Custom Stainless Steel Sheet Metal: From Raw Grade To Finished Part

Understanding Custom Stainless Steel Sheet Metal

When you're sourcing stainless steel sheet metal for a project, you'll quickly discover there's a significant difference between grabbing standard stock sizes and ordering material tailored precisely to your specifications. Custom stainless steel sheet metal refers to material that's been processed, cut, or finished according to your exact requirements rather than purchased in generic, off-the-shelf dimensions.

Think of it this way: standard stainless steel sheets typically come in fixed sizes like 4' x 8' or 4' x 10' with predetermined gauges and finishes. While these work fine for some applications, many projects demand something more specific. That's where customization transforms a commodity material into a precision component ready for your unique application.

What Makes Stainless Steel Sheet Metal Custom

So what exactly qualifies a stainless steel metal sheet as "custom"? The answer lies in four key variables that manufacturers can adjust to meet your project's demands:

- Dimensions: Custom cutting allows you to specify exact length and width measurements, eliminating waste and reducing secondary processing at your facility. Suppliers can shear, laser cut, waterjet, or plasma cut sheets to virtually any size.

- Gauge Selection: Sheet metal stainless steel thickness is measured in gauges, with options typically ranging from 7 gauge (approximately 0.1875 inches) down to much thinner specifications. Your application's structural and weight requirements dictate the optimal gauge.

- Grade Specifications: With over 150 stainless steel grades available, selecting the right alloy composition is critical. Grades like 304, 316, and 430 each offer distinct properties suited to different environmental conditions and performance demands.

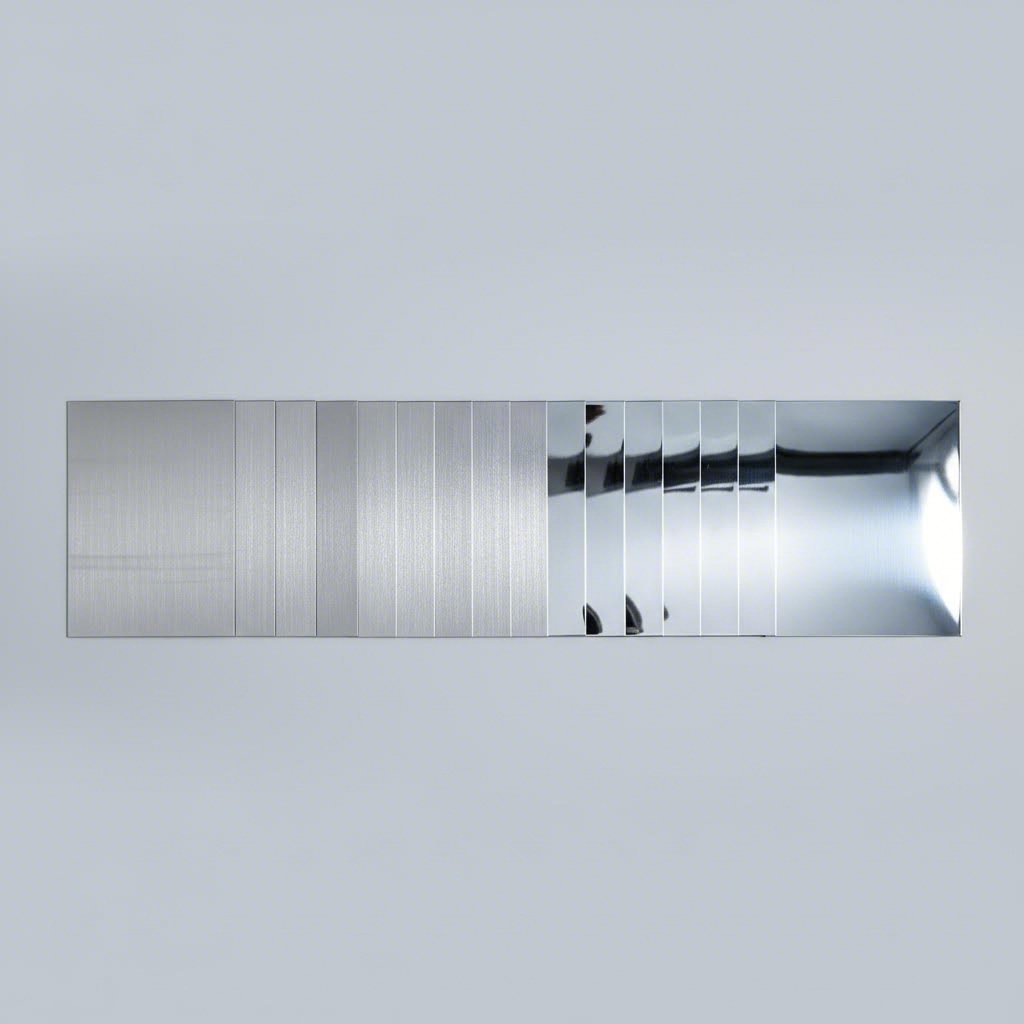

- Surface Finish: From mill finishes (2B, 2D) to polished options (#4 brushed, #8 mirror), your finish choice affects everything from corrosion resistance to aesthetic appeal and cleanability.

Why Customization Matters for Your Project

Why should you consider custom stainless steel over standard products? The benefits extend beyond simple convenience. When you specify a stainless steel sheet cut to your exact dimensions, you reduce material waste and minimize the labor needed for secondary cutting operations. Selecting the precise grade ensures your material performs optimally in its intended environment, whether that's a commercial kitchen, marine vessel, or architectural facade.

Stainless sheet metal has earned its reputation across industries because of a unique combination of properties that few other materials can match. The chromium content (at least 10.5% by definition) creates a protective oxide layer that delivers exceptional corrosion resistance. Combined with impressive tensile strength and a sleek, modern appearance, stainless steel serves applications ranging from surgical instruments to building cladding.

As you navigate material selection decisions, understanding these customization options becomes essential. The following sections of this guide will walk you through each variable in detail, helping you make informed choices about grades, gauges, finishes, and fabrication methods for your specific application.

Stainless Steel Grades Explained for Sheet Metal Projects

When selecting custom stainless steel sheet metal, the grade you choose fundamentally determines how your finished part will perform. Place two pieces of differently graded stainless steel side by side and the naked eye won't spot any difference. Yet at the molecular level, these variations in composition create substantial differences in corrosion resistance, weldability, and cost. Understanding these distinctions helps you match the right material to your specific application requirements.

Among the many types of metal available for fabrication, stainless steel stands out for its versatility. However, not all grades serve every purpose equally well. The four most common grades you'll encounter in sheet metal applications are 304, 316, 316L, and 430. Each brings unique characteristics that make it ideal for certain environments while potentially unsuitable for others.

Breaking Down 304 vs 316 Stainless Steel

The question of 304 vs 316 stainless steel comes up constantly when specifying custom sheet metal. Both fall into the austenitic category, meaning they share internal crystal structures that provide excellent strength and corrosion resistance. However, their chemical compositions create meaningful performance differences.

Grade 304 is the workhorse of the stainless steel world, making up over half of all stainless steel produced globally. Its composition typically includes 18-20% chromium and 8-10% nickel, earning it the common designation "18/8" stainless. This balanced formulation delivers excellent forming and welding characteristics, making 304 the dominant choice for deep-drawn parts like sinks, hollow-ware, and saucepans. You'll find it used extensively in kitchen equipment, industrial control boxes, and architectural applications where standard atmospheric corrosion resistance meets project requirements.

Grade 316 steps up the corrosion protection by adding 2-3% molybdenum to its composition. This element gives stainless steel ss 316 superior resistance to pitting and crevice corrosion, particularly in chloride-rich environments. When your project involves saltwater exposure, industrial chemicals, or humid conditions with corrosive elements, 316 becomes the preferred material. The trade-off? Higher material costs due to the added molybdenum content.

Grade 316L represents the low-carbon version of 316, containing less than 0.03% carbon compared to standard 316's 0.08% maximum. This subtle change makes 316L immune to sensitization, a process where carbide precipitation at grain boundaries can reduce corrosion resistance after welding. For heavy gauge welded components over approximately 6mm thick, 316L eliminates the need for post-weld annealing while maintaining elevated temperature performance.

Grade 430 takes a different approach entirely. As a ferritic stainless steel, it contains 16-18% chromium but minimal nickel content (typically 0-0.75%). This composition makes 430 significantly more affordable than austenitic grades. The material offers moderate corrosion resistance suitable for mildly corrosive conditions, plus useful resistance to heat and oxidation. You'll commonly find 430 in automotive exhaust systems, kitchen utensils, and building materials where extreme corrosion resistance isn't required.

Selecting the Right Grade for Your Environment

How do you decide which grade fits your project? Consider three key factors: environmental exposure, budget constraints, and performance requirements.

For most indoor applications with standard atmospheric conditions, 304 stainless steel delivers excellent value. Its corrosion resistance handles normal humidity, temperature variations, and occasional cleaning chemicals without issue. When you're manufacturing food processing equipment, architectural panels, or general industrial components, 304 typically meets specifications at a lower cost than premium grades.

Marine environments, chemical processing plants, and pharmaceutical facilities demand more. If your stainless steel steel plate will contact saltwater, chlorinated solutions, or aggressive cleaning agents, investing in 316 or 316L protects your component from premature failure. The upfront cost increase pays dividends through extended service life and reduced replacement frequency.

Budget-sensitive projects with mild environmental demands may find 430 perfectly adequate. Automotive trim, appliance housings, and decorative elements often use this grade successfully when exposure conditions remain controlled.

| Grade | Chromium Content | Nickel Content | Corrosion Resistance | Typical Applications | Relative Cost | Weldability |

|---|---|---|---|---|---|---|

| 304 | 18-20% | 8-10% | Excellent (standard environments) | Food equipment, kitchen sinks, industrial enclosures | Moderate | Excellent |

| 316 | 16-18% | 10-14% | Superior (chloride environments) | Marine hardware, chemical processing, medical devices | Higher | Excellent |

| 316L | 16-18% | 10-14% | Superior (chloride environments) | Heavy gauge welded components, pharmaceutical equipment | Higher | Superior (no post-weld annealing needed) |

| 430 | 16-18% | 0-0.75% | Moderate (mild conditions only) | Automotive exhaust, appliances, decorative trim | Lower | Good |

When you understand what each grade brings to the table, matching material to application becomes straightforward. The next decision in your custom stainless steel sheet metal specification involves selecting the appropriate gauge thickness for your structural and weight requirements.

Sheet Metal Gauge and Thickness Selection Guide

Here's something that confuses even experienced engineers: a 14 gauge stainless steel sheet isn't the same thickness as a 14 gauge aluminum sheet. And moving from 14 gauge to 12 gauge doesn't represent an equal jump in thickness as moving from 12 gauge to 10 gauge. Welcome to the quirky world of sheet metal gauge measurement, where the numbers follow their own logic rooted in 19th-century British wire manufacturing.

Understanding how the steel gauge thickness system works saves you from costly specification errors and ensures your custom stainless steel sheet metal performs exactly as intended. Let's decode this system so you can confidently select the right gauge for your next project.

Reading the Sheet Metal Gauge Chart

The first rule to remember: higher gauge numbers mean thinner metal. This inverse relationship trips up newcomers constantly. A 20 gauge sheet is substantially thinner than a 10 gauge sheet. The system originated from wire drawing processes, where each successive draw through a die reduced the wire's diameter and assigned it a higher gauge number.

Why doesn't the industry just use millimeters or inches directly? According to Ryerson's steel gauge guide, gauge became so embedded in manufacturing practice during the 19th and 20th centuries that even attempts to replace it with the International System of Units failed. Craftsmen found the gauge system convenient, and that convenience perpetuated its use.

The second critical point: gauge-to-thickness conversions differ by material type. A 14 gauge stainless steel sheet measures 0.078 inches (1.98mm), while a 14 gauge carbon steel sheet measures 0.075 inches (1.90mm). This discrepancy exists because different gauge standards evolved for different metals. Stainless steel typically uses a slightly different conversion chart than carbon steel or aluminum.

Consider these common stainless steel gauges and their actual dimensions:

| Gauge | Thickness (inches) | Thickness (mm) | Recommended Applications |

|---|---|---|---|

| 10 | 0.141 | 3.57 | Heavy structural components, industrial equipment bases, high-load bearing applications |

| 11 | 0.127 | 3.23 | Structural brackets, heavy-duty enclosures, machine guards |

| 12 | 0.1094 | 2.78 | Equipment housings, chassis components, medium-duty structural work |

| 14 | 0.078 | 1.98 | Kitchen equipment, countertops, general fabrication, automotive panels |

| 16 | 0.0625 | 1.59 | Decorative panels, light enclosures, appliance housings, HVAC components |

Notice the thickness jumps aren't uniform. The 10 gauge steel thickness of 3.57mm represents a substantial difference from 11 gauge steel thickness at 3.23mm. Meanwhile, the gap between 14 gauge and 16 gauge spans only about 0.4mm. This non-linear progression means you need to consult a sheet metal gauge chart rather than assuming equal intervals between numbers.

Matching Gauge to Application Requirements

Selecting the appropriate metal gauge thickness involves balancing several competing factors. Your application's structural demands, weight limitations, forming requirements, and budget all influence the optimal choice.

When evaluating gauge options for your project, consider these key decision factors:

- Structural Load Requirements: Heavy-duty applications like machine bases, structural brackets, and load-bearing components typically require 10-12 gauge material. The 12 gauge steel thickness of approximately 2.78mm provides substantial rigidity for industrial equipment and enclosures.

- Formability Needs: Thinner gauges bend and form more easily. If your design involves complex curves, deep draws, or tight bends, 14-16 gauge steel thickness offers better workability without cracking or excessive springback.

- Weight Constraints: Every gauge step down reduces weight significantly. Aerospace, automotive, and portable equipment applications often specify thinner gauges to minimize mass while maintaining adequate strength.

- Cost Considerations: Thicker gauges cost more per square foot due to increased material content. However, thinner materials may require additional reinforcement or more complex forming operations that offset raw material savings.

- End-Use Environment: Corrosive environments sometimes warrant thicker material to provide a corrosion allowance. In aggressive chemical or marine settings, specifying one gauge heavier than structurally necessary can extend component life.

For structural versus aesthetic applications, the gauge decision follows different logic. A decorative stainless steel wall panel might use 16 gauge steel thickness primarily for weight savings and ease of installation, since the panel doesn't bear loads. Conversely, a commercial kitchen prep table needs the rigidity of 14 gauge or thicker to resist denting and support heavy equipment.

HVAC ductwork commonly uses 20-24 gauge material, while automotive body panels typically specify 18-20 gauge. Industrial machine guards and enclosures often land in the 12-14 gauge range to withstand impact and provide security.

When you're uncertain, consulting with your fabricator helps match gauge selection to your specific performance requirements. They can advise whether a particular gauge will form cleanly in your design geometry and maintain structural integrity under expected service conditions. With gauge selection finalized, the next step in specifying your custom stainless steel involves choosing the appropriate surface finish for your application's functional and aesthetic demands.

Surface Finish Options and Their Applications

You've selected your grade and locked in your gauge. Now comes a decision that affects how your custom stainless steel sheet metal looks, performs, and cleans for years to come: surface finish. While two sheets might share identical alloy compositions and thicknesses, their finishes can make one perfect for a commercial kitchen and the other completely wrong for the job.

Surface finish isn't merely cosmetic. The texture and smoothness of stainless steel metal sheets directly influence corrosion resistance, bacterial attachment, light reflection, and maintenance requirements. Understanding your options helps you specify material that performs exactly as your application demands.

From Mill Finish to Mirror Polish

Stainless steel sheets arrive from the mill with one of two baseline finishes, each created during the cold-rolling process. From there, mechanical polishing can refine the surface to various degrees of smoothness and reflectivity.

- 2B Mill Finish: This bright, cold-rolled industrial surface represents the most common starting point for stainless steel sheets. It appears bright gray with low sheen and no directional grain pattern. According to Apache Stainless Equipment Corporation's finish research, 2B finish delivers an RA (roughness average) range of 15-40 microinches depending on gauge thickness, with thinner gauges producing smoother surfaces. It's widely used in industrial, chemical, and food applications where corrosion resistance matters more than appearance.

- 2D Mill Finish: A duller, matte cold-rolled surface with a rougher texture than 2B. This non-reflective finish works well for functional or hidden components where aesthetics aren't a priority. The RA values typically exceed 45 microinches, making it rougher than most other options.

- #4 Brushed Finish: Created using 150-180 grit abrasives, this satin sheen surface features visible directional grain lines. The brushed stainless sheet appearance balances professional aesthetics with practical durability. With an RA range of 29-40 microinches, #4 finish resists fingerprints better than mirror polish while still presenting an attractive appearance. Common applications include appliances, restaurant equipment, architectural trim, and backsplashes.

- #4 Dairy Finish: A refined version of #4 using 180 grit abrasives, achieving an RA of 18-31 microinches. This finish meets 3-A sanitary standards required by dairy and cheese manufacturing operations.

- #8 Mirror Finish: The most cosmetic option available, this polished stainless steel sheet metal surface reflects like glass. Grain marks are completely polished out, creating a highly reflective surface with RA values as low as 1-10 microinches. While stunning for decorative panels and signage, mirror finish shows fingerprints and scratches readily, requiring careful handling and regular maintenance.

Matching Surface Finish to Functional Needs

How do you choose between these options? Start by asking what functional requirements your application demands.

Cleanability and sanitation drive finish selection in food service and pharmaceutical environments. Smoother finishes resist bacterial attachment more effectively. Research cited by the U.S. Department of Agriculture found that among eleven different finishes tested, electropolished surfaces showed the greatest resistance to bacterial attachment. For food contact surfaces, #4 Dairy or electropolished finishes provide the easiest sanitation, while standard 2B mill finish works adequately for non-contact industrial equipment.

Corrosion resistance improves with smoother surfaces. The peaks and valleys in rougher finishes create more surface area for corrosive agents to attack and more crevices where contaminants can accumulate. If you're wondering how to polish stainless steel for maximum corrosion protection, electropolishing removes surface material electrochemically, producing improvements in RA smoothness up to 50% according to Apache Stainless testing.

Light reflection and aesthetics often determine finish selection in architectural applications. #8 mirror creates dramatic visual impact but demands constant cleaning. #4 brushed offers a more forgiving appearance that hides minor scratches and fingerprints while still projecting a modern, professional look. For projects requiring aesthetic consistency across large installations, #4 finish allows grain direction to be specified—an important detail when aligning multiple panels.

Fingerprint visibility matters wherever the public touches stainless surfaces. Elevator interiors, handrails, and appliance fronts benefit from brushed finishes that mask finger oils. Mirror polish, while beautiful, may frustrate maintenance staff who find themselves constantly wiping away marks.

Protective film ships on brushed and mirror surfaces to prevent damage during fabrication and installation. Mill finishes typically arrive without protective covering since their industrial character tolerates minor surface imperfections.

With your finish specified alongside grade and gauge, you've defined the raw material characteristics of your custom stainless steel. The next critical consideration involves selecting the right cutting method to transform that sheet into your finished component shape.

Cutting Methods for Stainless Steel Sheet Metal

You've specified the perfect grade, dialed in the right gauge, and selected an ideal surface finish. Now comes a question that can make or break your finished part: how do you cut stainless steel sheet metal without compromising the properties you've carefully selected?

Stainless steel presents unique cutting challenges. According to research published by AZoM, the material's high hardness and tensile strength cause rapid tool wear, while its low thermal conductivity concentrates heat at the cutting site. Add in the tendency to work-harden during processing, and you understand why cutting stainless steel sheets demands careful method selection.

The best way to cut stainless steel depends entirely on your project's requirements for precision, edge quality, material thickness, and budget. Let's examine the four primary methods and when each excels.

Laser Cutting vs Waterjet for Stainless Steel

When precision matters most, the conversation typically centers on laser cutting and waterjet cutting. Both technologies deliver tight tolerances and clean edges, but they achieve results through fundamentally different processes.

Laser cutting uses a focused, high-energy beam to melt or vaporize material along the cut path. Assist gases like oxygen or nitrogen expel molten metal and enhance the process. Fiber lasers have become the dominant technology for stainless steel cutting due to their efficiency and precision. According to Xometry's manufacturing guidance, laser is typically more precise than waterjet for thinner materials, with excellent repeatability across production runs.

The trade-off? Laser cutting creates a heat-affected zone (HAZ) along the cut edge. While modern fiber lasers minimize this effect, heat-sensitive applications may require consideration of alternative methods.

Waterjet cutting takes a completely different approach. A high-pressure stream of water mixed with abrasive particles erodes through the material without generating heat. This cold-cutting process prevents thermal distortion and preserves the stainless steel's inherent properties throughout the cut edge.

Waterjet shines when cutting thicker materials. As Xometry notes, the thicker the material, the more likely a waterjet will be used since waterjets can cut basically anything. For custom stainless steel applications requiring zero heat distortion or involving heat-sensitive secondary operations, waterjet often becomes the preferred choice.

Achieving Clean Cuts Without Material Damage

Beyond laser and waterjet, two additional methods serve specific stainless steel cutting needs.

Plasma cutting creates an ionized gas jet at extremely high temperatures to melt and expel material. Modern systems use water injection to reduce noise and improve cut quality. While plasma handles thick stainless steel efficiently, Xometry's manufacturing experts suggest counting it out for precision work: "Between fiber laser and waterjet, there is just so much more repeatability and precision than plasma cutting." Plasma-cut edges typically require secondary cleanup and are best suited for fabrication applications where welding will follow.

Mechanical shearing uses high-pressure blades to physically fracture the material. Band saws work for straight or curved cuts, while shears slice thinner sheets quickly and economically. These methods remain cost-effective for simpler geometries and thicker sections where thermal cutting isn't practical. However, chip formation requires careful attention—incorrect tooth geometry can cause work hardening or blade binding.

How do you cut stainless steel when tolerances are extremely tight? In some cases, sheet cutting processes alone won't achieve the required precision. As Xometry explains, tolerances beyond the norm for sheet cutting "may require machining (e.g., a 2.5-axis mill)" as a secondary operation.

| Cutting Method | Precision | Edge Quality | Thickness Range | Heat-Affected Zone | Relative Cost |

|---|---|---|---|---|---|

| Fiber Laser | Excellent (±0.005") | Clean, minimal burr | Up to ~1" typical | Minimal but present | Moderate |

| Waterjet | Very Good (±0.005-0.010") | Smooth, no thermal effects | Up to 6"+ possible | None (cold cutting) | Higher |

| Plasma | Moderate (±0.020") | Rougher, requires cleanup | Up to 2"+ typical | Significant | Lower |

| Mechanical Shearing | Good for straight cuts | Clean on thin material | Limited by blade capacity | None | Lowest |

When specifying stainless steel cutting for your project, communicate critical dimensions clearly. If certain features require tighter tolerances than standard manufacturing processes allow, flagging these requirements early enables your fabricator to apply appropriate methods or taper-correction techniques on deeper cuts.

Edge condition matters beyond just appearance. For components that will be welded, a rougher plasma-cut edge might actually improve weld penetration. For food-contact surfaces or visible architectural elements, laser or waterjet delivers the clean edge quality your application demands.

With your cutting method specified, the complete fabrication process can proceed from design file through finished part delivery—a workflow we'll examine next.

The Custom Fabrication Process Demystified

You've specified your grade, gauge, finish, and cutting method. Now what actually happens when you submit that order? Understanding the complete stainless steel sheet metal fabrication workflow helps you set realistic expectations, avoid delays, and ensure your custom stainless steel parts arrive exactly as specified.

The journey from design file to finished component follows a predictable sequence of steps. Each phase builds on the previous one, and any oversight early in the process can ripple through to the final product. Let's walk through what to expect when partnering with a metal fabrication company for your project.

From Design File to Finished Part

Every successful sheet metal fabrication project begins with a well-thought-out design. According to Cresco Custom Metals, concepts must be translated into workable blueprints and technical plans before any metal gets cut. Whether you're submitting CAD drawings or working from a napkin sketch, the fabricator needs clear documentation to proceed.

Here's the typical workflow from initial contact through delivery:

- Design Submission: You provide CAD files, drawings, or specifications describing your required stainless steel shapes and dimensions. Most fabricators accept standard formats like DXF, DWG, STEP, or PDF drawings. If you don't have formal drawings, many companies can help create them from scratch based on your concepts.

- DFM (Design for Manufacturability) Review: Engineers analyze your design for production feasibility. They identify potential issues like insufficient bend radii, problematic hole placements near edges, or features that could cause warping during fabrication. This upfront review catches problems before they become expensive mistakes.

- Material Selection Confirmation: The fabricator confirms your grade, gauge, and finish specifications align with your application requirements and are available in the quantities needed. If your specified material presents lead time or cost concerns, they may suggest alternatives.

- Cutting Operations: Raw stainless steel sheets are cut to your specified dimensions using the appropriate method—laser, waterjet, plasma, or mechanical shearing. Precision at this stage ensures all subsequent operations proceed smoothly.

- Forming and Shaping: Cut blanks move to bending, rolling, stamping, or other forming operations. For stainless steel sheet fabrication, high-grade equipment and precise techniques maintain structural integrity and prevent cracking at bend lines.

- Welding and Assembly: Components requiring joining undergo welding, fastening, or other assembly operations. Stainless steel demands particular attention to prevent contamination and maintain corrosion resistance at weld zones.

- Surface Finishing: Parts receive their final surface treatment—grinding weld seams, polishing, passivation, or applying protective coatings as specified.

- Quality Inspection: Finished components undergo dimensional verification, surface quality checks, and any application-specific testing before packaging and shipment.

What to Expect During Custom Fabrication

How long does all this take? A typical job can range from a few days to several weeks depending on volume, complexity, and material availability. Simple flat parts with standard finishes move through faster than complex assemblies requiring multiple forming operations and specialized finishing.

Several factors influence your project timeline:

- Design Complexity: Intricate stainless steel shapes with tight tolerances require more setup time and careful processing than simple geometries.

- Material Availability: Common grades like 304 in standard gauges ship quickly. Specialty alloys or unusual thicknesses may require mill orders with longer lead times.

- Order Volume: Larger production runs benefit from setup amortization but require more total processing time. Prototype quantities move faster but carry higher per-piece costs.

- Secondary Operations: Each additional step—welding, hardware insertion, special finishing—adds time to the overall schedule.

Quality certifications matter more than many buyers realize. ISO 9001:2015 certification indicates a fabricator maintains documented quality management systems with consistent procedures and continuous improvement practices. For automotive applications, IATF 16949 certification adds industry-specific requirements covering product safety, traceability, and defect prevention.

These certifications aren't just plaques on the wall. They represent systematic approaches to catching errors before parts ship and ensuring repeatable quality across production runs. For stainless steel used in food-grade or medical equipment, Cresco notes that strict finishing processes reduce contamination risks—something only achievable through disciplined quality systems.

Precise execution during the design phase assures fewer faults during production, improves lead times, and reduces costs. Investing time upfront in thorough DFM review and clear specification pays dividends throughout the fabrication process. With the manufacturing workflow understood, you're ready to explore how different industries leverage custom stainless steel for their specific application requirements.

Application Guide Across Key Industries

Imagine specifying the same stainless steel grade for a hospital surgical suite and a beachfront restaurant kitchen. Both environments demand corrosion resistance and cleanability, yet the specific requirements couldn't be more different. Understanding how each industry leverages custom stainless steel sheet metal helps you match material properties to real-world performance demands.

The properties of metals vary dramatically based on their composition, and stainless steel's flexibility makes it suitable across remarkably diverse applications. However, selecting the wrong grade or finish for your specific sector can lead to premature failure, compliance issues, or unnecessary expense. Let's examine what each major industry requires and which material specifications deliver optimal results.

Industry-Specific Grade and Finish Recommendations

Different sectors face unique environmental challenges, regulatory requirements, and performance expectations. Here's what you need to know about selecting custom stainless steel for each major application area:

- Food Service and Commercial Kitchens: This sector demands FDA-compliant materials that withstand constant cleaning and exposure to food acids. According to WebstaurantStore's industry guide, 304 stainless steel is the most common type used in commercial kitchens due to its bright shine and excellent resistance to corrosion and rust. For equipment contacting salty foods or exposed to harsh cleaning chemicals, 316 stainless steel provides superior protection thanks to its molybdenum content. Finish selection matters equally—#4 brushed or #4 Dairy finish facilitates easy sanitation while meeting 3-A sanitary standards. The smooth, non-porous surface prevents bacterial growth, making stainless steel metal plates the gold standard for food preparation surfaces, utensils, and equipment.

- Architectural and Decorative Applications: Aesthetic consistency drives material selection for building facades, elevator interiors, and decorative panels. Stainless steel metal panels must maintain their appearance despite weather exposure, temperature cycling, and constant human contact. Grade 316 excels for exterior installations where rain, humidity, and atmospheric pollution create corrosive conditions. For interior applications, 304 typically suffices while reducing material costs. Finish selection depends on visual goals—#8 mirror creates dramatic reflective surfaces for high-impact installations, while #4 brushed offers a more forgiving appearance that masks fingerprints and minor scratches. Specify grain direction when installing multiple panels to ensure visual continuity across large surfaces.

- Medical and Pharmaceutical Facilities: Sterilization compatibility defines material requirements in healthcare settings. Equipment must withstand repeated autoclaving cycles, aggressive disinfectants, and pharmaceutical compounds without degradation. Grade 316L emerges as the preferred choice for surgical instruments, processing equipment, and cleanroom components. Its low carbon content prevents sensitization during welding, maintaining corrosion resistance throughout the equipment's service life. Electropolished finishes maximize bacterial resistance—research cited by the USDA found electropolished surfaces showed the greatest resistance to bacterial attachment among all finishes tested. For ss steel plate used in pharmaceutical processing, surface roughness specifications often mandate RA values below 20 microinches.

- Marine Applications: Saltwater represents one of the most aggressive corrosive environments stainless steel encounters. Chloride ions attack standard grades relentlessly, causing pitting and crevice corrosion that leads to structural failure. Grade 316 becomes mandatory for marine hardware, boat fittings, and coastal architectural elements. The 2-3% molybdenum content provides essential protection against chloride-induced corrosion. For underwater or splash zone applications, some specifiers move to duplex grades or even higher-alloy materials. Surface finish plays a secondary role here—corrosion resistance trumps aesthetics, though smoother finishes do reduce surface area available for corrosive attack.

- Automotive and Industrial Manufacturing: Structural performance and cost efficiency balance against corrosion requirements in these sectors. Ferrous metals like 430 stainless steel find extensive use in automotive exhaust systems, where heat resistance matters more than extreme corrosion protection. This ferritic grade handles elevated temperatures well while costing significantly less than austenitic alternatives. For structural components, chassis parts, and suspension elements, 304 provides adequate corrosion resistance at moderate cost. Industrial equipment housings and machine guards typically specify 12-14 gauge stainless steel plate for impact resistance and structural rigidity. Finish requirements vary widely—functional components may use mill finish 2B, while visible panels demand brushed or polished surfaces.

Meeting Regulatory Requirements Across Sectors

Beyond material properties, regulatory compliance shapes stainless steel selection in many industries. Food processing facilities must meet FDA requirements for food-contact surfaces. As Metal Products of Cincinnati explains, food grade stainless steel must withstand acids, alkalis, and chlorides like salt without premature corrosion. If corrosion starts forming, equipment must be removed from circulation immediately due to its uneven surface creating contamination risks.

The 300 and 400 series stainless steels dominate food-grade applications for specific reasons. The 300 series (including 304 and 316) contains higher nickel content, providing superior corrosion resistance but at higher cost. The 400 series offers magnetic properties useful for conveyor dishwashers equipped with magnets to catch escaped flatware before it enters trash systems.

Pharmaceutical and medical device manufacturing imposes even stricter surface requirements. Equipment nameplates, processing vessels, and contact surfaces must demonstrate antibacterial properties and resistance to caustic cleaning agents. Stainless steel equipment nameplates have become the preferred choice in pharmaceutical facilities due to their excellent resistance to dents, scratches, and stains combined with superior performance in highly caustic or acidic environments.

For industrial food applications where corrosive exposure is particularly severe, electropolishing treatment enhances acid-resistance properties. This one-time treatment can prevent the corrosion that might otherwise lead to contamination—a worthwhile investment for equipment expected to provide years of reliable service.

Selecting the right custom stainless steel for your industry isn't just about checking boxes on a specification sheet. It's about understanding how material properties translate into real-world performance under your specific operating conditions. With clear industry requirements defined, the next step involves finding a supplier capable of delivering material that meets your exact specifications.

Sourcing and Supplier Selection Strategies

You've specified the perfect grade, gauge, finish, and cutting method for your project. Now comes a decision that can make or break your entire manufacturing timeline: where to buy stainless steel sheets that meet your exact requirements. The difference between an excellent supplier and a mediocre one extends far beyond price per pound—it affects your lead times, quality consistency, and ultimately your project's success.

Finding reliable stainless steel sheet metal suppliers requires evaluating multiple factors simultaneously. A supplier offering rock-bottom prices means nothing if they can't deliver on time or provide the custom cutting capabilities your project demands. Let's examine what separates exceptional fabrication partners from the rest of the pack.

Evaluating Custom Metal Suppliers

When you're ready to buy stainless steel sheet for your project, systematic evaluation prevents costly mistakes. According to Fry Steel's supplier comparison guide, selecting the right metal supplier isn't just a purchasing decision—it's a partnership that impacts your product quality, production timelines, and long-term profitability.

What should you look for when comparing potential partners for custom stainless steel products? Consider these essential evaluation criteria:

- Rapid Prototyping and DFM Support: Top-tier suppliers like Shaoyi (Ningbo) Metal Technology offer 5-day rapid prototyping services that let you validate designs before committing to production runs. Their comprehensive DFM (Design for Manufacturability) support catches potential issues early, saving time and money. This kind of upfront engineering collaboration separates true manufacturing partners from simple material distributors.

- Quote Turnaround Time: How quickly can you get pricing? Waiting days or weeks for quotes creates bottlenecks in your planning process. Leading suppliers provide 24-hour quote turnaround or faster, with some offering instant online quoting for standard configurations. Shaoyi exemplifies this approach with their rapid quote response times that keep your project moving forward.

- Custom Cutting Capabilities: Not every supplier can handle custom cut stainless steel requirements. Verify that your potential partner offers the specific cutting methods your project demands—laser, waterjet, plasma, or mechanical shearing. Ask about tolerance capabilities and maximum sheet sizes they can process.

- Available Grades and Finishes: Extensive on-hand inventory reduces lead times and ensures material availability. As Fry Steel notes, suppliers carrying 140+ grades with deep stock levels provide faster delivery and greater flexibility when specifications change mid-project.

- Quality Certifications: Look for ISO 9001:2015 certification as a baseline for quality management systems. For automotive applications, IATF 16949 certification indicates the supplier meets stringent industry requirements for product safety, traceability, and defect prevention. Shaoyi holds IATF 16949 certification, demonstrating their commitment to automotive-grade quality standards.

- Minimum Order Quantities: Some suppliers focus exclusively on high-volume production, making them unsuitable for prototype quantities or small batch runs. Clarify MOQs upfront to avoid wasted time pursuing partners who can't accommodate your order size.

- Value-Added Services: Beyond raw material supply, what additional capabilities does the supplier offer? In-house forming, welding, finishing, and assembly services streamline your procurement process. When materials pass through fewer hands, you reduce handling errors and simplify project management.

From Quote Request to Project Completion

Once you've identified promising stainless steel plate supplier candidates, the purchasing process follows a predictable pattern. Understanding what to expect helps you move efficiently from initial inquiry through delivery.

The Quote Request Phase: Submit your specifications including CAD files, required quantities, target delivery dates, and any special requirements. Be specific about tolerances, finish specifications, and certification documentation you'll need. Vague requests generate vague quotes—detailed inquiries receive accurate pricing.

Many buyers wonder where to buy stainless steel sheets when their custom stainless steel sheet requirements fall outside standard offerings. The answer often lies with specialized fabricators rather than general metal distributors. Companies focused on custom work maintain the equipment, expertise, and quality systems needed for precision manufacturing.

Lead Time Expectations: Standard custom cut stainless steel orders typically ship within 1-3 weeks depending on complexity and material availability. Prototype quantities often move faster—rapid prototyping services can deliver sample parts in as little as 5 business days. Production runs require longer lead times based on volume and secondary operations required.

Several factors influence your specific timeline:

| Factor | Impact on Lead Time | Mitigation Strategy |

|---|---|---|

| Material Availability | Specialty grades may require mill orders adding 4-8 weeks | Confirm stock status before finalizing specifications |

| Order Complexity | Multiple forming operations extend processing time | Simplify designs where possible during DFM review |

| Quantity | Higher volumes require proportionally longer production | Phase large orders into scheduled releases |

| Quality Documentation | Certified test reports and traceability add processing steps | Specify documentation requirements upfront |

| Secondary Finishing | Polishing, passivation, or coating extends total time | Consider mill finishes if aesthetics allow |

Project Support Throughout Production: The best suppliers provide visibility into your order's progress. Online order management platforms let you track production stages and delivery status without making phone calls. Automated notifications at key milestones—cutting complete, forming finished, shipped—keep your planning on track.

Responsive customer support proves essential when questions arise. Knowledgeable sales representatives don't just take orders—they partner with you to find optimal solutions. When Fry Steel describes their approach, they emphasize that "a knowledgeable sales rep doesn't just order supplies for you, but partners with you to help you find the perfect product."

Validating Before Production: For new designs or critical applications, rapid prototyping services provide essential validation. According to Hubs' prototyping guide, seeing a physical part before committing to production runs prevents costly mistakes. Modern prototyping platforms offer instant quotes, automated DFM feedback, and lead times as short as 4-6 business days.

Prototype evaluation lets you verify fit, function, and finish before scaling up. If adjustments are needed, making changes at the prototype stage costs a fraction of reworking production tooling or scrapping finished inventory.

Selecting the right partner for your custom stainless steel sheet metal needs sets the foundation for successful projects. By evaluating suppliers systematically against these criteria, you'll find partners capable of delivering quality materials on schedule—transforming raw stainless steel into the precision components your applications demand.

Frequently Asked Questions About Custom Stainless Steel Sheet Metal

1. What is the difference between 304 and 316 stainless steel?

Grade 304 contains 18-20% chromium and 8-10% nickel, making it ideal for standard environments like kitchens and industrial enclosures. Grade 316 adds 2-3% molybdenum, providing superior resistance to pitting and crevice corrosion in chloride-rich environments such as marine applications and chemical processing. While 316 costs more, it delivers significantly longer service life in aggressive conditions.

2. How do I choose the right gauge for stainless steel sheet metal?

Gauge selection depends on your application's structural requirements, formability needs, and weight constraints. Heavy-duty applications like machine bases require 10-12 gauge (2.78-3.57mm thick), while decorative panels typically use 16 gauge (1.59mm). Remember that higher gauge numbers mean thinner material. Consulting with your fabricator helps match gauge to your specific design geometry and performance requirements.

3. What is the best way to cut stainless steel sheet metal?

The optimal cutting method depends on your project requirements. Laser cutting offers excellent precision (±0.005") with minimal burr for thinner materials. Waterjet cutting provides zero heat-affected zone, making it ideal for heat-sensitive applications and thicker materials up to 6"+. Plasma cutting handles thick sections economically but requires edge cleanup. Mechanical shearing remains cost-effective for straight cuts on thinner sheets.

4. Where can I buy custom cut stainless steel sheets?

Specialized metal fabricators like Shaoyi (Ningbo) Metal Technology offer custom cutting services with rapid quote turnaround and DFM support. When selecting a supplier, evaluate their cutting capabilities, available grades and finishes, quality certifications (ISO 9001:2015, IATF 16949), minimum order quantities, and rapid prototyping services. Leading suppliers provide 12-hour quote responses and 5-day prototyping to validate designs before production.

5. What surface finish should I choose for food-grade stainless steel?

#4 Dairy finish or electropolished surfaces work best for food-contact applications. These smooth finishes meet 3-A sanitary standards with roughness averages of 18-31 microinches, preventing bacterial attachment and facilitating easy sanitation. Standard 2B mill finish suffices for non-contact industrial equipment. For maximum bacterial resistance, electropolishing reduces surface roughness by up to 50%.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —