Electrophoretic Coating Vs. Powder Coat And Liquid Paint

Electrophoretic Coating Essentials and Key Terms

Electrophoretic coating explained in plain terms

Ever wondered how manufacturers achieve such a smooth, even finish on metal parts, even in the tightest corners? That’s where electrophoretic coating comes in. Also known as e-coating or electrocoating, this process uses an electric field to deposit paint particles onto a metal surface. Imagine dipping a metal part into a bath of paint, then flipping a switch so the paint is drawn to every nook and cranny, covering even the most complex shapes. This isn’t just about looks—it’s about creating a uniform, protective layer that stands up to corrosion and wear.

- E-coating

- Electrocoating

- Electrophoretic deposition

- EP-coating

- Electropainting

- Cathodic electrodeposition

Define electrophoretic and how it differs from electroplating

Sounds complex? It’s simpler than it seems. In electrophoretic coating, the metal part acts as an electrode. When an electric current is applied, paint particles—suspended in a water-based bath—are attracted to the charged metal surface. This is called coating deposition by electric charge. The result: a thin, even layer of paint that covers the entire part, inside and out.

But how is this different from electroplating? While both use electricity, electroplating deposits a layer of metal (like nickel or chrome) onto the part, giving it a metallic finish and sometimes improving conductivity. In contrast, electrophoretic deposition applies a layer of paint or resin, which is primarily for protection and aesthetics. So, if you’re asking, what is e coated, it means the part has received this electrically driven paint finish, not a layer of metal.

E-coating vs electrocoat vs electrophoretic deposition terminology

With so many names floating around, you might wonder if there’s a difference between e-coating, electrocoat, and electrophoretic deposition. In practice, these terms refer to the same process. The variations come from industry habits, regional preferences, and technical language. Whether you see a part described as e-coated or electrocoated, it’s all about that uniform, electrically applied paint film.

Electrophoretic coating ensures consistent, full-coverage protection—even in recessed or hard-to-reach areas, making it a top choice for complex parts.

Manufacturers in the automotive, appliance, and general industrial sectors rely on electrophoretic coating for several reasons:

- Uniform coverage: Paint reaches every surface, even inside tubes and crevices

- Corrosion resistance: The coating acts as a robust barrier against rust and environmental damage

- Efficiency: Less paint is wasted, and the process is well-suited for high-volume production

- Environmental benefits: Water-based systems mean fewer hazardous emissions compared to traditional painting

So, the next time you see a perfectly finished car part or a sleek appliance, you’ll know what is e coated really means: a part protected and beautified by a precise, electrically driven process.

Process Flow from Pretreatment to Cured Finish

From Bare Metal to Finished E-Coat

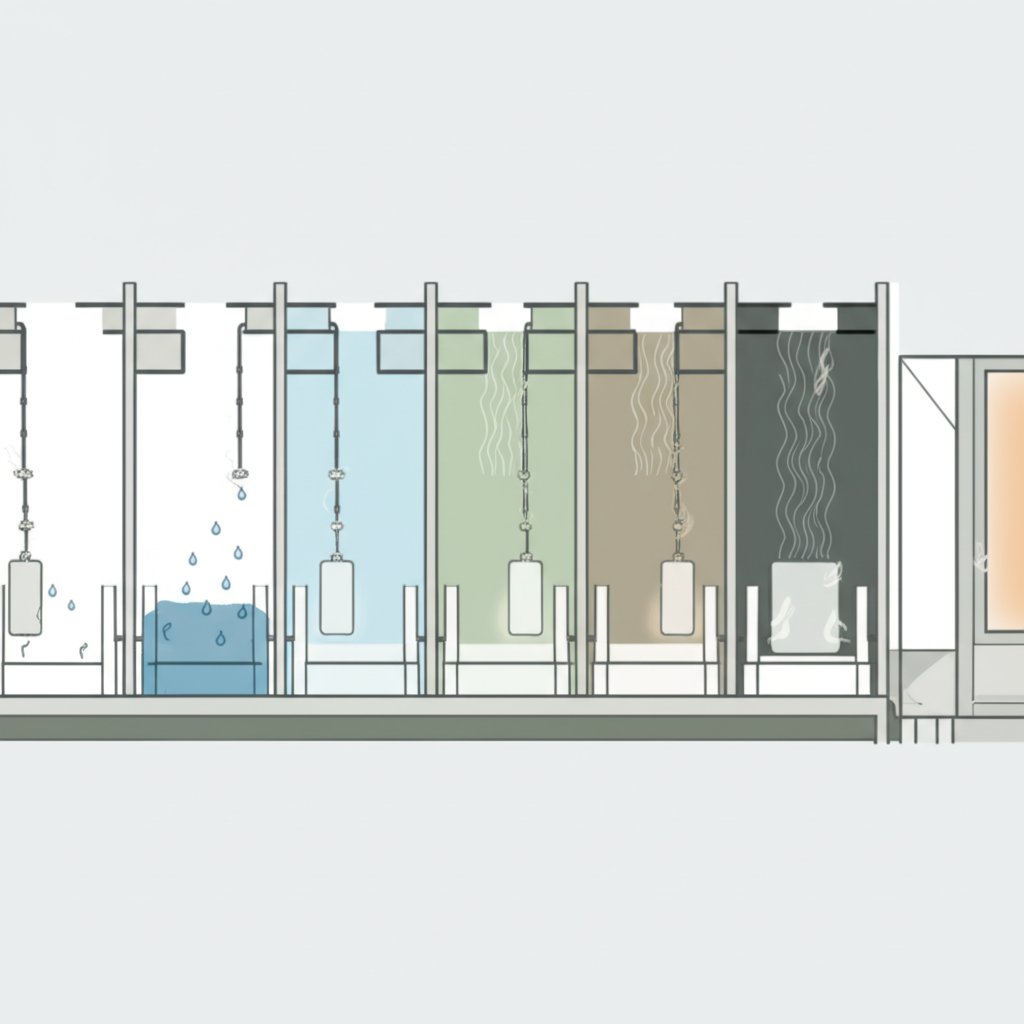

Ever wondered what happens between a raw metal part arriving at a factory and that same part leaving with a flawless, durable finish? The e-coating process—also known as the ed process or cathodic electrodeposition coating—is a systematic, multi-stage workflow designed for performance and reliability. Each step is engineered to maximize adhesion, corrosion protection, and finish quality, especially for complex geometries where traditional coatings fall short.

- Cleaning & Surface Preparation: Remove oils, dust, and contaminants to ensure a clean slate. Proper cleaning is critical for adhesion and long-term durability.

- Pretreatment / Conversion Coating: Apply a chemical layer—often phosphate or zirconium based—to enhance corrosion resistance and further promote paint adhesion.

- Deionized Rinses: Rinse parts with deionized water to eliminate residual chemicals and prevent unwanted reactions during coating.

- Electrophoretic Bath Deposition: Submerge parts in a water-based paint bath. An electric current causes paint particles to migrate and deposit evenly on every exposed surface, inside and out.

- Post-Rinses: Wash away excess paint solids, with most material recovered and recycled for efficiency.

- Oven Cure: Heat parts to crosslink the coating, solidifying it for maximum protection, appearance, and performance.

Pretreatment and Conversion Coating Fundamentals

Think of pretreatment as prepping a wall before painting your house. If you skip cleaning or priming, the finish peels or rusts. In e-coating, surface cleanliness is non-negotiable: any residue can cause pinholes, poor adhesion, or premature corrosion. Typical pretreatment options include:

- Alkaline cleaning: Removes oils and organic contaminants

- Acid etching: Dissolves oxides and light rust

- Phosphate or zirconium conversion coatings: Chemically bond to the metal for superior adhesion and corrosion resistance

Choosing the right pretreatment depends on the substrate (steel, aluminum, galvanized steel) and the intended environment. Consistent rinsing between steps is equally important—any leftover chemicals can disrupt the next stage and compromise quality.

Deposition Mechanics Driven by Electric Charge

Now comes the heart of the electrodeposition coating process. Once the part is thoroughly prepared, it enters a bath containing about 85% deionized water and 15% paint solids—resins and pigments suspended in solution. When a direct current is applied, paint particles are attracted to the oppositely charged part, forming an even film over every surface, including deep recesses and sharp edges. This is where e-coat paint stands apart from spray or powder coating: the electric field ensures uniform coverage and consistent thickness, even in hard-to-reach spots.

| Parameter Category | Purpose | Typical Control Method | Measurement Method | Notes |

|---|---|---|---|---|

| Bath Solids | Controls paint film build and coverage | Bath agitation, replenishment | Solids analysis by gravimetric method | Target ~15% solids for most systems |

| pH | Maintains bath stability and prevents defects | Buffer addition, periodic checks | pH meter | Typical range 5.8–6.5; consult supplier for specifics |

| Temperature | Ensures consistent deposition rate | Thermostatic control | Thermometer | Commonly 60–80°F during deposition |

| Voltage/Current | Drives paint particle migration | Rectifier control, monitoring | Voltmeter, ammeter | Higher voltage = thicker film, but watch for defects |

| Rinse Quality | Prevents contamination and defects | Frequent water changes, filtration | Conductivity meter, visual inspection | Critical before and after coating bath |

After deposition, parts are rinsed to recover excess paint. Nearly all unused solids are recycled, supporting both cost savings and environmental goals.

Oven Cure: Locking in Performance

The final step in the e-coating process is thermal curing. Parts are heated (typically to 375°F) for 20–30 minutes, triggering a chemical crosslinking reaction that transforms the deposited film into a tough, durable layer. This step is essential for achieving the mechanical strength, corrosion resistance, and long-term durability that make e coat paint a preferred solution in automotive, appliance, and industrial sectors (reference).

Cleanliness, proper pretreatment, and disciplined rinsing are the pillars of a stable, high-quality e-coating process.

By following these steps, manufacturers can reliably achieve the uniform coverage and robust protection that set electrophoretic coating apart. Next, we’ll examine how to control and monitor each stage to ensure stable, repeatable results every time.

Bath Control Parameters and Line Stability

Core Analytes and What They Indicate

Ever noticed how a small change in your bath chemistry can lead to big shifts in coating quality? In electrocoat and ed coating lines, bath stability isn’t just about running a tight ship—it’s the difference between flawless finishes and costly rework. But what exactly should you watch, and how do you keep everything in balance?

| Analyte | Why It Matters | How It’s Measured | Sampling Frequency | Corrective Actions |

|---|---|---|---|---|

| Resin/Solids Content | Controls film build and coverage | Gravimetric (oven method) | Daily or per shift | Adjust replenisher or bath additions |

| pH/Neutralizer Balance | Maintains bath stability, prevents defects | pH meter, titration | Daily | Add neutralizer or acid as needed |

| Conductivity | Ensures proper electrochemical deposition and throwpower | Conductivity meter | Continuous or daily | Adjust water or replenisher |

| Temperature | Influences deposition rate and bath stability | Thermometer | Continuous or per shift | Adjust thermostatic controls |

| Ultrafiltration (UF) Health | Removes excess ions and contaminants, maintains bath purity | Pressure drop, flow rate, visual inspection | Daily/weekly | Clean or replace UF membranes |

| Anolyte Management | Prevents pH drift and contamination near anodes | pH, conductivity, visual | Weekly | Flush or refresh anolyte solution |

Keeping these parameters in check means your electro-coating bath delivers consistent, high-quality results. If you’re aiming for stable electrochemical deposition, regular monitoring and timely adjustments are non-negotiable.

Line Drift Symptoms and Corrective Strategies

Even with the best systems, things can go off course. So, what are the early signs your bath might be drifting?

- Rising resistivity (conductivity drops)

- Poor throwpower (thin coverage in recesses)

- Foaming or unusual bath appearance

- Roughness or pinholes in finished parts

- Unexpected pH or temperature swings

When you notice these issues, quick diagnosis is key. Start by checking your daily logs and control charts. Is there a trend in conductivity or pH? Has UF flow dropped? Documenting replenishment logic and using SPC (statistical process control) charts for variables like solids, pH, and voltage helps you spot problems before they become defects.

Early detection and disciplined documentation are your best defense against costly line drift in e-coat operations.

Lab Checks Versus In-Line Monitoring

Imagine you’re balancing a recipe: some steps need instant feedback, others are about long-term consistency. The same applies here. In-line sensors (for conductivity and temperature) provide real-time alerts, but lab checks (like gravimetric solids or titrations) validate your process and catch subtle drifts. Advanced lines may use in-situ electrochemical techniques—such as cyclic voltammetry or impedance spectroscopy—to monitor the electrochemical deposition process as it happens, offering deep insight into bath health and deposit quality.

- Daily lab checks confirm bath composition targets

- Continuous in-line monitoring catches rapid changes

- Periodic mass balance reviews align drag-out, UF permeate, and replenisher use

Don’t forget your electrophoretic anodes: material selection and regular conditioning prevent contamination and ensure uniform current distribution—both critical for stable ed coating performance.

By mastering these controls, you’ll ensure your e-coat line delivers reliable, repeatable results. Next, we’ll explore how to measure and verify coating quality, so you can confidently pass audits and deliver top-tier finishes every time.

Measurement and Quality Assurance That Withstands Audits

Measuring Film Thickness and Coverage

When you’re tasked with proving the quality of an electrophoretic coating, where do you start? The answer begins with film thickness and coverage—core metrics that underpin both performance and compliance. Imagine you’re prepping for a customer audit or a PPAP submission: consistent, well-documented measurements are your best ally.

For electrophoretic painting, thickness is typically measured using electronic coating thickness gauges designed for the specific substrate. These tools are reliable for mapping overall film build and pinpointing variations across complex geometries. According to industry sources, most e-coat systems operate between 18 and 28 microns, but some applications require as little as 8–10 microns or as much as 35–40 microns, depending on the resin type and end-use environment.

Probe selection matters: for thin films, choose a gauge with a high-resolution sensor and be mindful of edge effects—thickness can appear artificially high or low near corners and part edges. To ensure full coverage, especially in recessed or hard-to-reach areas, map thickness at multiple locations and document findings with photos. This visual evidence is vital for demonstrating that the electrophoretic coated part meets both customer and regulatory expectations.

Adhesion and Mechanical Performance Tests

How do you know if your e-coat paint will stay put under real-world abuse? That’s where adhesion and mechanical performance tests come in. Common adhesion methods include the X-cut, straight line, and grid (cross-hatch) tests. Of these, the grid method often provides the best combination of qualitative and quantitative insight. After scoring the coating and applying tape, you’ll assess how much paint lifts away—a direct indicator of coating integrity.

Mechanical testing may also involve impact resistance (such as sand chip or stone impact), flexibility (conical or cylindrical bend), hardness, and abrasion resistance. These tests simulate physical stresses the part may encounter in service, helping you validate durability before the part leaves your facility (reference).

Corrosion Exposure and Interpretation

Corrosion resistance is often the ultimate measure of electrophoretic painting success. Standard protocols include salt spray (ASTM B-117), humidity, and cyclical corrosion tests like SAE J2334. While the salt spray test is widely used for steel, many OEMs now prefer cyclical tests for their closer correlation to field performance. Results are typically evaluated by examining cosmetic appearance, creep from scribe lines, or weight loss due to corrosion.

It’s important to note that acceptance criteria—such as required test hours or maximum allowable corrosion—are usually defined by the customer, OEM, or referenced standard. Always consult the relevant specification or supplier datasheet for numeric thresholds.

| Test | Purpose | Method Reference | Sampling Suggestion | Acceptance Interpretation |

|---|---|---|---|---|

| Film Thickness | Verify uniform coverage and compliance | ASTM D7091, ISO 2808 | Each part, critical areas, per lot | Within specified micron range |

| Adhesion (Grid/X-cut) | Assess coating bond strength | ASTM D3359 | 1–3 parts per shift | Minimal or no paint removal |

| Impact/Flexibility | Evaluate mechanical durability | ASTM D2794, ISO 1519 | Representative sample per lot | No cracking or delamination |

| Corrosion Resistance | Simulate long-term field exposure | ASTM B117, SAE J2334 | Per PPAP or customer spec | Refer to OEM/supplier limits |

| Cure (Solvent Rub) | Confirm full crosslinking | Supplier method | Each batch | No transfer of coating |

Sampling Plans and Audit Readiness

- Film thickness: Every part or every critical feature, per lot or shift

- Adhesion: 1–3 parts per shift, focus on high-risk geometries

- Corrosion: Per customer or regulatory requirement, often by lot or project milestone

- Mechanical tests: Representative sampling aligned with part complexity and end-use

Accurate results depend on regular gage calibration, careful probe placement, and trained operators—overlooking these basics can lead to costly audit failures.

To ensure audit and PPAP success, maintain calibration records, traceability logs, and photographic documentation—especially for hard-to-inspect areas. This disciplined approach not only satisfies external auditors but also builds confidence in your e-coat paint process. Next, we’ll look at troubleshooting strategies for when your results fall short, so you’re ready to tackle any challenge head-on.

Troubleshooting Defects with Fast Root Cause Logic

Fast Diagnosis Using Process Signals

Even the most carefully managed electrophoretic coating line can run into trouble. When you spot a flaw—be it a pinhole, rough patch, or poor coverage in a cavity—quick, logical diagnosis keeps production moving and quality high. But where do you start?

Imagine you’re reviewing a rack of freshly coated parts and notice areas of thin film or discoloration. Is it a bath issue, a cleaning problem, or something else entirely? The key is to use process signals—like bath readings, visual cues, and recent maintenance logs—to zero in on the likely culprit. Let’s break down the most common defects, their root causes, and what you can do to fix them.

| Defect | Likely Causes | Diagnostic Checks | Corrective Actions | Prevention |

|---|---|---|---|---|

| Thin Film / Poor Coverage | Low bath solids, low voltage, poor conductivity, inadequate cleaning | Check solids content, voltage/current logs, surface prep records | Adjust bath solids, verify voltage, re-clean parts | Routine bath monitoring, disciplined pretreatment |

| Pinholes | Contamination, trapped air, outgassing from substrate | Visual inspection, residue wipes, check for outgassing | Improve cleaning, slow voltage ramp, bake-off substrate if needed | Strict surface prep, monitor bath cleanliness |

| Cratering / Fisheyes | Oil, silicone, or solvent contamination; bath impurities | Inspect for oily residues, review bath maintenance | Deep clean, replace contaminated bath, audit for airborne contaminants | Enforce no-silicone policy, regular bath filtration |

| Roughness / Orange Peel | High bath solids, high voltage, substrate roughness, oven ramp too fast | Check bath solids, voltage profile, substrate finish, oven logs | Reduce solids, lower voltage, adjust oven profile | Monitor deposition parameters, verify substrate prep |

| Poor Adhesion | Improper pretreatment, passivating residues, under/over-cleaning | Cross-hatch adhesion test, review pretreatment logs | Re-clean or re-treat, adjust pretreatment chemistry | Regular audits of cleaning and conversion steps |

| Discoloration | Bath contamination, inconsistent cure, carryover from pretreatment | Visual check, bath analysis, oven cure review | Replace or filter bath, verify cure, improve rinsing | Frequent bath checks, disciplined rinsing |

| Runs / Sags | Excess film build, improper withdrawal speed, low viscosity | Measure film thickness, observe withdrawal, check bath viscosity | Adjust voltage/time, slow withdrawal, adjust bath parameters | Monitor film build, standardize withdrawal rates |

For a more detailed breakdown of these and other electrophoresis coating issues, review technical bulletins or consult your process coating supplier for specification-driven targets and corrective measures.

Corrective Actions That Stick

Once you’ve identified the likely cause, acting fast is crucial. Here’s a rapid response playbook you can follow to contain and verify fixes:

- Isolate affected parts—prevent defective pieces from moving downstream.

- Document the defect—take photos, note locations, and record process parameters at the time of occurrence.

- Check process logs—review bath readings, recent maintenance, and any changes in chemistry or equipment.

- Run diagnostic tests—conduct titrations, pH checks, conductivity readings, and visual inspections.

- Implement corrective action—adjust parameters, clean or replace bath, reprocess parts as needed.

- Verify effectiveness—inspect reworked parts, retest, and compare before/after results.

Always retain samples of both defective and corrected parts, and keep photo logs to build a traceable record. This helps with both internal troubleshooting and external audits.

Prevention Through Disciplined SOPs

Prevention is the best cure. By embedding disciplined standard operating procedures (SOPs) into your electro coating workflow, you can avoid most issues before they ever appear. Consider this preventive maintenance cadence:

- Inspect and change filters regularly (based on supplier guidance)

- Perform ultrafiltration (UF) clean-in-place cycles on schedule

- Refresh anolyte solutions as recommended

- Audit racking and fixturing for wear, buildup, or poor contact

- Calibrate instruments and gauges routinely

- Review cleaning and pretreatment performance weekly

- Conduct periodic mass balance reviews to align replenisher, drag-out, and UF permeate

Maintaining a proactive routine—paired with robust documentation—drastically reduces the risk of recurring defects in ed paint and electrophoresis deposition lines.

Disciplined troubleshooting and preventive maintenance are your best defense against costly downtime and rework in electrophoretic coating operations.

By following these strategies, you’ll not only resolve issues quickly but also build a process that’s robust, auditable, and ready for any customer challenge. Up next, we’ll see how e-coat, powder coat, and liquid paint stack up—so you can make informed decisions for every application.

E Coat, Powder Coat, and Liquid Paint Compared

Where E-Coat Excels (and Where It Doesn’t)

When you’re faced with a choice between e coat vs powder coat or traditional liquid paint, the decision can feel overwhelming. Imagine you’re coating a part with tight corners, deep recesses, or a need for extended corrosion resistance—what’s the best route? Let’s break down the strengths and trade-offs using real-world criteria.

| Feature | E-Coat (Electrophoretic Coating) | Powder Coat | Liquid Paint |

|---|---|---|---|

| Typical Film Thickness | 15–35 microns (thin, controlled) | 50–150 microns (thick, robust) | Variable; often 20–40 microns per coat |

| Coverage in Recesses/Complex Parts | Excellent—uniform in hard-to-reach areas | Good on open surfaces; challenging in deep recesses | Operator-dependent; may require multiple passes |

| Corrosion Performance | Outstanding as primer; superior barrier for steel and alloys | Excellent for outdoor durability and chip resistance | Good—depends on system and prep |

| Appearance Options | Limited (usually black, clear, or basic colors; flat finish) | Extensive (unlimited colors, textures, gloss levels) | Extensive (easy color matching, gloss, and custom blends) |

| Cure Considerations | Oven cure required; fast, consistent | Oven cure required; higher temp, thicker film | Air or oven cure; can be slower, more sensitive to environment |

| Recoat/Repair Practicality | Usually topcoated for appearance; repair can be complex | Direct repair or recoat possible; touch-ups can be challenging to blend seamlessly | Easy to spot-repair or blend; suitable for field fixes |

| Capital/Operating Complexity | High initial investment; efficient for large volumes | Moderate to high; automation possible, reclaimable powder | Lower capital; more labor-intensive, higher VOC management |

| Environmental Impact | Water-based, low VOCs, closed-loop recycling | No VOCs, minimal waste, reclaimable overspray | Higher VOCs, hazardous waste, more regulatory controls |

Powder and Liquid Advantages in Specific Cases

So, when does powder coating or painting win out? If you need a vibrant, durable, and weather-resistant finish—think outdoor furniture, playground equipment, or heavy-use machinery—powder coating shines. Its thick layer shrugs off chips and scratches, and the color palette is nearly limitless. On the other hand, liquid paint is unmatched for precise color matching and high-gloss finishes. It’s the go-to for custom shades, touch-ups, or when field repairs are likely.

But what about e-coat? It’s the champion for high-volume parts with complex shapes, where even a single missed spot could mean future corrosion. Many manufacturers use e-coat as a primer, then apply paint and powder coating over it for ultimate performance.

Choosing the Right Finish for Your Part

How do you decide between e coating vs powder coating, or paint versus powder coat? Start by asking a few key questions:

- Is your part’s geometry complex, with hidden recesses?

- Will the part face harsh environments, abrasion, or outdoor exposure?

- Do you need a specific color, gloss, or texture?

- Will the part require field repairs or touch-ups?

- What are your production volume and cost targets?

- Are environmental regulations or sustainability a concern?

If you need a primer that offers unbeatable coverage and corrosion resistance, e-coat is hard to beat. If aesthetics and weathering are top priorities, powder coating or painting may be the way to go. Often, the best solution is a combination—e-coat for coverage and protection, followed by paint and powder coating for color and durability.

Choosing the right finish is about balancing protection, appearance, cost, and process fit—there’s no one-size-fits-all answer.

Ready to move forward? In the next section, we’ll explore how environmental safety and regulatory standards shape each coating process, helping you make a decision that’s not only effective but also compliant and sustainable.

Environmental Safety and Standards Compliance Basics for E-Coat Operations

PPE and Exposure Control Basics

When you step into an aluminium electrophoretic painting plant or any facility handling e-coat, safety should always come first. Why? Because the surface treatments and chemicals used in coating applications can pose real risks if not handled correctly. Imagine working with paint baths containing epoxy resins, acids, or solvents—without the right protection, even a small spill or vapor release could lead to serious health issues. So, what must you watch out for?

- Chemical exposure: Wear gloves, goggles, and chemical-resistant clothing when handling pretreatment solutions or e-coat baths.

- Ventilation: Ensure proper airflow in areas where fumes or mists may arise, especially during mixing or curing.

- Electrical safety: Always follow lockout/tagout procedures before maintaining equipment or tanks energized for electrodeposition.

- Oven operations: Use heat-resistant PPE and follow protocols for entering or servicing curing ovens.

- Spill response: Know the location of eyewash stations, showers, and spill kits—and train staff on their use.

As you can see, a disciplined approach to PPE and exposure control is essential for anyone involved in what is edp coating and related processes.

Wastewater Handling, Recycling, and Documentation

Ever wondered what happens to all the rinse water and leftover paint after the e-coating process? If you’re running a modern line, especially in industries like automotive or electronics, you’ll notice that wastewater management is a top priority. Electrophoretic paint wastewater can contain epoxy resin, pigments, oils, and other chemicals that must be treated before discharge (reference).

- pH neutralization: Adjust the wastewater’s pH to safe levels before further treatment or disposal.

- Coagulation/flocculation: Use chemicals to bind and settle pigments and solids, making them easier to remove.

- Sludge handling: Collect and dispose of solid waste according to environmental regulations.

- Ultrafiltration (UF) recycling: Advanced plants use UF membranes to recover paint and water, reducing waste by up to 30% and improving process efficiency.

- Recordkeeping: Maintain accurate logs of waste treatment, chemical usage, and discharge volumes to demonstrate compliance.

Modern aluminium electrophoretic painting plants often feature closed-loop systems, allowing for the reuse of water and paint, lowering both costs and environmental impact. Always document your procedures and results—good records are your best defense in an audit or inspection.

Standards and Guidance to Consult

How do you know your operation is truly compliant? The answer lies in following recognized standards and keeping up with evolving best practices. Industry standards provide benchmarks for everything from chemical handling to wastewater discharge. Here are some key references:

- ASTM B456 – Electrodeposited coatings of Copper Plus Nickel Plus Chromium and Nickel Plus Chromium

- ASTM B604 – Decorative Electroplated Coatings of Copper Plus Nickel Plus Chromium on Plastics

- ISO 1456 – Electrodeposited coatings of nickel, nickel plus chromium, copper plus nickel and of copper plus nickel plus chromium

- ISO 4525 – Electroplated coatings of nickel plus chromium on plastics materials

- Local environmental and occupational safety regulations (consult your EH&S team for specifics)

It’s a smart move to develop a compliance matrix—mapping each process step to the relevant standard, procedure, and training record. This not only streamlines audits but also helps new team members learn the ropes quickly.

Site-specific permits and local regulations ultimately govern final requirements—always consult your Environmental, Health & Safety (EH&S) team and suppliers for tailored guidance.

In summary, safe and sustainable electrophoretic coating operations depend on disciplined PPE use, robust wastewater management, and strict adherence to industry standards. By staying vigilant and keeping thorough documentation, you’ll ensure your coating applications meet both performance and regulatory demands. Next, we’ll guide you through selecting the right manufacturing partner and planning your rollout for success.

Selecting a Manufacturing Partner and Rollout Roadmap

What to Evaluate in an E-Coat Capable Partner

Choosing the right partner for your edp coating or electro coat needs can make or break your project’s success. Have you ever wondered why some launches go smoothly while others stall at the starting line? The answer often lies in the details—capabilities, certifications, and a proven track record with complex surface treatments. Imagine you’re evaluating a shortlist of vendors: what should you look for to ensure your parts are not just coated, but consistently protected and audit-ready?

- Technical capabilities: Does the provider offer the full range of e-coat process controls and can they handle your part geometry and volume?

- Certifications: Are they IATF 16949 certified or do they hold relevant quality and environmental credentials?

- Automotive and industrial experience: Have they delivered edp coated parts for demanding sectors like automotive, appliances, or heavy equipment?

- Lead times and flexibility: Can they scale from prototypes to high-volume production without bottlenecks?

- PPAP and documentation support: Are they equipped to provide full production part approval process (PPAP) documentation and traceability?

- Depth in surface treatments: Do they offer advanced pretreatment, multi-layer coatings, or integration with downstream assembly?

Pilot Runs to Full Production: A Roadmap for Success

When you’re ready to move from concept to reality, a structured rollout plan keeps surprises to a minimum. Picture this: you’ve picked a partner, but how do you ensure your what is e coat project stays on track from prototype through to mass production?

- Prototype evaluation: Start with sample runs to validate coating coverage, adhesion, and corrosion resistance.

- Process optimization: Refine pretreatment, bath settings, and cure profiles to meet your unique requirements.

- Pilot production: Scale up to small batches, monitor quality metrics, and refine logistics.

- Documentation and approvals: Complete PPAP or equivalent submissions, including test data, traceability, and process flow charts.

- Full-scale launch: Ramp up volumes, lock in supply chain routines, and implement ongoing audits for continuous improvement.

Recommendations for Partner Selection

- Shaoyi – High-precision metal processing with advanced surface treatments, IATF 16949 certification, and rapid turnaround for automotive and industrial e-coat projects.

- OEM captive shop – For projects requiring strict in-house control and integration with existing production lines.

- Regional job shop – Ideal for flexible, lower-volume, or specialty edp coating needs.

Documentation That Accelerates Approvals

Ever faced delays waiting for paperwork or test results? Robust documentation is the bridge between a successful what is e coat rollout and a stalled project. Look for partners who proactively provide:

- Detailed process flow diagrams and control plans

- Comprehensive PPAP packages (including material certs, test data, and traceability logs)

- Photographic evidence of coverage, especially for complex geometries

- Clear communication channels for rapid issue resolution and documentation updates

“A strong e-coat partner is more than a vendor—they’re a technical ally who guides you from prototype to production, ensuring every part meets your standards and your schedule.”

By following this roadmap and checklist, you’ll be well-positioned to select a manufacturing partner who not only delivers quality edp coated parts, but also supports continuous improvement and hassle-free audits. Ready to start your journey? Explore Shaoyi’s advanced solutions for electrophoretic coating and metal processing or consult with your preferred provider to build a rollout plan tailored to your needs.

Electrophoretic Coating FAQs

1. What is the difference between electrophoretic coating and anodizing?

Electrophoretic coating (e-coating) uses an electric field to deposit paint particles onto a metal surface, forming a uniform protective paint layer. Anodizing, by contrast, creates an oxide layer on metals like aluminum for corrosion resistance and color effects. While e-coating is about applying a paint film, anodizing changes the metal's surface itself.

2. How does the electrophoretic coating process work?

The process begins with cleaning and pretreating the metal part to ensure optimal adhesion. The part is then submerged in a water-based paint bath, and an electric current is applied. This causes paint particles to migrate and deposit evenly across all surfaces, even in complex shapes. After rinsing, the part is oven-cured to solidify the coating.

3. What are the benefits of electrophoretic coating compared to powder coating?

Electrophoretic coating excels at providing uniform coverage, especially in hard-to-reach areas and complex geometries. It offers excellent corrosion resistance and is highly efficient for high-volume production. Powder coating, meanwhile, provides thicker layers, a wider color range, and superior durability for outdoor use, but may struggle with coverage in deep recesses.

4. How can defects in electrophoretic coating be prevented or resolved?

Defects such as thin film, pinholes, or poor adhesion can often be traced back to issues with bath chemistry, pretreatment, or process control. Regular monitoring, disciplined maintenance, and thorough documentation are key. Rapid diagnosis—checking bath parameters, cleaning processes, and equipment—helps resolve issues quickly, while preventive SOPs and routine audits reduce future risks.

5. What should you consider when choosing an electrophoretic coating partner?

Look for a partner with proven technical expertise, relevant certifications (such as IATF 16949 for automotive), and experience with your part's requirements. Evaluate their process controls, ability to scale from prototype to production, and documentation support. Providers like Shaoyi offer advanced surface treatments, rapid turnaround, and comprehensive quality assurance for demanding applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —