with certified die engineering specialists who combine CAE simulation capabilities with quality-certified manufacturing. The stakes in automotive applications—safety implications, OEM traceability requirements, and zero-defect expectations—demand precision-engineered solutions rather than off-the-shelf approaches. Companies like Shaoyi exemplify this capability, offering rapid prototyping in as little as 5 days and achieving a 93% first-pass approval rate through simulation-driven design methodology. Their IATF 16949 certification and comprehensive mold design expertise make them a valuable resource when your application demands professional die engineering support.

- For thin materials under 1.5mm thickness: Fixed stripper plates offer cost-effective, reliable performance. The rigid mounting design provides excellent punch guidance, minimal maintenance requirements, and consistent behavior across millions of cycles. High-speed electronics stamping, thin-gauge automotive brackets, and simple blanking operations typically fall into this category. Don't over-engineer these applications—save your premium tooling budget for projects that genuinely require floating or precision-engineered solutions.

- For thick materials or progressive dies: Floating stripper plates provide the controlled pressure and material handling these applications demand. The spring-loaded design counteracts material springback, prevents slug pulling, and accommodates the punch wear that occurs during extended production runs. When processing stock over 1.5mm or running progressive dies with multiple stations, the adjustability and active stripping force of floating designs typically justify their higher initial investment.

- For prototype and development work: Start with fixed strippers unless specific application requirements clearly indicate otherwise. Lower initial investment makes sense when designs may evolve before production launch. You can always upgrade to floating systems during production tooling if tryout results indicate the need.

- For specialized equipment applications: Consider the specific demands of your equipment. A yardmax log splitter stripper plate, for example, faces entirely different requirements than precision stamping tooling—heavy impact loading, outdoor environmental exposure, and different material characteristics. Match your stripper selection to the actual operating environment rather than applying stamping die guidelines universally. Similarly, ingun stripper plate applications for testing equipment demand precision alignment that may favor fixed designs despite other factors suggesting floating alternatives.

Match Your Application to the Right Stripper Type

Beyond the prioritized recommendations, consider these application-specific insights that fine-tune your selection:

- When part flatness is critical: Floating strippers' controlled hold-down force prevents the material lifting that causes dimensional distortion during cutting

- When running multiple material thicknesses: Adjustable stripper plates paid dividends through their ability to accommodate different stock without die modifications

- When slug pulling causes quality issues: The active downward pressure of floating designs dramatically reduces slug retention on punch faces

- When die height is constrained: Fixed strippers' minimal vertical profile conserves precious shut height in press-limited applications

- When maintenance windows are limited: Fixed designs' reduced component count means fewer parts to inspect, adjust, or replace

- When processing abrasive materials: Pair your stripper selection with appropriate surface treatments and premium pilot punch materials to extend service life

Note that specialized applications like yardmax log splitter stripper plate replacements follow different selection criteria entirely—focusing on durability and impact resistance rather than the precision considerations dominating stamping die decisions.

Expert Recommendations for Common Scenarios

For readers facing specific decision points, here's direct guidance based on the most common application scenarios:

- Launching a new progressive die program: Invest in CAE simulation during design to optimize stripper plate configuration before cutting steel. The simulation cost represents a fraction of tryout modifications.

- Experiencing inconsistent part quality: Evaluate whether your current stripper type matches material thickness and complexity requirements. Upgrading from fixed to floating often resolves persistent quality issues.

- Planning high-volume automotive production: Engage with IATF-certified die engineering specialists early in the program. Shaoyi's engineering team delivers cost-effective, high-quality tooling tailored to OEM standards, with high-volume manufacturing capabilities that scale with your production demands.

- Balancing budget constraints with performance needs: Use fixed strippers where appropriate to preserve budget for floating or precision-engineered solutions where they're genuinely required.

- Retrofitting existing dies: Ring strippers offer a practical upgrade path for adding floating-style stripping to specific punch locations without full plate replacement.

The fixed vs floating stripper plate decision ultimately comes down to one principle: match your solution to your actual requirements. Under-engineering creates quality problems; over-engineering wastes resources. The sweet spot lies in honest assessment of what your application truly demands.

As you move forward with your stripper plate selection, remember that this decision integrates with every other aspect of die design. The best stripper plate choice considers punch geometry, material characteristics, production volumes, quality requirements, and maintenance capabilities as interconnected factors rather than isolated variables. When in doubt, consult with experienced die engineers who can evaluate your complete application picture and recommend solutions optimized for your specific success.

Frequently Asked Questions About Fixed vs Floating Stripper Plates

1. What is a stripper plate in a press tool?

A stripper plate is a critical die component that removes workpiece material from punches after each stroke. It can be either fixed (rigidly mounted) or floating (spring-loaded). Fixed strippers strip stock but don't hold it during operation, while floating strippers actively hold down material during stamping and use spring force for controlled ejection. The choice between types directly impacts part quality, tool longevity, and production efficiency.

2. What is stripping force in press tool applications?

Stripping force is the force required to detach material stuck to the punch after cutting. It typically ranges from 10-25% of the blanking force. Floating stripper plates deliver adjustable stripping force through spring selection, while fixed plates rely on the press stroke itself. Proper stripping force prevents slug pulling, ensures clean part separation, and maintains consistent cycle times in stamping operations.

3. When should I use a fixed stripper plate instead of floating?

Fixed stripper plates are ideal for thin gauge materials under 1.5mm, high-speed stamping operations exceeding 400 strokes per minute, and simple blanking dies. They cost 20-30% less than floating alternatives, require minimal maintenance, and provide excellent stability for precision electronics stamping. Choose fixed strippers when material behavior is predictable and controlled hold-down pressure isn't critical.

4. What are the main advantages of floating stripper plates?

Floating stripper plates excel with thick materials over 1.5mm, progressive dies, and applications requiring precise part positioning. Key advantages include superior material control during punching, reduced slug pulling through active downward pressure, automatic compensation for punch wear, and adjustable spring force. They're essential when material springback, complex geometries, or zero-defect production requirements demand controlled stripping force.

5. How do stripper bars and rings differ from stripper plates?

Stripper bars are narrow hardened steel strips spanning the die opening—ideal for simple blanking, large parts, and quick-change tooling at lower cost. Ring strippers wrap around individual round punches, perfect for single-punch operations and turret tooling. Plates provide full material control for complex progressive dies. Choose based on die complexity: plates for multi-station precision work, bars for simple operations, rings for isolated round punches.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —