Metal Stamping Burr Removal Techniques: Engineering Guide

TL;DR

Metal stamping burr removal techniques are critical for ensuring part safety, assembly fit, and aesthetic quality. For high-volume production, Mass Finishing (vibratory tumbling) remains the industry standard, offering consistent edge breaking and polishing. Complex geometries or precision parts often require Thermal Energy Method (TEM) or Electrochemical Deburring (ECD) to reach internal areas without damaging critical dimensions.

Ultimately, the most cost-effective strategy involves prevention at the source through proper die maintenance and clearance optimization. Engineers should select methods based on production volume, material ductility, and tolerance requirements to balance cost per part with quality standards.

Understanding Stamping Burrs: Causes & Characteristics

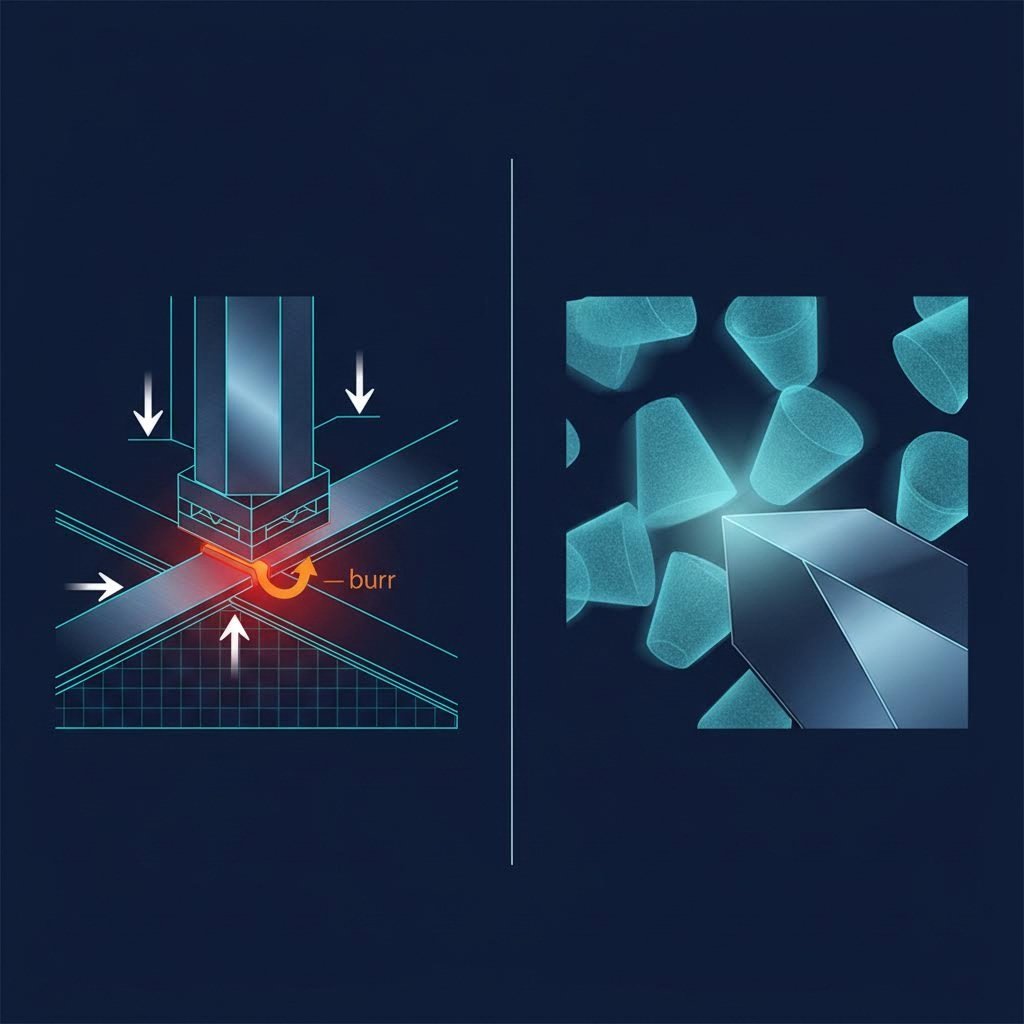

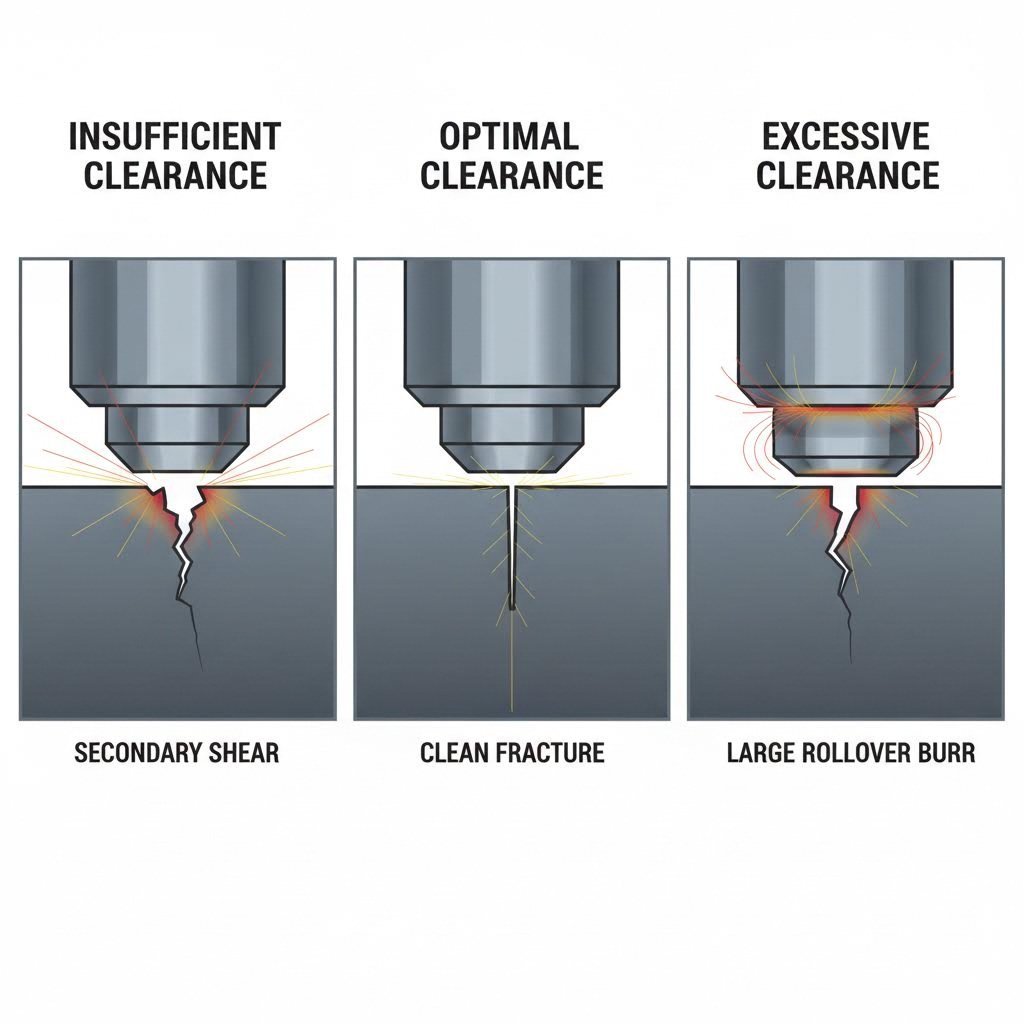

In metal stamping, a burr is not merely a rough edge; it is a specific defect caused by plastic deformation during the shearing process. As the punch strikes the metal, the material undergoes compressive stress until it reaches its fracture point. If the die clearance—the gap between the punch and the die—is incorrect, the material tears rather than shears cleanly, leaving a protruding “tooth” or ridge known as a burr.

The size and severity of a burr are directly influenced by material properties and tooling conditions. Ductile materials like aluminum and copper alloys are more prone to substantial “rollover” burrs because they stretch before breaking. Conversely, harder materials may exhibit cleaner fractures but can still develop sharp, jagged edges if the tool is dull.

The 10% Clearance Rule

Industry consensus suggests that die clearance is the primary variable in burr control. Typically, a clearance of approximately 10% of the material thickness is recommended for standard steel. Excessive clearance causes the material to roll over the die edge, creating large burrs. Insufficient clearance forces the punch to cut through more material than necessary, increasing tool wear and secondary shearing, which also results in significant burring.

Mass Finishing Techniques (High-Volume Solutions)

For the vast majority of stamped parts—brackets, washers, and clips—manual deburring is economically unfeasible. Mass finishing allows thousands of parts to be processed simultaneously, ensuring consistency across large production runs. This category primarily includes barrel tumbling and vibratory finishing.

Vibratory Bowl Finishing

Vibratory finishing is the dominant method for precision stamped parts. Parts are placed in a bowl or tub mounted on eccentric springs. The machine vibrates at high frequency, causing the parts to move in a circular, toroidal path through a bed of abrasive media. The constant friction between the media (ceramic, plastic, or steel) and the parts erodes sharp edges and polishes surfaces.

- Ceramic Media: Best for heavy cutting and hard metals like stainless steel. It provides aggressive removal rates.

- Plastic Media: Softer and lighter, ideal for aluminum or soft metals where surface impingement (denting) is a concern.

- Compounds: Liquid additives are often introduced to clean the parts, inhibit rust, and improve the lubricity of the media.

Barrel Tumbling

A simpler and more aggressive approach, barrel tumbling involves a rotating drum that lifts the load of parts and media and drops them (cascading). This high-energy impact is excellent for heavy burr removal on robust parts but poses a risk of damaging delicate features. It is generally slower than vibratory finishing but offers a lower capital equipment cost.

For automotive manufacturers requiring certified precision, integrating these finishing steps directly into the supply chain is crucial. Shaoyi Metal Technology’s comprehensive stamping solutions bridge the gap between raw fabrication and finished assembly, delivering high-volume components like control arms that meet strict IATF 16949 standards without the need for third-party finishing logistics.

Precision & Advanced Removal Methods

When stamped parts feature complex geometries, internal threads, or strict dimensional tolerances that cannot withstand the physical impact of tumbling, engineers turn to thermal and chemical solutions.

Thermal Energy Method (TEM)

Also known as “thermal deburring,” this process is highly effective for removing burrs from internal cavities and intersecting holes. Parts are sealed in a pressurized chamber filled with a mixture of fuel gas and oxygen. The mixture is ignited, creating a momentary heat wave that reaches temperatures up to 6,000°F (3,300°C) within milliseconds.

Because burrs have a high surface-area-to-mass ratio, they absorb the heat instantly and vaporize (oxidize). The main body of the part, having a much larger thermal mass, remains unaffected. This method guarantees zero edge rounding on the main surfaces but requires a post-process acid wash to remove the oxide layer formed during combustion.

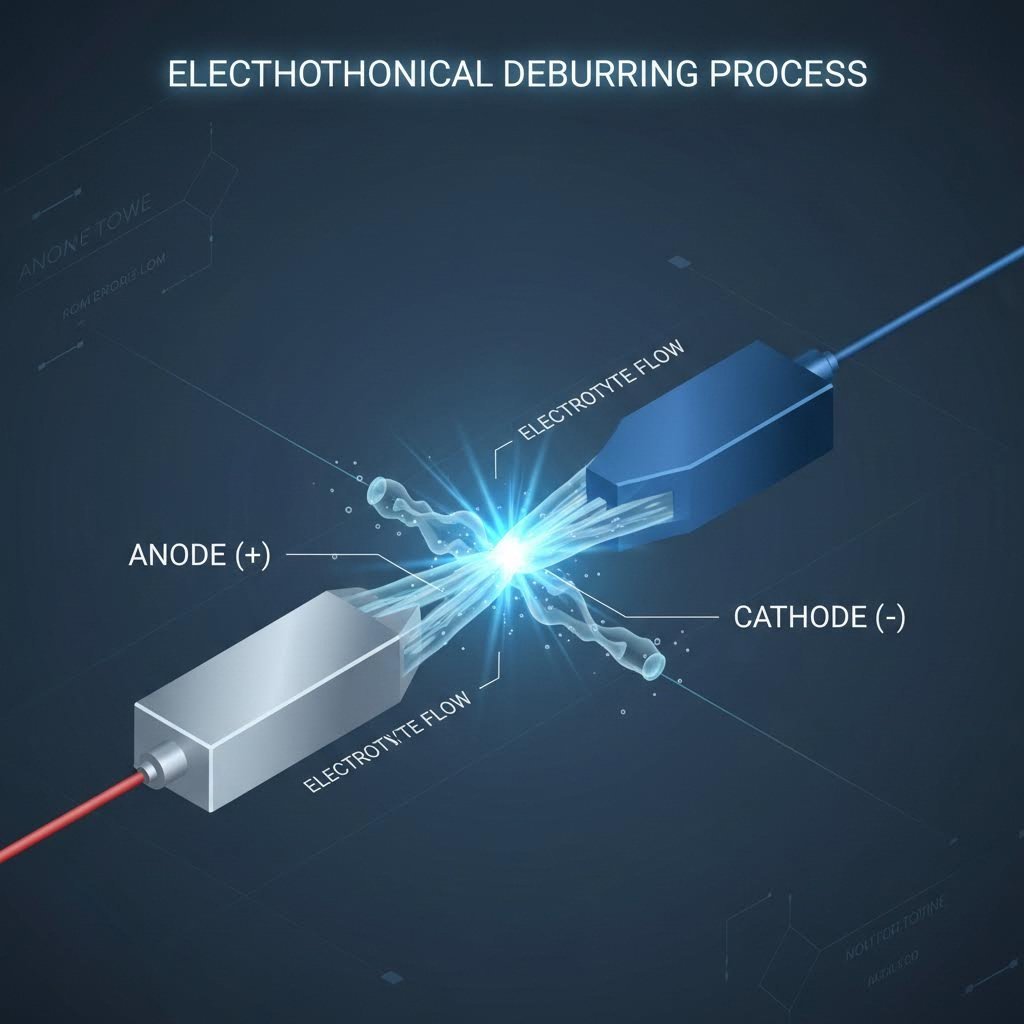

Electrochemical Deburring (ECD)

ECD is a subtractive method that uses electrolysis to dissolve burrs. The part serves as the anode (+), and a custom-shaped tool serves as the cathode (-). An electrolyte solution (often sodium nitrate) flows between the gap, which is typically kept between 0.3mm and 1mm.

When a DC current is applied, the material at the peak of the burr dissolves into the solution. This process is non-contact, meaning there is no tool wear and no mechanical stress on the part. It is the preferred method for high-value components like fuel injector nozzles or hydraulic valve bodies where even microscopic burrs can cause catastrophic system failure.

Mechanical & Die-Integrated Solutions

The most efficient way to handle burrs is often to address them while the part is still in the press or immediately after, using mechanical means tailored to the part's geometry.

| Method | Mechanism | Best Application |

|---|---|---|

| Die Punching (Shave Die) | A secondary die station "shaves" or coins the burr flat. | High-volume flat parts; integrated into progressive dies. |

| Brush Deburring | Rotary nylon/abrasive brushes sweep across the flat surface. | Flat blanks requiring surface graining or specific texture. |

| Spring-Loaded Hole Tools | A tool enters the stamped hole and actuates a cutter on the exit side. | Selectively deburring holes without affecting the outer profile. |

| Belt Grinding | Abrasive belts sand the burr face down. | Simple, flat parts where thickness tolerance is loose. |

Die Punching is particularly notable for high-speed stamping. By adding a “coining” station to the progressive die, the burr can be flattened back into the material. While this doesn't remove the material, it renders the edge safe for handling and is virtually free in terms of cycle time.

Prevention Strategy: Optimizing the Stamping Process

While removal techniques are necessary, the engineering goal should always be minimization. As noted by industry experts, “prevention first, treatment second” is the most economical approach.

- Cutting Clearance Optimization: Maintaining the optimal clearance (5-10% of thickness) prevents the excessive plastic deformation that causes large burrs.

- Tool Maintenance: A dull cutting edge tears metal rather than shearing it. Regular sharpening schedules are far cheaper than downstream deburring costs.

- Advanced Coatings: Applying Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) coatings to punches reduces friction and wear, maintaining a sharp cutting edge for significantly longer production runs.

- Design for Manufacturability (DFM): Engineers should design parts so that the “burr side” is oriented towards a non-critical face, or include chamfers in the design to mitigate sharp edges naturally.

Selecting the Right Deburring Strategy

Choosing the correct metal stamping burr removal technique is a balance of precision, volume, and cost. There is no single “best” method; rather, there is an optimal method for each specific application.

For general high-volume hardware, vibratory finishing offers the best economy of scale. For precision components with internal features, TEM or ECD provides the necessary access and accuracy. However, for every project, the journey to a burr-free part begins at the design table and the die station. By prioritizing tool health and proper clearance, manufacturers can drastically reduce the reliance on expensive secondary operations.

Frequently Asked Questions

1. What is the most common method for deburring stamped parts?

Mass finishing, specifically vibratory bowl finishing or barrel tumbling, is the most common method. It allows thousands of parts to be processed simultaneously, making it highly cost-effective for the high volumes typical of metal stamping.

2. How does die clearance affect burr formation?

Die clearance is the gap between the punch and the die. If the clearance is too tight, it increases tool wear and force. If it is too loose, the metal rolls over instead of shearing cleanly, creating large burrs. A clearance of roughly 10% of the material thickness is standard for minimizing burrs.

3. Can burrs be removed without affecting part dimensions?

Yes. Methods like Electrochemical Deburring (ECD) and Thermal Energy Method (TEM) remove burrs selectively without altering the main dimensions of the part. ECD targets high-current density areas (sharp edges), while TEM vaporizes thin burrs before the bulk material can heat up.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —