-

Progressive Die Vs Transfer Die For Stamping: Your Selection Framework

2026/01/05Compare progressive die vs transfer die stamping with our decision framework. Learn which die type fits your part geometry, volume, and budget requirements.

-

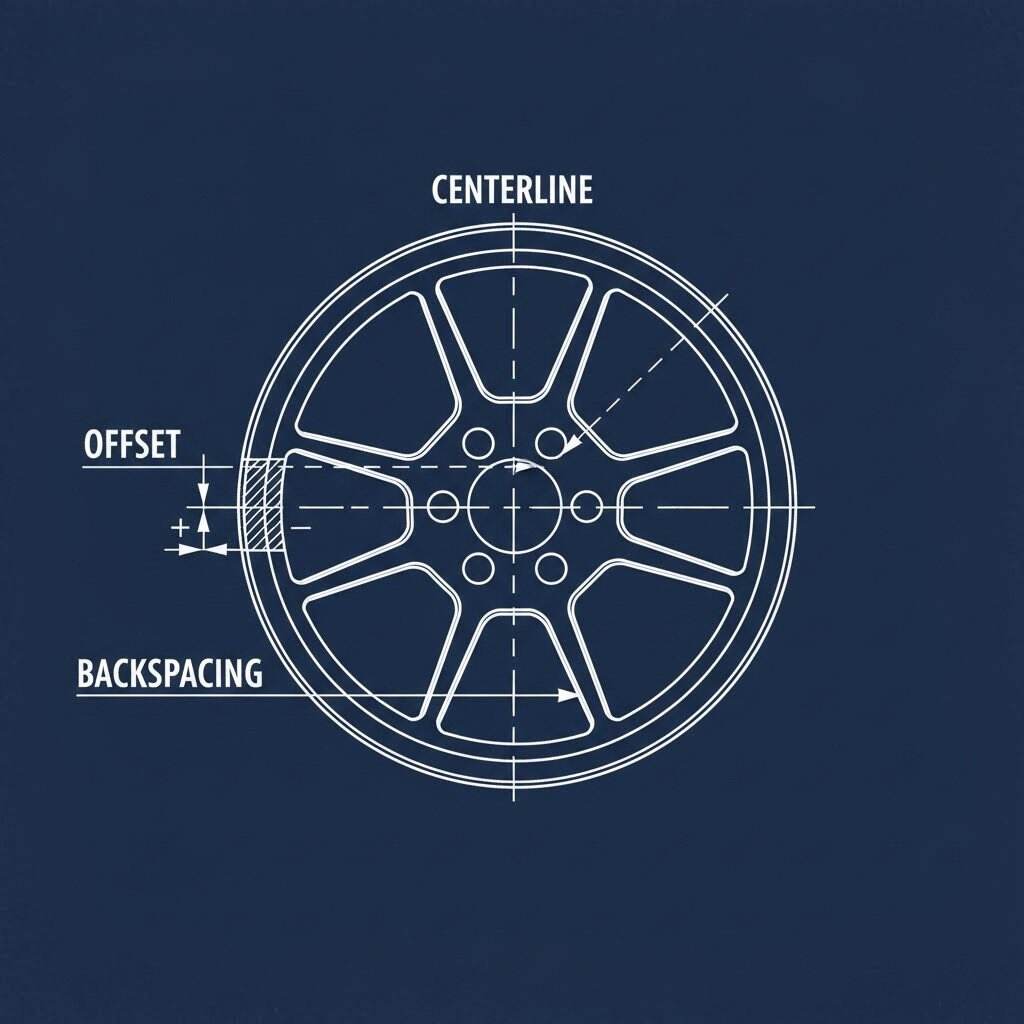

Custom Forged Wheel Fitment Guide: From Measurement To Perfect Stance

2026/01/05Master custom forged wheel fitment with this complete guide covering measurements, offset calculations, platform specs, and ordering workflows for perfect stance.

-

Carbide Inserts For Stamping Dies: Grade Selection That Stops Premature Failure

2026/01/05Learn how to select carbide inserts for stamping dies that prevent premature failure. Expert guide on grades, materials, troubleshooting, and maintenance strategies.

-

Vanadis 4 Extra Vs CPM 10V: Which Steel Matches Your Blade Style?

2026/01/05Vanadis 4 Extra vs CPM 10V: Compare toughness, edge retention, sharpening ease & best uses. Find which premium powder metallurgy steel matches your blade needs.

-

Preventing Galling In Stamping Dies: From Root Cause To Retrofit Fix precision stamping die forming metal with optimized surfaces designed to prevent galling damage

2026/01/05Learn proven strategies for preventing galling in stamping dies—from material-specific solutions and advanced coatings to lubrication methods and retrofit fixes.

-

Coating Technologies For Die Punches: Match Materials, Slash Tool Costs

2026/01/05Learn how coating technologies for die punches extend tool life 6-10x. Compare TiN, TiCN, TiAlN, CrN, and DLC coatings with material matching guides.

-

Lubricants For Automotive Stamping: Match The Right Formula To Your Metal precision lubricant application enables flawless automotive stamping operations

2026/01/05Learn how to select the right lubricants for automotive stamping. Match formulations to AHSS, aluminum, and zinc-coated steel for optimal tool life and part quality.

-

Fixed Vs Floating Stripper Plate: The Die Decision That Makes Or Breaks Your Tooling

2026/01/05Learn when to use fixed vs floating stripper plates in die design. Compare stripping force, material thickness, costs, and maintenance for optimal tooling selection.

-

Springback Compensation Methods That End Sheet Metal Guesswork Forever

2026/01/05Master springback compensation methods with this complete guide covering material-specific strategies, tooling design, simulation vs empirical approaches, and step-by-step implementation workflows.

-

Eliminating Burrs In Metal Stamping: From Hidden Costs To Clean Edges

2026/01/05Learn proven strategies for eliminating burrs in metal stamping through die design optimization, process control, and efficient removal methods to cut costs.

-

Die Roll Vs Burr Height: 5 Ranked Fixes For Edge Quality Control

2026/01/05Learn 5 ranked fixes for balancing die roll vs burr height in stamping. Get clearance guidelines, geometry tips, and maintenance protocols for edge quality.

-

Slug Pulling Causes And Fixes: Stop The Chaos Wrecking Your Dies

2026/01/05Learn what causes slug pulling in stamping operations and how to fix it. Get systematic troubleshooting methods, prevention strategies, and permanent solutions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —