Stamping Fuel Tank Straps: Precision Manufacturing & Efficiency

TL;DR

Stamping fuel tank straps is a precision metal fabrication process critical for securing fuel systems in automotive, heavy-duty, and agricultural vehicles. The manufacturing workflow requires rigorous adherence to safety standards, utilizing progressive die stamping to transform high-strength or stainless steel coils into corrosion-resistant components. Key critical factors include material selection (typically 304 Stainless or Galvanized Steel), advanced coating technologies like EDP, and process efficiency through one-piece flow systems. For procurement officers and engineers, selecting a partner with capabilities in both tooled (high-volume) and un-tooled (prototype) runs is essential for optimizing the total cost of ownership and ensuring regulatory compliance.

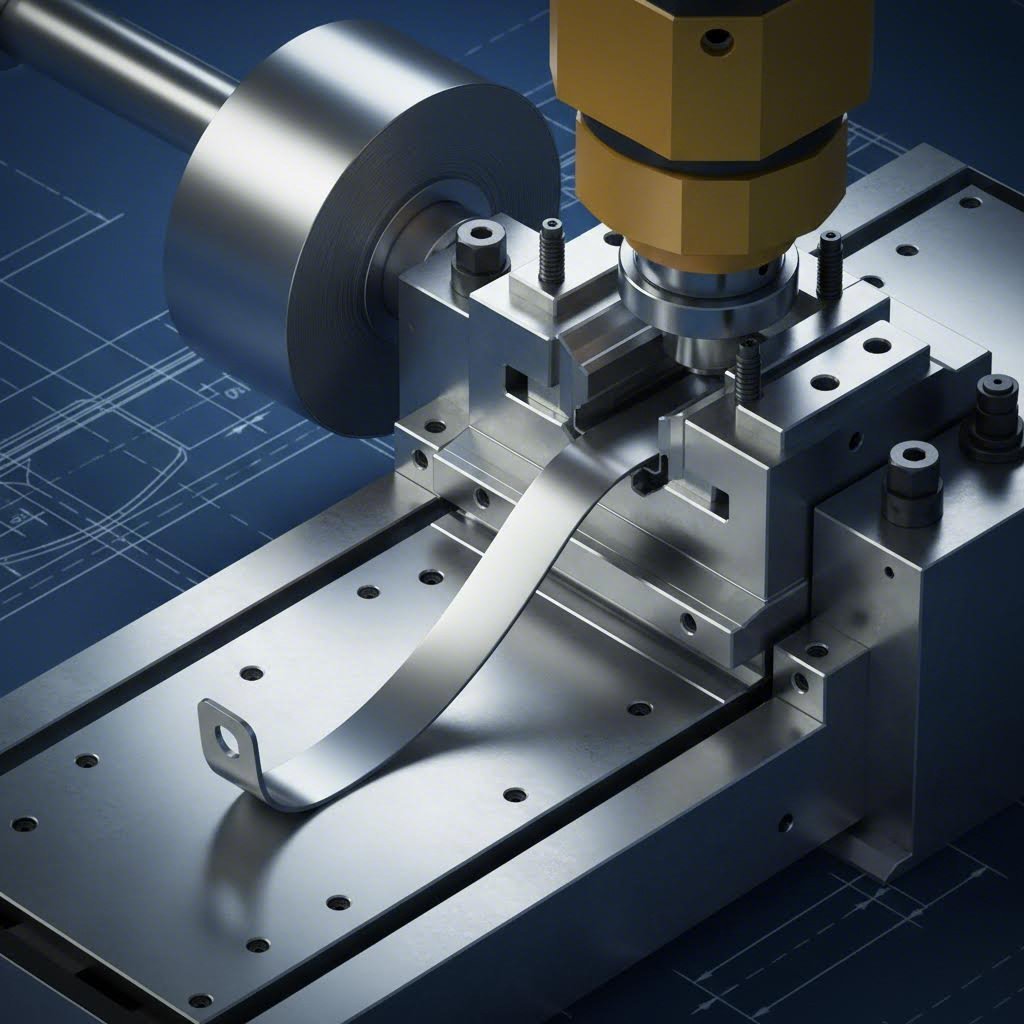

The Stamping Ecosystem: From Coil to Component

The journey of a fuel tank strap from a raw metal coil to a finished safety component defines the intersection of efficiency and engineering precision. In modern automotive manufacturing, the process typically begins with **progressive die stamping**. Unlike transfer die operations where parts are mechanically moved between isolated stations, progressive stamping feeds a metal strip through a single press with multiple stations. Each stroke of the press performs a specific operation—blanking, piercing, bending, and forming—simultaneously on different parts of the strip.

For high-volume production, this method is superior due to its speed and consistency. Leading manufacturers, such as Falls Stamping, have evolved this concept into a "one-piece flow" ecosystem. In this advanced setup, a strap is not just stamped but also finished in a continuous sequence. A raw blank enters the line and undergoes forming, spot welding, and riveting without ever leaving the cell or accumulating in work-in-process inventory. This reduces material handling damage and significantly improves throughput.

The choice between "tooled" and "un-tooled" runs is a critical decision point for engineers. Tooled runs, utilizing dedicated hard tooling, offer the lowest per-unit cost for mass production (500,000+ units annually) but require significant upfront capital. Un-tooled runs, often using laser cutting and press brakes, are ideal for prototyping or low-volume heavy-duty truck variants where tooling investment isn't justifiable. Furthermore, assembly techniques have diversified; while traditional spot welding remains common, specialized processes like **orbital riveting** are increasingly favored for their superior fatigue resistance in high-vibration environments.

Material Science & Corrosion Resistance

Fuel tank straps are safety-critical components exposed to some of the harshest underbody environments, including road salt, moisture, and debris. Consequently, material selection is not merely a design choice but a safety mandate. The two dominant materials are **High-Strength Mild Steel** and **304 Stainless Steel**. Mild steel offers excellent formability and cost-effectiveness but relies entirely on secondary coatings for protection. Stainless steel provides inherent corrosion resistance but comes with higher material costs and "springback" challenges during stamping.

To combat oxidation, manufacturers employ multi-layered defense systems. **Galvanized steel** is the industry standard for general applications, featuring a zinc coating that sacrifices itself to protect the underlying steel. For superior protection, particularly in aftermarket or restoration contexts, **EDP (Electrophoretic Deposition)** coatings are applied. This black, primer-like finish is electrically bonded to the metal, ensuring coverage even in hard-to-reach crevices that spray painting might miss.

The table below compares the primary material options available to engineers:

| Material Type | Corrosion Resistance | Cost Profile | Primary Application |

|---|---|---|---|

| High-Strength Mild Steel (Galvanized) | Moderate (Depends on coating thickness) | Low | Passenger vehicles, Economy aftermarket |

| 304 Stainless Steel | Excellent (Native resistance) | High | Marine, Heavy-duty, Premium restoration |

| Aluminized Steel | High (Heat & corrosion resistant) | Medium | Exhaust proximity applications |

Beyond the metal itself, the interface between the strap and the tank is crucial. Direct metal-to-tank contact can cause abrasion and galvanic corrosion. To prevent this, liners made from extruded nitrile rubber or anti-squeak materials are frequently integrated. These liners dampen vibration and provide a non-abrasive barrier, extending the lifespan of both the tank and the strap.

Process Innovation Case Study: Folding vs. Welding

In the pursuit of manufacturing efficiency, the industry is moving away from complex multi-part assemblies toward smart, single-piece designs. A prime example of this innovation is the "folded strap" approach pioneered by companies like Penne. The traditional method for manufacturing a complex fuel strap often involved up to four separate molds: one for the main strap and three for various reinforcing brackets. These components would then require manual spot welding and bolt attachment, introducing high labor costs and potential for human error.

The innovative solution revolutionized this workflow by utilizing a single progressive mold. By extending the length of the raw strap material by two to three times, engineers could design the strap to fold back onto itself. This folding action creates the necessary reinforcing brackets out of the continuous strip of metal, rather than attaching separate pieces. This "origami" approach eliminates the need for multiple molds and manual handling.

Furthermore, this process replaces traditional spot welding with **clinching**, a mechanical joining technique. Clinching uses high pressure to interlock the metal sheets without heat, preserving the protective coating that welding would typically burn off. The result is a dramatic reduction in Total Cost of Ownership (TCO): the production rate jumps to 25–30 strokes per minute, manual labor is eliminated, and the part emerges from the press fully assembled and ready for painting.

Engineering Challenges & Solutions

Stamping fuel tank straps introduces unique metallurgical challenges, primarily **springback**. High-strength steels and stainless alloys have a "memory"; after being bent, they tend to return slightly to their original shape. In a component that must hug a fuel tank with precise tension, even a degree of deviation can lead to fitment failure. To compensate, die designers employ over-bending techniques and variable binder pressure to set the geometry permanently.

Another common issue is **work hardening**. As stainless steel is formed, it becomes harder and more brittle, potentially leading to cracking in complex geometries like T-bolt loops or sharp mounting bends. Advanced simulation software is used to predict thinning rates and strain distribution before a single tool is cut. For complex assemblies requiring tight tolerances, collaboration with specialized partners is often necessary. Companies like Hatch Stamping have even collaborated with OEMs to establish SAE standards, ensuring that dimensional accuracy meets rigorous safety criteria across the industry.

Balancing these technical demands with production speed is the ultimate goal. Whether you require rapid prototyping to validate a new design or high-volume stamping for a global platform, finding a partner who can bridge these phases is critical. Shaoyi Metal Technology specializes in this exact transition, offering services ranging from 50-piece prototype runs to mass production of millions of units, all while maintaining strict IATF 16949 compliance.

Applications & Industry Standards

The application of stamped straps extends far beyond passenger cars. In the **heavy-duty truck and bus** sector, straps must withstand extreme vibration and chassis flex. These components are often wider, thicker, and engineered with redundant safety features. In the **agricultural** sector, resistance to chemical fertilizers and off-road debris dictates the use of specialized coatings and stainless grades.

Regulatory compliance is non-negotiable. Fuel systems are governed by strict crash safety standards (such as FMVSS in the US), which dictate that the tank must remain secure even during high-impact collisions. This places an immense burden on the strap's tensile strength and the integrity of its fasteners. Restoration markets also drive demand for "OEM-correct" stampings, where enthusiasts seek exact replicas of factory straps for vehicles like the 1984 Cougar, requiring manufacturers to reverse-engineer obsolete tooling to achieve authentic aesthetics with modern durability.

Securing Quality and Performance

The manufacturing of fuel tank straps is a discipline that tolerates no shortcuts. From the selection of corrosion-resistant substrates to the implementation of innovative folding techniques that eliminate failure points, every step is calculated to ensure vehicle safety. For engineers and procurement professionals, the value lies not just in the price per part, but in the capability of the manufacturer to deliver consistent, certified quality that withstands the test of time and terrain. As the industry evolves, the integration of smart manufacturing—combining progressive stamping with automated assembly—will continue to set the standard for fluid handling security.

Frequently Asked Questions

1. Are fuel tank straps necessary for vehicle safety?

Yes, fuel tank straps are absolutely essential. They are the primary mechanism responsible for securing the fuel tank to the vehicle's chassis. Without them, the tank could shift during operation or detach completely, leading to catastrophic fuel leaks, fire hazards, and vehicle inoperability. Regular inspection for corrosion is recommended, especially in salt-belt regions.

2. How much does it cost to replace fuel tank straps?

The cost varies significantly based on the vehicle and material. For a standard passenger car, aftermarket straps can cost between $20 and $50 for a pair. However, professional installation can add $100 to $200 in labor costs. Custom or heavy-duty stainless steel straps will be more expensive due to the higher material grade and manufacturing complexity.

3. What is the difference between progressive die stamping and transfer stamping?

Progressive die stamping feeds a continuous coil of metal through a single press with multiple stations, performing all operations (cutting, bending, forming) in a sequence with each stroke. It is ideal for high-speed, high-volume production of smaller parts like straps. Transfer stamping involves moving separate blanks between different die stations, which is better suited for larger, more complex parts but is generally slower and more expensive for simple components.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —