Plating Stamped Automotive Contacts: Reliability & Cost

TL;DR

Plating stamped automotive contacts is a critical step in ensuring electrical reliability, preventing corrosion, and maintaining signal integrity under harsh vehicle conditions. While Tin offers a cost-effective solution for general use, Gold and Silver are essential for safety-critical and high-voltage EV applications, respectively. For high-volume manufacturing, Reel-to-Reel (Continuous) plating is the industry standard, offering precision control and the ability to use Selective Plating—depositing precious metals only where the contact mates—to significantly reduce costs. Engineers must balance the trade-offs between Pre-plating (cheaper, but leaves bare edges) and Post-plating (100% coverage) based on the component's exposure to moisture and vibration.

Critical Functions of Plating in Automotive Stamped Parts

In the automotive environment, a stamped contact is never just a piece of metal; it is a critical interface that must survive thermal shock, humidity, and constant mechanical stress. The primary function of plating is to stabilize the contact resistance over the vehicle's lifespan. Without the correct surface finish, base metals like copper or brass would rapidly oxidize, leading to open circuits or intermittent failures in systems ranging from infotainment to autonomous braking.

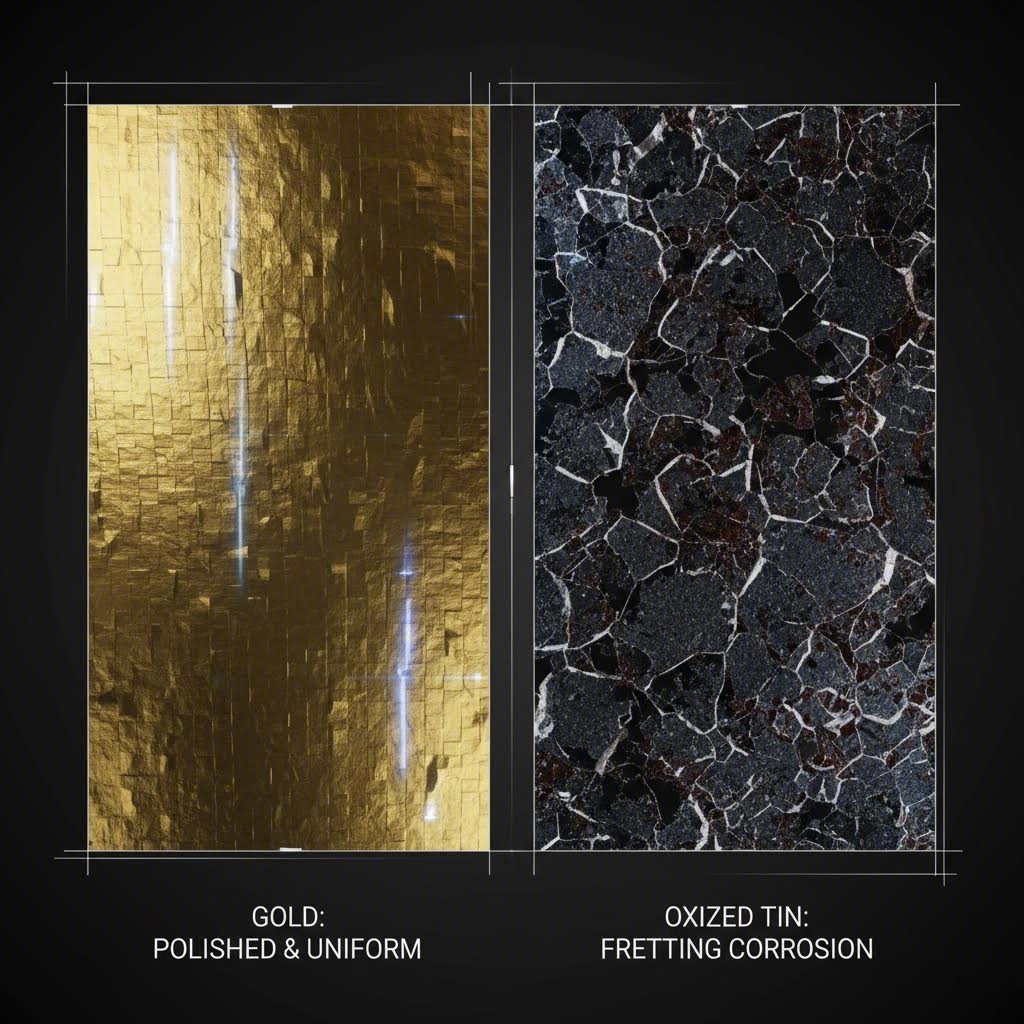

One of the most insidious failure modes is fretting corrosion. This occurs when micromotions induced by engine vibration or thermal expansion cause the contact surfaces to rub against each other. If the plating is too soft or poorly adhered, this motion wears through the protective oxide layer, generating debris that increases resistance. Plating materials like hard gold or palladium-nickel are often specified for high-vibration zones because they resist this wear mechanism better than soft tin.

Beyond electrical performance, plating serves a vital barrier function. Galvanic corrosion is a major risk when dissimilar metals (e.g., an aluminum wire terminal mating with a copper contact) are in the presence of an electrolyte like salt spray. A well-chosen plating layer, such as nickel, acts as an intermediate barrier to prevent the galvanic cell from forming, ensuring the structural integrity of the connection.

Material Selection Matrix: Tin, Gold, Silver, & Nickel

Selecting the right plating material is a trade-off between performance requirements (voltage, cycle life, temperature) and cost. Below is a comparison of the standard options used in automotive stamping.

| Material | Type | Key Benefit | Typical Thickness | Ideal Automotive Application |

|---|---|---|---|---|

| Tin (Sn) | Passive | Low cost, excellent solderability | 100–300 µin | General sensors, lighting, non-critical cabin electronics (< 10 mating cycles). |

| Gold (Au) | Noble | Zero oxidation, low contact resistance | 10–50 µin (Flash to Hard) | Safety systems (Airbags, ABS), ECU connectors, low-voltage signal lines. |

| Silver (Ag) | Noble | Highest conductivity, handles high current | 100–300 µin | EV powertrains, high-power charging contacts, battery interconnects. |

| Nickel (Ni) | Passive | Hardness, diffusion barrier | 50–300 µin | Underplate for Gold/Silver; high-temperature sensors requiring wear resistance. |

| Palladium-Nickel | Noble Alloy | Durability, lower cost than pure gold | 10–30 µin | High-cycle connectors, switches requiring extreme reliability. |

Gold remains the standard for high-reliability signals because it does not form insulating oxides. However, its cost drives engineers toward selective plating techniques. Conversely, Silver is seeing a resurgence due to the electrification of vehicles; its superior conductivity minimizes heat generation in high-current EV connectors, though it carries a risk of tarnishing (sulfide formation) that must be managed. For general purpose terminals, Tin and Tin-Lead alloys (where permitted) provide a "good enough" solution for static connections that are not unplugged frequently.

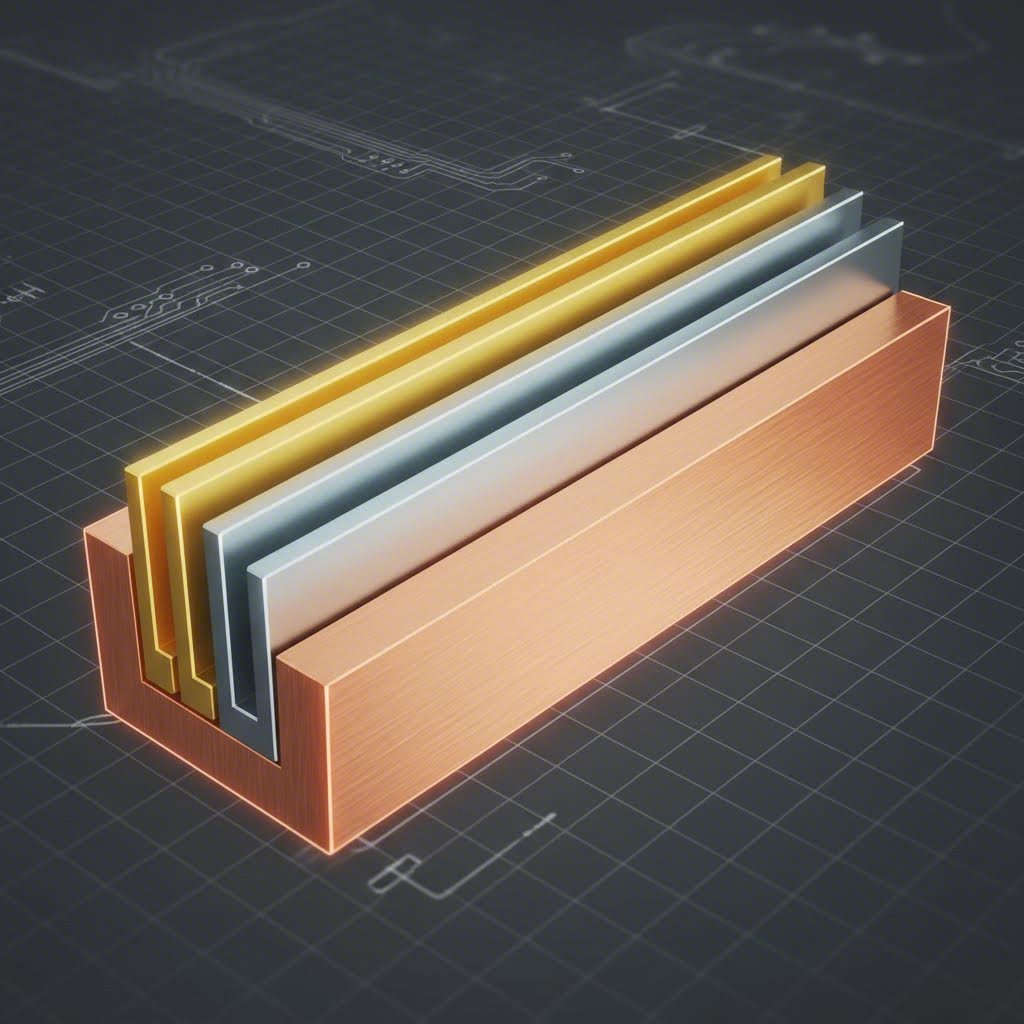

Process Comparison: Reel-to-Reel vs. Barrel vs. Rack

The manufacturing method dictates both the cost and quality of the final part. Reel-to-Reel (Continuous) plating is the dominant process for stamped automotive contacts. In this method, the stamped strip is fed through a series of plating baths before being cut into individual parts. This allows for Selective Plating (or spot plating), where precious metals like gold are deposited only on the contact area, while the rest of the part receives a cheaper flash or no plating at all.

A case study by CEP Technologies highlights the value of this approach: by redesigning a welded contact into a stamped part with selective gold plating, they eliminated a costly secondary welding operation and reduced precious metal usage, improving both manufacturability and cost. This precision is impossible with Barrel Plating, where loose parts are tumbled in a drum. While barrel plating is economical for coating entire parts (like screws or simple clips) with zinc or tin, it risks tangling delicate stamped arms and cannot apply selective zones.

Rack Plating is reserved for complex, fragile, or heavy geometries that cannot be reeled. Parts are mounted on fixtures to prevent damage. While it offers excellent quality control, it is generally too slow and labor-intensive for the high-volume commodity nature of most automotive terminals.

Pre-Plating vs. Post-Plating: The Bare Edge Dilemma

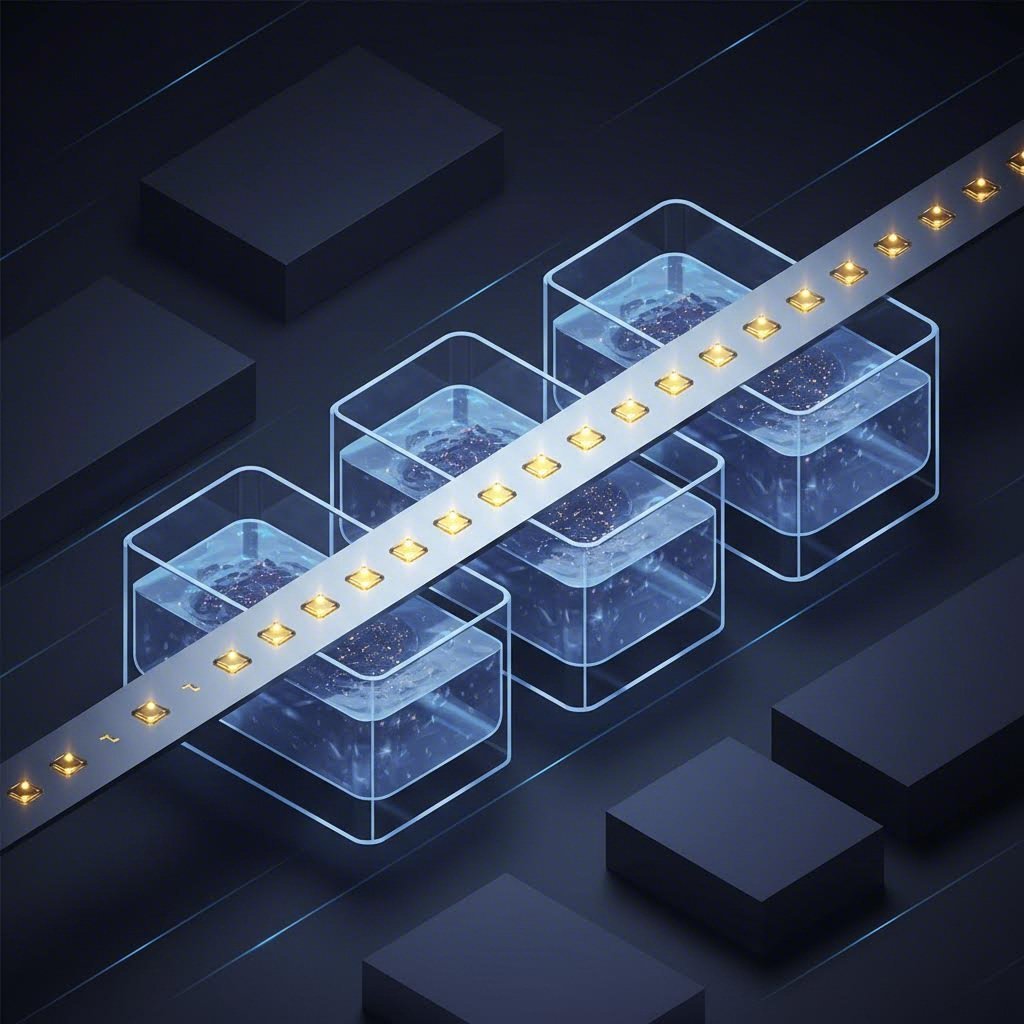

A fundamental decision in the stamping workflow is whether to plate the raw strip before stamping (Pre-plating) or plate the finished parts after stamping (Post-plating). Pre-plating is typically more cost-effective and faster, as the raw material arrives at the press ready to process. However, the stamping action—cutting and punching the metal—exposes the unplated base metal (usually copper or steel) at the sheared edges.

This "bare edge" can be a vulnerability in corrosive environments, potentially leading to rust or oxidation that creeps under the plating. For cabin applications, this is rarely an issue. However, for under-hood or exterior sensors, Post-plating is often required to seal the entire component. Kenmode notes that post-plating stamped strips reel-to-reel offers a middle ground: it ensures full coverage of the stamped edges while maintaining the efficiency of continuous processing, though it requires careful design to ensure the carrier strip does not mask critical areas.

Design for Plating (DFM) for Stamped Contacts

Successful plating starts on the drafting board. Engineers must design the carrier strip—the metal skeleton that holds the parts during stamping—to be robust enough for the plating line's tension but flexible enough to guide through the baths. Pilot holes must be precisely spaced to align the strip with the selective plating masks. If the part is designed for barrel plating, it must have features that prevent "nesting" (parts locking together), which causes unplated spots.

Transitioning from a prototype design to a high-volume stamped reality often requires a partner who understands these nuances. For instance, Shaoyi Metal Technology provides comprehensive stamping solutions that bridge this gap, offering precision fabrication from rapid prototyping to mass production while adhering to IATF 16949 standards. Collaborating with a capable manufacturer early in the design phase ensures that features like drain holes (to prevent chemical entrapment) and contact geometries are optimized for the chosen plating method.

Furthermore, material selection influences plating adhesion. Base metals like Phosphor Bronze or Beryllium Copper are excellent for spring properties but may require a copper underplate to ensure the final nickel or gold layer adheres correctly without blistering.

Automotive Industry Standards & Testing

Validation in the automotive sector is rigorous. Plating specifications are governed by standards such as USCAR-2 (Performance Specification for Automotive Electrical Connector Systems) and ASTM B488 (Standard Specification for Electrodeposited Coatings of Gold). These standards dictate not just the thickness of the plating, but its porosity, adhesion, and hardness.

Common validation tests include:

- Salt Spray Test (ASTM B117): Exposes parts to a saline fog to test corrosion resistance. Essential for verifying that bare edges or pores do not lead to failure.

- Mixed Flowing Gas (MFG): Simulates complex atmospheric pollutants (chlorine, sulfur, nitrogen dioxide) to test performance in industrial or polluted environments.

- Fretting Corrosion Test: Cycles the contact mechanically while monitoring resistance spikes, ensuring the plating can withstand engine vibration.

- Solderability Testing: Verifies that tin-plated tails will wet properly during PCB assembly, even after "steam aging" to simulate storage.

Manufacturers like TE Connectivity rigorously test their DEUTSCH contacts to these standards, ensuring reliable operation in temperatures ranging from -55°C to 150°C. Specifying compliance with these standards on the engineering drawing is the only way to guarantee the final part will meet the demanding reliability targets of modern vehicles.

FAQs: Plating Automotive Contacts

1. What is the difference between "flash" gold and "hard" gold?

"Flash" gold is a very thin layer (typically 3–5 micro-inches) used primarily for preventing oxidation on parts that will be soldered or have very low mating cycles. "Hard" gold is a thicker deposit (30–50 micro-inches) alloyed with small amounts of cobalt or nickel to increase durability. Hard gold is required for sliding contacts or connectors that will be plugged and unplugged frequently, as flash gold would wear through almost immediately.

2. Why is an underplate usually required?

An underplate, most commonly Nickel, serves two critical roles. First, it acts as a "diffusion barrier," preventing atoms from the base metal (like copper or zinc) from migrating through the gold layer and oxidizing on the surface, which would ruin conductivity. Second, it provides a hard, leveling base that improves the wear resistance and brightness of the final topcoat.

3. Can I use Silver plating for all automotive connectors?

While Silver is the best conductor, it is not a universal solution. It is prone to "tarnishing" (forming silver sulfide) when exposed to sulfur in the atmosphere or from rubber gaskets. While this tarnish is conductive enough for high-voltage (high-force) applications like EV charging, it can cause resistance issues in low-voltage, low-force signal circuits. Silver is also susceptible to electromigration in high-humidity environments, which can cause short circuits.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —