Brake Backing Plate Stamping: Process, Precision & Technology

TL;DR

Brake backing plate stamping is the precision manufacturing process responsible for creating the structural steel foundation of a brake pad. This process utilizes high-tonnage presses—typically ranging from 400 to 1,000 tons—to form steel coils into rigid plates that must withstand immense shear forces and thermal cycling. The industry relies on two primary methods: conventional stamping, which offers speed and cost-efficiency for standard parts, and fine blanking, which delivers superior edge quality and flatness (tolerances as tight as ±0.0005 inches) for complex, high-performance applications.

Beyond basic forming, modern backing plate manufacturing integrates critical safety features like mechanical retention systems (NRS) directly into the stamping process to prevent friction material delamination. Whether ensuring the perfect flatness required for noise-free braking or applying galvanized coatings to resist "rust jacking," the stamping quality directly dictates the safety and longevity of the final brake pad.

The Manufacturing Process: From Coil to Component

The journey of a brake backing plate begins long before it enters a press. The process is a sequence of precision operations designed to transform raw steel into a safety-critical component capable of enduring thousands of braking cycles.

1. Material Preparation and Feeding

Production starts with high-strength hot-rolled or cold-rolled steel coils, typically varying in thickness from 2mm to 6mm depending on the vehicle application (heavy-duty commercial vehicles may require up to 12mm). These coils are fed through a straightener/leveller to remove coil set and internal stresses, ensuring the material is perfectly flat before entering the die. Flatness is non-negotiable; any curvature here will translate to brake noise (NVH) in the final assembly.

2. The Stamping Phase

In this critical stage, the steel strip enters a high-tonnage press—often a progressive die setup or a dedicated transfer press. This is where the plate's geometry is defined. The press performs multiple operations in a single stroke:

- Blanking: Cutting the outer perimeter of the plate.

- Piercing: Creating holes for caliper pins or sensors.

- Forming: Stamping features like abutment clips or retention patterns.

For manufacturers seeking a balance between high-volume output and engineering precision, partners like Shaoyi Metal Technology utilize presses up to 600 tons to deliver IATF 16949-certified components. Their capabilities bridge the gap from rapid prototyping (as few as 50 parts) to mass production, ensuring that even complex geometries meet global OEM standards.

3. Secondary Operations and Finishing

After the plate leaves the press, it undergoes secondary processing to ensure surface readiness. This often includes shot blasting to roughen the surface for adhesive bonding (if mechanical retention isn't used) and tumble deburring to remove sharp edges that could cut into shims or cause assembly injuries. Finally, plates are washed and often treated with anti-corrosion coatings like zinc plating or black oxide.

Fine Blanking vs. Conventional Stamping

For engineers and procurement managers, the choice between fine blanking and conventional stamping is the most significant technical decision in the supply chain. While both processes cut metal, the mechanics—and the results—are fundamentally different.

Conventional Stamping

In conventional stamping, a punch impacts the metal, shearing it for about one-third of its thickness before the material fractures or "breaks" the rest of the way. This leaves a characteristic rough edge with a "die break" zone that is often tapered. While efficient and cost-effective for standard applications, conventional stamping typically requires secondary grinding or shaving if a perfectly smooth edge is needed for precise caliper fitment.

Fine Blanking

Fine blanking is a cold extrusion process that uses a triple-action press. It applies three distinct forces: a downward punch force, a counter-pressure from below, and a "V-ring" impingement force that clamps the material securely before cutting. This prevents the material from flowing away from the punch, resulting in a 100% sheared edge that is smooth, vertical, and free of fractures.

| Feature | Conventional Stamping | Fine Blanking |

|---|---|---|

| Edge Quality | Rough, tapered fracture zone (approx. 70% die break) | 100% smooth, sheared, vertical edge |

| Tolerances | Generally ±0.005" - ±0.010" | Precision down to ±0.0005" |

| Flatness | Good, but may require levelling | Superior, near-perfect flatness out of press |

| Secondary Steps | Often requires deburring, shaving, or grinding | Net-shape part; often ready for assembly immediately |

| Cost | Lower tooling and operation costs | Higher tooling investment; slower cycle times |

| Best For | Standard aftermarket pads, high-volume economy parts | OEM specs, complex geometries, intricate features |

Mechanical Retention Systems (NRS) vs. Adhesive Bonding

One of the most critical functions of the backing plate is to hold the friction material (the brake pad puck) securely. Historically, this was done using adhesives, but modern engineering prefers Mechanical Retention Systems (MRS), often referred to by the trade name NRS (Nucap Retention System).

The Failure of Adhesives

Traditional brake pads rely on heat-cured glue to bond the friction material to the steel plate. While effective initially, this bond is susceptible to two major failure modes:

- Thermal Shear: Extreme braking temperatures can degrade the adhesive's chemical bonds, causing the pad to shear off under heavy load.

- Rust Jacking: In corrosive environments, rust forms on the steel plate and creeps under the glue. As the rust expands (occupying more volume than the steel), it physically lifts the friction material off the plate, leading to delamination and catastrophic failure.

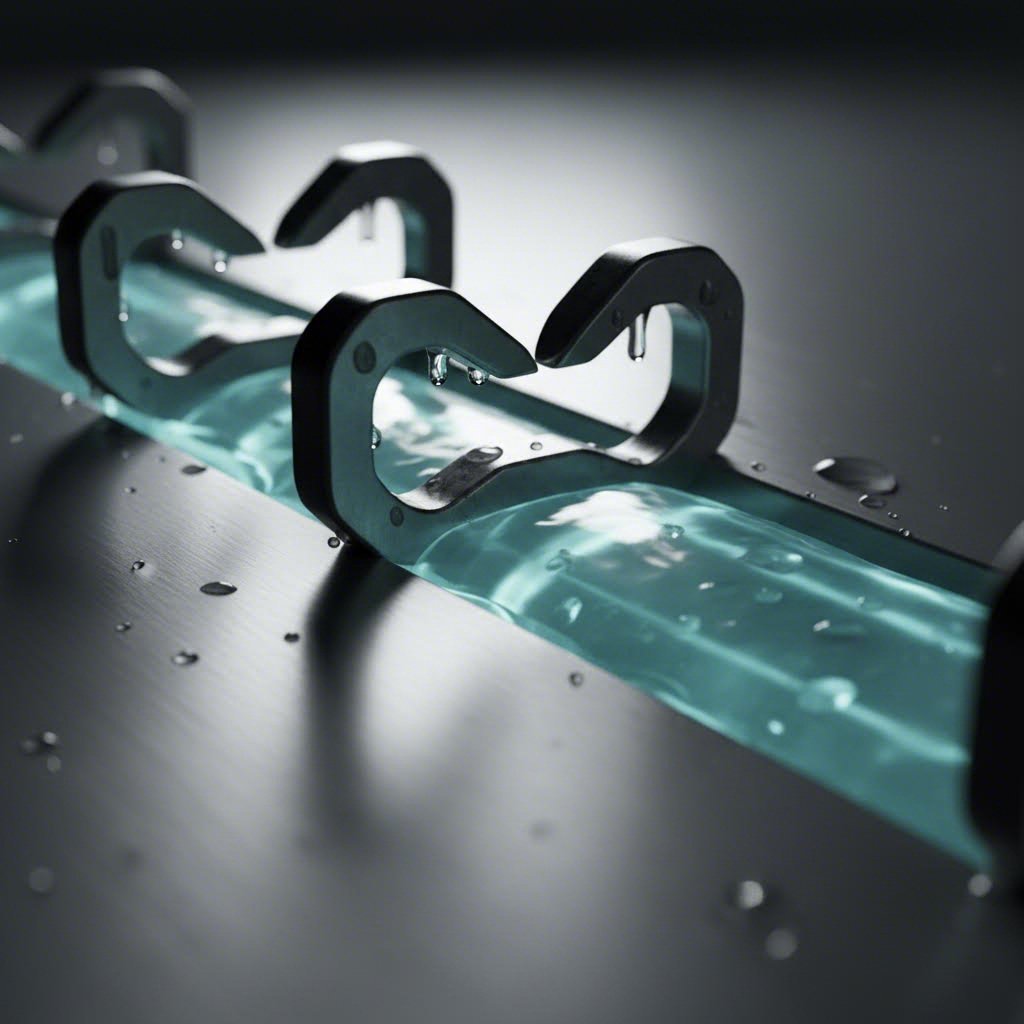

The Mechanical Solution

Mechanical retention involves stamping hundreds of tiny, bi-directional steel hooks directly onto the face of the backing plate. During the molding process, the friction material flows around and under these hooks, curing into a solid, interlocked composite. This creates a physical bond that cannot be broken by heat or chemicals.

When combined with galvanized steel, mechanical retention eliminates rust jacking entirely. Since there is no adhesive layer to fail, the bond remains secure down to the last millimeter of friction material, significantly extending the safe service life of the brake pad.

Material Specifications & Quality Standards

The integrity of a brake backing plate depends entirely on the quality of the raw material. Manufacturers typically use specific grades of hot-rolled steel, such as SAPH440 or Q235, which offer the necessary tensile strength and ductility.

Critical Defect Prevention

Quality control in stamping focuses on identifying and eliminating microscopic defects that could lead to field failures:

- Die Roll: The depression on the upper surface of the stamped edge. Excessive die roll can reduce the effective contact area for the brake shim, leading to noise issues.

- Burrs: Sharp projections on the cut edge. Burrs exceeding 0.2mm can interfere with the caliper's anti-rattle clips, preventing the pad from retracting properly and causing drag.

- Fracture Zones: In conventional stamping, deep fractures can propagate cracks under the cyclic stress of braking.

To ensure reliability, top-tier manufacturers subject plates to rigorous testing, including salt spray tests (to verify corrosion resistance of coatings) and shear testing (to measure the force required to separate the friction material from the plate). Standard shear strength requirements often exceed 4-5 MPa to ensure safety under panic-stop conditions.

Engineering Precision for Safety

The manufacturing of brake backing plates is far more than simple metal punching; it is a discipline of microns and metallurgy. Whether employing the cost-effective speed of conventional stamping or the surgical precision of fine blanking, the goal remains the same: to provide a rigid, unyielding foundation for the vehicle's braking system. As vehicles become heavier (with EVs) and quieter, the demand for backing plates with tighter tolerances, superior flatness, and fail-safe mechanical retention systems will only increase. For buyers and engineers, understanding these underlying technologies is the first step in ensuring safety and performance on the road.

Frequently Asked Questions

1. What happens if a backing plate rusts through?

If a backing plate corrodes significantly, it can lead to "rust jacking," where the rust layer expands and forces the friction material to separate (delaminate) from the steel plate. This causes severe noise, vibration, and potentially a complete loss of braking power if the friction puck detaches. Galvanized plates with mechanical retention systems are designed specifically to prevent this failure.

2. Why is fine blanking preferred for OEM brake parts?

Fine blanking is preferred by Original Equipment Manufacturers (OEMs) because it produces parts with superior flatness and 100% smooth, sheared edges without the need for secondary machining. This ensures a precise fit within the brake caliper, minimizing vibration and noise (NVH) which is critical for new vehicle quality standards.

3. Can mechanical retention hooks be used with any friction material?

Yes, mechanical retention hooks are compatible with most friction formulations, including semi-metallic, ceramic, and organic compounds. The friction material is molded directly over the hooks during the pressing and curing stage, creating a permanent physical interlock regardless of the chemical composition of the pad.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —