Professional Sheet Metal Fabrication: From Raw Material To Finished Part

Understanding Professional Sheet Metal Fabrication

Have you ever wondered what separates a flawless automotive chassis from a warped garage project? The answer lies in professional sheet metal fabrication—a precision-driven manufacturing discipline that transforms flat metal sheets into complex, load-bearing components used across virtually every industry.

Professional sheet metal fabrication is the industrial process of cutting, forming, and assembling metal sheets (typically 0.5mm to 6mm thick) into finished parts or products using specialized equipment, certified techniques, and quality-controlled workflows that meet specific engineering tolerances and industry compliance standards.

Unlike DIY or hobbyist approaches that rely on basic hand tools and approximate measurements, this industrial process demands advanced machinery, trained technicians, and strict adherence to international specifications like ISO 2768 tolerance standards. The difference matters more than you might think—especially when structural integrity, safety compliance, and long-term durability are on the line.

What Sets Professional Fabrication Apart

Imagine bending a piece of aluminum in your workshop versus having that same bend executed by a robotized bending cell with controlled repeatability. The outcomes are worlds apart. Professional-grade work delivers:

- Precision tolerances: Measurements accurate to fractions of a millimeter, critical for parts that must fit together perfectly

- Material integrity: Proper techniques prevent cracking, warping, and stress concentrations that weaken finished components

- Compliance certification: Documentation proving parts meet industry standards for automotive, aerospace, medical, and construction applications

- Consistent repeatability: Whether producing 10 parts or 10,000, each one matches the original specifications

According to TRA-C industrie, precision sheet metal work is integral to sectors including automotive, aeronautics, food processing, railways, nuclear, and defense—industries where failure simply isn't an option.

The Industrial Foundation of Modern Manufacturing

Professional fabrication serves as the backbone of modern manufacturing. When you consider that sheet metal parts appear in everything from hospital equipment to commercial HVAC systems, you begin to appreciate why professional-grade execution matters so much.

The distinction between sheet metal manufacturing and fabrication is also worth noting. Manufacturing focuses on producing raw metal sheets at scale, while fabrication transforms those sheets into custom components for specific applications. Professional fabricators bridge this gap, taking standardized materials and creating tailored solutions that meet exacting requirements.

Throughout this guide, you'll discover the core processes that define quality fabrication, learn how to select appropriate materials for your application, understand design principles that reduce costs while improving outcomes, and explore how different industries leverage these capabilities. Whether you're an engineer specifying parts, a procurement professional sourcing suppliers, or simply curious about how precision metal components come to life—this resource will give you the foundational knowledge you need.

Core Fabrication Processes and Techniques

So how does a flat metal sheet actually become a precision component? The transformation happens through a carefully orchestrated sequence of processes—each one building upon the last. Understanding these techniques helps you communicate more effectively with fabricators and make smarter decisions about your project requirements.

Professional sheet metal fabrication relies on four fundamental process categories: cutting, forming, punching, and joining. Let's break down each one so you can see exactly what happens on the shop floor.

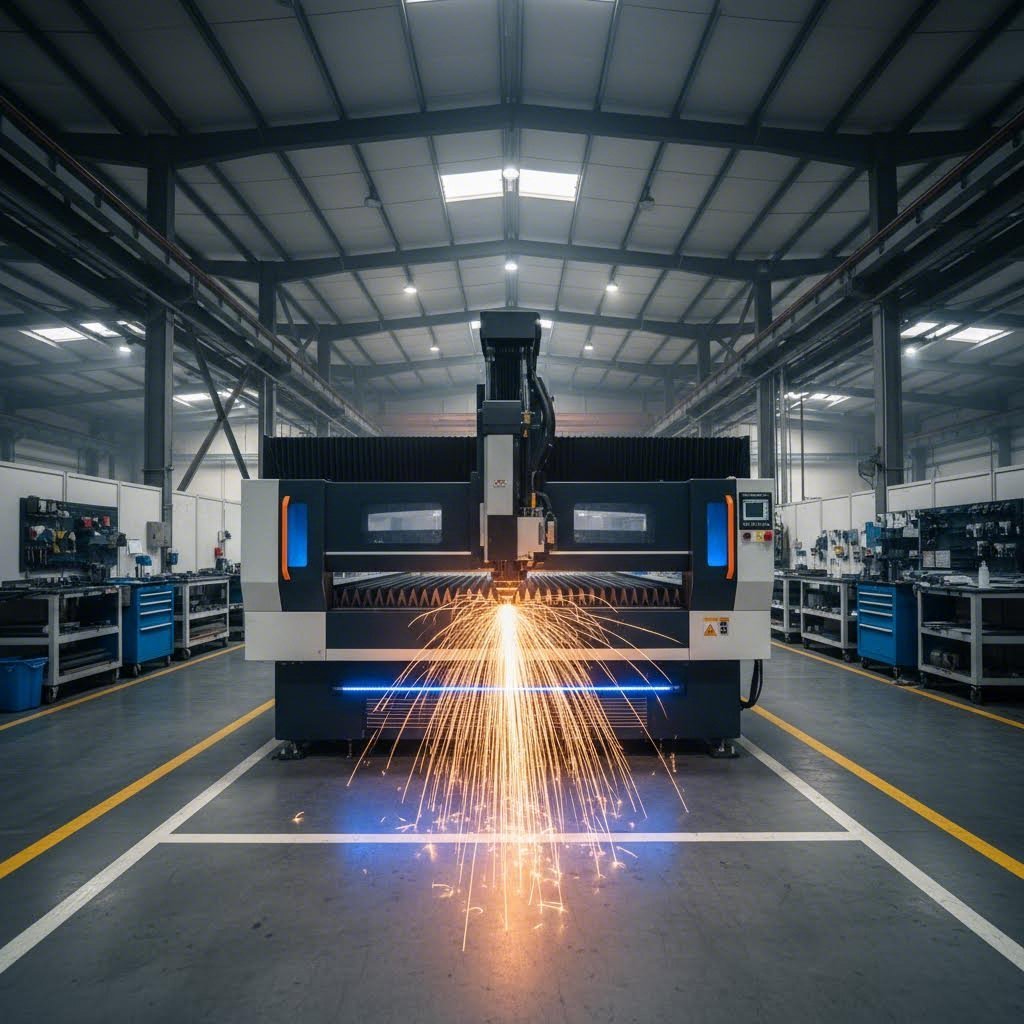

Cutting Technologies and Their Applications

Cutting is where every fabrication project begins. The goal? Remove excess material and create the precise outline your part requires. But here's where it gets interesting—the cutting method you choose dramatically affects edge quality, tolerance capabilities, and overall cost.

Modern fabrication shops typically offer several cutting options:

- Laser cutting: A focused laser beam melts, burns, or vaporizes material with exceptional precision. According to MetalsCut4U, laser cutters achieve accuracy of approximately 0.0125 inches (0.32 mm) and produce sleek edges with smooth finishes. This method excels at intricate designs and minimizes material warping since heat remains localized.

- Plasma cutting: A hot jet of ionized gas cuts through electrically conductive metals at high speeds. Plasma cutters handle thicker materials better than lasers and have become increasingly affordable. Newer models now feature smaller nozzles and thinner plasma arcs that rival laser precision levels.

- Shearing: A mechanical process using opposing blades to separate metal sheets. Shearing works best for straight cuts on thicker sheets and produces clean, accurate results without heat distortion—though it can create minor edge imperfections called burrs.

- Water jet cutting: High-pressure water mixed with abrasive particles slices through metal without generating heat. This technique preserves the material's inherent structure and handles intricate shapes beautifully. It's particularly valuable when working with metals sensitive to heat-affected zones.

Which method should you specify? Laser cutting dominates for thin-to-medium gauge sheets requiring complex geometries. Plasma handles heavier stock more economically. Water jet becomes essential when thermal distortion must be eliminated entirely.

Forming and Joining Techniques Explained

Once your parts are cut to shape, forming processes create the bends, angles, and curves that give sheet metal its three-dimensional character. Think brackets, enclosures, chassis components—anything beyond flat stock.

Professional fabricators employ several bending and forming methods:

- Air bending: The metal sheet bends over a die with controlled force, creating flexible angle options. This technique accommodates a range of radii and remains the most common approach for standard bends.

- Bottoming (coining): The sheet is pressed firmly between a punch and die for extremely precise, consistent bends with minimal springback. This method suits applications demanding tight tolerances.

- V-bending: A specialized air bending technique using V-shaped dies to create sharp angles and precise geometries—commonly seen in professional stamped sheet metal parts fabrication.

- Deep drawing: Metal sheets are drawn into die cavities to form hollow shapes like cans, housings, and automotive components.

- Hydroforming: High-pressure fluid shapes metal into complex geometries, producing lightweight yet strong parts frequently used in automotive and aerospace applications.

Punching operations complement these forming techniques by creating holes, slots, and cutouts within your parts. CNC punching machines automate this process, enabling complex patterns with remarkable efficiency and repeatability.

Finally, welding joins individual components into finished assemblies. The technique you'll encounter depends on material type, thickness, and quality requirements:

- MIG welding (Metal Inert Gas): Uses a continuously fed wire electrode shielded by inert gas. Known for versatility and speed across various metals and thicknesses.

- TIG welding (Tungsten Inert Gas): Employs a non-consumable tungsten electrode for precise, high-quality welds—ideal for thin sheets requiring exceptional control and clean results.

- Spot welding: Applies pressure and electrical current at specific points to create strong, localized joins. This resistance welding technique dominates automotive manufacturing.

Quality welding matters enormously. The AWS D9.1:2018 Sheet Metal Welding Code establishes qualification, workmanship, and inspection guidelines covering sheet metal up to 6.07 mm thick. AWS Certified Welders represent the industry's quality benchmark—a credential worth verifying when evaluating potential fabrication partners.

Now that you understand how these processes work, the next critical decision involves choosing the right materials to run through them.

Material Selection and Specifications Guide

Choosing the right material can make or break your fabrication project. Sounds complex? It doesn't have to be. Once you understand how material properties align with application requirements, the decision becomes much clearer—and you'll avoid costly mistakes down the line.

Professional sheet metal fabrication suppliers work with a diverse range of metals, each offering distinct advantages depending on your performance needs, environmental conditions, and budget constraints. According to JLCCNC, the most commonly used materials include stainless steel, aluminum, cold-rolled steel, galvanized steel, and copper—each selected based on strength, durability, formability, cost-efficiency, and corrosion resistance.

Material Properties and Performance Characteristics

Before diving into specific materials, consider these critical factors that should guide your selection:

- Mechanical requirements: What loads, stresses, or impacts will the part endure?

- Environmental exposure: Will the component face moisture, chemicals, or extreme temperatures?

- Formability needs: How complex are your bends, draws, and shapes?

- Weight constraints: Does your application demand lightweight solutions?

- Budget parameters: What cost-per-part can your project sustain?

Here's how the most popular materials compare across key performance characteristics:

| Material | Key Properties | Common Gauges | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Stainless Steel (304/316) | High strength, excellent durability, self-healing oxide layer | 16-26 gauge (1.5mm-0.45mm) | Excellent—especially 316 grade in marine/chemical environments | Food processing, medical equipment, outdoor architecture, marine components |

| Aluminum (5052/6061) | Lightweight (1/3 density of steel), good strength-to-weight ratio, natural oxide protection | 14-24 gauge (1.6mm-0.5mm) | Very Good—resists rust naturally, performs well in coastal areas | Aerospace parts, electronics enclosures, signage, automotive panels |

| Cold-Rolled Steel | High precision, smooth surface finish, excellent formability, easy to weld | 10-26 gauge (3.4mm-0.45mm) | Poor—requires coating or painting for protection | Automotive parts, appliance housings, furniture frames, indoor structural components |

| Galvanized Steel | Zinc-coated for protection, moderate strength, cost-effective | 12-26 gauge (2.7mm-0.45mm) | Good—zinc layer provides sacrificial protection | HVAC ductwork, roofing, fencing, outdoor enclosures |

| Copper | Superior electrical/thermal conductivity, antimicrobial properties, develops protective patina | 16-24 gauge (1.3mm-0.5mm) | Excellent—forms protective patina over time | Electrical components, heat exchangers, decorative elements, roofing |

When comparing strength, stainless steel and cold-rolled steel lead the pack, while aluminum offers the best weight advantage. For corrosion resistance, stainless steel and copper outperform alternatives significantly—making them ideal for harsh or humid environments.

Matching Materials to Application Requirements

Understanding gauge specifications is equally important. Unlike standard metric measurements where thickness reads directly in millimeters, the gauge system works inversely—a lower gauge number means thicker material. According to Xometry, a 10-gauge standard steel sheet measures approximately 3.4mm (0.1345 inches), while 26-gauge is only about 0.45mm thick (note that gauge thickness varies between steel, aluminum, and galvanized metals).

Here's how to match thickness to your application:

- Heavy-duty structural components: 10-14 gauge provides the rigidity needed for load-bearing applications like chassis components or industrial equipment frames

- Standard enclosures and housings: 16-20 gauge balances strength with formability—ideal for electrical cabinets, appliance housings, and HVAC equipment

- Lightweight precision parts: 22-26 gauge suits decorative panels, electronic enclosures, and components where weight reduction matters

Beyond standard options, specialized materials serve niche applications. Lead-coated copper provides enhanced corrosion protection for roofing in historic restoration projects. Perforated metal offers ventilation and aesthetic options for architectural facades. Expanded metal creates walkways, guards, and screening applications where strength and visibility matter.

The right material choice depends on balancing multiple factors simultaneously. Stainless steel delivers unmatched durability but costs more per volume. Aluminum saves weight but may require additional surface treatments in certain environments. Cold-rolled steel offers the most economical option when indoor use allows for protective coatings.

With your material selected, the next challenge becomes designing parts that fabricators can produce efficiently—and that's where Design for Manufacturability principles come into play.

Design for Manufacturability Best Practices

You've selected the perfect material and understand the fabrication processes available. Now comes the critical question: will your design actually work on the shop floor? This is where Design for Manufacturability (DFM) becomes your secret weapon for reducing costs, improving quality, and getting parts faster.

Think of DFM as designing with the end in mind. When your CAD model accounts for how metal actually behaves during bending, cutting, and forming, you eliminate the "manufacturing friction" that drives up prices and extends lead times. According to Consac Industries, design changes become exponentially more expensive as a project progresses—making early attention to manufacturability essential.

Essential DFM Principles for Sheet Metal

Imagine folding a piece of cardboard too sharply. The outer edge cracks, right? Metal behaves similarly. Every fabrication process has physical limits, and designing within these constraints ensures your parts come out right the first time.

Here are the fundamental DFM guidelines every designer should follow:

- Maintain proper bend radii: The inside curve of your bend should at least equal the material thickness. Designing all bends with consistent radii allows fabricators to use a single tool for every fold—saving setup time and reducing your costs.

- Position holes correctly relative to bends: Keep holes a minimum of 2× material thickness away from any bend location. When holes sit too close, the stretching during bending pulls them into oval shapes, making it impossible to pass screws or pins through accurately.

- Include bend relief cuts: When bending metal alongside a flat edge, the material tends to tear at corners. Adding small rectangular or circular cut-outs at bend line ends—typically 1 to 1.5× material thickness—prevents deformation and ensures clean, professional finishes.

- Respect minimum flange lengths: The bent-up portion of your design needs enough surface area for tooling to grip. According to Norck, flanges should be at least 4× material thickness. Shorter "illegal" flanges require custom, expensive tooling that can double production costs.

- Design with grain direction in mind: Metal sheets have a grain from the rolling process at the mill—similar to wood grain. Bending parallel to this grain dramatically increases cracking risk. Orienting bends across the grain prevents parts from failing months after delivery.

- Avoid narrow cutouts and slots: Laser cutters generate intense heat. Very thin features (less than 1.5× material thickness in width) can warp or twist during cutting. Keeping cutouts wider ensures parts stay flat and fit assemblies correctly.

- Use standard hole sizes: Specifying a 5.123mm hole means the fabricator must source a custom drill bit. Using off-the-shelf sizes like 5mm, 6mm, or standard imperial increments allows high-speed punching with existing tooling—accelerating turnaround dramatically.

Understanding the K-factor also matters for accurate flat pattern development. According to Geomiq's design guide, the K-factor represents the ratio between the neutral axis location and material thickness, ranging between 0 and 0.5. Getting this value correct in your CAD software ensures bent parts match your intended dimensions precisely.

Common Design Mistakes to Avoid

Even experienced engineers fall into these traps. Here's what to watch for:

- Overly tight tolerances: Specifying tolerances below ±0.005" drives costs up dramatically. Standard sheet metal processes economically achieve ±0.010" to ±0.030"—reserve tighter specs only for features that genuinely require them.

- Ignoring springback: Metal is slightly elastic. When you bend it to 90 degrees and release, it naturally springs back to perhaps 88 or 89 degrees. Building flexibility into your tolerance specifications where perfect angles aren't critical keeps inspection costs reasonable.

- Forgetting coating thickness: Powder coating and other surface treatments add measurable thickness. Failing to account for this in tolerance calculations leads to assembly problems down the line.

- Neglecting assembly access: Hidden fasteners may look cleaner, but they dramatically increase assembly time. Ensure sufficient clearance for tools during final assembly—it pays dividends in reduced labor costs.

The smartest approach? Engage with experienced fabricators early in your design phase. They can identify potential issues before they become expensive problems—prevention always costs less than correction.

With your design optimized for manufacturability, the next step is understanding how these principles apply across different industries and their specialized requirements.

Industry Applications and Use Cases

Where does professional sheet metal fabrication actually show up in the real world? The answer might surprise you—these precision components are literally everywhere, from the air conditioning system cooling your office to the medical equipment in your local hospital. Understanding how different industries leverage this manufacturing capability helps you appreciate why quality matters so much.

According to MakerVerse, sheet metal fabrication creates durable, high-precision parts across virtually every sector by cutting, bending, and assembling metal sheets into components with exceptional strength, flexibility, and accuracy. Let's explore the specific applications that drive demand for professional-grade work.

Commercial and Industrial Applications

Commercial projects demand fabrication capabilities that go far beyond what residential work requires. The scale is larger, tolerances are often tighter, and compliance requirements multiply significantly.

HVAC Systems and Building Infrastructure:

- Ductwork and air handling: Aluminum and galvanized steel sheets form the main ducts, elbows, and connectors that move conditioned air throughout commercial buildings. According to Seather Technology, aluminum handles heat exceptionally well and resists corrosion—keeping systems running efficiently for years without rust-related failures.

- Equipment housings: HVAC units, rooftop equipment, and mechanical room enclosures require weather-resistant fabrication that withstands temperature extremes and moisture exposure.

- Ventilation components: Dampers, registers, and diffusers demand precise fabrication for proper airflow control and building comfort.

Commercial Construction and Architecture:

- Metal roofing systems: Standing seam panels, flashings, and trim pieces protect commercial structures while delivering aesthetic appeal. Professional fabrication ensures weathertight performance that meets warranty requirements.

- Architectural cladding: Custom metal panels create striking building facades—think modern office towers, retail spaces, and institutional buildings where appearance matters as much as performance.

- Structural components: Brackets, supports, and framing elements provide the hidden backbone that keeps buildings safe and stable.

Restaurant and Food Service:

- Stainless steel work surfaces: Prep tables, counters, and serving stations require NSF-certified fabrication meeting strict sanitation standards.

- Exhaust hoods and ventilation: Commercial kitchens depend on properly fabricated hood systems to remove smoke, grease, and heat safely.

- Equipment enclosures: Walk-in cooler panels, refrigeration housings, and warming stations all start as flat metal sheets.

Healthcare and Medical:

- Hospital equipment: Beds, cabinets, carts, and storage systems use fabricated stainless steel that handles aggressive cleaning protocols and constant use.

- Diagnostic machine housings: CT scanners, X-ray equipment, and laboratory instruments require precision enclosures with tight tolerances and clean finishes.

- Surgical furniture: Operating tables, instrument trays, and mobile workstations demand antimicrobial properties and seamless construction.

Specialized Sector Requirements

What separates residential fabrication from commercial work? The differences run deeper than you might expect—and understanding them helps explain why professional aerospace sheet metal fabrication or OEM professional sheet metal fabrication commands premium pricing.

According to Sheffield Metals, commercial projects differ from residential in several critical ways:

- Installation complexity: Commercial jobs typically require standing seam systems rather than simpler exposed fastener approaches. These demand specialized clips, precise spacing per engineering specifications, and often mechanical seaming—skills that take significant training to master.

- Scheduling rigidity: Residential customers work around contractor schedules. Commercial general contractors dictate timelines and expect roofing contractors to coordinate with multiple trades simultaneously. Delays cascade expensively.

- Labor requirements: Government facilities and secure locations may require background checks for all workers. Finding qualified installers who meet both skill and security requirements narrows the available labor pool significantly.

- Payment structures: Commercial projects often involve progress payments, with 10% retention held until project completion—sometimes months after your work finishes.

- Insurance demands: Additional liability coverage for vehicles, equipment, and larger crews becomes mandatory for commercial contracts.

Residential and Ornamental Applications:

Residential work operates differently but still demands professional execution:

- Custom architectural elements: Decorative railings, pergola components, and garden structures where aesthetics and durability intersect.

- Roofing and flashing: Chimney caps, roof valleys, and custom trim pieces that protect homes from water intrusion.

- HVAC components: Ductwork, equipment supports, and ventilation accessories sized for residential systems.

- Ornamental metalwork: Gates, fencing, decorative panels, and artistic installations requiring both fabrication skill and finishing expertise.

Aerospace and Automotive:

These industries represent the pinnacle of fabrication precision:

- Aircraft components: Fuselage panels, wing sections, brackets, and heat shields fabricated from aluminum and titanium sheets—where failure literally isn't an option.

- Automotive body panels: Doors, hoods, fenders, and chassis components engineered for crash resistance and weight optimization.

- Exhaust systems: Lightweight, heat-resistant components like pipes and catalytic converter housings that endure extreme temperatures.

The fabrication requirements for professional aerospace sheet metal fabrication far exceed standard commercial work. Tolerances tighten to fractions of a millimeter. Material certifications must trace back to original mill sources. Inspection protocols multiply dramatically.

Whether you're sourcing components for a commercial construction project or evaluating China professional sheet metal fabrication price options for volume production, understanding these application-specific requirements helps you communicate more effectively with fabricators—and ensures you get parts that actually perform in your intended environment.

Now that you understand where fabricated components go, the next critical question becomes: how do you identify fabricators capable of delivering the quality your application demands?

Quality Standards and Professional Certifications

How do you tell the difference between a professional sheet metal fabrication factory and a basic shop with outdated equipment? The answer often comes down to certifications, inspection protocols, and operational capabilities that separate world-class fabricators from those simply going through the motions.

When you're sourcing precision components—especially for demanding applications like automotive, aerospace, or medical equipment—quality isn't just a nice-to-have. It's the foundation that determines whether your parts perform reliably or fail catastrophically in the field. Understanding what quality markers to look for helps you make smarter sourcing decisions and avoid costly mistakes.

Critical Quality Certifications to Look For

Certifications function as third-party validation that a fabricator's systems, processes, and outputs meet rigorous international standards. They're not just plaques on the wall—they represent documented quality management systems that ensure consistency across every project.

IATF 16949 Certification for Automotive Applications:

If you're sourcing components for the automotive supply chain, IATF 16949 certification should top your requirements list. According to Meridian Cable Assemblies, this certification was created in 1999 by the International Automotive Task Force—a consortium of automotive trade associations and manufacturers working with the International Organization for Standardization (ISO). The certification brings unity to assessment and certification systems worldwide in the automotive supply chain.

What does IATF 16949 actually signify? According to the National Quality Assurance Limited (NQA), it reveals that a company has developed a "process-oriented quality management system that provides for continual improvement, defect prevention and reduction of variation and waste." This systematic approach leads to production processes that consistently deliver grade-level automotive parts and assemblies.

Major automakers including BMW, Stellantis (Chrysler, Dodge, Jeep), and Ford Motor Company require their supply chain partners to maintain IATF 16949 certification. Companies like Shaoyi (Ningbo) Metal Technology hold this certification for their custom metal stamping parts and precision assemblies—validating their capability to produce chassis, suspension, and structural components meeting automotive industry standards.

AWS Welding Certifications:

For fabricated assemblies involving welded joints, AWS (American Welding Society) certifications matter enormously. The AWS D9.1 Sheet Metal Welding Code establishes qualification, workmanship, and inspection guidelines covering sheet metal up to 6.07mm thick. AWS Certified Welders have demonstrated their skills through rigorous testing—not just claimed expertise.

ISO 9001 Quality Management:

This foundational certification covers general quality management systems across all industries. While less specialized than IATF 16949, ISO 9001 indicates a fabricator has documented processes for consistently meeting customer requirements and applicable regulatory standards.

ISO/ITAR Certifications for Specialized Applications:

According to Thin Metal Parts, always verify that shortlisted fabricators are ISO or ITAR certified if your product requires it. ITAR (International Traffic in Arms Regulations) certification ensures proper documentation trails and traceability—essential for defense and aerospace applications.

Inspection and Testing Standards

Certifications establish systems, but inspection protocols ensure every part actually meets specifications. Professional fabricators implement quality control across multiple dimensions:

According to YEEN Technology, quality inspection standards for metal sheet metal processing involve:

- Dimensional accuracy verification: National standards typically require linear dimensional tolerances between ±0.1mm and ±1mm, measured using vernier calipers and micrometers. Critical dimensions like aperture and slot width face even stricter requirements.

- Surface quality examination: Sheet metal surfaces undergo inspection for cracks, scratches, and indentations. Surface roughness must meet design specifications through visual inspection combined with roughness measurement instruments.

- Structural strength testing: Tensile and bending tests verify mechanical properties, ensuring parts have sufficient strength and toughness for practical applications.

- Raw material verification: Quality control begins at the source—inspecting material certifications and specification parameters to confirm sheets meet design requirements before cutting even begins.

Professional operations combine full inspection for critical dimensions with sampling inspection for mass-produced items. This balanced approach catches defects without creating bottlenecks that slow production.

Key Quality Indicators Buyers Should Evaluate:

- Rapid prototyping capabilities: Can the fabricator produce prototype parts quickly for validation before committing to production tooling? Professional operations like Shaoyi offer 5-day rapid prototyping—enabling you to verify fit and function before scaling up.

- Quote turnaround time: How long does it take to receive detailed pricing? Fabricators with efficient systems can provide quotes within hours rather than days. A 12-hour quote turnaround, for example, indicates streamlined operations and engineering capacity.

- Comprehensive DFM support: Does the fabricator offer design feedback to optimize your parts for manufacturability? Professional partners review designs proactively, identifying potential issues before they become expensive problems.

- Repeatability on production runs: Some batches shouldn't be exceptional while others are nearly unusable. Ask about quality consistency across runs—reliable fabricators maintain tight statistical process control.

- Traceability systems: Can the fabricator trace any part back through its production history? Sound quality traceability allows rapid identification of issues and implementation of corrective actions.

- Equipment calibration protocols: Cutting and bending equipment requires regular calibration to maintain accuracy. Professional shops document calibration schedules and results.

- In-house engineering support: Fabricators with engineering staff can optimize your designs, troubleshoot manufacturing challenges, and accelerate project timelines significantly.

The difference between professional fabricators and basic shops becomes clear when you examine these quality indicators systematically. Certifications provide external validation. Inspection protocols catch defects. Operational capabilities like rapid prototyping and DFM support accelerate your product development while reducing risk.

Armed with this understanding of quality standards, the next step involves knowing how to actually engage with professional fabricators—from initial inquiry through production.

Working With Professional Fabricators

You understand the processes, you've selected your materials, and your design follows DFM principles. Now comes the moment of truth—actually partnering with a fabricator who can transform your specifications into real parts. This transition from theory to execution trips up many buyers, but it doesn't have to.

Think of engaging a professional fabricator like planning a road trip. According to AMG Industries, you can't just start driving without a plan—you need to map it out first, or you'll end up lost, frustrated, or paying too much. A little preparation makes all the difference between a smooth project and an expensive disaster.

Preparing Your Project Specifications

Before sending that first email or making an inquiry call, take time to organize your thoughts. This groundwork prevents major headaches later and signals to fabricators that you're a professional worth prioritizing.

What information should you have ready?

- Part type and complexity: Are you requesting simple brackets or complex multi-bend enclosures? The more specific you are, the less guesswork for the fabricator.

- Material specifications: Define the material type, grade, and thickness. According to TrueCADD, callouts of material selection must specify the type, grade, and thickness—noting that stock size thickness tolerance can vary by manufacturer.

- Finish requirements: Include surface preparation specifications, primer requirements if applicable, and any paint or powder coat details with manufacturer designation numbers and desired coating thickness.

- Quantity estimates: Larger quantities typically reduce per-piece cost. Prepare both initial quantities and anticipated annual volumes to help fabricators optimize pricing.

- Timeline expectations: When do you realistically need parts? Understanding your flexibility helps fabricators accommodate your project within their production schedule.

Documentation essentials:

Professional fabricators expect clear technical documentation. Your package should include:

- CAD files: 3D models in formats like STEP or IGES, plus 2D drawings in PDF or DWG format

- Dimensioned drawings: Complete with tolerances, bend specifications, and hole callouts

- Material certifications: If you're supplying material, include mill test reports

- Assembly context: Show how your part fits into larger assemblies—this helps fabricators understand critical fit requirements

According to TrueCADD, technical drawings lacking sufficient information force fabricators to rely on guesswork—leading to wasted material, costly rework, and project delays. Your documentation should eliminate ambiguity entirely.

Evaluating Fabricator Capabilities

Not every shop offers every service, so matching fabricator capabilities to your project requirements saves time and frustration. According to York Sheet Metal, several key factors separate quality suppliers from the rest.

Questions to ask potential fabricators:

- Quality track record: Can you count on quality parts coming in consistently? If a supplier can't pass your quality test, it's time to find a new one.

- On-time delivery confidence: The key isn't how quickly they can get it to you—it's how confident they are that you'll receive parts when promised. Honest suppliers push back on unrealistic dates rather than making aggressive promises and missing deliveries.

- Reputation and longevity: How long has the fabricator been in business? Are they modernizing their systems and equipment? Suppliers that stay ahead of technology and invest in their teams demonstrate health you want in a partner.

- Communication responsiveness: When you call or email, how long does it take for them to respond? What's the quality of that communication? Working with global customers and compressed lead times requires a fabricator able to keep up with dynamic needs.

- Willingness to tackle challenges: Does the supplier shy away from difficult projects? Growing your business means incorporating new materials or technologies—find a partner willing to take risks alongside you.

- Accountability for mistakes: When things don't go as planned, does the fabricator take responsibility and work to improve? Accountability is the foundation of trust.

Assembly capabilities matter:

Many projects require more than just fabricated parts—they need complete assemblies. Verify whether your fabricator offers welding, hardware insertion, finishing, and final assembly services. Consolidating these steps with a single supplier simplifies logistics and reduces coordination headaches.

Step-by-step process for engaging professional fabricators:

- Define your requirements completely: Gather all specifications, drawings, material requirements, quantities, and timeline expectations before reaching out.

- Identify 3-5 qualified candidates: Research fabricators with experience in your industry and the specific processes your project requires. Check certifications and capabilities.

- Submit formal RFQ packages: Send complete documentation to each candidate simultaneously. Include company information, project scope, and evaluation criteria.

- Evaluate quotes systematically: Compare pricing, but also assess lead times, quality commitments, and communication quality. The lowest price isn't always the best value.

- Request samples or visit facilities: For significant projects, validate capabilities firsthand. See equipment condition, meet the team, and assess quality systems directly.

- Negotiate terms and establish agreements: Clarify payment terms, quality expectations, delivery schedules, and procedures for handling issues before production begins.

- Approve first articles: Review initial production samples against your specifications before authorizing full production runs.

- Maintain ongoing communication: Stay in regular contact throughout production. Address issues immediately and provide feedback that helps your fabricator improve.

The best fabricator relationships develop into true partnerships where both parties benefit from open communication, mutual respect, and shared commitment to quality outcomes. Finding the right match takes effort upfront but pays dividends throughout your project—and often for years of future collaboration.

Moving Forward With Your Fabrication Project

You've now journeyed through the complete landscape of professional sheet metal fabrication—from understanding what separates industrial-grade work from DIY approaches to evaluating fabricator capabilities. But knowledge without action remains just theory. So where do you go from here?

The answer depends entirely on where you stand in your fabrication journey. Whether you're still exploring fundamentals or ready to request quotes tomorrow, the path forward looks different for everyone.

The success of any professional sheet metal fabrication project hinges on three pillars: selecting materials matched to your application requirements, designing parts that fabricators can produce efficiently, and partnering with certified fabricators whose capabilities align with your quality standards.

Key Takeaways for Your Fabrication Project

Let's distill everything covered into actionable insights organized by where you are right now:

If you're still learning about processes:

- Understand that cutting, forming, punching, and joining represent the four fundamental process categories—each affecting your part's final quality and cost differently

- Recognize that laser cutting dominates for precision work on thin-to-medium gauge sheets, while plasma handles heavier stock more economically

- Remember that AWS Certified Welders represent the industry's quality benchmark for joined assemblies—always verify this credential when welding matters

If you're selecting materials:

- Match mechanical requirements, environmental exposure, and budget constraints to material properties before finalizing specifications

- Stainless steel delivers unmatched durability for harsh environments; aluminum offers weight savings; cold-rolled steel provides the most economical indoor option

- Gauge numbers work inversely—lower numbers mean thicker material. A 10-gauge sheet measures approximately 3.4mm, while 26-gauge is only about 0.45mm

If you're focused on design optimization:

- Maintain inside bend radii at least equal to material thickness to prevent cracking

- Keep holes a minimum of 2× material thickness away from bend locations to avoid deformation

- Specify standard hole sizes and consistent bend radii to reduce tooling costs and accelerate production

- Engage fabricators early in your design phase—prevention always costs less than correction

If you're ready to find a fabricator:

- Verify certifications like IATF 16949 for automotive applications and AWS welding certifications for critical assemblies

- Prepare complete documentation including CAD files, dimensioned drawings, material specifications, and finish requirements before requesting quotes

- Evaluate rapid prototyping capabilities, quote turnaround times, and DFM support as indicators of professional operations

- Ask about accountability when things don't go as planned—this reveals true partnership potential

Taking the Next Step

Your professional sheet metal fabrication guide wouldn't be complete without pointing you toward concrete action. Here's how to move forward based on your current needs:

For sheet metal fabrication project planning:

Start by documenting your requirements completely. Gather part drawings, material specifications, quantity estimates, and timeline expectations before contacting any fabricator. According to industry best practices, engaging partners early in ideation—rather than waiting until designs are finalized—dramatically improves outcomes. Precision fabricators can offer recommendations that ensure your vision remains achievable while minimizing obstacles.

For custom sheet metal fabrication services:

Identify fabricators whose certifications and capabilities match your specific application. For automotive stamping and precision metal assemblies, manufacturers like Shaoyi (Ningbo) Metal Technology offer IATF 16949-certified quality with 5-day rapid prototyping and comprehensive DFM support—enabling you to validate designs quickly before committing to production tooling. Their 12-hour quote turnaround also indicates the operational efficiency that accelerates project timelines.

For ongoing fabrication partnerships:

The best supplier relationships evolve into true collaborations. Treat quality fabricators as extensions of your engineering team. Share forecasts, provide feedback, and invest in communication infrastructure that keeps projects running smoothly. Companies that nurture these partnerships consistently outperform those treating fabrication as transactional purchasing.

Whatever stage you're at, remember this: professional sheet metal fabrication transforms flat metal sheets into precision components that power virtually every industry. The knowledge you've gained here positions you to make smarter decisions, communicate more effectively with fabricators, and ultimately get better parts faster at lower cost. Now it's time to put that knowledge to work.

Frequently Asked Questions About Professional Sheet Metal Fabrication

1. What is the difference between sheet metal manufacturing and fabrication?

Sheet metal manufacturing focuses on producing raw metal sheets at scale through rolling and processing operations. Fabrication transforms those sheets into custom components through cutting, bending, punching, and joining processes. Professional fabricators bridge this gap by taking standardized materials and creating tailored solutions meeting specific engineering tolerances and compliance standards for applications ranging from automotive chassis to HVAC systems.

2. What certifications should I look for in a professional sheet metal fabricator?

For automotive applications, IATF 16949 certification is essential as it validates process-oriented quality management systems for defect prevention. AWS welding certifications ensure welders meet industry standards for sheet metal up to 6.07mm thick. ISO 9001 covers general quality management, while ITAR certification is required for defense and aerospace applications. Fabricators like Shaoyi (Ningbo) Metal Technology hold IATF 16949 certification for precision automotive stamping and assemblies.

3. What materials are commonly used in professional sheet metal fabrication?

The most common materials include stainless steel (304/316) for corrosion resistance in food and medical equipment, aluminum for lightweight aerospace and automotive parts, cold-rolled steel for economical indoor applications, galvanized steel for HVAC and outdoor enclosures, and copper for electrical components. Material selection depends on mechanical requirements, environmental exposure, formability needs, weight constraints, and budget parameters.

4. What is Design for Manufacturability (DFM) in sheet metal fabrication?

DFM principles optimize designs for efficient production while reducing costs. Key guidelines include maintaining bend radii at least equal to material thickness, positioning holes 2x material thickness from bends, including bend relief cuts at corners, ensuring flanges are at least 4x material thickness, and orienting bends across the grain direction. Professional fabricators like Shaoyi offer comprehensive DFM support to identify potential issues before production.

5. How do I prepare specifications when requesting a sheet metal fabrication quote?

Prepare complete documentation including CAD files in STEP or IGES format, dimensioned 2D drawings with tolerances, material type and grade specifications, finish requirements with coating details, quantity estimates for initial and annual volumes, and timeline expectations. Clear specifications eliminate ambiguity, prevent costly rework, and enable fabricators to provide accurate quotes quickly—some professional operations offer 12-hour quote turnaround with proper documentation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —