Stamping Brake Backing Plates: Process, Precision & Specs

TL;DR

Stamping brake backing plates is the industry-standard manufacturing process for creating the steel structural foundation of brake pads, utilizing high-tonnage presses (typically 200T–500T) to cut and form coiled steel with extreme precision. While conventional stamping offers speed and cost-efficiency for mass production, fine blanking is increasingly preferred for its ability to produce smooth, fracture-free edges and tight tolerances without secondary machining. Modern specifications often require Mechanical Retention Systems (NRS)—hooks stamped directly into the plate surface—to prevent friction material delamination caused by rust jacking. This guide explores the machinery, material selection, and quality control standards defining top-tier backing plate production.

The Stamping Line: Machinery & Materials

The production of a high-quality brake backing plate begins long before the press hits the metal; it starts with the selection of the correct raw material. Manufacturers typically utilize hot-rolled steel coils, specifically grades like Q235B, which offer the necessary tensile strength to withstand the extreme shear forces generated during braking. A critical distinction in material sourcing is the preference for "Pickled & Oiled" steel over standard black steel. The pickling process removes the oxide layer (mill scale), which is essential because any residual scale can lead to coating failures and subsequent rust issues later in the component's lifecycle.

Once the material enters the stamping line, the machinery requirements are dictated by the vehicle class. According to industry data, producing backing plates for passenger cars (PC) generally requires a pneumatic precision punch press in the 200-ton range. However, for Commercial Vehicles (CV) and heavy-duty trucks, the tonnage requirements escalate significantly to 360T–500T or even higher to punch through thicker gauge steel (up to 12mm). The line setup follows a strict sequence: a decoiler feeds the steel strip into a straightener (leveller) to remove coil set, followed by a servo feeder that positions the strip under the die with micron-level accuracy.

For manufacturers seeking to scale from prototype to mass production, partnering with a facility that offers a wide range of press capabilities is vital. Shaoyi Metal Technology provides comprehensive stamping solutions with IATF 16949 certification, utilizing presses up to 600 tons to deliver critical automotive components that meet global OEM standards. Whether you need a rapid run of 50 prototypes or a continuous supply of millions of parts, their capabilities bridge the gap between engineering samples and high-volume output.

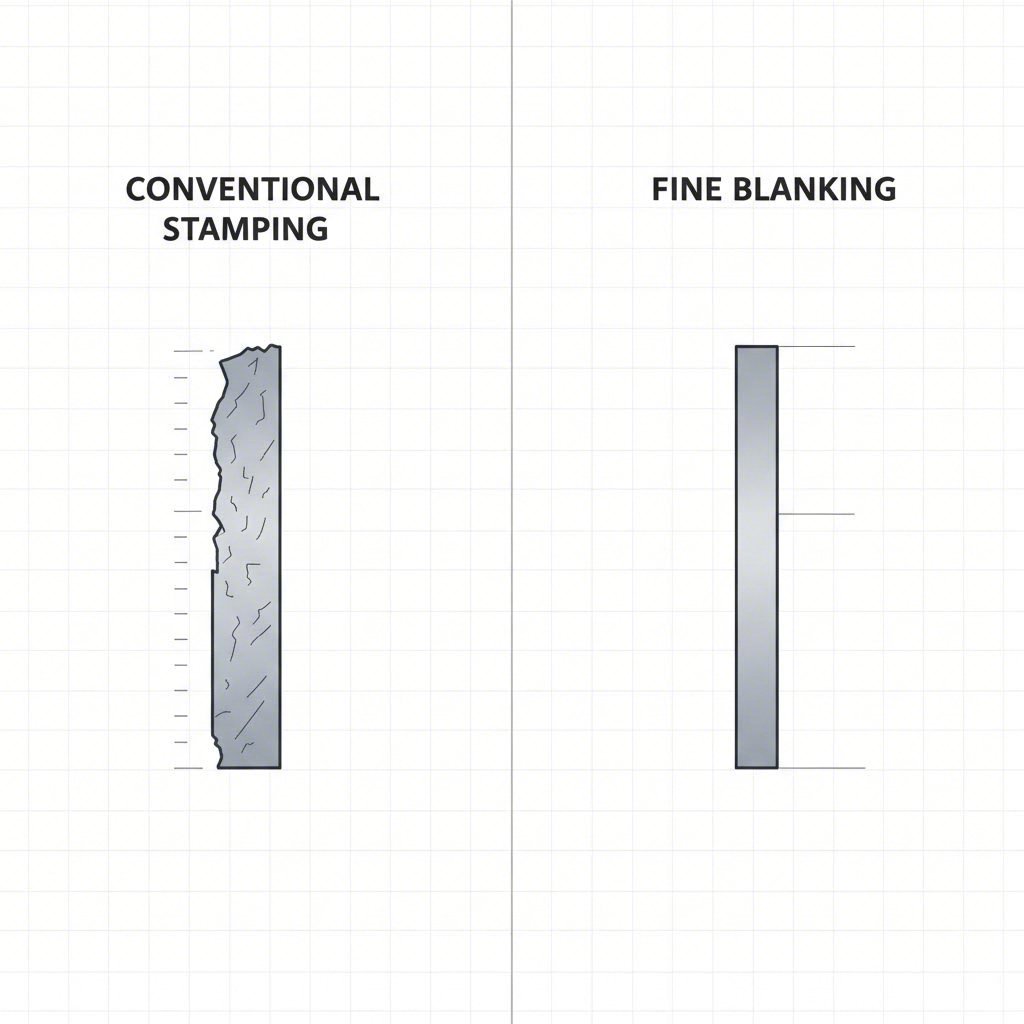

Process Showdown: Fine Blanking vs. Conventional Stamping

In the world of brake component manufacturing, the choice between conventional stamping and fine blanking defines both the cost and the quality of the final part. Conventional Stamping is a high-speed process where the punch strikes the metal, shearing about one-third of the thickness before the material fractures and breaks away. This leaves a characteristic "die roll" on the top edge and a rough "fracture zone" on the cut surface. While highly efficient for standard applications, these parts often require secondary tumbling or deburring to remove sharp edges that could damage other brake caliper components.

Fine Blanking, by contrast, utilizes a complex triple-action press. Before the punch descends, a "V-ring" impingement ring presses into the steel to lock the material in place, while a counter-punch applies upward pressure from below. This prevents the material from flowing away from the punch, resulting in a fully sheared, smooth edge with 100% clean-cut surfaces and virtually no die roll. This level of precision is critical for backing plates that double as structural guides within the caliper, where flatness and edge perpendicularity are non-negotiable.

| Feature | Conventional Stamping | Fine Blanking |

|---|---|---|

| Edge Quality | Rough fracture zone (approx. 70% of thickness) | 100% smooth, sheared edge |

| Tolerance | Standard (typically ±0.1mm) | Precision (microns, often ±0.01mm) |

| Process Speed | Very High (ideal for mass volume) | Slower (complex cycle time) |

| Secondary Steps | Often requires deburring/machining | Finished part directly from press |

| Cost | Lower tooling & piece price | Higher tooling & piece price |

Punching vs. Laser Cutting: Choosing the Right Method

While stamping (punching) is the dominant method for mass production, laser cutting plays a crucial role in the development phase. Understanding when to deploy each method is a key strategic decision for automotive suppliers. Punching is the undisputed king of volume. Once the dedicated hard tooling (die) is built, a press can produce thousands of parts per hour with perfect consistency. However, the initial investment in dies is substantial, and modifying a design requires expensive tool re-machining.

Laser Cutting offers the ultimate flexibility. It requires no physical dies—only a CAD file—making it ideal for prototyping, aftermarket short runs, or validating a design before committing to hard tooling. However, it is significantly slower. Production data indicates that a typical laser cutter might produce only 1,500–2,000 passenger car backing plates per 8-hour shift, whereas a stamping press could produce that volume in under an hour. Furthermore, laser cutting often requires oxygen as a consumable assist gas to ensure edge quality, adding a variable cost that stamping does not incur.

Decision Matrix:

- Use Laser Cutting when: You need 50–500 parts for testing, the design is not yet frozen, or you are producing low-volume aftermarket applications for vintage cars.

- Use Punching when: The design is finalized (OEM spec), volume exceeds 5,000 units, and unit cost is the primary driver.

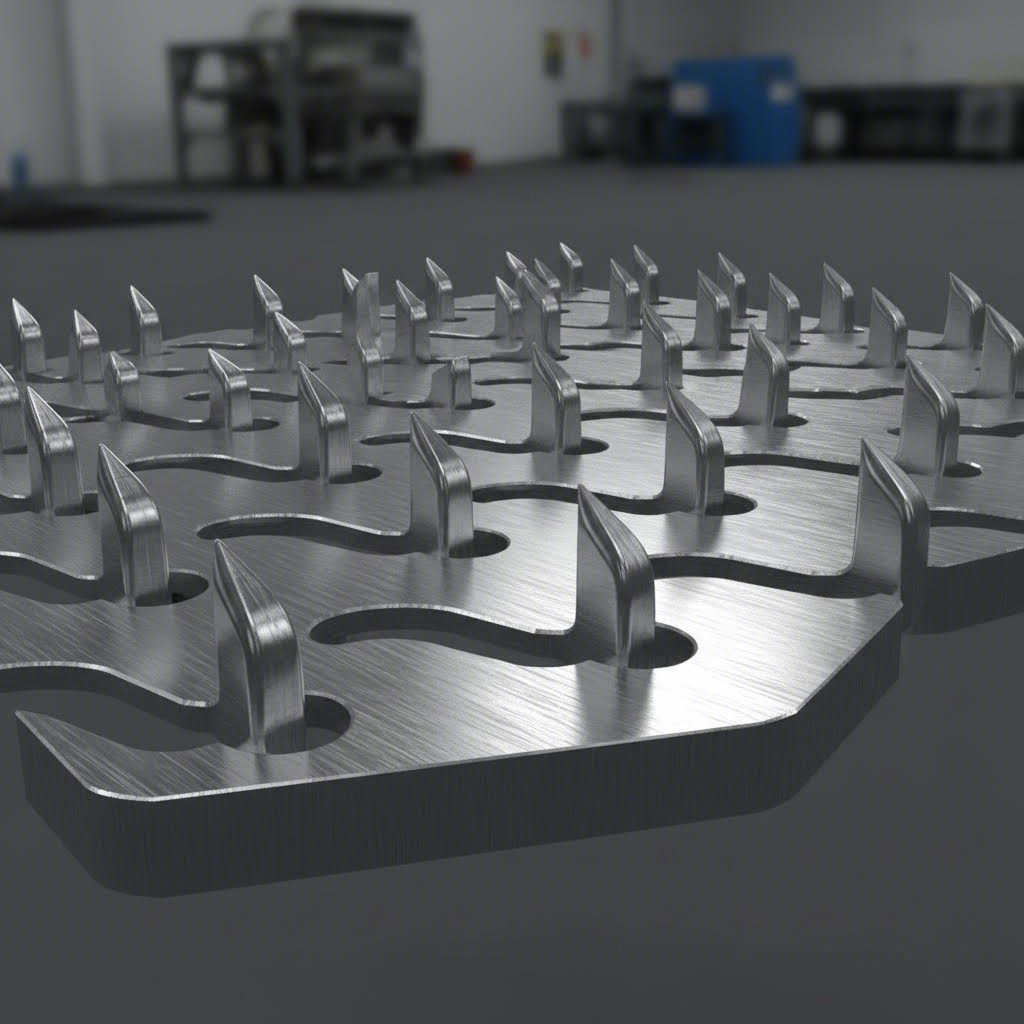

Critical Feature: Mechanical Retention Systems (NRS)

The most significant evolution in backing plate stamping is the move away from adhesive-only bonding toward Mechanical Retention Systems (NRS). In traditional manufacturing, the friction material (brake pad) is glued to the steel plate. Over time, moisture can penetrate the bond line, causing the steel to rust. This rust expands (a process known as "rust jacking"), forcing the friction material to delaminate and detach from the plate—a catastrophic safety failure.

To combat this, modern stamping dies are equipped with specialized tooling that modifies the surface of the plate. Instead of leaving it flat, the press raises hundreds of bi-directional steel hooks or patterns directly from the backing plate's surface. These hooks act like velcro made of steel, physically locking the friction material in place during the molding process. This mechanical bond ensures that even if the adhesive degrades or the plate corrodes, the friction material remains securely attached, maintaining shear strength even in harsh environments like electric vehicles (which rely less on friction braking and are prone to brake corrosion due to disuse).

Quality Control & Common Defects

The output of a stamping line must meet rigorous quality standards, with flatness being the most critical metric. A backing plate that bows or twists due to "springback" (the steel trying to return to its original coil shape) will cause uneven pad wear and noise. Manufacturers employ multi-stage levelling and flattening stations within the progressive die to counteract this. The target is often a flatness tolerance of less than 0.05mm across the entire surface.

Common stamping defects include:

- Burrs: Sharp projections on the cut edge. While minor burrs are inherent to conventional stamping, excessive burr height indicates worn punches and requires immediate tool maintenance or secondary grinding.

- Die Roll: The rounded edge on the punch side. Excessive die roll can reduce the effective contact area for the friction material bond.

- Fractures/Cracks: Often caused by using steel with poor formability or incorrect grain direction relative to the bend.

By strictly monitoring these parameters and maintaining the press line, manufacturers ensure that every backing plate provides a safe, quiet, and durable foundation for the braking system.

Conclusion

Stamping brake backing plates is a discipline that balances brute force with microscopic precision. For automotive engineers and procurement teams, the choice between conventional stamping, fine blanking, or laser cutting is not just about cost—it is about aligning the manufacturing method with the vehicle's performance requirements and safety standards. As the industry shifts toward electric mobility, the demand for tighter tolerances and mechanical retention features like NRS will only increase, making the selection of a capable manufacturing partner more critical than ever.

Frequently Asked Questions

1. What material is a brake pad backing plate made of?

Backing plates are typically manufactured from hot-rolled steel, such as Q235B or SAPH440 grades. These steels are chosen for their high tensile strength and durability. For high-performance or corrosion-prone environments, manufacturers may specify "pickled and oiled" steel to ensure a clean surface free of mill scale, which improves the bonding of the friction material.

2. What happens if a backing plate rusts through?

If a backing plate corrodes significantly, it can lead to "rust jacking," where the rust builds up under the friction material and pushes it away from the steel surface. This causes delamination, resulting in increased noise, vibration, and harshness (NVH). In severe cases, the friction material can completely detach from the plate, leading to total brake failure.

3. Why is fine blanking better than conventional stamping?

Fine blanking produces parts with superior edge quality (smooth and square) and tighter dimensional tolerances compared to conventional stamping. It eliminates the "fracture zone" and often removes the need for secondary machining steps like deburring or flattening, making it ideal for precision components that require exact fitment within the brake caliper.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —