Precision Metal Working Decoded: From Micron Tolerances To Partner Selection modern cnc machining achieving micron level precision in metal component manufacturing

What Makes Metal Working Truly Precision

When you hear the term "metal working," you might picture sparks flying in a workshop or heavy machinery shaping raw steel. But precision metal working operates in an entirely different realm—one where success and failure are separated by measurements thinner than a human hair.

So how do we define metalworking at this level? At its core, precision metal working refers to manufacturing processes that achieve tolerances measured in microns (one-thousandth of a millimeter) rather than millimeters. This seemingly small shift in measurement fundamentally transforms what's possible in modern manufacturing. According to NVT Technology, precision machining becomes necessary when tolerances less than 0.01mm are required—a threshold where even the smallest error can lead to complete component failure.

From Millimeters to Microns: The Precision Difference

Imagine a shaft designed to be exactly 10.000 mm in diameter. In general sheet metal working, a tolerance of ±0.5 mm might be perfectly acceptable. But in precision metal applications, that tolerance shrinks to ±0.005 mm or even tighter. This means any diameter between 9.995 mm and 10.005 mm passes inspection—a variation invisible to the naked eye yet critical to performance.

This ridge in metalworking capability didn't happen overnight. It evolved alongside advancing technology, driven by industries demanding ever-greater accuracy.

As manufacturing technology has advanced, tolerance requirements have shifted from millimeters to microns, transforming precision from a luxury into an absolute necessity for high-performance industries.

Before diving deeper, let's clear up some terminology confusion. You'll encounter terms like precision fabrication, precision machining, and precision metal forming used interchangeably—but they're not identical. Precision machining typically refers to subtractive processes like CNC milling and turning. Precision fabrication encompasses a broader range including stamping, laser cutting, and assembly. Precision metal working serves as the umbrella term covering all manufacturing processes that achieve micron-level accuracy.

Why Tolerance Levels Define Modern Manufacturing

Why do these microscopic measurements matter so much? Consider the consequences: in aerospace, a turbine blade slightly outside tolerance can cause dangerous vibrations. In medical devices, imprecise implants won't integrate properly with human tissue. In electronics, components measured in microns must fit together in increasingly compact spaces.

Throughout this article, you'll discover the complete journey from raw material to finished precision component. We'll explore the technologies making micron-level accuracy possible, the industries driving demand for such precision, and ultimately, how to select a manufacturing partner capable of delivering consistent results. Whether you're an engineer specifying parts or a buyer sourcing components, understanding precision metal working is essential for navigating today's manufacturing landscape.

Evolution of Precision in Metal Manufacturing

How did we get from hand-forged horseshoes to components measured in microns? The answer lies in a century of relentless innovation that transformed metal machining from a skilled trade into a technology-driven science. Understanding this evolution helps explain why today's metal working machines can achieve what seemed impossible just decades ago.

In the early 1900s, metalworking was predominantly done using manual tools and machines. The lathe, mill, and drill press represented significant milestones, yet these machines had inherent limitations in accuracy and repeatability. Skilled craftsmen—practitioners of what many called machine craft—relied on experience, intuition, and steady hands to achieve precision. According to Metal Works Corporation, early machining methods were labor-intensive and relied heavily on skilled craftsmanship, but as demand for precision components grew, so did the need for more advanced techniques.

The Technology Leap That Changed Everything

The mid-20th century witnessed a transformative moment with the advent of punched tape technology—a critical precursor to modern CNC systems. This innovative approach revolutionized manufacturing by allowing machines to follow complex sets of instructions stored on long strips of paper. For the first time, manufacturers could repeat processes flawlessly with minimal human intervention.

Then came the real breakthrough. The development of Computer Numerical Control machines in the 1950s fundamentally changed what was possible in metals technology. Unlike manual machines where precision depended on operator skill, CNC technology automated the machining process through computer-executed pre-programmed commands. This shift represented more than just technological advancement—it was a complete paradigm change in how precision was achieved.

CNC machines offered several distinct advantages over traditional metalworking equipment:

- Enhanced repeatability: Once programmed, CNC machines produce identical parts consistently, eliminating human variability

- Greater complexity: Intricate designs and complex geometries became achievable with unprecedented precision

- Reduced errors: Computer control minimized mistakes that previously occurred during manual operations

- Faster production: Automated processes significantly increased throughput without sacrificing accuracy

The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software marked another major stride in the evolution of precision manufacturing. As noted by Machining Concepts, CAD software enabled designers to create detailed digital models while CAM software translated these designs into precise machine instructions. This seamless integration streamlined the entire design-to-production process, bridging what was once considered the tooling art of design with manufacturing reality.

How Computer Control Achieved Micron Accuracy

What makes computer control capable of achieving tolerances measured in microns? The answer involves multiple technological advances working together. Modern CNC systems combine sophisticated software algorithms, advanced sensor technology, and computing power that would have been unimaginable to early machinists.

A historical comparison between early CNC models and their modern counterparts strikingly illustrates this progress. Early machines were groundbreaking for their time, offering precision far beyond manual capabilities. Today, advances in computing power have propelled these machines to produce components with tolerances as tight as ±0.000050 inches—that's approximately 1.27 microns.

The latter half of the 20th century also saw the rise of automation and robotics in precision machining. Automated systems and robotic arms integrated into machining processes perform repetitive tasks with unwavering precision. This integration improved efficiency, consistency, and safety across manufacturing environments.

Yet here's what many overlook: despite all this automation, human expertise remains essential. Programmers must understand both the capabilities of their metalworking equipment and the physical properties of materials being machined. Setup technicians ensure machines are calibrated correctly. Quality verification specialists interpret measurement data and make critical decisions. The shift from skilled hand work to programmable precision didn't eliminate the need for expertise—it transformed what that expertise looks like.

Each technological advancement—from punched tape to CNC, from CAD/CAM integration to modern sensors—enabled tighter tolerances and more complex geometries. This evolution continues today with developments like artificial intelligence and machine learning promising to further enhance precision capabilities. But to truly appreciate what these technologies can achieve, we need to examine the core processes that deliver micron-level accuracy in modern precision metal working.

Core Processes That Deliver Micron-Level Accuracy

You've seen how technology transformed metalworking from craft to science. But which specific processes actually achieve those micron-level tolerances? Understanding the core methods of precision metal fabrication—and knowing when to use each—separates successful projects from costly failures.

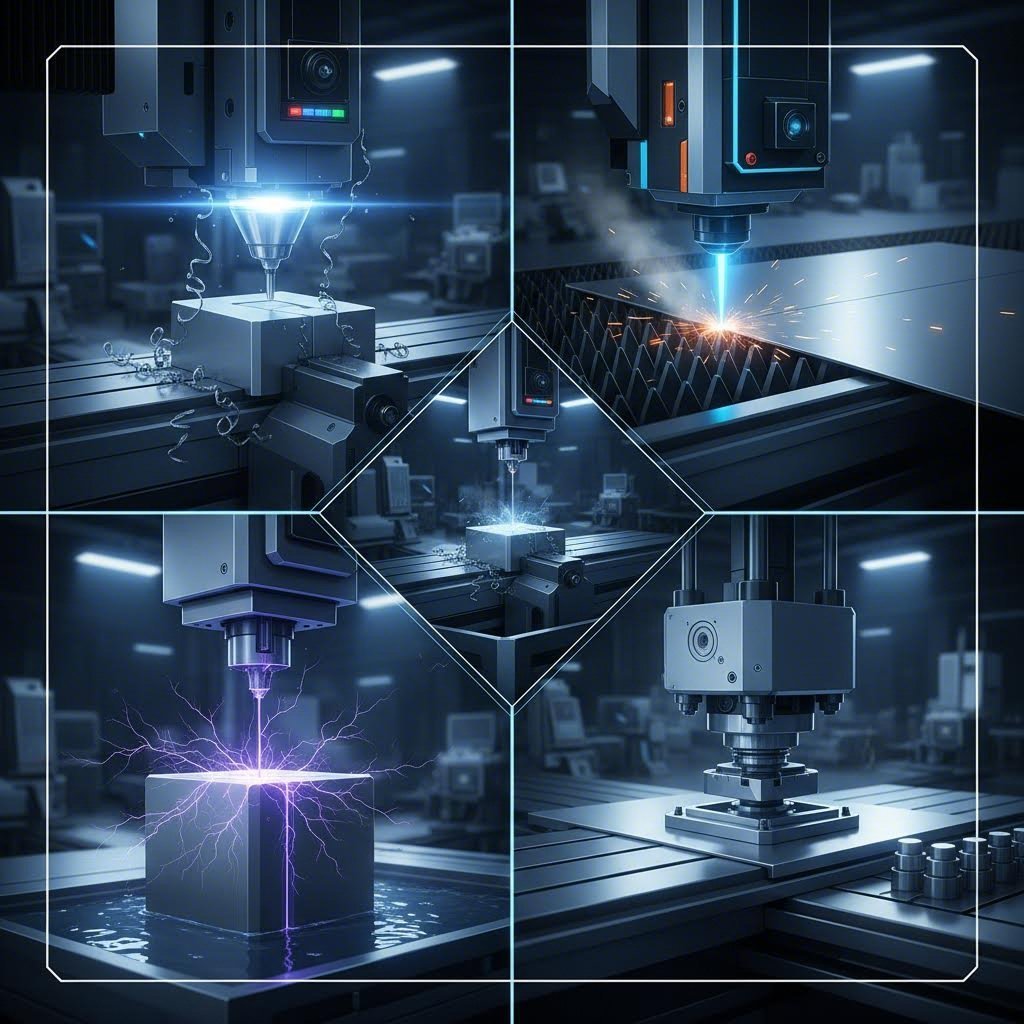

Four primary technologies dominate modern precision metal working: CNC machining, precision stamping, laser cutting, and EDM (Electrical Discharge Machining). Each operates on fundamentally different principles, delivers distinct tolerance ranges, and excels in specific applications. Let's break down how each achieves precision and when operators select one method over another.

CNC Machining: The Backbone of Precision Production

When engineers need consistent, high-precision metal forming, CNC machining typically comes first to mind—and for good reason. This subtractive process removes material from solid blocks using computer-controlled cutting tools, achieving tolerances as tight as ±0.001 inches (approximately 25 microns) in standard applications and even tighter in ultra-precision environments.

What makes CNC machining so reliable for precision work? Several factors work together:

- Multi-axis control: Modern 5-axis machines manipulate workpieces from virtually any angle, enabling complex geometries without repositioning

- Real-time compensation: Advanced systems monitor and adjust for tool wear, thermal expansion, and material variations during cutting

- Programmable repeatability: Once a program is verified, identical parts emerge time after time

According to A-Laser, high-precision CNC machining achieves ±0.001 inches for aerospace and automotive applications, while ultra-precision work reaches ±0.0005 inches for medical implants and semiconductor components. Understanding how to drill a hole in metal at these tolerances requires not just sophisticated equipment, but also careful consideration of material properties and cutting parameters.

The precision stamping process operates on entirely different principles. Rather than removing material, stamping uses dies to form sheet metal through controlled deformation. This makes it exceptionally efficient for high-volume production of identical parts requiring tight tolerances.

A sheet metal punch operation in precision stamping can achieve tolerances of ±0.05mm to ±0.10mm, as documented by Komaspec. Progressive stamping takes this further—coiled metal passes through a sequence of dies, with each station performing a specific forming operation. This approach excels for small parts requiring micro-precision and proves highly cost-effective at volumes exceeding 10,000 units.

Laser Cutting and EDM for Complex Geometries

When parts demand intricate shapes or materials resist conventional machining, laser cutting and EDM provide solutions that traditional methods cannot match.

Laser cutting uses focused light energy to melt, burn, or vaporize material along programmed paths. Modern fiber lasers cut faster than their CO2 predecessors and handle a wider range of thicknesses—from delicate 0.5mm sheets to 20mm plate. The process achieves linear tolerances of ±0.10mm and leaves minimal heat-affected zones when properly controlled.

What situations call for laser cutting over mechanical methods?

- Complex contours that would require multiple tool changes in conventional machining

- Thin materials prone to deformation from mechanical cutting forces

- Rapid prototyping where tooling costs must be avoided

- Bending metal preparation where clean, precise edges matter for subsequent forming

EDM (Electrical Discharge Machining) takes a completely different approach—it erodes material through precisely controlled electrical sparks. This non-contact process excels where conventional tools struggle: hardened steels, exotic alloys, and geometries with extremely tight internal corners. Wire EDM achieves tolerances of ±0.0001 inches in optimal conditions, making it invaluable for tooling and die production.

Interestingly, while advanced equipment like laser systems have largely replaced older technologies, some shops still maintain cutting torch hoses and acetylene setups for rough cutting operations where precision isn't critical—a reminder that the right tool depends entirely on the application.

| Process Type | Typical Tolerance Range | Best Applications | Material Compatibility |

|---|---|---|---|

| CNC Machining | ±0.001" to ±0.0002" (±25 to ±5 microns) | Aerospace components, precision fittings, complex 3D geometries | Most metals including aluminum, steel, titanium, brass |

| Precision Stamping | ±0.05mm to ±0.10mm | High-volume production, sheet metal assembly, automotive brackets | Malleable metals: steel, aluminum, copper, brass |

| Laser Cutting | ±0.10mm linear | Complex 2D profiles, prototyping, thin materials | Steel, stainless, aluminum (0.5mm to 20mm thickness) |

| EDM (Wire/Sinker) | ±0.0001" to ±0.0005" (±2.5 to ±12.7 microns) | Hardened materials, dies, intricate internal features | Any electrically conductive metal |

How do operators select the right method? The decision involves balancing multiple factors simultaneously. Part geometry often narrows the options—a steel cutter operation using CNC milling works beautifully for prismatic parts but struggles with thin sheet metal work. Tolerance requirements may eliminate certain processes entirely; if your design demands ±0.0002" accuracy, laser cutting won't suffice.

Production volume significantly influences the choice as well. Precision stamping requires substantial tooling investment (often $10,000 to $100,000+ for progressive dies) but delivers the lowest per-piece cost at high volumes. Laser cutting and CNC machining involve minimal setup costs, making them ideal for prototypes and low volumes, but per-piece costs remain higher throughout production.

Material properties add another layer of complexity. Hardened tool steels that would destroy conventional cutting tools machine cleanly with EDM. Aluminum's tendency to gum up requires specific tooling in CNC operations but cuts cleanly with lasers. Understanding these interactions between process and material is essential for achieving consistent precision metal forming results.

The most successful precision metal fabrication projects often combine multiple processes strategically. A chassis component might begin with laser-cut blanks, move through precision stamping for forming, and receive CNC-machined features for critical interfaces. This hybrid approach leverages each technology's strengths while respecting its limitations—a strategy that becomes especially important when specific industries demand not just precision, but documentation and traceability to prove it.

Industries That Demand Precision Metal Components

You've explored the processes that achieve micron-level accuracy. But where does this precision actually matter—and what happens when it fails? The answer varies dramatically across industries, with each sector defining acceptable tolerance levels based on the real-world consequences of deviation.

Four industries drive the majority of precision metal fabrication demand: aerospace, medical devices, automotive, and electronics. Each presents unique challenges, operates under distinct regulatory frameworks, and defines precision success differently. Understanding these differences helps explain why the metal industry has developed such specialized capabilities—and why jobs in sheet metal industry continue to evolve toward higher-skill positions.

Aerospace: Where Microns Mean Safety

In aerospace manufacturing, precision isn't a competitive advantage—it's a non-negotiable safety requirement. Components must withstand extreme forces, temperature fluctuations, and years of continuous operation. A turbine blade slightly outside tolerance can create dangerous vibrations. A fuel system fitting that doesn't seal perfectly can lead to catastrophic failure.

According to Buell Automatics, aerospace parts often require tolerances within ±0.0001 inches—approximately 2.5 microns. To put that in perspective, a human hair measures roughly 70 microns in diameter. Aerospace components must be manufactured with variations smaller than a fraction of that hair's width.

Critical aerospace metal fabrication parts include:

- Turbine blades and engine components: Must maintain precise aerodynamic profiles under extreme heat

- Hydraulic valve bodies: Require exact internal geometries for proper fluid control

- Structural fasteners and fittings: Need consistent dimensions for reliable assembly and load distribution

- Landing gear components: Demand tight tolerances for proper movement and load bearing

- Fuel system connectors: Must seal perfectly to prevent leaks under varying pressures

The consequences of tolerance failures in aerospace extend beyond component failure. Regulatory bodies require complete traceability and documentation. Every part must have a paper trail from raw material to installation. As Buell Automatics notes, this documentation supports "ISO 9001:2015, ITAR and IATF 16949 compliance"—standards that govern how aerospace suppliers operate.

Medical Device Manufacturing: Precision Saves Lives

When a metal component enters the human body, precision takes on life-or-death significance. Medical devices must achieve exact fits, maintain biocompatibility, and function flawlessly for years—sometimes decades—inside patients.

According to H&S Manufacturing, medical instruments, equipment, and devices have strict specifications for materials, dimensions, tolerances, and finishing processes. They must be safe for critical healthcare applications and meet US and international standards before reaching market.

What makes medical precision requirements unique? Beyond dimensional accuracy, surface finish becomes critical. Roughness matters especially for sealing surfaces or implantable devices. Metal finishing technologies like electropolishing and passivation remove microscopic burrs and create surfaces that won't harbor bacteria or cause adverse tissue reactions.

Medical applications demanding precision include:

- Orthopedic implants: Hip and knee replacements requiring exact anatomical fits

- Surgical instruments: Cutting tools and clamps needing consistent performance

- Pacemaker and defibrillator housings: Hermetically sealed enclosures protecting sensitive electronics

- Dental implants: Components measured in millimeters that must integrate with bone tissue

- Diagnostic equipment frames: Structures maintaining precise alignment for accurate imaging

The consequences of medical tolerance failures can be devastating. An implant slightly too large may not seat properly in bone. An instrument with microscopic burrs can damage tissue. A poorly sealed device housing can allow moisture to compromise internal electronics. These aren't hypothetical concerns—they're why regulatory approval processes for medical devices are so rigorous.

As H&S Manufacturing emphasizes, achieving both high precision and accuracy is the goal in medical device machining and manufacturing, regardless of the equipment and processes used. The stakes simply don't allow for compromise.

Automotive Metal Fabrication: Performance Meets Volume

Automotive precision presents a unique challenge: achieving tight tolerances at massive production volumes while maintaining cost competitiveness. A single vehicle contains thousands of metal components, and each must fit precisely with others during assembly.

According to Contract Production Ltd, automotive components must survive a brutal operating environment: extreme temperatures, high vibration, voltage fluctuations, and years of continuous operation. This demanding environment means precision manufacturing and adherence to strict automotive standards are non-negotiable.

Automotive metal fabrication parts requiring precision include:

- Chassis and structural components: Critical for vehicle safety and crash performance

- Suspension brackets and mounting points: Precise geometry ensures proper handling dynamics

- Transmission housings: Exact dimensions required for gear alignment

- Brake system components: Safety-critical parts with zero tolerance for failure

- Engine mounting brackets: Must dampen vibration while maintaining structural integrity

What happens when automotive tolerances slip? Parts that don't fit during assembly create production line delays costing thousands per minute. Components with marginal fits may pass initial inspection but fail prematurely in the field—leading to warranty claims, recalls, and brand damage. Safety-critical failures can result in injuries, fatalities, and massive liability exposure.

For those wondering "is metal fabrication a good career path," the automotive sector provides compelling evidence. The industry's demanding precision requirements create ongoing demand for skilled technicians who understand both the processes and the stakes involved.

Electronics: Miniaturization Drives Extreme Precision

The electronics industry pushes precision boundaries through relentless miniaturization. Components shrink constantly while performance expectations increase. This creates demand for metal parts measured not in millimeters, but in fractions of millimeters—and sometimes microns.

Consider the challenge: smartphone components must fit within ever-thinner profiles. 5G infrastructure requires precisely machined housings for sensitive RF components. Data center equipment needs heat sinks with exact surface geometries for optimal thermal transfer. Each application demands tighter tolerances than the last.

Electronics applications requiring precision metal components include:

- Semiconductor equipment parts: Components for chip manufacturing measured in microns

- RF shielding enclosures: Precise fits preventing electromagnetic interference

- Connector housings: Exact dimensions ensuring reliable electrical contact

- Heat sink assemblies: Surface flatness critical for thermal conductivity

- Server chassis components: Tight tolerances enabling high-density equipment mounting

Tolerance failures in electronics often manifest as intermittent problems—the most frustrating type to diagnose. A connector housing slightly out of spec may work initially but fail under thermal cycling. A heat sink with poor surface flatness creates hot spots that degrade performance over time. An RF enclosure with imprecise mating surfaces allows interference that corrupts signals unpredictably.

Each of these industries defines acceptable precision differently based on application requirements and failure consequences. Aerospace demands documentation proving every measurement. Medical requires biocompatibility alongside dimensional accuracy. Automotive balances precision with volume economics. Electronics pushes the boundaries of what's physically achievable. Yet all share a common thread: precision isn't optional, and the design and planning process must account for these requirements from the very beginning.

Design and Planning for Precision Manufacturing

You've seen how industries define precision requirements based on application stakes. But how do engineers translate those requirements into manufacturable designs? The answer lies in a disciplined approach that considers precision constraints from the very first sketch—not as an afterthought when parts arrive out of spec.

Here's the reality that experienced engineers understand: approximately 70% of manufacturing costs are determined during the design phase. This means decisions made before metal processing even begins—material selection, tolerance allocation, feature geometry—lock in most of your project's cost and quality outcomes. Getting design right isn't just good practice; it's the foundation of accurate metal fabricating.

DFM Principles for Precision Components

Design for Manufacturing (DFM) takes on special significance in precision metal fab applications. Unlike general fabrication where generous tolerances forgive design oversights, precision work demands that every feature be evaluated for manufacturability before committing to production.

What does DFM mean in practical terms? According to Die-Matic, DFM is an engineering concept that involves creating products to optimize their manufacturing process. By considering manufacturing constraints early in the design phase, engineers can ensure that the product can be efficiently and cost-effectively produced while reducing defects and improving overall quality.

Consider how precision requirements influence specific design decisions:

- Hole and slot placement: The diameter of tight tolerance holes generally must equal or exceed material thickness. Holes require minimum spacing of twice the material thickness from each other or part edges to prevent bulging.

- Bend considerations: Inside bend radius should at minimum equal material thickness. Overall bend height needs to be at least 2.5 times material thickness plus the bend radius. Understanding how bending metal affects dimensional stability is critical for precision work.

- Flange widths: Minimum flange width should be 2.5 times material thickness to ensure formability without distortion.

- Corner radii: Blank corners should have radii of at least half the material thickness to prevent cracking during forming.

The journey from concept to production-ready specifications follows a systematic progression. Each step builds on the previous, with precision considerations woven throughout:

- Define functional requirements: Identify which dimensions truly impact part performance. Critical mating surfaces, bearing diameters, and mounting features demand your tightest tolerances.

- Establish tolerance hierarchy: Apply tight tolerances only where function requires them. Over-tolerancing every dimension doesn't make a part better—it makes it more expensive and harder to manufacture.

- Select appropriate materials: Choose materials with properties that support your tolerance requirements (more on this below).

- Design for minimal setups: Each time a part is repositioned in a machine, you introduce potential error sources. Design parts that can be machined in a single setup whenever possible.

- Analyze tolerance stack-up: When multiple tolerances interact, cumulative effects can be significant. Use worst-case or statistical analysis to ensure assemblies function properly.

- Review with manufacturing partners: Share design intent, not just specifications. When machinists understand your goals, they can suggest modifications that improve manufacturability without compromising function.

- Document and freeze design: Establish clear protocols for changes. Late-stage modifications often prove expensive and may compromise optimal solutions.

Even seemingly simple operations require careful planning. Knowing how to drill a hole in metal at precision tolerances involves more than selecting the right drill bit—it requires understanding material behavior, chip evacuation, and thermal effects that influence final dimensions.

Material Selection: The Foundation of Achievable Tolerances

The material you select fundamentally determines what tolerances are achievable and how consistently they can be maintained. Not all metals respond equally to precision metal processing—and choosing the wrong material can make your tolerance requirements impossible to meet regardless of equipment quality.

According to Epec Engineered Technologies, aluminum alloys like 6061-T6 and 7075-T6 are excellent choices for tight-tolerance work. These materials machine cleanly, have predictable thermal expansion properties, and maintain dimensional stability well. Their relatively low cutting forces also reduce tool deflection—crucial for maintaining accuracy.

How do different materials compare for precision work?

| Material Category | Precision Suitability | Key Considerations | Typical Applications |

|---|---|---|---|

| Aluminum Alloys (6061-T6, 7075-T6) | Excellent | Clean machining, predictable thermal expansion, low cutting forces | Aerospace structures, precision housings |

| Steel Alloys (4140, 4340) | Very Good | Exceptional stability once stress-relieved, requires robust tooling | Gears, shafts, structural components |

| Stainless Steel (316L) | Good (with care) | Tends to work-harden, requires sharp tooling and proper techniques | Medical devices, food processing |

| Plastics and Composites | Challenging | Significant thermal expansion, moisture absorption, stress relaxation | Special applications requiring non-metallic properties |

Why do material properties matter so much? Consider thermal expansion. A material with high thermal expansion will require more careful temperature control during both machining and measurement phases. A part that measures perfectly at room temperature may fall outside tolerance in its operating environment—or may shift during the machining process itself as cutting generates heat.

The relationship between tolerance and cost follows an exponential curve. As Modus Advanced documents, moving from standard tolerances (±0.13mm) to precision requirements (±0.025mm) can multiply part costs by factors of three to five. Ultra-precision tolerances (±0.010mm) increase costs by factors of eight to fifteen due to specialized equipment, environmental controls, and 100% inspection requirements.

Smart engineers in metal design systems balance these factors continuously. They specify the loosest tolerances that maintain part functionality—not because tighter is impossible, but because unnecessary precision wastes resources without improving performance. A precision metal fab project succeeds when every tolerance serves a purpose and every material choice supports achievable accuracy.

This balance between precision requirements and practical constraints explains why quality standards and certifications exist. They provide frameworks for ensuring that precision claims can be verified consistently—and that manufacturing partners have the systems in place to deliver what they promise.

Quality Standards and Certifications in Precision Work

You've seen how material selection and DFM principles set the foundation for achievable tolerances. But how do you verify that a manufacturer can actually deliver those tolerances consistently—batch after batch, year after year? The answer lies in quality certifications and the rigorous verification methods that validate precision claims.

Think of certifications as a manufacturer's resume, verified by independent auditors. They don't guarantee perfection, but they confirm that documented systems exist for maintaining quality, catching errors, and continuously improving. For anyone evaluating precision production occupations or considering metal fabrication certification requirements, understanding these standards is essential.

Understanding IATF 16949 and Automotive Quality Standards

ISO 9001 serves as the foundation—the baseline certification that verifies a supplier has standardized processes for quality control, documentation, and continuous improvement. According to Modo Rapid, ISO 9001 requires an independent audit of supplier procedures, resulting in better traceability, smoother communication, and fewer surprises during inspection.

But for industries demanding tighter controls, ISO 9001 is just the starting point. IATF 16949 builds upon this foundation with automotive-specific requirements:

- Advanced Product Quality Planning (APQP): Structured processes for developing new products that meet customer requirements

- Production Part Approval Process (PPAP): Documentation proving manufacturing processes can consistently produce parts meeting specifications

- Statistical Process Control (SPC): Real-time monitoring to detect process drift before defects occur

- Failure Mode and Effects Analysis (FMEA): Systematic identification of potential failures and preventive actions

- Measurement System Analysis (MSA): Verification that measurement equipment provides reliable, repeatable results

AS9100 takes precision requirements even further for aerospace and defense applications. As American Micro Industries explains, this standard "emphasizes risk management, stringent documentation and product integrity control throughout complex supply chains." When lives depend on component reliability, these additional controls become non-negotiable.

What about specialized industries? ISO 13485 governs medical device manufacturing, outlining strict controls over design, traceability, and risk mitigation. NADCAP accreditation validates special processes critical to aerospace manufacturing, including heat treating and nondestructive testing. Each certification addresses specific industry concerns that general quality standards don't cover.

How Certifications Guarantee Consistent Precision

Certifications matter because they transform precision from a promise into a verifiable system. But certifications alone don't measure parts—that's where inspection and verification methods come in.

Coordinate Measuring Machines (CMM) represent the gold standard for dimensional verification in all metals processing. These computer-controlled systems use probes to measure exact coordinates on part surfaces, comparing actual dimensions against CAD models with micron-level accuracy. CMM inspection provides documented evidence that tolerances have been achieved—not estimates, but measured values.

Optical measurement systems complement CMM capabilities for features where contact probing isn't practical. Vision systems can measure hundreds of features in seconds, making them ideal for high-volume metal processing services. They excel at verifying hole positions, edge profiles, and surface features on flat parts.

Statistical Process Control (SPC) prevents problems rather than just detecting them. By monitoring key dimensions throughout production runs, manufacturers identify trends before parts drift out of specification. According to Modo Rapid, IATF 16949-certified suppliers use SPC to detect potential issues "before your parts hit the CMM report stage."

What do these measurement capabilities mean for fabricator job requirements? Modern precision manufacturing demands technicians who understand not just machining processes, but also measurement theory and statistical analysis. The ability to interpret SPC charts and CMM reports has become as essential as running the machines themselves.

For manufacturers producing accurate molds or precision components, verification isn't optional—it's integrated into every production step. First article inspection validates that new setups meet requirements. In-process checks catch drift before it creates scrap. Final inspection documents conformance for customer records and regulatory compliance.

The combination of certified quality systems and rigorous measurement creates accountability. When a supplier holds IATF 16949 certification, you know their processes have been audited, their measurement systems validated, and their personnel trained. When they provide CMM reports with your shipment, you have documented proof of dimensional conformance. This systematic approach to quality distinguishes professional precision metalworking from shops that simply claim to be precise—a distinction that becomes critical when evaluating how manufacturers handle the inevitable challenges that arise during production.

Common Challenges and How Manufacturers Overcome Them

You've learned about quality systems designed to ensure consistent precision. But what happens when theory meets the shop floor? Even with certified processes and advanced metal fabrication machines, real-world manufacturing introduces challenges that can push parts outside tolerance. Understanding these obstacles—and how experienced manufacturers prevent them—separates successful projects from costly failures.

According to NVT Technology, despite advances in technology and machinery, precision engineering still faces common challenges that can affect the quality and accuracy of final products. The good news? Each challenge has proven solutions when manufacturers understand the underlying causes.

Thermal Management: The Hidden Precision Killer

Imagine machining a part to perfect specifications, only to discover it's out of tolerance after cooling. This scenario plays out more often than you might expect—and thermal expansion is usually the culprit.

Materials expand or contract when temperature changes. Even a small dimensional shift can cause a part to fall outside specification. Consider aluminum, which expands at approximately 23 micrometers per meter for every degree Celsius of temperature change. A 200mm aluminum part experiencing a 15°C temperature rise during machining expands by 0.069mm—potentially enough to exceed your tolerance budget.

How do manufacturers combat this invisible enemy? Temperature-controlled environments provide the first line of defense. Many precision shops maintain machining areas within ±1°C to minimize thermal variation. Using materials with low thermal expansion coefficients helps when application requirements allow material substitution. Real-time monitoring enables process adjustments before thermal effects accumulate.

The challenge extends beyond machining itself. Steel cutting tools generate heat during operation, and metal cutting coolant systems must effectively transfer that heat away from both tool and workpiece. When coolant delivery fails or proves inadequate, localized heating distorts the very dimensions you're trying to control.

Tool wear represents another persistent challenge. As cutting edges dull, they require more force to remove material—and increased force means increased deflection and heat generation. According to NVT Technology, regular monitoring of tool condition is necessary, with tools replaced or re-sharpened on schedule. Hardened metal drill bits with wear-resistant coatings extend service life, but no tool lasts forever.

When Tolerances Stack: Understanding Cumulative Error

Here's where precision metal working becomes particularly complex. Individual feature tolerances don't exist in isolation—they accumulate across dimension chains. According to Anebon, tolerance stackup describes the total variation that results when multiple dimensions or geometric controls link together.

Consider a steel bracket with a base surface, two mounting holes, and a locating slot. The base surface has a flatness callout of 0.05mm. Each hole carries a positional tolerance of 0.10mm relative to the base. The slot position is specified at 0.08mm. In worst-case analysis, maximum deviation between the slot and the farther hole could reach 0.23mm. If the mating part allows only 0.15mm total clearance, the bracket won't assemble reliably.

Multiple error sources contribute to cumulative deviation beyond specified tolerances:

- Fixturing errors: A vise with 0.02mm parallelism deviation shifts the part datum for every subsequent operation

- Tool deflection: A 10mm end mill deflects approximately 0.015mm under typical cutting loads—multiply this across multiple features

- Machine repeatability: Even high-precision equipment has positioning tolerances that accumulate

- Material inconsistencies: Cast blanks may contain 0.03mm core shift; forged stock may have 0.05mm ovality

An automotive supplier machining transmission cases observed 0.18mm cumulative error across twelve bore locations. Investigation traced 40% to fixture wear, 30% to tool deflection, and 20% to thermal spindle growth. Addressing these largest contributors reduced total stackup to 0.06mm.

While these challenges sound technical, the prevention strategies are practical. Proper acetylene torch settings matter for cutting operations just as proper CNC parameters matter for precision machining—each process requires appropriate controls. Similarly, maintaining a cutting torch head in good condition prevents rough cuts that create downstream problems during precision operations.

| Challenge | Primary Causes | Prevention Strategies |

|---|---|---|

| Thermal Expansion | Ambient temperature fluctuation, cutting heat, coolant inadequacy | Temperature-controlled environments, low-expansion materials, effective coolant systems, thermal compensation in programming |

| Tool Wear | Extended cutting time, improper speeds/feeds, inadequate lubrication | Scheduled tool replacement, wear-resistant coatings, spindle load monitoring, proper metal cutting coolant application |

| Tool Deflection | Excessive overhang, aggressive cutting parameters, insufficient tool rigidity | Stiffer tool materials, reduced depth of cut, climb milling strategies, overhang limited to 4x shank diameter |

| Fixturing Errors | Worn locators, improper clamping, inconsistent setup procedures | Standardized setup procedures, dial indicator verification, periodic fixture inspection, modular fixturing systems |

| Material Inconsistencies | Casting defects, forging variations, residual stresses | Incoming material inspection, high-quality certified suppliers, stress-relief before final machining |

| Tolerance Stackup | Multiple features in chain, multi-setup operations, datum shifts | Consolidate setups, in-process probing, statistical tolerance analysis, Monte Carlo simulation |

| Vibration/Chatter | Insufficient rigidity, improper speeds, resonance conditions | Increase machine/fixture rigidity, vibration dampers, optimized cutting parameters |

| Measurement Errors | Uncalibrated instruments, operator technique, environmental conditions | Regular calibration, operator training, temperature-controlled inspection, CMM verification |

Effective control begins during process planning. Sequencing operations to machine related features in the same setup minimizes datum shifts. For the transmission case example, consolidating bore machining into two setups instead of six cut the stackup contribution from fixturing by 65%.

In-process probing provides another powerful prevention tool. A touch probe can measure actual position after roughing and apply offsets automatically, compensating for tool wear and thermal drift in real time. This approach transforms potential errors into measured corrections—before they create scrap.

According to FM Machine, precision doesn't end when a part is machined—it must be measured and verified to ensure compliance. CMM inspection, optical measurement, and surface analyzers all contribute to catching deviations before parts ship to customers.

The manufacturers who excel at precision metal working treat these challenges as engineering problems with engineering solutions. They don't hope for precision—they design processes that achieve it systematically. This problem-solving mindset becomes particularly important when evaluating potential manufacturing partners, where the ability to prevent and address challenges distinguishes capable suppliers from those who merely promise precision.

Selecting the Right Precision Metalworking Partner

You've explored the challenges manufacturers face and the systems they use to overcome them. But here's the question that determines your project's success: how do you find a partner who actually delivers consistent precision—not just one who promises it?

Selecting a precision metalworking supplier requires more than comparing quotes. According to Larson Tool & Stamping, when choosing a precision metal stamping company, you want to approach it deliberately and with forethought. Quality, delivery, and price are the basics every buyer wants—but what assurance do you have that those commitments will be met time after time?

For engineers wondering what does a metal fabricator do at the precision level, or buyers searching for custom metal fabricators near me, the evaluation process should follow a structured approach. Think of it like interviewing a prospective employee—you need to verify capabilities, not just accept claims.

Evaluating Equipment and Technology Capabilities

What questions should guide your evaluation? Start with technical capabilities. According to Die-Matic, press tonnage, material range, and part size capacity all determine whether a supplier can meet your production requirements. A manufacturer with diverse press sizes can support everything from lightweight, intricate parts to larger, robust components while maintaining consistent precision.

Use this checklist when evaluating precision metal fabricators:

- Certification status: Verify ISO 9001 as baseline. For automotive applications, IATF 16949 certification is essential. Aerospace requires AS9100. Medical demands ISO 13485. Don't just accept claims—ask to see current certificates.

- Equipment capabilities: Request an equipment list with specifications. Can their presses, CNC machines, and cutting systems handle your material types and thicknesses? Do they have in-house tooling capabilities?

- Quality systems: Ask about their performance objectives. A well-run supplier tracks on-time delivery rates, customer complaint rates, and reject rates—and should share these metrics openly.

- Measurement capabilities: What inspection equipment do they use? CMM machines, optical systems, and calibration records all matter. A precision sheet metal fabricator should have verification capabilities matching their tolerance claims.

- Workforce stability: Find out what percentage is permanent versus contract help. High turnover can lead to poorly trained operators making costly mistakes with your product and tooling.

- Material relationships: Do they have long-standing relationships with reliable material suppliers? Strong supply chain partnerships mean fewer disruptions to your production schedule.

- Communication processes: How quickly do they respond to inquiries? Do they use ERP systems with EDI capabilities? Modern suppliers should provide real-time visibility into order status.

- Facility condition: Is the shop floor well-organized and clean? Equipment appearance often reflects maintenance practices that directly impact part quality.

For those exploring how to become a fabricator or advance in all metal fabrication careers, understanding these evaluation criteria provides insight into what distinguishes top-tier manufacturers from average shops.

What Rapid Prototyping Reveals About a Partner

Rapid prototyping capability serves as a revealing indicator of overall manufacturing competence. According to Creatingway, prototypes allow you to see, feel, and test your designs early in the development process—catching problems before they become expensive production issues.

Why does prototyping speed matter for evaluating what is a metal fabricator's true capabilities? A manufacturer who can deliver functional prototypes quickly demonstrates several critical competencies simultaneously:

- Engineering depth: Fast prototyping requires competent engineering support that understands your design intent

- Process flexibility: Quick turnaround shows they can adapt workflows without compromising quality

- Equipment availability: Rapid response indicates adequate capacity and good scheduling practices

- Communication efficiency: Speed reflects streamlined internal processes and clear customer communication

As Die-Matic emphasizes, early-stage collaboration through Design for Manufacturability (DFM) can identify opportunities to reduce scrap, streamline tooling, and improve product performance before production begins. Suppliers who provide prototyping and simulation support test part geometry and material behavior under real-world conditions.

Consider manufacturers like Shaoyi (Ningbo) Metal Technology, which offers 5-day rapid prototyping combined with IATF 16949-certified quality for automotive precision components. Their comprehensive DFM support and 12-hour quote turnaround demonstrate how modern precision metalworking combines rapid response with certified quality systems—exactly the combination that indicates manufacturing competence.

Beyond speed, evaluate the prototyping process itself:

- DFM feedback quality: Do they identify manufacturability issues proactively, or just build what you send?

- Documentation provided: Prototypes should come with dimensional reports showing actual versus specified measurements

- Iteration support: How quickly can they incorporate design changes and produce revised samples?

- Production path clarity: Does the prototype process translate directly to production tooling, or will redesign be needed?

According to Larson Tool, suppliers should demonstrate Advanced Quality Planning (AQP) practices that establish systematic communication from the beginning of the manufacturing relationship. The benefits flow both ways—customers get better products while manufacturers achieve more efficient production.

Capacity and scalability deserve careful attention too. Die-Matic notes that a dependable stamping manufacturer should demonstrate the ability to respond to fluctuating demand, scale production efficiently, and maintain consistent lead times. Ask about their capacity planning, tooling changeover efficiency, and ability to handle both low- and high-volume orders.

Domestic versus offshore sourcing affects responsiveness significantly. U.S.-based manufacturers often provide tighter delivery schedules, more predictable communication, and better alignment with just-in-time manufacturing goals. Reduced logistics complexity minimizes delays that commonly impact overseas sourcing.

Finally, request references from customers in your industry. As Creatingway advises, check what other clients say about the manufacturer, especially those with similar requirements. Good feedback from companies facing comparable precision challenges indicates they'll likely meet your needs too.

The vetting process may seem extensive, but it prevents costly surprises later. A well-chosen precision metalworking partner becomes an extension of your engineering team—contributing expertise, solving problems proactively, and delivering consistent quality that supports your own reputation. This partnership approach transforms supplier selection from a purchasing decision into a strategic advantage for your manufacturing operations.

Mastering Precision Metal Working for Manufacturing Excellence

You've journeyed from understanding micron-level tolerances to evaluating manufacturing partners. Now it's time to synthesize these insights into actionable principles you can apply immediately—whether you're an engineer specifying parts, a buyer sourcing components, or a professional exploring what is a fabricator and how precision fabrication shapes modern industry.

Throughout this exploration, one truth emerges clearly: precision metal working isn't just about machines or measurements. It represents the intersection of advanced technology, rigorous quality systems, and skilled human expertise working together. Remove any one element, and the entire system falters.

Precision metalworking succeeds when every tolerance serves a purpose, every process is verified, and every partner understands that micron-level accuracy requires millimeter-level attention to detail across the entire manufacturing chain.

Key Principles for Precision Success

What separates successful precision projects from costly failures? After examining technologies, industries, and challenges, several foundational principles stand out:

- Precision starts at design, not production: Approximately 70% of manufacturing costs are locked in during design. Specify tolerances based on functional requirements—not habit or assumption. A metalworker who receives well-designed specifications delivers better results than one fighting poorly conceived drawings.

- Material selection determines achievable accuracy: Your tolerance targets must align with material properties. Aluminum machines differently than titanium; stainless steel behaves unlike carbon steel. Match materials to requirements before committing to specifications.

- Certifications verify systems, not individual parts: ISO 9001, IATF 16949, and AS9100 confirm that documented processes exist for maintaining quality. They don't guarantee perfection—but they ensure accountability and continuous improvement mechanisms.

- Measurement validates claims: CMM inspection, optical systems, and statistical process control transform precision from promises into documented evidence. Any metal workshop claiming tight tolerances should readily provide measurement data proving their capabilities.

- Challenges have engineering solutions: Thermal expansion, tool wear, and tolerance stackup aren't mysteries—they're understood phenomena with proven prevention strategies. The best manufacturers anticipate problems rather than react to them.

For anyone wondering what's a fabricator in the precision context, the answer extends beyond someone who shapes metal. A precision metal worker combines technical knowledge, quality discipline, and problem-solving skills to create components where accuracy is measured in microns and failure isn't an option.

Your Next Steps in Precision Manufacturing

Ready to apply these principles? Your path forward depends on your role:

For engineers specifying parts: Review your tolerance callouts critically. Are you specifying tighter tolerances than function actually requires? Over-tolerancing increases costs without improving performance. Apply GD&T principles to communicate design intent clearly, and engage manufacturing partners early through DFM reviews.

For buyers sourcing components: Use the evaluation checklist from the partner selection section systematically. Verify certifications, request capability data, and assess rapid prototyping competence as an indicator of overall manufacturing maturity. Remember that the lowest quote rarely represents the best value when precision matters.

For professionals exploring the field: Precision manufacturing offers compelling career opportunities as industries demand ever-tighter tolerances. Whether in aerospace, medical devices, automotive, or electronics, the need for skilled professionals who understand both processes and quality systems continues growing.

The future of precision metal working points toward even greater integration of digital technologies. AI-powered predictive maintenance, real-time process monitoring, and advanced simulation tools are already transforming how manufacturers achieve and verify accuracy. Companies that combine these technological capabilities with certified quality systems and responsive customer service set the standard for what precision manufacturing can deliver.

Manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate this integration effectively—combining 12-hour quote turnaround and 5-day rapid prototyping with IATF 16949-certified quality for demanding automotive applications. This blend of speed and precision reflects where the industry is heading: responsive partnerships that don't sacrifice accuracy for agility.

Precision metal working has evolved from craft to science, from millimeters to microns, from manual skill to computer-controlled accuracy. Yet the fundamental goal remains unchanged: creating components that perform exactly as designed, every time, without exception. Master the principles outlined here, and you'll navigate this demanding field with confidence—whether you're designing parts, sourcing suppliers, or building a career in precision fabrication.

Frequently Asked Questions About Precision Metal Working

1. What is precision metalworking?

Precision metalworking refers to manufacturing processes that achieve tolerances measured in microns (one-thousandth of a millimeter) rather than millimeters. It encompasses CNC machining, precision stamping, laser cutting, and EDM to create components for aerospace, medical, automotive, and electronics industries. Unlike general metalworking, precision work requires tolerances less than 0.01mm, where even microscopic errors can cause component failure. This level of accuracy demands advanced computer-controlled equipment, certified quality systems like IATF 16949, and skilled technicians who understand both processes and measurement verification.

2. What does a precision machinist do?

A precision machinist sets up, programs, and operates CNC machines to create components with micron-level accuracy. Their responsibilities include interpreting engineering drawings, selecting appropriate cutting tools and parameters, monitoring machining processes for quality, and performing dimensional verification using CMM equipment. They must understand material properties, thermal management, and tolerance stackup to prevent errors. Modern precision machinists also work with CAD/CAM software to translate designs into machine instructions, making them essential for industries requiring consistent, high-accuracy parts.

3. What are the three methods of metal working?

The three primary metalworking categories are forming, cutting, and joining. In precision applications, cutting includes CNC machining and laser cutting for subtractive manufacturing. Forming encompasses precision stamping and bending operations that shape metal through controlled deformation. Joining involves welding and assembly processes. Each method achieves different tolerance ranges—CNC machining reaches ±0.001 inches, precision stamping achieves ±0.05mm, and laser cutting delivers ±0.10mm linear accuracy. Selecting the right method depends on part geometry, volume requirements, and material properties.

4. How to make precise metal cuts?

Achieving precise metal cuts requires matching the cutting method to your accuracy requirements. For micron-level precision, CNC machining with proper tooling and coolant systems delivers the tightest tolerances. Laser cutting provides excellent accuracy for complex 2D profiles with ±0.10mm linear tolerance. Key factors include using temperature-controlled environments to manage thermal expansion, selecting appropriate cutting parameters for your material, maintaining sharp tools to prevent deflection, and verifying dimensions with CMM inspection. Statistical process control helps detect drift before parts fall outside specification.

5. How do I choose a precision metal fabrication partner?

Evaluate potential partners using certification verification (ISO 9001, IATF 16949 for automotive, AS9100 for aerospace), equipment capability assessment, and quality system documentation. Request CMM reports demonstrating tolerance achievement and check their rapid prototyping capabilities—manufacturers offering fast turnaround like 5-day prototyping often demonstrate strong engineering depth and process flexibility. Verify workforce stability, material supplier relationships, and communication responsiveness. Companies like Shaoyi (Ningbo) Metal Technology exemplify modern precision manufacturing with 12-hour quote turnaround and comprehensive DFM support alongside certified quality systems.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —