What CNC Services Actually Cost And Why Quotes Vary So Much

Understanding CNC Services and How They Transform Raw Materials

Ever wondered how a digital design on your computer screen becomes a precise metal or plastic component you can hold in your hand? That's exactly what CNC services make possible. CNC, which stands for Computer Numerical Control, represents a manufacturing approach where computers direct machine tools to cut, shape, and form materials with remarkable accuracy. Unlike traditional manual machining where a skilled operator guides every cut, CNC technology follows programmed instructions down to fractions of a millimeter.

From Digital Design to Physical Reality

The journey from concept to finished part follows a surprisingly straightforward path. You start with a CAD (Computer-Aided Design) file, essentially a digital blueprint of your component. This file gets exported into formats like STEP or IGES that machining software can interpret. From there, CAM (Computer-Aided Manufacturing) software translates your design into toolpaths, which are the precise movements cutting tools will follow. Finally, a post-processor converts everything into G-code, the language CNC machines understand.

Here's how the typical workflow unfolds:

- CAD design creation using software like Fusion 360 or SolidWorks

- Export to CNC-compatible format (STEP, IGES, or Parasolid)

- Import into CAM software for toolpath generation

- Post-processing to machine-specific G-code

- Loading instructions into the CNC machine

- Automated machining begins

The Technology Behind Modern Manufacturing

So, what is CNC routing specifically? CNC routing uses rotating cutting tools to carve away material from a workpiece, typically sheets of wood, plastic, or soft metals. The router head moves along multiple axes while the workpiece remains stationary, allowing for intricate cnc cutting patterns and complex geometries. This process excels at creating everything from signage and cabinetry to aerospace panels and electronic enclosures.

The real power of any CNC service lies in its repeatability. Once you've programmed a part correctly, the machine can produce identical copies, whether you need ten or ten thousand. Each component matches the original specifications precisely, eliminating the variability that comes with manual machining operations.

CNC machines follow instructions down to fractions of a millimeter, which means your finished part is only as accurate as the file you provide. Precision starts at the design level, not at the machine.

Why CNC Changed Everything

Before CNC technology emerged, skilled machinists controlled every aspect of production manually. This meant quality varied between operators, complex geometries required exceptional talent, and production speeds had natural limits. CNC fabrication eliminated these constraints by putting computers in control of the mechanical operations.

Today's CNC capabilities extend far beyond basic cutting. Modern machines can perform drilling, threading, contouring, and surface finishing, often in a single setup. Multi-axis systems rotate workpieces while simultaneously moving cutting tools, enabling the creation of parts that would be impossible to produce manually. This technological leap transformed industries from automotive to medical devices, making precision accessible at virtually any production volume.

Understanding these fundamentals helps explain why quotes for seemingly similar projects can vary dramatically. The machining process selected, tolerances specified, and design complexity all influence both the approach and the final cost, topics we'll explore in detail throughout this guide.

CNC Milling Turning and Multi-Axis Machining Processes Compared

When you request a quote for CNC services, you'll encounter terms like milling, turning, and multi-axis machining. But what do these actually mean for your project? Understanding the differences helps you communicate effectively with manufacturers and explains why two shops might quote the same part using completely different approaches.

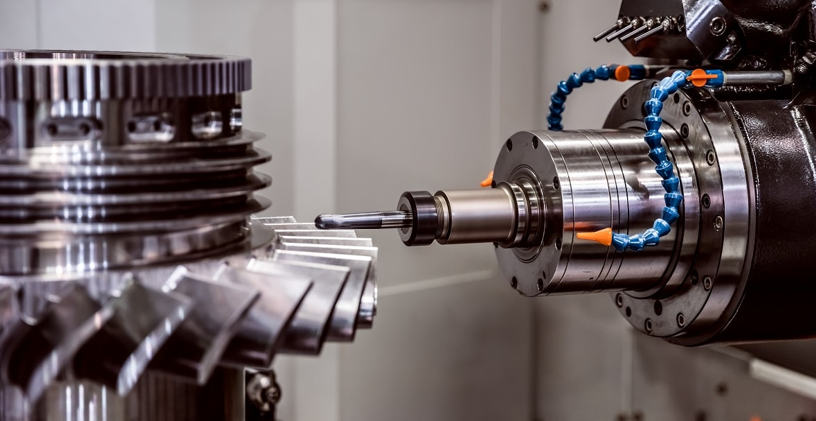

Milling Operations Explained

CNC machining milling involves rotating cutting tools that remove material from a stationary workpiece. Imagine a drill bit moving not just up and down, but also side to side and front to back, carving away material to reveal your part. The spindle holds various cutting tools, including end mills and face mills, each designed for specific operations like creating flat surfaces, pockets, or intricate contours.

Milling excels when your part features:

- Flat surfaces and angular features

- Slots, pockets, and cavities

- Complex 3D contours and shapes

- Non-rotationally symmetric geometries

- Multiple features requiring access from different angles

The process works across an impressive range of materials. CNC milling parts can be produced from aluminum, steel, brass, titanium, and engineering plastics with equal precision. This versatility makes milling the go-to choice for prototypes, custom components, and production runs where part complexity demands flexibility.

When Turning Makes Sense

CNC turning flips the script entirely. Instead of the tool rotating, the workpiece spins while a stationary cutting tool removes material. Picture a lathe spinning a cylinder of metal while a blade shapes its exterior, creating shafts, pins, bushings, and other rotationally symmetric components.

CNC turning services prove most cost-effective for parts featuring cylindrical symmetry. Think about components like threaded fasteners, valve stems, or hydraulic fittings. The process naturally produces excellent surface finishes on exterior surfaces and handles operations like threading, grooving, and boring with remarkable efficiency.

Swiss machining takes turning further by adding a sliding headstock that supports the workpiece close to the cutting action. This configuration enables the production of long, slender parts with exceptional precision, making it invaluable for medical components, watch parts, and precision pins where length-to-diameter ratios would cause problems on conventional lathes.

Advanced Multi-Axis Capabilities

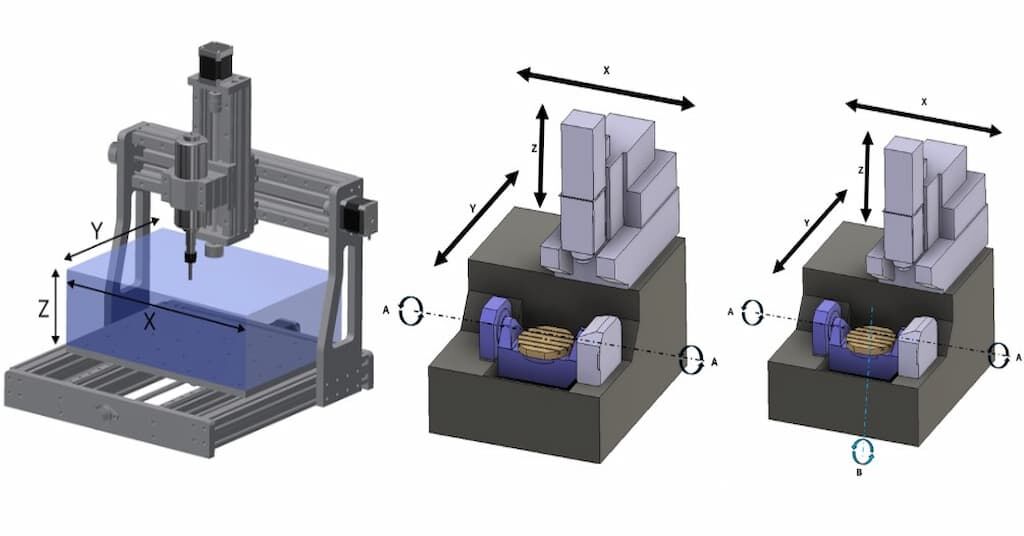

Standard 3-axis machines move cutting tools along X, Y, and Z planes, essentially left-right, front-back, and up-down. While capable of producing many parts, this configuration requires multiple setups for complex geometries, with each repositioning introducing potential errors.

5 axis CNC machining services add two rotational movements, typically labeled A and B or B and C axes. These additional degrees of freedom allow the cutting tool to approach the workpiece from virtually any angle. For you as a customer, this means:

- Complex parts completed in single setups

- Tighter tolerances from eliminated repositioning errors

- Better surface finishes using optimal cutting angles

- Access to undercuts and compound-angle features

- Reduced lead times despite increased complexity

When manufacturers discuss 5-axis capabilities, they might reference simultaneous machining where all axes move together, or 3+2 positioning where rotational axes lock into specific orientations before cutting begins. Simultaneous operations produce flowing surfaces like turbine blades, while 3+2 positioning handles angled holes and multi-sided features more simply.

Beyond 5-axis, some facilities offer 7-axis, 9-axis, or even 12-axis configurations. According to Fictiv's comparison of CNC capabilities, 9-axis machines combine 5-axis milling with 4-axis turning in a single setup, eliminating secondary fixturing entirely. These advanced configurations primarily serve aerospace, medical, and defense applications where precision cnc machining requirements justify the additional investment.

| Process Type | Best Applications | Typical Tolerances | Complexity Level |

|---|---|---|---|

| 3-Axis Milling | Flat parts, simple pockets, basic contours | ±0.005" (±0.127mm) | Low to Medium |

| CNC Turning | Shafts, pins, bushings, threaded components | ±0.002" (±0.05mm) | Low to Medium |

| 4-Axis Milling | Cylinder work, arc cuts, rotational engravings | ±0.003" (±0.076mm) | Medium |

| 5-Axis Milling | Complex surfaces, turbine blades, impellers | ±0.001" (±0.025mm) | High |

| Swiss Machining | Long slender parts, medical screws, precision pins | ±0.0005" (±0.0127mm) | Medium to High |

| 9-Axis Mill-Turn | Complete parts requiring both milling and turning | ±0.0005" (±0.0127mm) | Very High |

Process selection directly impacts your quote in several ways. Simpler processes cost less per hour but may require multiple setups, adding labor and introducing tolerance stack-up. Advanced multi-axis machines carry higher hourly rates but often complete parts faster with better precision. When a manufacturer recommends a specific approach, they're balancing these factors against your tolerance requirements, quantity needs, and timeline expectations.

Now that you understand how different machining processes work, the next critical factor affecting your quote becomes the material you select and how its properties influence machinability, tool wear, and ultimately, cost.

Material Selection Guide for CNC Machined Components

Why does one shop quote aluminum at half the price of stainless steel for the same part geometry? The answer lies in how different cnc machining materials behave under cutting tools. Material selection affects everything from machining speed and tool wear to achievable tolerances and surface finish quality. Choosing wisely can save significant money without sacrificing performance.

Metals and Their Machining Characteristics

Not all metals machine equally. Some cut like butter while others fight back, wearing down tools and demanding slower speeds. Understanding these differences explains why material choice drives such dramatic quote variations.

Aluminum machining stands out as the most cost-effective option for many projects. Aluminum alloys cut quickly, produce excellent surface finishes, and extend tool life significantly compared to harder metals. The 6061-T6 alloy offers a balanced combination of strength, corrosion resistance, and machinability, making it the default choice for prototypes and production parts alike. Softer grades like 6063 machine even faster but sacrifice some structural properties.

Common metals and their machining characteristics include:

- Aluminum (6061, 7075, 2024): Excellent machinability, low tool wear, fast cycle times, good corrosion resistance

- Mild Steel (1018, A36): Moderate machinability, affordable raw material cost, requires surface treatment for corrosion protection

- Stainless Steel (303, 304, 316): Challenging to machine, work hardens easily, longer cycle times but excellent corrosion resistance

- Brass (C360): Outstanding machinability, produces clean cuts, ideal for decorative and electrical applications

- Bronze (C932, C954): Good machinability with self-lubricating properties, excellent for bearings and bushings

Machining bronze offers unique advantages for wear applications. According to Fictiv's material guide, bronze alloys provide natural lubricity that reduces friction in bearing surfaces, extending component life in demanding environments. CNC bronze components frequently appear in marine hardware, industrial bushings, and heavy equipment where durability matters most.

Stainless steel presents the greatest machining challenge among common metals. The material work hardens during cutting, meaning each pass makes subsequent passes more difficult. Machinists must maintain constant chip evacuation and appropriate cutting speeds to prevent this hardening effect. These requirements translate directly into longer cycle times and higher quotes.

Engineering Plastics for Precision Parts

When your application calls for lightweight components, electrical insulation, or chemical resistance, engineering plastics often outperform metals. However, plastics introduce their own machining considerations that affect both cost and quality.

Delrin plastic, also known by its chemical name acetal or the brand name delrin material, represents the gold standard for machined plastic components. This crystalline thermoplastic machines cleanly, holds tight tolerances, and resists moisture absorption that can cause dimensional changes. Delrin excels in gears, bushings, and precision mechanical components where dimensional stability matters.

Common engineering plastics for CNC applications:

- Delrin/Acetal: Excellent dimensional stability, low friction coefficient, ideal for gears and bearings

- Nylon (PA6, PA66): Good impact resistance, absorbs moisture affecting dimensions, cost-effective for many applications

- Polycarbonate: Outstanding impact strength, optical clarity, requires careful machining to prevent stress cracking

- PEEK: High-performance thermoplastic, exceptional chemical resistance, expensive but necessary for demanding environments

- UHMW Polyethylene: Excellent wear resistance, low friction, challenging to hold tight tolerances

Machining nylon requires understanding its moisture sensitivity. Nylon absorbs water from ambient humidity, causing parts to swell slightly. For precision applications, manufacturers often dry the material before machining and recommend controlled storage conditions afterward. This extra handling adds cost but ensures your parts meet specifications.

CNC polycarbonate machining demands particular care around internal stresses. Aggressive cutting can cause stress cracking, especially near drilled holes or sharp internal corners. Experienced machinists use appropriate speeds, feeds, and generous radii to prevent these failures, but these precautions add time to the process.

Matching Materials to Application Requirements

Selecting the right material means balancing multiple competing factors. The cheapest material that machines fastest isn't always the best choice if it fails in service. Consider these key questions when evaluating options:

- Environmental exposure: Will the part face moisture, chemicals, UV light, or temperature extremes?

- Mechanical requirements: What loads, impacts, or wear conditions must it survive?

- Electrical properties: Does the application require conductivity or insulation?

- Weight constraints: Is minimizing mass a priority for your design?

- Finishing requirements: Does the material accept the coatings, plating, or treatments you need?

Material selection also affects achievable tolerances. Aluminum holds tighter tolerances more easily than plastics because it doesn't flex or deform under cutting pressure. Stainless steel can achieve excellent precision but requires more careful machining to prevent work hardening and distortion. Understanding these relationships helps you set realistic expectations for your specifications.

The cost equation extends beyond raw material price. A more expensive material that machines twice as fast may actually reduce your total project cost. Conversely, choosing a difficult-to-machine material for a complex geometry multiplies the machining challenges, pushing quotes higher than the material price alone would suggest.

With material selection clarified, the next factor significantly affecting your quote becomes the tolerances you specify. Understanding the relationship between precision requirements and manufacturing cost helps you avoid over-specifying parts and paying for accuracy you don't actually need.

Tolerances and Precision Standards in CNC Manufacturing

You've selected your material and machining process, but here's where quotes can diverge dramatically: tolerance specifications. That ±0.005" callout on your drawing might seem like standard practice, but tightening it to ±0.001" could double your manufacturing cost. Understanding why this happens helps you specify exactly what you need without paying for precision that adds no functional value.

Standard vs Precision Tolerances Explained

Tolerances define the acceptable variation from your specified dimension. When you call out a 1.000" dimension with ±0.005" tolerance, you're telling the machinist that anything between 0.995" and 1.005" works perfectly fine. Simple enough, right?

The challenge comes from how dramatically different tolerance levels affect manufacturing. Standard machining tolerances typically fall in the ±0.005" to ±0.010" range (±0.127mm to ±0.254mm). Most CNC equipment achieves these specifications routinely without special procedures. Precision machining services operate tighter, around ±0.001" to ±0.002" (±0.025mm to ±0.051mm), requiring more careful process control and measurement.

At the extreme end, tight tolerance CNC machining achieves ±0.0001" (±0.0025mm) or better. According to Modus Advanced, industry leaders routinely hold tolerances of 1-3 microns for medical and aerospace applications. However, this level of precision demands specialized equipment, environmental controls, and extensive inspection protocols.

How Tolerance Requirements Affect Your Quote

Here's what many buyers don't realize: the relationship between tolerance and cost isn't linear. Moving from ±0.05mm to ±0.02mm might raise costs by around 50%. But going further from ±0.02mm to ±0.01mm can multiply costs several times over, according to research on precision manufacturing economics.

Why does this happen? Tighter tolerances trigger a cascade of additional requirements:

- Slower machining speeds: Cutting tools must move more carefully to maintain dimensional control

- More frequent tool changes: Even minor tool wear affects precision at tight tolerances

- Enhanced fixturing: Workholding must eliminate micro-movements during cutting

- Temperature control: Thermal expansion affects dimensions at the micron level

- Extensive inspection: Every critical dimension requires verification, often using coordinate measuring machines

Precision machining companies invest heavily in equipment designed specifically for tight-tolerance work. High-resolution encoders monitor tool position to sub-micron accuracy. Thermal compensation systems adjust for temperature variations throughout production. Spindle runout specifications measure less than 0.0013mm for demanding applications. This infrastructure justifies higher hourly rates.

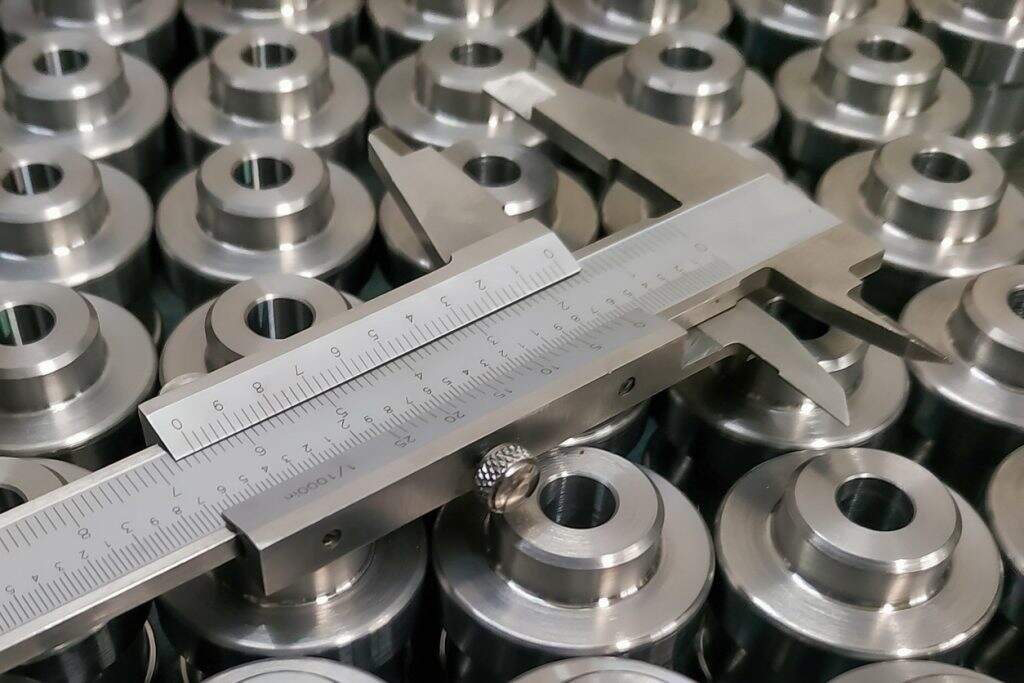

The inspection burden alone can dramatically affect costs. A standard CNC machining part might require spot-checking a few dimensions. A precision component demands comprehensive measurement of every critical feature, often with statistical process control documentation tracking results across the production run.

Application-Driven Tolerance Selection

The smartest approach to tolerancing asks one fundamental question: what does this dimension actually need to accomplish? A clearance hole for a bolt doesn't require the same precision as a bearing journal. Yet many drawings apply blanket tolerances that over-specify non-critical features.

| Application Type | Typical Tolerance Range | Example Parts | Key Considerations |

|---|---|---|---|

| General Purpose | ±0.005" to ±0.010" (±0.127mm to ±0.254mm) | Brackets, housings, covers | Standard equipment handles easily; minimal inspection |

| Precision Assembly | ±0.001" to ±0.002" (±0.025mm to ±0.051mm) | Connector housings, valve bodies, hydraulic components | Requires process control; moderate inspection |

| Aerospace CNC Machining | ±0.0005" to ±0.001" (±0.013mm to ±0.025mm) | Engine components, structural elements, control surfaces | Certified processes; full documentation required |

| Medical Machining | ±0.0001" to ±0.0005" (±0.0025mm to ±0.013mm) | Surgical instruments, implants, precision bearings | Biocompatible finishes; extensive validation |

Over-specifying tolerances wastes money without adding function. One European automotive supplier discovered that multiple non-critical features were specified at ±0.01mm when the assembly would function perfectly at ±0.03mm. By relaxing these non-essential tolerances while maintaining tight specs only where functionally required, they reduced machining costs by approximately 22%.

Under-specifying creates the opposite problem. Precision machining parts that don't fit during assembly require rework or scrapping, both expensive outcomes. Mating surfaces, bearing fits, and sealing interfaces typically demand tighter control than general dimensions.

The practical guidance? Apply your tightest tolerances only to features where dimensional precision directly affects function. Use standard tolerances everywhere else. This value-driven approach delivers the precision you need without paying for accuracy that serves no purpose. When reviewing quotes, understand that tolerance specifications often drive more cost variation than material selection or basic geometry.

Preparing Your Design Files for CNC Machining Success

You've nailed down your material choice and tolerance requirements. Now comes the step that trips up many first-time buyers: submitting design files that manufacturers can actually work with. The quality of your CAD files directly affects quote accuracy, lead times, and whether your finished cnc machine parts match your expectations. Getting this right from the start prevents costly revisions and miscommunication down the line.

CAD File Formats and Requirements

Not all file formats are created equal when it comes to CNC machining. The format you submit determines how easily manufacturers can program toolpaths and verify your design intent.

STEP files (with .stp or .step extensions) serve as the universal standard for CNC services. According to Komacut's machining guidelines, STEP files are universally accepted because they preserve solid geometry that CAM software can interpret directly. Unlike surface-based formats, STEP files define your part as a complete solid, enabling accurate analysis of wall thicknesses, feature depths, and material volumes.

Recommended file formats for CNC submission:

- STEP (.stp, .step): Preferred format; universally compatible; preserves complete solid geometry

- IGES (.igs, .iges): Widely supported; occasionally loses some surface data during translation

- Parasolid (.x_t, .x_b): Excellent geometry preservation; common in professional CAD systems

- Native CAD formats: SolidWorks, Fusion 360, or Inventor files work if the shop uses the same software

Here's a critical point many designers miss: your 3D model should be a solid object, not a collection of surfaces. Manufacturers need closed geometry to calculate toolpaths and verify that cutting operations won't accidentally break through walls or miss features. Surface models create ambiguity that leads to quoting delays and potential manufacturing errors.

While 3D models drive the machining process, 2D drawings remain essential for communicating tolerances, surface finish requirements, and inspection criteria. Your drawing should clearly indicate which dimensions are critical, what tolerances apply to specific features, and any special callouts the model alone can't convey.

Design for Manufacturability Essentials

Design for Manufacturability, commonly called DFM, refers to the practice of designing parts that can be efficiently produced using your chosen manufacturing process. In CNC machining, DFM principles focus on creating geometries that standard cutting tools can access without requiring specialized setups or equipment.

According to Modus Advanced's engineering guide, effective DFM implementation can reduce manufacturing costs by 15-40% and cut lead times by 25-60% compared to non-optimized designs. Those aren't minor savings.

Key DFM guidelines for CNC prototyping and production:

- Internal corner radii: Specify at least 0.030" (0.76mm) minimum radius on internal corners. End mills are cylindrical, so they physically cannot create sharp 90-degree internal corners.

- Wall thickness: Maintain minimum wall thicknesses of 0.040" (1mm) for metals and 0.060" (1.5mm) for plastics. Thinner walls deflect under cutting pressure, causing chatter and dimensional inaccuracy.

- Hole depths: Standard drills can reach depths of 4-6 times their diameter efficiently. Deeper holes require specialized tooling and slower operations that increase costs.

- Feature accessibility: Ensure cutting tools can physically reach every feature. Deep pockets with small openings may require long, thin tools that deflect and vibrate.

- Threading considerations: Provide adequate tapping depth beyond your required thread engagement. Taps have lead-in threads that don't cut fully, so you need extra depth to achieve complete threading.

The relationship between radii and tooling deserves special attention. Larger internal radii allow manufacturers to use larger, more rigid cutting tools that resist deflection. A 0.125" radius enables a 0.25" diameter end mill, while a 0.015" radius demands a tiny 0.030" tool that's prone to breakage and requires dramatically slower feed rates. The cnc cut becomes more expensive simply because of this geometry choice.

Common Design Mistakes to Avoid

Even experienced engineers occasionally submit designs with features that complicate manufacturing unnecessarily. Recognizing these pitfalls before submission saves time and money.

Sharp internal corners: As mentioned above, true sharp corners are physically impossible with rotating cutting tools. When your design shows sharp internal corners, manufacturers must either add radii themselves or use expensive secondary processes like EDM. Specify the largest radius your design can accommodate.

Knife edges: Where two surfaces meet at an extremely acute angle, you create fragile features that chip during machining and handling. According to manufacturing experts, adding small outside fillets of 0.005-0.015" eliminates knife edges and actually improves part durability.

Unnecessarily complex curves: Decorative curves and varying radii that serve no functional purpose dramatically increase programming time. Simple, consistent geometry machines faster and more reliably. Ask yourself: does this curve serve a specific functional purpose, or is it purely aesthetic?

Features requiring 5-axis when 3-axis would suffice: According to Modus Advanced, 5-axis machining costs 300-600% more than 3-axis operations. Aligning features with standard X, Y, and Z planes whenever possible significantly reduces costs.

Ignoring material machinability: Designing without considering how your chosen material behaves under cutting creates problems. Uptive Manufacturing notes that neglecting machinability leads to increased tool wear, extended production times, and overall inefficiencies. Consult with your manufacturer early if you're uncertain about material-specific design considerations.

For cnc prototyping projects especially, these mistakes compound quickly. Prototype machining typically involves small quantities where setup and programming time represent larger portions of total cost. A design optimized for manufacturability might cut your prototype machining costs in half while also accelerating delivery.

The workflow from file submission to production follows a predictable path. You submit your CAD files and drawings, the manufacturer runs DFM analysis to identify potential issues, you receive a quote based on that analysis, and upon approval, programming and production begin. Many shops now offer instant DFM feedback through automated systems that flag common problems before you even receive a formal quote. Taking advantage of these tools helps you refine designs iteratively, ensuring your cnc cuts proceed smoothly once production starts.

With your design files properly prepared, the next consideration becomes whether your industry imposes specific requirements on materials, documentation, or quality processes that affect which manufacturers can actually produce your parts.

Industry Applications from Automotive to Aerospace Manufacturing

Here's something that catches many buyers off guard: two CNC shops might quote the same part at dramatically different prices, and the difference often comes down to certifications you've never heard of. When your cnc machining parts are destined for a car engine, an aircraft fuselage, or a surgical instrument, the manufacturing requirements extend far beyond basic dimensional accuracy. Understanding these industry-specific demands explains why some quotes seem inflated and helps you identify which providers can actually deliver compliant components.

Automotive Component Manufacturing Requirements

The automotive industry operates on razor-thin margins with zero tolerance for quality escapes. A single defective component can trigger recalls affecting millions of vehicles. This reality shaped the development of IATF 16949, the global quality management standard specifically designed for automotive supply chains.

What does IATF 16949 certification actually mean for you as a customer? According to American Micro Industries, this standard combines ISO 9001 principles with sector-specific requirements for continuous improvement, defect prevention, and stringent supplier oversight. Companies that manufacture custom metal parts for automotive applications must demonstrate:

- Statistical Process Control (SPC): Real-time monitoring of critical dimensions throughout production runs, ensuring consistency from the first part to the last

- Product traceability: Complete documentation linking every component to specific material lots, machine settings, and operator records

- PPAP documentation: Production Part Approval Process records proving the manufacturing process can consistently produce conforming parts

- Continuous improvement protocols: Systematic approaches to identifying and eliminating sources of variation

For high-tolerance chassis assemblies and precision components, these requirements aren't bureaucratic overhead. They're the mechanisms that prevent quality problems from reaching your production line. When evaluating providers for automotive machined parts, IATF 16949 certification serves as your baseline qualification filter.

Manufacturers serving the automotive sector invest significantly in these quality systems. That investment gets reflected in their quotes, but it also delivers the reliability and documentation that OEMs demand. Working with certified providers who can scale seamlessly from rapid prototyping to mass production with consistent quality control eliminates the risk of mid-program supplier changes.

Aerospace and Defense Precision Standards

If automotive standards seem demanding, aerospace requirements operate on another level entirely. When components fly at 30,000 feet or support defense operations, the consequences of failure extend beyond financial losses to human lives and national security.

AS9100 certification builds upon ISO 9001 with aerospace-specific additions that emphasize risk management, configuration control, and absolute traceability. According to CNC Machines, this certification is fundamental for quality management in aerospace CNC shops, providing documentation to ensure products meet safety thresholds that major aerospace clients require.

Key aerospace certifications and their significance:

- AS9100: Core quality management system for aviation and defense manufacturing; addresses traceability, risk management, and documentation control specific to aerospace

- NADCAP: Accreditation for special processes like heat treating, chemical processing, and non-destructive testing; validates that specialized operations meet aerospace-level standards

- ITAR compliance: International Traffic in Arms Regulations governing defense-related components; requires registration with the U.S. Department of State and strict information security protocols

- Customer-specific approvals: Major OEMs like Boeing maintain their own supplier programs with unique qualification requirements

ITAR compliance deserves special attention for anyone producing custom machined parts with potential military applications. This isn't simply a quality certification. It's a legal requirement regulating how sensitive technical data and defense articles are handled. Facilities must implement access controls, secure data protocols, and export licensing procedures that fundamentally change how they operate.

The audit requirements for aerospace certifications are notably rigorous. Third-party registrars conduct regular assessments verifying compliance, while document control systems must maintain complete lot traceability throughout production. For precision cnc machining services serving aerospace customers, these systems ensure every critical component can be traced back through its entire manufacturing history.

CNC aluminum components represent a significant portion of aerospace machining work, given aluminum's favorable strength-to-weight ratio. However, the material itself is only part of the equation. The documentation, process controls, and validation procedures surrounding that material often determine whether a supplier can actually serve aerospace customers.

Medical Device Machining Considerations

Medical device manufacturing introduces requirements that differ fundamentally from other industries. When components contact human tissue or support life-critical functions, the stakes demand exceptional precision and absolute process control.

ISO 13485 serves as the definitive quality management standard for medical device manufacturing. According to PTSMAKE, this standard outlines strict controls over design, manufacturing, traceability, and risk mitigation that exceed standard manufacturing practices. The certification demonstrates a supplier's ability to consistently meet medical device regulatory requirements.

What makes medical machining unique:

- FDA compliance: Facilities must follow 21 CFR Part 820 (Quality System Regulation), governing product design, manufacturing, and tracking throughout the entire product lifecycle

- Biocompatibility requirements: Materials contacting the human body must meet USP Class VI standards or have FDA master files proving safety

- Complete traceability: Every component must be traceable from raw material through manufacturing to final delivery, enabling rapid response if safety issues arise

- Validated processes: Manufacturing processes must be formally validated to demonstrate they consistently produce components meeting predetermined specifications

The precision requirements for medical components often exceed those in other industries. Implantable devices may require tolerances as tight as ±0.0001 inches (2.54 micrometers), with surface finishes specified at the microinch level. Surgical instruments must balance functionality with cleanability, while fluid-handling components demand finishes that prevent bacterial harborage.

Documentation in medical manufacturing isn't an afterthought. It's a core deliverable. Comprehensive records covering material certifications, process parameters, inspection results, and operator qualifications accompany every shipment. This documentation supports regulatory submissions and provides the audit trail that FDA investigators expect during facility inspections.

For companies sourcing machined parts for medical applications, verifying these certifications upfront prevents costly surprises. A shop that lacks ISO 13485 certification simply cannot supply components for regulated medical devices, regardless of their machining capabilities or competitive pricing.

Matching Provider Capabilities to Your Industry

Understanding these certification frameworks helps you quickly filter potential suppliers. Before requesting quotes, ask yourself which regulatory environment governs your end application. The answer determines which certifications your CNC provider must hold.

- Automotive applications: IATF 16949 certification, SPC capabilities, PPAP documentation experience

- Aerospace and defense: AS9100 certification, NADCAP accreditation for special processes, ITAR registration if applicable

- Medical devices: ISO 13485 certification, FDA registration, validated processes, cleanroom capabilities if required

- General industrial: ISO 9001 provides baseline quality management for non-regulated applications

Certification status directly affects pricing. Maintaining these quality systems requires significant ongoing investment in personnel, training, equipment calibration, and audit preparation. Shops serving regulated industries build these costs into their rates. When you see a quote that seems unusually low for aerospace or medical work, investigate whether the provider actually holds the necessary certifications.

The certification discussion leads naturally to comparing CNC machining against alternative manufacturing methods. Understanding when machining makes sense versus when other processes might serve you better helps you make informed sourcing decisions from the start.

CNC Machining vs Alternative Manufacturing Methods

So you need a part manufactured. But is CNC machining actually the right choice? Sometimes the answer is yes. Sometimes 3D printing, injection molding, or casting serves you better. Understanding when each method excels helps you avoid overpaying for capabilities you don't need or choosing a process that can't deliver what you require.

The decision isn't always straightforward. Factors like production volume, geometric complexity, material requirements, and timeline all influence which manufacturing approach makes economic and practical sense. Let's break down the key decision criteria so you can match your project to the right process.

CNC vs 3D Printing Decision Criteria

These two technologies often compete for the same projects, especially during prototyping phases. Both start from digital files and can produce complex geometries. But they work in fundamentally opposite ways that affect when each makes sense.

CNC machining is subtractive. You start with a solid block of material and cut away everything that isn't your part. According to Hubs, CNC delivers exceptional accuracy, repeatability, and surface quality while supporting a broad selection of materials and post-processing options. The mechanical properties remain consistent because you're working with solid material stock that hasn't been melted or fused layer by layer.

3D printing is additive. Parts build up layer by layer from nothing, which means complex internal geometries, lattice structures, and organic shapes become possible without additional cost or setup time. However, printed parts often exhibit anisotropic properties, meaning they may be weaker along layer lines.

When should you choose 3D printing over CNC machined parts?

- Complex geometries: Internal channels, lattice structures, or topology-optimized shapes that cutting tools simply cannot access

- Rapid turnaround: Need parts within 24 hours? Printing often delivers faster for simple prototypes

- Very low quantities: For quantities under 10 units, additive manufacturing typically costs less due to minimal setup

- Specialty materials: Flexible TPU or high-performance metal superalloys are often better suited to printing than machining

- Carbon fiber prototyping: Some additive processes handle composite materials more economically than subtractive methods

When does CNC machining win? Rapid CNC prototyping makes sense when you need tight tolerances, smooth surface finishes, or production-grade materials. If dimensional accuracy is a top priority, CNC generally outperforms 3D printing. According to Hubs, while industrial additive systems can achieve excellent tolerances, they generally don't match the precision of CNC machining, especially for larger parts or features requiring sub-thousandth-inch accuracy.

For CNC prototype machining, you also benefit from using the exact same material that will go into production. A machined aluminum prototype behaves identically to machined aluminum production parts. Printed prototypes often use different materials or exhibit different properties than the final manufacturing method would produce.

When Injection Molding Makes More Sense

Here's a question worth asking early: how many parts do you actually need? The answer dramatically affects which process serves you best.

Injection molding involves significant upfront tooling costs. According to RPWorld, an aluminum tool typically costs more than a thousand dollars, with complex geometries and tight tolerances pushing that figure higher. You're essentially investing in a custom machine that can produce only one specific part.

That investment pays off at volume. Once the mold exists, each additional part costs a fraction of what CNC machining would charge. The process becomes economical starting around 1,000 pieces, with per-unit costs continuing to drop as quantities increase into tens of thousands or hundreds of thousands.

But molding imposes design constraints that machining doesn't:

- Draft angles: Parts must taper slightly to release from molds

- Uniform wall thickness: Varying thickness causes sink marks and warping

- Limited undercuts: Complex internal features require expensive side actions or multi-part molds

- Long lead times: Tool creation adds 3-5 weeks before first parts arrive

CNC machining parts face none of these constraints. You can produce parts with varying wall thicknesses, sharp internal corners, and complex features that would require expensive multi-cavity molds. For low-to-medium volumes or parts requiring frequent design changes, machining delivers flexibility that molding cannot match.

Many product development programs use both processes strategically. Machine prototypes and initial production batches while mold tooling is being created. Once the design stabilizes and volumes justify the tooling investment, transition to injection molding for ongoing production. This hybrid approach balances time-to-market with long-term cost optimization.

Casting vs Machining Trade-offs

Casting offers advantages that neither machining nor molding can easily replicate. When you need complex internal cavities, large structural components, or near-net-shape parts in specific alloys, casting deserves consideration.

According to 3ERP, casting excels at producing multiple identical parts in a single mold cycle, which speeds up production. Once the mold and pouring conditions are optimized, the process delivers highly repeatable results across thousands of units.

The trade-offs become clear when you examine precision requirements. Casting typically achieves tolerances around ±0.1mm per 25mm of dimension. That's acceptable for many applications, but machining parts requiring tighter fits need secondary operations. Die casting improves on these numbers, but still doesn't match what a custom machine equipped with precision spindles can deliver.

Surface finish represents another key difference. Cast parts, particularly those from sand casting, have rougher textures requiring grinding or polishing for cosmetic applications. Machining produces smooth surfaces directly, often eliminating finishing operations entirely.

When does casting make sense for your project?

- Internal cavities: Sealed chambers, curved passages, and flow paths that machining cannot access

- Very large parts: Structural components exceeding typical CNC work envelopes

- High volumes: Thousands of identical parts where mold amortization dramatically reduces unit costs

- Near-net-shape efficiency: Minimizing material waste when working with expensive alloys

Many manufacturers combine casting and machining. Cast the rough shape to minimize material removal, then machine critical features to achieve tight tolerances. This hybrid approach captures casting's material efficiency while delivering machining's precision where it matters most.

Comparing Your Manufacturing Options

The following comparison summarizes key decision factors across manufacturing methods. Use this as a starting point for conversations with potential suppliers about which approach fits your specific requirements.

| Method | Best Volume Range | Precision Level | Material Options | Typical Lead Time |

|---|---|---|---|---|

| CNC Machining | 1 to 1,000 parts | ±0.001" to ±0.005" (±0.025mm to ±0.127mm) | Extensive: metals, plastics, composites | 1-3 weeks |

| 3D Printing (FDM/SLS) | 1 to 50 parts | ±0.005" to ±0.015" (±0.127mm to ±0.381mm) | Growing: engineering plastics, some metals | 1-7 days |

| Injection Molding | 1,000+ parts | ±0.002" to ±0.005" (±0.05mm to ±0.127mm) | Thermoplastics, some thermosets | 4-8 weeks (including tooling) |

| Die Casting | 500+ parts | ±0.004" per inch (±0.1mm per 25mm) | Aluminum, zinc, magnesium alloys | 4-10 weeks (including tooling) |

| Sand Casting | 10 to 500 parts | ±0.030" (±0.76mm) | Wide range of castable metals | 2-6 weeks |

Notice how machining parts fills a unique niche. It handles the low-to-medium volume range where tooling investments for molding or casting don't make economic sense, while delivering precision that additive manufacturing struggles to match. For production runs between 10 and 500 units, CNC often represents the most practical choice regardless of part complexity.

Volume thresholds aren't absolute. Part complexity, material costs, and tolerance requirements all shift the break-even points. A geometrically simple part might justify injection molding at 500 units, while a complex component might remain more economical to machine up to several thousand pieces. Discuss your specific situation with manufacturers who offer multiple processes for objective guidance on which approach truly serves your needs.

With manufacturing method selection clarified, the next major factor affecting your CNC quotes becomes understanding exactly what drives costs and where opportunities exist to optimize your project budget.

Understanding CNC Machining Costs and Pricing Factors

Ever received two quotes for the same part that differed by 300%? You're not alone. CNC machining price variations frustrate buyers who expect straightforward pricing, but the reality is that dozens of factors influence what you'll pay. Understanding these variables helps you budget accurately, optimize your designs for cost-effectiveness, and recognize when a quote represents genuine value versus unnecessary markup.

The good news? Once you understand what drives costs, you gain leverage. You can make informed design decisions that reduce expenses without sacrificing quality. Let's break down exactly where your money goes when you submit a project to a CNC machining shop.

What Drives CNC Machining Costs

Think of CNC pricing as a formula with multiple inputs. According to industry pricing guides, the basic calculation follows this structure: Cost = Machine Time × Hourly Rate + Material Cost + Setup Cost + Finishing + Shipping. Each element contributes to your final quote, and understanding the weight of each helps you identify optimization opportunities.

Primary cost drivers that affect every CNC quote:

- Machine hourly rates: Standard 3-axis milling runs $70 to $125 per hour, while 5-axis operations command $150 to $250 per hour. The machine type your part requires directly impacts this core cost.

- Material costs: Raw material prices fluctuate with market conditions. Aluminum remains economical, while titanium and specialty alloys carry significant premiums.

- Part complexity: Deep pockets, thin walls, and intricate features slow machining speeds and increase programming time. Complex parts require more tool changes and careful process planning.

- Tolerance requirements: Tighter tolerances demand slower cutting speeds, more frequent tool changes, and extensive inspection. Moving from ±0.005" to ±0.001" can double machining time.

- Surface finish specifications: Mirror finishes require additional passes with fine tooling, adding time to every part.

- Setup and programming: CAM programming and machine setup represent one-time costs that get distributed across your order quantity.

The interplay between these factors explains why seemingly similar parts can have dramatically different quotes. A simple aluminum bracket might cost $50 per unit in a batch of 100, while a titanium aerospace component with tight tolerances could run thousands of dollars for a single piece.

For small cnc machining projects, setup costs often dominate the equation. Programming the machine, loading fixtures, and running first-article inspections take the same time whether you're making one part or twenty. This fixed overhead explains why per-unit costs drop so dramatically as quantities increase.

Volume Pricing and Economies of Scale

Here's where smart ordering decisions can save you significant money. The relationship between quantity and unit cost isn't linear, and understanding this curve helps you optimize your purchasing strategy.

When you request a cnc quote online for a single prototype, you're paying for all the setup work that would otherwise be spread across hundreds of units. According to pricing research, a simple aluminum part might cost over $100 as a single prototype, but drop to just a few dollars per unit at production volumes. That's not price gouging. It's economics.

The cost reduction comes from several sources:

- Setup amortization: Programming and fixturing costs spread across more parts, reducing per-unit burden

- Material efficiency: Bulk material purchases cost less per pound, and nesting multiple parts from single stock pieces reduces waste

- Process optimization: Higher volumes justify automation investments like bar feeders and pallet systems that reduce labor per part

- Reduced handling: Continuous production runs eliminate repeated setup and teardown between small batches

- Learning curve benefits: Operators become more efficient as they produce more of the same part

When requesting online machining quotes, consider ordering slightly more than your minimum requirement if the price break is significant. The incremental cost of additional parts often drops sharply at certain quantity thresholds. A good CNC machining shop will clearly show these break points in their quotes, helping you make informed decisions about order quantities.

The opposite also applies. If you only need five parts, don't feel obligated to order fifty just for a better unit price. The total expenditure matters more than the per-unit cost. Calculate your actual needs and compare total costs at different quantity levels.

Hidden Cost Factors to Consider

The quote you receive covers machining, but your total project cost often includes elements that aren't immediately obvious. According to comprehensive cost analyses, these hidden factors frequently surprise first-time buyers.

Watch for these commonly overlooked expenses:

- Custom tooling and fixtures: Parts with unusual geometries may require specialized workholding devices. This one-time cost gets added to your first order but benefits subsequent runs.

- Material waste factor: CNC is subtractive, meaning significant material becomes chips. Your machinist metal cost includes this waste, especially for complex parts machined from large blocks.

- Secondary operations: Anodizing, plating, heat treating, and other finishing processes add substantial cost. A $50 machined part might require $30 in post-processing.

- Inspection and documentation: Standard spot-checking differs vastly from comprehensive CMM inspection with certified reports. Regulated industries require documentation that adds time and cost.

- Packaging and shipping: International orders involve customs duties, specialized packaging for delicate parts, and potentially significant freight charges.

Lead time represents another hidden cost variable. Standard turnaround might be two to three weeks, but expedited service comes with premium pricing. According to manufacturing experts, rush orders can increase costs by 25-50% or more because they disrupt normal production scheduling and may require overtime labor.

The trade-off between speed and price deserves careful consideration. If your timeline allows flexibility, standard lead times deliver better value. If your project genuinely requires rapid turnaround, budget accordingly and communicate your deadline clearly when requesting quotes.

Optimizing Designs for Cost-Effectiveness

You have more control over your CNC costs than you might realize. Design decisions made early in development significantly impact manufacturing expenses. According to Fictiv's cost reduction guide, careful planning during the design phase can put substantial money back in your pocket without sacrificing quality.

Practical strategies to reduce your CNC machining price:

- Choose materials wisely: If your application allows, select the most machinable material that meets functional requirements. Aluminum machines faster than stainless steel, directly reducing cycle time and tool wear.

- Simplify where possible: Every complex feature adds programming time and machining operations. Ask yourself whether decorative curves and tight internal radii serve functional purposes or simply add cost.

- Standardize tolerances: Apply tight tolerances only to features that genuinely require them. Blanket tolerance callouts waste money on precision that adds no functional value.

- Minimize setups: Design parts that can be machined in one or two orientations rather than requiring multiple repositioning operations. Each setup adds labor and introduces potential tolerance stack-up.

- Avoid deep, narrow features: Holes deeper than four times their diameter and narrow slots require specialized tooling and slower machining speeds. Design around these constraints when possible.

- Consider standard sizes: Designing around readily available stock sizes reduces material waste and eliminates special ordering delays.

Working with an experienced CNC machining shop early in your design process pays dividends. Many manufacturers offer Design for Manufacturability consultations that identify cost reduction opportunities before you finalize drawings. A small design change suggested during quoting might save 30% on production costs.

The transparency around pricing builds trust between buyers and manufacturers. When you understand what drives costs, you can have informed conversations about trade-offs. Maybe you can accept a slightly rougher surface finish to reduce cycle time. Perhaps relaxing a non-critical tolerance saves significant inspection time. These discussions become productive when both parties understand the underlying cost structure.

Armed with this understanding of pricing factors, your next consideration becomes selecting the right provider for your specific project requirements, certifications, and volume needs.

Selecting the Right CNC Service Provider for Your Project

You've defined your tolerances, selected your material, and optimized your design for manufacturability. Now comes the decision that determines whether your project succeeds or stumbles: choosing the right CNC service provider. This isn't simply about finding the lowest quote. The manufacturer you select affects quality, lead times, communication, and your ability to scale from prototype to production without switching partners midstream.

The challenge? Hundreds of machining shops near me results appear when you search online, each claiming precision, quality, and competitive pricing. How do you separate genuinely capable providers from those who overpromise and underdeliver? Let's walk through a systematic evaluation framework that protects your project from costly mistakes.

Evaluating Provider Capabilities and Equipment

A CNC machining shop is only as capable as its equipment and the expertise behind it. According to 3ERP's selection guide, the variety and quality of machinery can make or break your project. Different types of CNC machines cater to different tasks, and a service with diverse, high-tech equipment demonstrates their ability to handle a range of projects.

When evaluating cnc machine shops near me, look beyond the marketing claims. Ask specific questions about their equipment list:

- Machine types and axis capabilities: Do they operate 3-axis, 4-axis, or 5-axis equipment? Can they handle both milling and turning operations?

- Work envelope sizes: What's the largest part they can accommodate? Oversized components require specific machines.

- Spindle speeds and power: Higher-performance spindles enable faster cycle times and better surface finishes on demanding materials.

- Age and maintenance: Well-maintained older equipment often outperforms neglected newer machines. Ask about their preventive maintenance schedules.

Technical capability extends beyond hardware. According to supplier auditing experts, many new shops have brand-new equipment but lack the deep process knowledge and engineering talent to run it effectively. The ability to understand complex designs, optimize CAM strategies, and troubleshoot machining challenges separates competent providers from exceptional ones.

Here's a practical tip: ask to see examples of parts similar to yours that they've produced. A shop claiming 5-axis capability should readily show you complex components they've successfully manufactured. If they hesitate or offer only simple examples, consider whether their stated capabilities match reality.

Quality Assurance and Certification Verification

A certificate hanging on the wall looks impressive, but does it reflect daily practice? According to Zenithin's audit framework, a quality certificate proves they have a system, but your evaluation needs to prove they actually use it. The proof is in the execution, not the certification.

When vetting precision machining companies, dig deeper than surface-level credentials:

- ISO 9001: The baseline standard for quality management systems. Essential for any serious manufacturing operation.

- Industry-specific certifications: IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical devices. These indicate capability to serve regulated industries.

- Inspection equipment: Coordinate measuring machines (CMMs), optical comparators, surface finish testers, and calibrated hand tools ensure dimensional verification.

- Statistical Process Control: Real-time monitoring of critical dimensions throughout production runs ensures consistency from first part to last.

Here's a technique that reveals true quality commitment: request documentation from a random recent production batch. Ask for material certifications, inspection reports, and process records. According to experienced auditors, a supplier with genuine quality practices can produce complete records within hours. Those with superficial systems struggle to piece together documentation or provide incomplete, contradictory records.

Don't fall for the "perfect sample" trap either. A flawless sample part arriving on your desk might have been painstakingly crafted by their top machinist on their best machine, completely outside normal production flow. Always demand that samples be accompanied by First Article Inspection reports and process capability data proving they can produce that part repeatedly.

Scaling from Prototype to Production

Many projects start with prototype machining services before transitioning to volume production. The ideal scenario? Working with a single provider who handles both phases seamlessly. This continuity eliminates the quality risks and communication challenges that arise when switching suppliers mid-program.

When evaluating custom cnc machining services, consider their ability to scale:

- Prototype capabilities: Can they deliver rapid prototyping with fast turnaround? Some facilities offer lead times as quick as one working day for urgent prototype needs.

- Production capacity: Do they have sufficient machine hours and staffing to handle your projected volumes without becoming a bottleneck?

- Process consistency: Will your production parts match your approved prototypes? Consistent quality control across volumes prevents unpleasant surprises.

- Inventory management: Can they hold safety stock or implement blanket order arrangements for ongoing production needs?

Scalability matters because your needs will change. A provider suited only for prototypes forces you to requalify new suppliers when volumes increase. Conversely, a high-volume shop may lack interest in small prototype orders. The sweet spot is a partner equipped to handle your project from initial concept through ongoing production, maintaining consistent quality throughout.

Working with certified providers who can scale seamlessly from rapid prototyping to mass production with consistent quality control delivers real advantages. Facilities backed by IATF 16949 certification and strict Statistical Process Control ensure high-tolerance components maintain specifications whether you order ten or ten thousand. For complex chassis assemblies or custom metal bushings, this reliability prevents mid-program disruptions that cost time and money.

Geographic Considerations: Local vs. Overseas

Should you search for cnc services near me or consider overseas manufacturers? According to manufacturing experts, location significantly impacts shipping costs, lead times, and communication ease. The right choice depends on your specific priorities.

Advantages of local machine shops and domestic manufacturing:

- Faster turnaround: Shipping measured in days rather than weeks. Critical for urgent prototypes or unexpected production needs.

- Easier communication: Same time zones and language eliminate delays and misunderstandings.

- Lower shipping costs: Domestic freight costs a fraction of international air or sea shipment.

- Easier site visits: You can inspect facilities, review processes, and build relationships in person.

- IP protection: Domestic legal frameworks provide stronger intellectual property safeguards.

When searching machinist shops near me, you may find that overseas alternatives offer cost advantages. However, according to sourcing guides, those savings can evaporate when you factor in longer lead times, communication barriers, quality inspection challenges, and potential duty costs. For time-sensitive or quality-critical projects, domestic sourcing often proves more economical despite higher per-unit pricing.

The hybrid approach works for many companies: use local providers for prototypes, urgent orders, and complex components requiring close collaboration. Consider overseas manufacturing for stable, high-volume production where lead time flexibility exists and established quality systems mitigate risk.

Step-by-Step Provider Evaluation Checklist

Ready to systematically evaluate potential CNC providers? Follow this structured approach to ensure you're making an informed decision based on capability, not just price.

- Define your requirements clearly: Document material specifications, tolerances, quantities, timeline expectations, and any industry certifications required before contacting providers.

- Create a shortlist based on capabilities: Filter potential cnc machine shop near me options by their stated capabilities, certifications, and relevant experience. Aim for 3-5 qualified candidates.

- Request detailed quotes with specifications: Submit identical RFQs to each candidate, including complete CAD files, drawings, and quantity requirements. Compare responses for completeness and professionalism.

- Verify certifications independently: Don't take claimed certifications at face value. Request certificate copies and verify with issuing bodies when relevant to your industry.

- Evaluate communication responsiveness: How quickly do they respond to questions? Are answers clear and complete? Poor pre-order communication predicts post-order problems.

- Request references and samples: Ask for customer references in your industry and sample parts demonstrating relevant capabilities. Contact references and inspect samples critically.

- Assess their engineering support: Do they offer Design for Manufacturability feedback? Providers who proactively suggest improvements add value beyond basic machining.

- Understand their quality processes: Ask how they verify parts meet specifications, what happens when issues arise, and how they document traceability.

- Clarify lead times and expedite options: Confirm standard lead times and understand costs for accelerated delivery. Some facilities deliver reliable manufacturing solutions with lead times as fast as one working day when needed.

- Start with a trial order: Before committing to large volumes, place a small test order to evaluate actual quality, communication, and delivery performance against promises.

Building a Partnership, Not Just Placing Orders

The most successful manufacturing relationships transcend transactional purchasing. According to industry experts, a good partnership with a CNC machining service provider isn't just about meeting current needs. It's about their ability to meet future demands, scale with your growth, and continually improve their service.

Look for providers who demonstrate interest in understanding your broader objectives, not just the immediate part requirements. Do they ask about your application? Do they suggest alternatives that might serve you better? Do they flag potential issues before they become problems?

Data security deserves attention in today's environment. Ensure that your CNC provider has robust protocols protecting your project data and intellectual property. This becomes especially critical for proprietary designs or defense-related components.

Ultimately, the CNC machining supplier you choose should function as a trusted partner who adds value beyond simply cutting metal or plastic. They should bring expertise that improves your designs, flexibility that accommodates your changing needs, and reliability that lets you focus on your core business rather than worrying about component supply.

Whether you're searching for custom cnc machining services for a complex aerospace assembly or local machine shops for straightforward bracket production, applying this evaluation framework helps you identify providers who deliver genuine value. The investment in proper vetting pays dividends through fewer quality issues, more predictable lead times, and partnerships that strengthen over time.

Frequently Asked Questions About CNC Services

1. What are CNC services?

CNC services encompass manufacturing processes where pre-programmed computer software controls the movement of factory tools and machinery to cut, shape, and form materials with remarkable precision. These services include CNC milling, turning, routing, and multi-axis machining operations. Unlike manual machining, CNC technology follows programmed instructions down to fractions of a millimeter, ensuring exceptional repeatability across production runs. Modern CNC capabilities extend to drilling, threading, contouring, and surface finishing, often completing complex parts in a single setup.

2. How much does CNC service cost?

CNC machining costs depend on multiple factors including machine hourly rates ($70-$250 depending on axis count), material selection, part complexity, tolerance requirements, and order quantity. A simple aluminum prototype might cost over $100 as a single piece but drop to a few dollars per unit at production volumes. Setup and programming costs significantly impact small orders since these fixed expenses get distributed across fewer parts. Tighter tolerances, complex geometries, and specialty materials all increase pricing. Secondary operations like anodizing or plating add additional costs beyond base machining.

3. What is the hourly rate for a CNC machine?

CNC machine hourly rates vary significantly based on equipment type and complexity. Standard 3-axis milling operations typically run $70 to $125 per hour, while advanced 5-axis machining commands $150 to $250 per hour. Swiss machining and specialized precision operations may cost even more. These rates reflect equipment investment, maintenance costs, and the expertise required to operate complex machinery. Geographic location also influences rates, with domestic shops generally charging more than overseas alternatives but offering faster turnaround and easier communication.

4. What certifications should I look for in a CNC service provider?

The certifications required depend on your industry application. ISO 9001 serves as the baseline quality management standard for general manufacturing. Automotive applications require IATF 16949 certification with Statistical Process Control capabilities. Aerospace and defense work demands AS9100 certification, NADCAP accreditation for special processes, and ITAR registration for defense-related components. Medical device manufacturing requires ISO 13485 certification and FDA compliance. Providers like Shaoyi Metal Technology maintain IATF 16949 certification to ensure high-tolerance automotive components meet stringent quality requirements throughout production.

5. How do I choose between CNC machining and 3D printing for my project?

Choose CNC machining when you need tight tolerances, smooth surface finishes, production-grade materials, or quantities above 10 units. CNC delivers exceptional dimensional accuracy and consistent mechanical properties using solid material stock. Select 3D printing for complex internal geometries that cutting tools cannot access, rapid prototypes needed within 24 hours, very low quantities under 10 units, or specialty materials like flexible TPU. CNC machining excels in the low-to-medium volume range where tooling investments for molding don't make sense while delivering precision that additive manufacturing struggles to match.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —