Stamped Steel Control Arms and Your Vehicle's Alignment

TL;DR

Stamped steel control arms are fundamental to your vehicle's suspension, directly dictating wheel alignment angles like camber and caster. Because of their design, they can limit adjustment options, especially after modifying your vehicle's height. Replacing a stamped steel control arm or installing a lift or leveling kit almost always requires a professional wheel alignment to correct the suspension geometry, prevent poor handling, and avoid rapid, uneven tire wear.

The Fundamental Role of Control Arms in Vehicle Alignment

If you've ever experienced a car that pulls to one side or noticed your tires wearing out unevenly, the issue often traces back to the suspension system, and specifically, the control arms. A control arm is a critical suspension link that connects your vehicle's frame to the steering knuckle, which holds the wheel. Its job is to allow the wheel to move up and down over bumps while precisely maintaining its angle relative to the road and the vehicle's body.

This positioning is what we refer to as wheel alignment. Any change to the control arm—whether from wear, damage, or replacement—directly impacts the alignment angles that are essential for safe handling and tire longevity. A worn ball joint or degraded bushing on a control arm can introduce excessive play, making a precise alignment impossible to hold. Understanding the control arm's role is the first step in diagnosing and fixing many common steering and suspension problems.

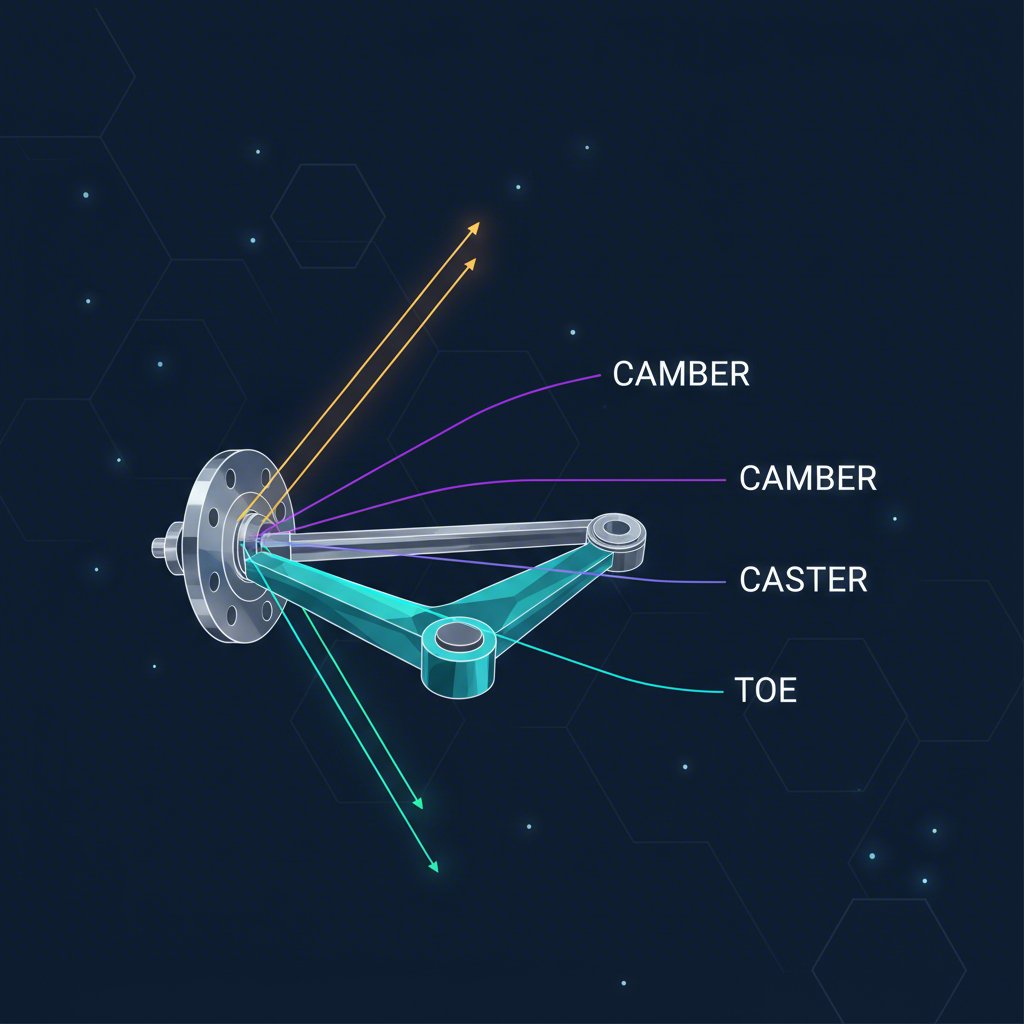

The three primary alignment angles managed by the control arms are:

- Caster: This is the angle of the steering axis when viewed from the side of the vehicle. Proper positive caster helps with straight-line stability and ensures the steering wheel returns to center after a turn.

- Camber: This is the inward or outward tilt of the top of the wheel when viewed from the front. Incorrect camber is a primary cause of wear on the inner or outer edge of a tire.

- Toe: This refers to the direction the front of the wheels are pointing in relation to each other, similar to looking down at your feet. Toe angle is a major factor in tire wear and steering stability.

Stamped Steel vs. Other Materials: A Comparative Analysis

Control arms are not all created equal; their material and manufacturing process significantly affect a vehicle's performance, weight, and durability. While stamped steel is a common choice for original equipment manufacturers (OEM) due to its low cost, several alternatives offer distinct advantages for different applications, from daily driving to off-road adventures.

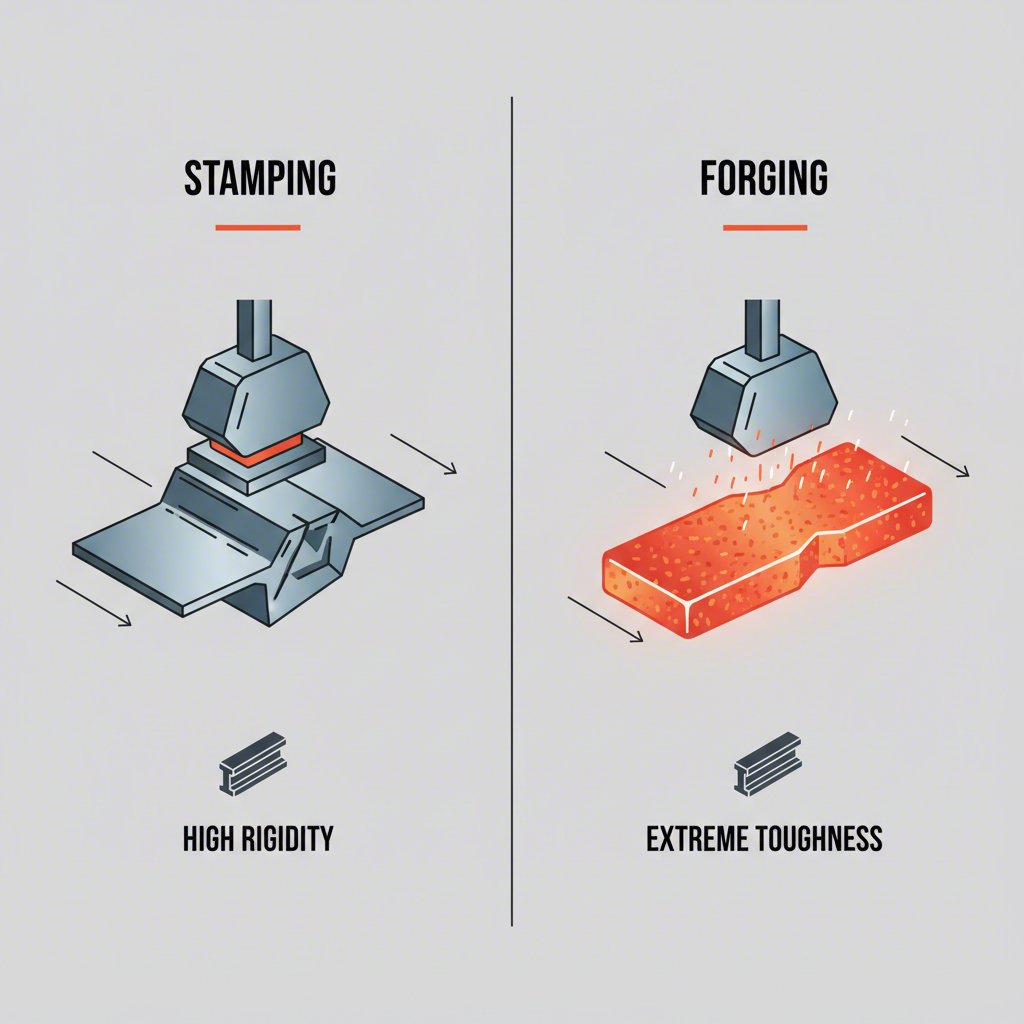

Stamped steel arms are made by pressing sheets of steel into a desired shape. This method is cost-effective but can result in a heavier component that may flex under high stress. In contrast, forged arms are created from a single piece of heated metal, resulting in a denser, stronger part. Tubular arms, often made from high-strength steel, offer an excellent balance of strength and low weight, which reduces unsprung mass and allows the suspension to react more quickly to the road surface. For automotive manufacturers, achieving the right balance of cost, weight, and durability is key. Companies that specialize in precision manufacturing, such as Shaoyi (Ningbo) Metal Technology Co., Ltd., provide advanced auto stamping parts that meet the rigorous IATF 16949 standards required by the industry, ensuring high-quality components from prototyping to mass production.

Here’s a breakdown of the common control arm types:

| Material Type | Manufacturing Process | Strength/Durability | Weight | Typical Use/Cost |

|---|---|---|---|---|

| Stamped Steel | Metal sheets are cut and pressed into shape using a die. | Adequate for standard use but can flex under load. | Heavy | OEM factory parts; lowest cost. |

| Forged Steel/Aluminum | A single piece of metal is heated and forged into shape. | Very strong and rigid due to dense grain structure. | Heavy (steel) to light (aluminum). | Heavy-duty trucks and performance vehicles; higher cost. |

| Cast Steel/Iron | Molten metal is poured into a mold. | Strong but can be brittle compared to forged. | Heavy | Common on many trucks and older vehicles; moderate cost. |

| Tubular Steel | High-strength steel tubes are bent and welded. | Excellent strength-to-weight ratio. | Lightweight | Aftermarket performance and off-road; moderate to high cost. |

How Stamped Steel Control Arms Specifically Impact Alignment

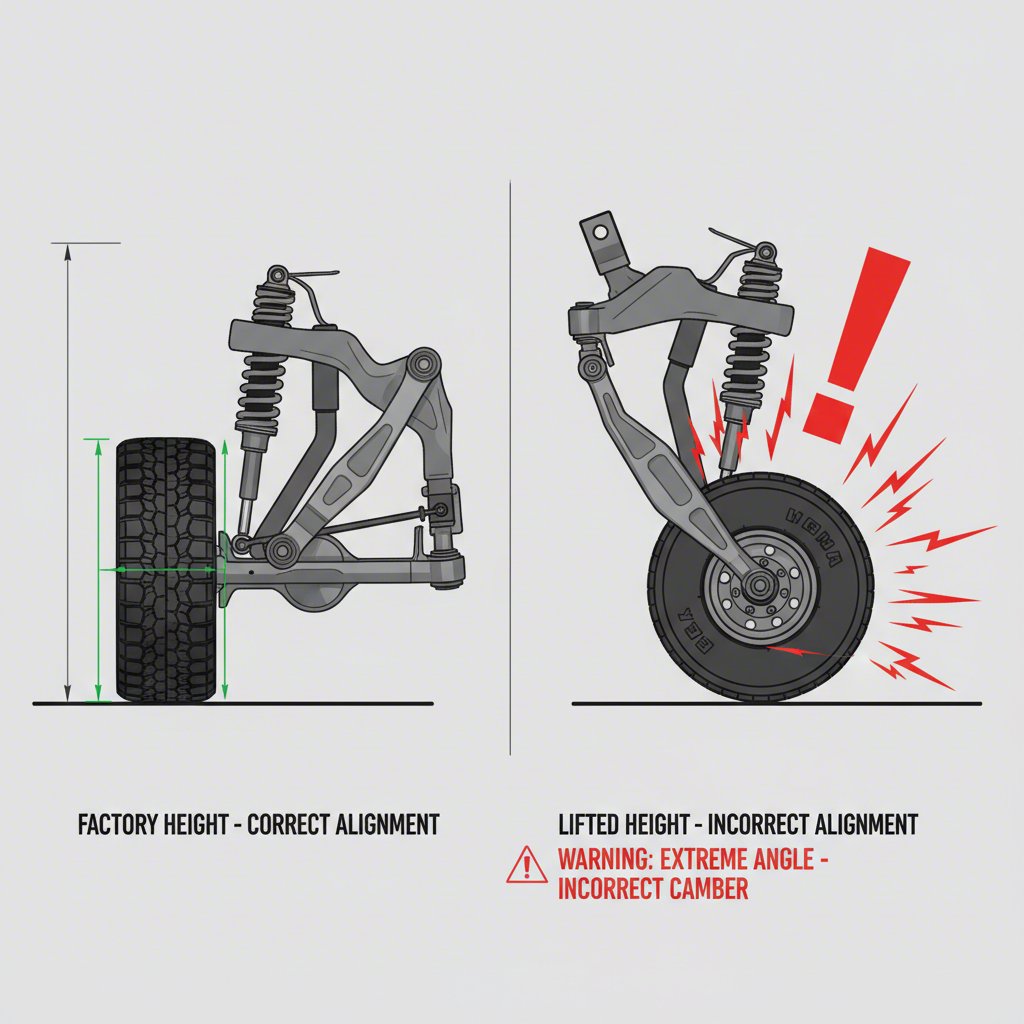

Factory-installed stamped steel control arms are designed to work perfectly with a vehicle's stock suspension height and geometry. However, their design often becomes a limiting factor when modifications are introduced, particularly when it comes to wheel alignment. The primary issue is a lack of built-in adjustability for camber and caster angles.

As detailed in an analysis by QA1, many factory suspension systems were designed with minimal positive caster, which can lead to a vague or “twitchy” steering feel by modern standards. Aftermarket tubular control arms are often engineered with additional positive caster built-in (e.g., 5-7 degrees) to improve straight-line stability and handling. Stamped steel arms lack this optimized geometry, making it difficult to achieve ideal alignment specs, especially on a lifted vehicle.

This problem is magnified when installing a leveling or lift kit. Raising the suspension changes the angle of the control arm, which in turn alters the camber and caster. The factory stamped steel arms may not have enough adjustment range to bring these angles back into specification. On many trucks like the Chevy Silverado, this can place excessive stress on the ball joints.

Warning: Exceeding a 2-inch leveling kit on some trucks with factory stamped steel control arms can put too much stress on the ball joints, potentially leading to premature failure and unsafe driving conditions.

To solve this, owners of modified vehicles often upgrade to adjustable aftermarket upper control arms. These products are specifically designed to provide the additional camber and caster adjustment needed to achieve a proper alignment after changing the vehicle's ride height, as noted by experts at Shock Surplus. This not only restores handling but also prevents premature wear on tires and other suspension components.

When a Wheel Alignment Is Necessary After Control Arm Work

A common question among DIY mechanics is whether a wheel alignment is truly needed after replacing a control arm. The answer, authoritatively, is yes. Any time a front control arm is removed and reinstalled, a professional alignment is not just recommended—it is a required final step for a complete and safe repair.

Even if you replace an old control arm with an identical new one, tiny differences in manufacturing tolerances, along with fresh, tighter bushings and ball joints, will slightly alter the final position of the wheel hub. As explained by the specialists at GSW Auto Parts, a professional alignment is non-negotiable because it measures and corrects all critical angles, including toe, which is impossible to set accurately at home and is a primary cause of rapid tire wear.

Think of the alignment as a small investment to protect your larger investment in tires and suspension parts. Driving without a proper alignment after control arm work will almost certainly lead to poor handling, reduced safety, and tires that wear out in a fraction of their expected lifespan.

A wheel alignment is essential in the following situations:

- After replacing any control arm, upper or lower.

- After installing a lift, leveling, or lowering kit.

- Whenever you notice uneven tire wear, especially on the inner or outer edges.

- If your vehicle pulls to one side or the steering wheel feels off-center.

Frequently Asked Questions

1. What is the main difference between stamped and forged control arms?

The primary difference is the manufacturing process and resulting strength. Stamped steel control arms are made from pressed metal sheets, making them cost-effective but potentially more flexible than other designs. Forged control arms are made from a single piece of metal that is heated and hammered into shape, creating a denser, stronger, and more durable component ideal for heavy-duty or performance applications.

2. Can I replace my stamped steel control arms with aluminum or tubular ones?

Yes, in most cases, you can upgrade to aftermarket aluminum or tubular control arms. These are often designed as direct-fit replacements that offer benefits like reduced weight and improved geometry for better alignment capabilities, especially on vehicles with modified suspensions. However, always ensure the replacement part is compatible with your specific vehicle make and model.

3. How long do stamped steel control arms typically last?

The lifespan of a stamped steel control arm depends heavily on driving conditions, climate (exposure to road salt), and maintenance. The arm itself is durable, but the integrated bushings and ball joints are wear items. Under normal conditions, they can last 80,000 to 150,000 miles or more. However, components may fail sooner in vehicles used for heavy hauling or on rough terrain.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —