Automation in Metal Stamping Industry: The Central Nervous System

TL;DR

Automation in the metal stamping industry has evolved from simple mechanical handling into the "central nervous system" of modern manufacturing facilities. It is no longer just about faster production; it represents a holistic integration of three core pillars: advanced hardware (servo presses and robotics), intelligent software (IIoT and predictive data), and optimized processes (vision inspection and safety). This guide explores how these technologies work together to drive zero-defect quality and maximize ROI.

For plant managers and engineers, the shift to automation means moving beyond standalone machines to a fully synchronized ecosystem. By leveraging technologies like tandem press-to-press transfer systems and real-time vision validation, manufacturers can overcome labor shortages, enhance safety by removing operators from hazardous zones, and achieve the precision required by automotive and aerospace standards.

The Technological Ecosystem: Beyond Just Robots

The foundation of any automated stamping line lies in its hardware. While robots are the most visible component, the true power comes from the integration of specialized machinery that communicates seamlessly. Understanding the specific roles of servo technology and transfer systems is critical for selecting the right equipment for your facility.

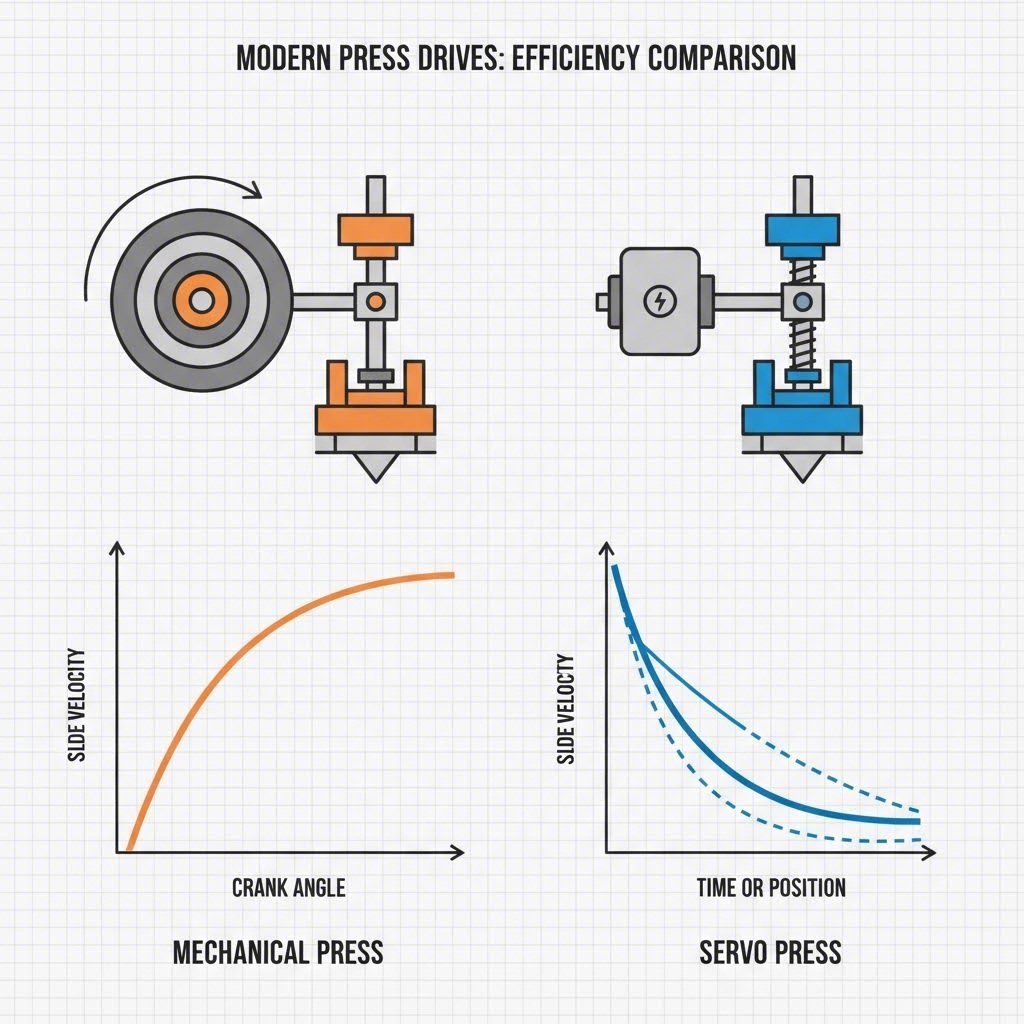

Servo-Driven Presses vs. Mechanical Systems

Traditional mechanical presses operate on a fixed flywheel system, limiting flexibility. In contrast, servo press technology allows for precise control over slide velocity and position at any point in the stroke. This capability enables manufacturers to adjust dwell times for specific forming operations, reducing spring-back and improving part quality. By controlling the die travel speed and pressure in real-time, servo presses can produce complex geometries that would be impossible with standard mechanical systems.

Front-of-Line (FOL) Destacking Solutions

Automation begins at the front of the line. The destacking process—separating raw blanks and feeding them into the first press—requires absolute reliability to prevent double-blanking, which can cause catastrophic die crashes. Two primary technologies dominate this space:

- Magnetic Fanners: Effective for ferrous materials but prone to picking up multiple sheets if the oil film is too heavy.

- Vacuum Cup Systems: Preferred for their precision. As noted by experts at JR Automation, vacuum cups minimize the risk of double-blanking and ensure single-sheet feeding, making them the standard for high-speed lines.

Robotic Tandem Press-to-Press (P2P) Transfer

Moving parts between stations in a tandem line is often the biggest bottleneck. Modern P2P transfer systems utilize high-speed, multi-axis robots that synchronize with the press cycle. Unlike rigid hard automation, these robotic systems offer the flexibility to handle high-mix, low-volume production runs. They can be reprogrammed in minutes to accommodate different part geometries, significantly reducing changeover time—a critical KPI for modern stamping facilities.

Smart Manufacturing & Data: The "Digital Nervous System"

Hardware alone is insufficient without the intelligence to drive it. Smart manufacturing transforms a stamping plant into a data-driven enterprise, often referred to as Industry 4.0. This "digital nervous system" relies on sensors and connectivity to monitor machine health and process stability in real-time.

Predictive Maintenance and IIoT

Reactive maintenance—fixing machines after they break—is costly and inefficient. By integrating Industrial Internet of Things (IIoT) sensors, manufacturers can monitor critical variables such as motor vibration, oil temperatures, and press tonnage. Ulbrich highlights how predictive maintenance algorithms analyze this data to forecast equipment failures days or weeks before they occur. This shift allows maintenance teams to schedule repairs during planned downtime, drastically improving Overall Equipment Effectiveness (OEE).

The Role of Digital Twins

A "Digital Twin" is a virtual replica of the physical stamping process. Before a single sheet of metal is stamped, engineers can simulate the entire production run in a virtual environment. This allows them to identify potential collisions, optimize robot paths, and validate cycle times. Digital twins reduce the trial-and-error phase of physical commissioning, ensuring that the automated line performs at peak efficiency from Day One.

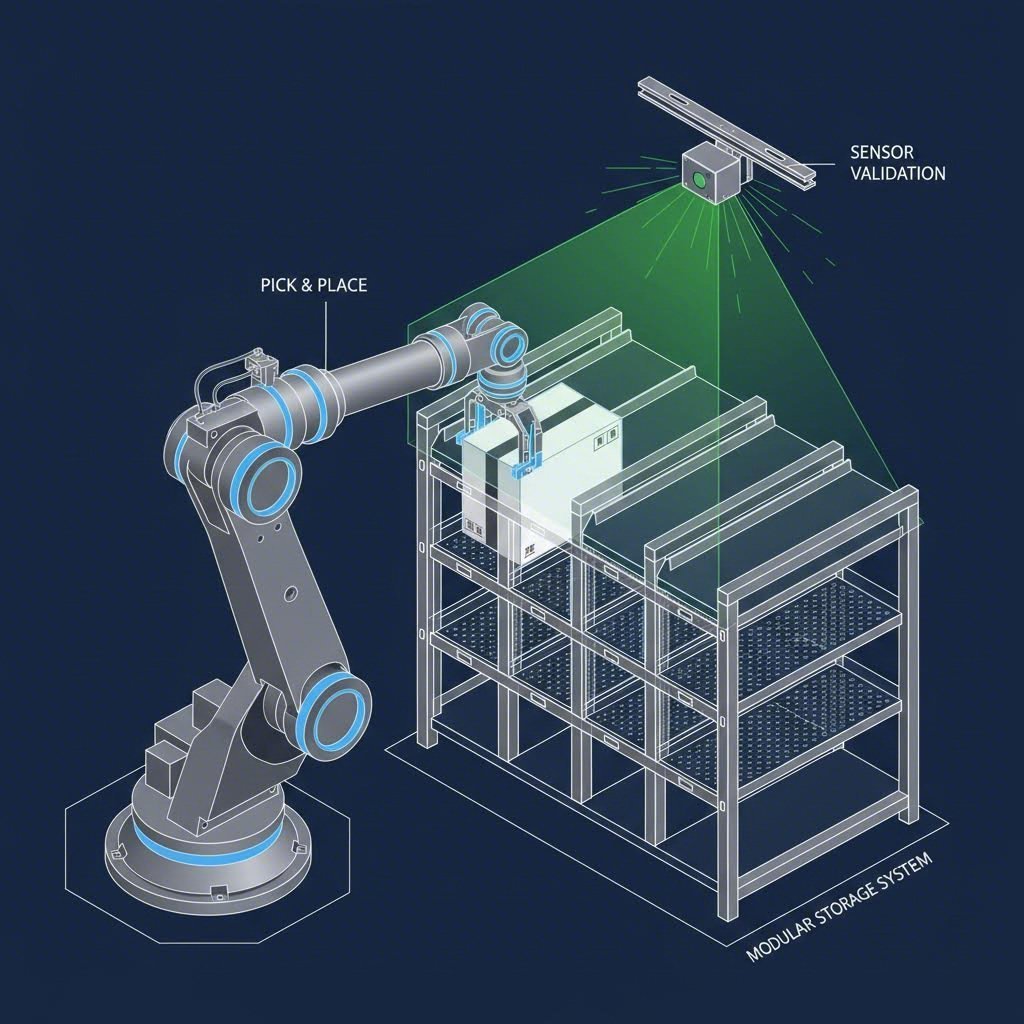

Critical Integration Points: Racking & Inspection

The most complex challenges in automation often occur at the end of the line (EOL). As finished parts exit the press, they must be inspected, racked, and prepared for shipment without creating a bottleneck.

End-of-Line (EOL) Racking Strategies

Automating the racking process is notoriously difficult due to the variability of shipping containers. There are generally two approaches:

- Fully Automatic Racking: Robotic arms pick finished parts and place them directly into shipping racks. This requires precise dunnage and rack positioning.

- Hybrid Systems: These systems allow for both manual and automatic racking, providing flexibility. However, they require sophisticated safety zoning (using light curtains and scanners) to ensure human operators can work safely alongside robots.

Vision Validation Systems

A robot cannot "see" a misaligned rack or a piece of debris without help. Advanced 3D vision systems are essential for validating the position and integrity of racks before a part is placed. These systems scan the container to ensure it is free of obstructions and correctly oriented. Additionally, inline vision inspection checks parts for surface defects, cracks, or dimensional variances immediately after stamping, ensuring that zero-defect parts reach the customer.

The Business Case: ROI, Safety, and Capacity

Investing in automation is a significant capital expenditure, but the return on investment (ROI) is driven by measurable gains in efficiency, quality, and workforce utilization.

Safety and Labor Upskilling

One of the most compelling arguments for automation is safety. By removing operators from the press line, manufacturers eliminate the risk of severe hand and limb injuries. Furthermore, Manor Tool emphasizes that automation does not necessarily eliminate jobs; rather, it upskills the workforce. Operators transition from repetitive manual loading tasks to higher-value roles such as system programming, quality control, and maintenance technician positions.

Partnering for High-Volume Success

For automotive and industrial OEMs, the choice of a stamping partner often hinges on their automation capabilities and quality certifications. A fully automated facility can guarantee the throughput needed for mass production while maintaining strict tolerances. For example, Shaoyi Metal Technology leverages IATF 16949-certified precision and press capabilities up to 600 tons to bridge the gap from rapid prototyping to high-volume manufacturing. Their approach demonstrates how advanced fabrication services can deliver critical components like control arms and subframes that meet rigorous global standards.

The Future is Synchronized

Automation in the metal stamping industry has matured from a competitive advantage to a fundamental operational standard. The future belongs to facilities that can synchronize servo-driven precision with data-driven insights. By treating the stamping line as a cohesive, intelligent system, manufacturers can achieve the holy grail of production: higher speed, lower cost, and perfect quality. As technology advances, we can expect even deeper integration of AI and machine learning, further blurring the line between physical manufacturing and digital optimization.

Frequently Asked Questions

1. What is the difference between hard automation and robotic transfer?

Hard automation uses fixed mechanical systems to move parts between presses. It is extremely fast but lacks flexibility, making it ideal for high-volume, low-mix production. Robotic transfer uses programmable robot arms, offering slightly slower speeds but immense flexibility for high-mix operations where part designs change frequently.

2. How does servo press technology improve part quality?

Servo presses allow for programmable slide motion, meaning the speed and pressure can be adjusted at different points in the stroke. This enables "dwell" functions that reduce material spring-back and allow for better metal flow, resulting in higher dimensional accuracy and superior surface finish compared to traditional mechanical presses.

3. What are the main safety benefits of automating a stamping line?

The primary safety benefit is the physical separation of the operator from the press machinery. Automated systems handle the loading, transfer, and unloading of heavy, sharp metal parts, significantly reducing the risk of crush injuries, cuts, and ergonomic strain associated with manual handling.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —