Custom Laser Cutting Metal Costs Exposed: What Shops Won't Tell You

What Is Custom Laser Cutting Metal

Remember playing with a magnifying glass as a kid, focusing sunlight into a tiny, intense point? Custom laser cutting metal works on a similar principle—but amplified to an extraordinary degree. Instead of sunlight, manufacturers use highly concentrated laser beams that can reach temperatures exceeding 20,000 degrees Celsius to cut through steel, aluminum, and other metals with surgical precision.

So, what is laser cutting exactly? At its core, this process uses focused optical light energy to melt or vaporize metal along computer-programmed paths. The result? Parts fabricated to your exact specifications, whether you need one prototype or a hundred custom brackets. Unlike standard production runs that churn out identical pieces from pre-set templates, laser cutting metal gives you complete design flexibility—transforming your unique CAD file into a tangible component.

How Laser Beams Transform Raw Metal into Precision Parts

Imagine you've designed a complex mounting plate with intricate cutouts and precise hole patterns. Here's how metal laser cutting brings that design to life:

- Laser Generation: The machine produces a powerful beam using either CO2 gas mixtures or fiber optics infused with rare-earth elements

- Focusing: Mirrors and lenses concentrate the beam into an extraordinarily fine point of energy

- Material Interaction: When this focused beam contacts the metal surface, it instantly melts or vaporizes the material at the point of impact

- CNC Control: Computer Numerical Control systems guide the laser head with extreme precision, following your programmed design path

The beauty of this process lies in its made-to-order nature. You're not limited to existing templates or catalog designs. Whether you need architectural panels with decorative patterns or aerospace components with tight tolerances, laser metal cutting adapts to your requirements rather than forcing you to adapt to manufacturing limitations.

The Science Behind Thermal Cutting Technology

Why does cutting laser metal work so effectively? The answer comes down to two key scientific principles.

First, there's absorption. Different metals absorb different wavelengths of light. When the laser's photons interact with the metal's electrons, rapid heating occurs at the precise point of contact. This targeted energy transfer means the cut zone heats up almost instantaneously while surrounding material stays relatively cool.

Second, metals are excellent thermal conductors. Heat quickly dissipates away from the cut zone, preventing damage to adjacent areas. This combination—intense localized heating with rapid heat dissipation—produces those clean, precise edges that make laser cutting ideal for detailed work.

Custom laser cutting metal achieves tolerances and intricate patterns that were once thought impossible, making it the go-to solution for everything from jewelry design to aerospace components.

What truly sets custom work apart from standard production? Flexibility. Standard runs optimize for efficiency on repeated designs. Custom projects optimize for your specific needs—unique dimensions, non-standard materials, or complex geometries that off-the-shelf parts simply can't deliver. When you understand how the technology actually works, you're better equipped to design parts that leverage its strengths and avoid unnecessary costs.

CO2 Versus Fiber Laser Technology Explained

Here's something most shops won't tell you upfront: the type of laser that cuts metal significantly impacts your project's cost, quality, and turnaround time. Yet many fabricators gloss over this crucial detail when providing quotes. Understanding the difference between CO2 and fiber laser technology helps you ask the right questions—and potentially save hundreds on your next order.

Both technologies use concentrated light to cut through metal, but they generate that light in fundamentally different ways. A CO2 laser produces its beam by electrically stimulating a gas mixture (primarily carbon dioxide), while a fiber laser uses optical fibers doped with rare-earth elements like ytterbium. This distinction might sound technical, but it directly affects which metals get cut efficiently and how much you'll pay.

Fiber Laser Advantages for Reflective Metals

Ever wondered why copper laser cutting quotes sometimes come in surprisingly high? Traditional CO2 lasers struggle with reflective metals because their longer wavelength (10.6 micrometers) tends to bounce off shiny surfaces like aluminum, brass, and copper. This reflection can actually damage the laser's optics—a costly repair that shops factor into your quote.

Fiber lasers changed the game. Operating at a wavelength of 1.064 micrometers—roughly ten times shorter than CO2—they're readily absorbed by reflective metals rather than bounced back. According to industry analysis, fiber lasers can cut highly reflective materials without risk of back reflections damaging equipment, opening up possibilities for working with a broader range of materials.

What does this mean for your project? If you're working with aluminum, brass, or copper, a shop using a fiber laser cutting machine for metal will likely deliver:

- Faster cutting speeds (3 to 5 times more productive on appropriate jobs)

- Cleaner edge quality with minimal heat-affected zones

- Lower per-part costs due to reduced processing time

- Greater reliability without reflective damage concerns

Matching Laser Technology to Your Metal Type

So which is the best laser for cutting your specific material? The answer depends on what you're cutting and how thick it is.

CO2 lasers remain excellent workhorses for thicker mild steel plates—particularly in the 10-20mm range and above. Some operations even use oxygen assist to cut through steel plates up to 100mm thick. They're also the go-to choice for non-metallic materials like acrylic, wood, and leather, making them versatile machines for mixed-material shops.

Fiber lasers, however, dominate when precision and speed matter most. They excel with thin to medium-thick metal sheets (typically 20mm or less) and handle difficult-to-cut metals like titanium with ease. Their efficiency exceeds 90%—meaning they convert most electrical input into actual cutting power—compared to just 5-10% for CO2 systems.

| Factor | CO2 Laser | Fiber Laser |

|---|---|---|

| Best Metal Types | Mild steel, thicker plates | Stainless steel, aluminum, brass, copper, titanium |

| Optimal Thickness Range | 10-100mm+ (with oxygen assist) | Up to 20mm |

| Edge Quality | Good | Excellent (smoother, more precise) |

| Energy Efficiency | 5-10% | 90%+ |

| Operating Costs | Higher (more power consumption, cooling) | Lower (reduced energy, minimal maintenance) |

| Equipment Lifespan | ~2,500 hours typical | 25,000-100,000+ hours |

| Upfront Cost | Lower initial investment | 5-10x higher purchase price |

| Best Applications | Heavy plate work, mixed materials | Precision parts, reflective metals, high-volume production |

Here's the insight that affects your wallet: while fiber metal cutting laser machines cost significantly more upfront, their operational savings add up quickly. Lower energy consumption, minimal maintenance requirements, and working lives that can exceed 100,000 hours mean shops with fiber equipment often pass these savings along in competitive pricing—especially for aluminum and stainless steel projects.

When requesting quotes, don't hesitate to ask which laser technology a shop uses. A co2 laser cut metal machine might be perfect for your 15mm steel plate project, while a fiber laser cutter for metal could cut your costs substantially on that batch of aluminum brackets. Understanding this distinction puts you in a stronger position to evaluate quotes and choose the right partner for your specific needs.

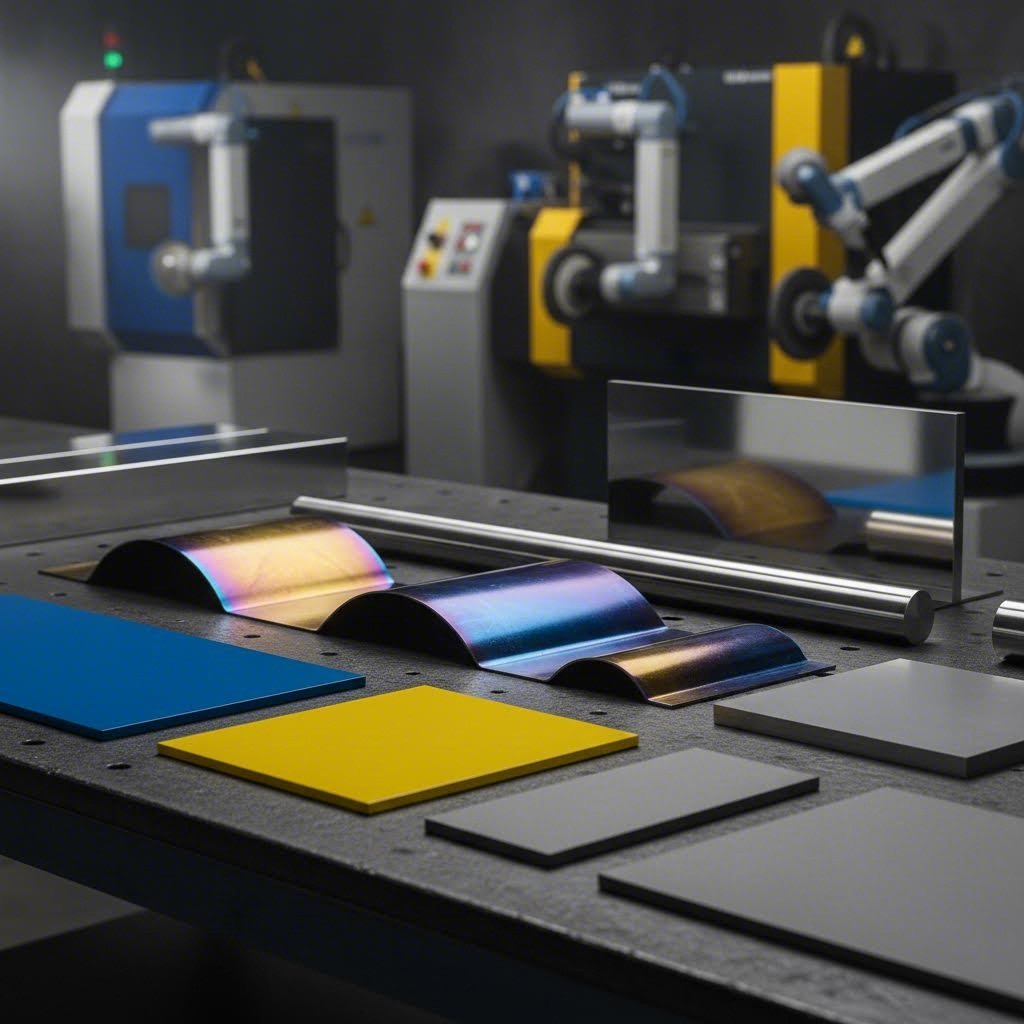

Metal Types and Material Selection for Laser Cutting

You've figured out the technology—but here's where material selection can make or break your budget. Different metals respond to laser cutting in dramatically different ways, affecting everything from edge quality to maximum thickness capabilities. Yet most shops assume you already know which metal suits your project. Let's fill that knowledge gap so you can make informed decisions before requesting quotes.

When choosing materials for custom laser cutting metal projects, you're essentially balancing five key factors: strength requirements, corrosion resistance, weight constraints, aesthetic needs, and cost. The metal you select directly influences cutting speed, edge finish, and ultimately what you'll pay. Understanding how each material behaves under the laser beam helps you optimize both performance and budget.

Steel and Stainless Steel Cutting Characteristics

Mild steel remains the workhorse of laser cutting steel applications—and for good reason. This iron-carbon alloy offers high strength and hardness at a cost-effective price point, making it ideal when corrosion and aesthetics aren't primary concerns. Steel laser cutting produces clean edges with minimal post-processing required, and shops can handle impressive thicknesses depending on their equipment.

What thickness can you realistically cut? Entry-level fiber lasers (500W-1.5kW) handle thin sheets up to 3mm efficiently. Mid-range systems (3kW-6kW) tackle most industrial jobs, while high-power equipment (10kW-40kW) cuts through heavy plates exceeding 25mm. The thicker your material, the more power required—which directly impacts your quote.

- Mild Steel Characteristics: Excellent weldability, easy to form and machine, high strength-to-cost ratio, susceptible to corrosion without finishing

- Best Applications: Construction components, automotive parts, agricultural equipment, furniture frames, machinery housings

- Thickness Range: Up to 100mm+ with oxygen assist on high-power CO2 systems; up to 25mm on standard fiber lasers

Stainless steel laser cutting demands more laser power than mild steel—but delivers exceptional results. The chromium content that gives stainless its corrosion resistance also affects how it interacts with the laser beam. However, laser cut stainless steel parts emerge with smooth finishes that often don't require additional finishing processes.

- Stainless Steel Characteristics: Superior corrosion resistance, excellent strength, good weldability, harder than mild steel, higher material cost

- Best Applications: Medical equipment, food processing components, aerospace parts, architectural features, marine applications

- Edge Quality: Clean cuts with minimal oxidation when using nitrogen assist gas

Pro tip: When requesting quotes for stainless steel, specify whether you need oxidation-free edges. Nitrogen assist cutting costs more but eliminates the discoloration that oxygen assist can cause—a detail that matters for visible components or food-grade applications.

Working with Aluminum, Brass, and Copper

Remember the reflective metal challenge we discussed earlier? This is where material selection intersects directly with technology choice. Aluminum laser cutting, brass fabrication, and copper processing all require fiber laser technology for optimal results—and understanding their unique characteristics helps you design smarter parts.

Laser cut aluminum offers an unbeatable combination of low weight, durability, and cost-effectiveness. It's roughly one-third the weight of steel while maintaining good strength, making it perfect for applications where every gram counts. Aluminium laser cutting produces clean edges, though the material's thermal conductivity can create slightly larger heat-affected zones than steel.

- Aluminum Characteristics: Lightweight (one-third steel's weight), excellent thermal and electrical conductivity, good corrosion resistance, easily anodized for enhanced protection

- Best Applications: Automotive panels, aerospace components, electronics enclosures, heat sinks, architectural elements

- Thickness Considerations: Cuts efficiently up to 20mm on fiber lasers; requires higher power settings than equivalent steel thickness

- Design Note: Aluminum's softness means intricate designs with very fine features may require careful consideration of minimum feature sizes

Copper and laser cut brass present unique opportunities—and challenges. Both metals offer excellent electrical conductivity and natural antimicrobial properties, making them essential for electrical components, decorative hardware, and specialized applications. Fiber lasers handle both materials effectively, though cutting speeds are typically slower than steel due to their high reflectivity and thermal conductivity.

- Copper Characteristics: Superior electrical conductivity, excellent corrosion resistance, antimicrobial properties, distinctive aesthetic appeal

- Brass Characteristics: Enhanced strength and ductility compared to pure copper, lower friction point, excellent for decorative applications, easily machined and soldered

- Best Applications: Electrical connectors, architectural features, musical instruments, decorative hardware, heat exchangers

- Cost Consideration: Higher material costs and slower cutting speeds mean copper and brass projects typically carry premium pricing

Sounds complex? Here's a simplified decision framework: Choose mild steel when cost and strength matter most and corrosion isn't critical. Select stainless steel for demanding environments or food-grade applications. Opt for aluminum when weight savings justify the modest price premium. Reserve copper and brass for applications requiring their unique electrical, thermal, or aesthetic properties.

Understanding these material characteristics before you contact a fabricator puts you in a stronger negotiating position. You'll know why that stainless steel quote costs more than mild steel, why your aluminum parts might need specific edge considerations, and whether copper is truly necessary—or if a less expensive alternative could work. Armed with this knowledge, you're ready to tackle the next critical step: preparing your design files correctly.

Design Guidelines and File Preparation Requirements

You've selected your metal and understand the technology—but here's where many projects hit unexpected delays. Submitting design files that don't meet fabrication requirements means back-and-forth revisions, wasted time, and sometimes costly redesigns. Yet most shops bury their design guidelines in hard-to-find documentation, leaving you to discover problems only after you've uploaded your files.

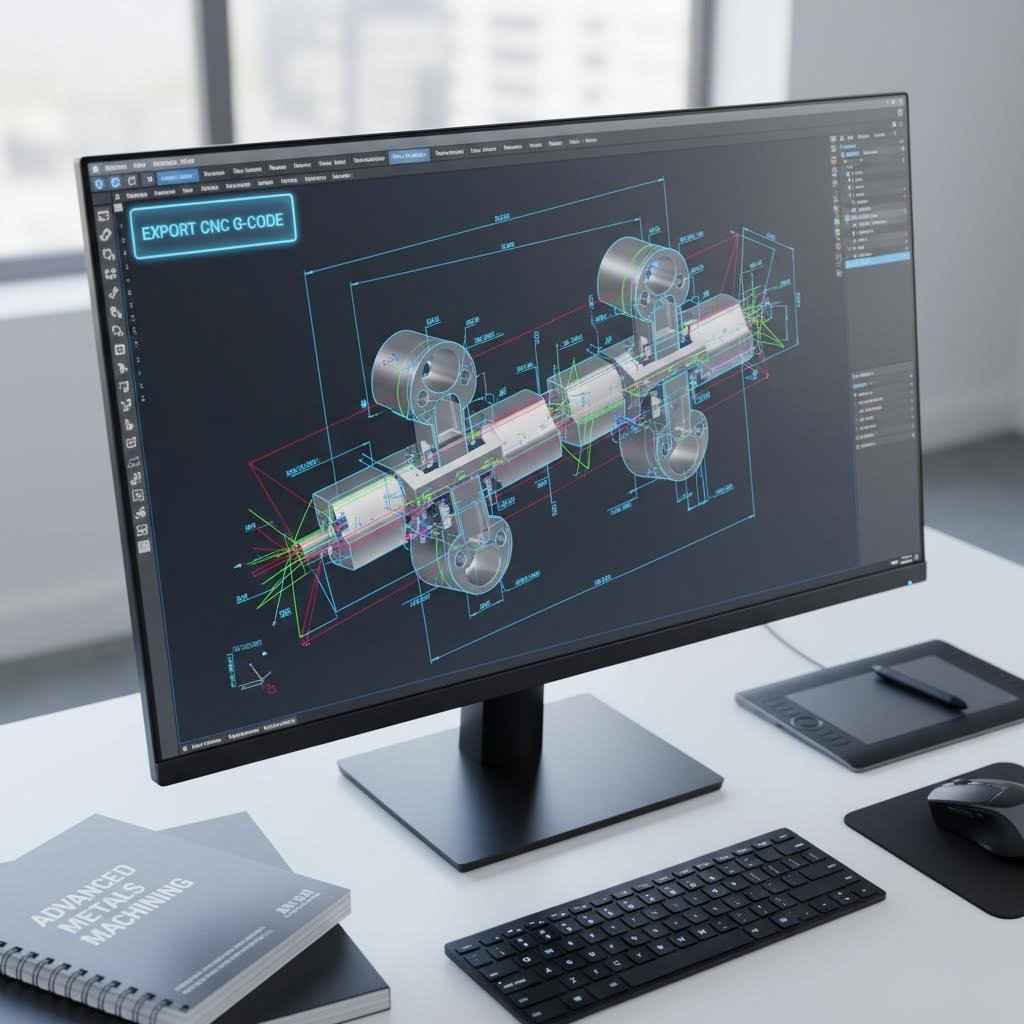

Getting your design right the first time isn't just about avoiding frustration—it directly impacts your quote. Precision laser cutting requires files that translate seamlessly into machine instructions. The better your file preparation, the faster your turnaround and the more accurate your laser cut parts will be.

File Formats and Design Software Compatibility

Which file format should you submit? This depends on your design software and the shop's capabilities, but most fabricators accept a core set of vector-based formats.

The industry standards include:

- DXF (Drawing Exchange Format): The universal language of laser and CNC equipment. Nearly every fabricator accepts DXF files, making this your safest choice for compatibility

- DWG (AutoCAD Native): Common in engineering and architectural applications. Most shops convert these to DXF internally

- AI (Adobe Illustrator): Popular for decorative and artistic projects. Ensure all text is converted to outlines before submission

- EPS and SVG: Vector formats that work well for simpler designs, though some shops prefer DXF for precision work

Here's a detail that catches many first-time customers: if you've converted your file from a raster image, verify your dimensions carefully. Tracing a JPEG or PNG into vectors can introduce scaling errors. Printing your design at 100% scale helps confirm that measurements match your intentions before submitting.

Using student software? Don't worry—"Student Version" watermarks that appear in files from programs like SolidWorks are typically ignored by fabrication systems. However, any active text boxes must be converted to shapes. In Illustrator, this means "converting to outlines." In CAD programs, look for commands like "explode" or "expand."

Critical Design Rules for Clean Cuts

Laser cutting precision depends heavily on understanding the physical constraints of the process. Even the most advanced laser cut CNC machine has limitations—and designing within these parameters ensures your parts come out exactly as intended.

Kerf Width Allowances

When a laser cuts metal, it vaporizes a thin strip of material called the kerf. This width typically ranges from 0.1mm to 0.5mm depending on material thickness, laser type, and power settings. Why does this matter? If you're designing interlocking parts or precise assemblies, you need to account for this material removal in your dimensions.

Minimum Feature Sizes

Those intricate details in your design might look perfect on screen—but features that are too small simply cannot be cut correctly. General guidelines include:

- Minimum hole diameter: Typically equal to or greater than material thickness

- Minimum slot width: Usually 1.5x material thickness

- Minimum text height: Often 3mm or larger for legibility

- Minimum web width (material between cuts): Generally matches material thickness

Corner Radius Requirements

Laser beams have physical width, meaning perfectly sharp internal corners aren't achievable. Internal corners will naturally have a small radius equal to roughly half the kerf width. For stress-critical parts, adding intentional corner radii (0.5mm-1mm) actually improves structural integrity by eliminating stress concentrations.

Spacing Between Cuts

Placing cut lines too close together causes heat buildup, potentially warping thin sections or compromising edge quality. Maintain spacing between parallel cuts at least 1.5 times your material thickness—more for heat-sensitive applications.

Tolerance Specifications

What precision levels can you realistically expect? Standard laser CNC operations typically achieve tolerances of ±0.1mm to ±0.2mm. For applications requiring tighter specs, discuss your requirements upfront—achieving ±0.05mm tolerances may require specialized processes or post-machining, affecting both cost and timeline.

File Preparation Checklist

Before submitting your design, work through this step-by-step verification process to avoid common errors that delay production:

- Convert all text to outlines or shapes—hover over text elements to confirm they're no longer editable as text

- Verify dimensions at 100% scale—print your design or use software measurement tools to confirm accuracy

- Check for duplicate or overlapping lines—these cause the laser to cut the same path twice, wasting time and potentially damaging edges

- Remove all hidden layers and construction geometry—only include elements you want cut

- Ensure all shapes are closed paths—open paths create confusion about which areas to cut versus ignore

- Verify minimum feature sizes meet material requirements—check holes, slots, and text against your chosen thickness

- Account for kerf width on precision assemblies—adjust dimensions if interlocking parts require exact fits

- Confirm retained cutouts are properly connected—interior pieces that aren't bridged to the main design will fall out and be lost

- Save in an accepted vector format—DXF provides the most universal compatibility

- Include a dimensioned reference drawing if tolerances are critical—helps fabricators understand your precision requirements

How does design complexity affect your costs? Every pierce (where the laser starts a new cut) and every direction change adds cutting time. A simple rectangle with four corners cuts faster than an ornate decorative pattern with hundreds of intricate curves. When budget matters, consider whether simplified designs could achieve your functional goals—or whether the aesthetic value justifies additional cutting time.

Following these guidelines doesn't just prevent delays—it demonstrates to fabricators that you understand the process. Shops appreciate well-prepared files, and that goodwill can translate into better communication, faster quotes, and smoother project execution. With your design files properly prepared, you're ready to evaluate how this technology stacks up against alternative cutting methods.

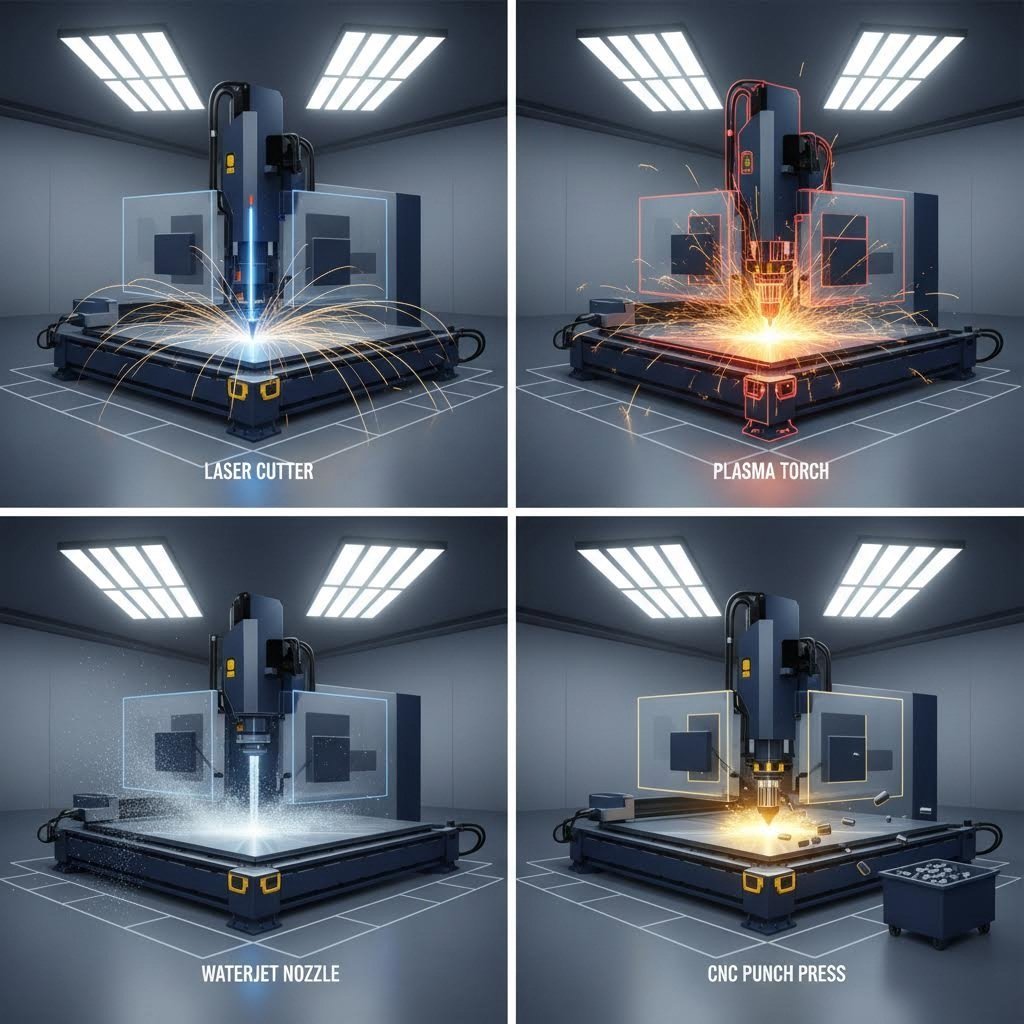

Laser Cutting Compared to Alternative Methods

So you know custom laser cutting metal delivers precision—but is it always the right choice? Here's what many fabricators won't volunteer: depending on your project requirements, alternative technologies might actually serve you better. Choosing the wrong cutting method can cost you thousands in unnecessary expenses or compromise part quality. Understanding when each technology excels puts you in control of that decision.

Four primary technologies dominate metal cutting near me searches: laser cutting, waterjet cutting, plasma cutting, and CNC punching. Each has distinct strengths, and the "best" option depends entirely on your material, thickness, precision requirements, and budget constraints. Let's break down when to choose each—and when to look elsewhere.

When Laser Cutting Outperforms Alternatives

CNC laser cutting shines brightest with thin-to-medium thickness materials requiring intricate details or tight tolerances. If your project demands clean edges, small holes, or complex geometries, laser technology typically delivers superior results.

According to industry testing across multiple technologies, laser cutting offers key advantages:

- Exceptional precision: Tolerances of ±0.1mm achievable on appropriate materials

- Superior edge quality: Clean cuts often requiring no secondary finishing

- Fast processing: High-speed cutting on materials up to 20-25mm thick

- Minimal kerf width: Less material waste compared to plasma or waterjet

- Intricate capability: Small holes, sharp corners, and detailed patterns executed with precision

Precision metal cutting applications like electronics enclosures, medical device components, and decorative architectural panels typically favor laser technology. When your parts need to fit together precisely or feature fine details, a laser for cutting steel and other metals usually delivers the best value proposition.

However, laser cutting has limitations. Very thick materials (over 25mm for most systems), heat-sensitive alloys, and non-metallic materials may require alternative approaches. Understanding these boundaries helps you avoid frustrating conversations with fabricators who can't deliver what you need.

Choosing Between Thermal and Non-Thermal Cutting

Here's a distinction that affects both part quality and material selection: laser and plasma cutting are thermal processes, while waterjet cutting uses no heat whatsoever. This fundamental difference determines which technology suits specific applications.

Plasma Cutting: The Thick Metal Specialist

When you're searching for plasma cutting near me or a plasma cutting service near me, you're typically dealing with thick conductive metals where speed and cost matter more than ultra-fine precision. Plasma cutters use an electrical arc and compressed gas to melt through steel, aluminum, and copper efficiently.

Plasma cutting dominates when working with:

- Steel plates over ½" (12mm) thick

- Structural steel fabrication projects

- Heavy equipment manufacturing

- Applications where slight edge roughness is acceptable

The cost advantage is substantial—plasma systems cost around $90,000 compared to $195,000 for comparable waterjet equipment. For metal fabrication shops focused on thick steel and aluminum, plasma often provides the best return on investment.

Waterjet Cutting: Zero Heat, Maximum Versatility

Waterjet cutting uses high-pressure water mixed with abrasive particles to cut virtually any material without heat effects. This cold-cutting process eliminates warping, hardening, and heat-affected zones entirely.

Choose waterjet when your project involves:

- Heat-sensitive materials that would warp or harden under thermal cutting

- Thick materials beyond laser capabilities (up to several inches)

- Non-metallic materials like stone, glass, or composites

- Applications requiring absolutely no thermal distortion

The waterjet market is growing quickly, projected to reach over $2.39 billion by 2034, driven by demand for heat-free cutting in aerospace, medical, and precision manufacturing applications.

CNC Punching: High-Volume Simple Shapes

For projects requiring thousands of identical parts with relatively simple geometries—think mounting holes, louvers, or basic cutouts—CNC punching often beats laser cutting on cost. Punching machines use shaped dies to stamp through sheet metal rapidly, making them ideal for high-volume production runs where setup costs can be amortized across many parts.

CNC punching excels when:

- You need very high quantities of identical parts

- Shapes match available die sets (circles, rectangles, standard patterns)

- Material thickness falls within punching range (typically up to 6mm)

- Speed and cost-per-part matter more than intricate detail capability

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | CNC Punching |

|---|---|---|---|---|

| Precision | ±0.1mm (excellent) | ±0.5-1mm (moderate) | ±0.1-0.2mm (very good) | ±0.1mm (good) |

| Material Thickness | Up to 25mm typical | Up to 150mm+ | Up to 200mm+ | Up to 6mm typical |

| Edge Quality | Excellent, minimal finishing | Rougher, may need grinding | Smooth, slight taper possible | Clean, slight rollover |

| Heat-Affected Zone | Small but present | Larger, significant | None (cold process) | None (mechanical) |

| Best For | Precision parts, thin-medium metal | Thick steel, cost-sensitive projects | Heat-sensitive materials, thick cuts | High-volume simple shapes |

| Relative Cost | Moderate | Lower for thick materials | Higher (slower process) | Lowest for high volumes |

Making Your Decision

Ask yourself these questions when choosing a cutting technology:

- How thick is your material? Under 20mm favors laser; over 25mm points toward plasma or waterjet

- How precise must cuts be? Tight tolerances favor laser or waterjet

- Is heat a concern? Heat-sensitive applications require waterjet

- What's your quantity? High volumes of simple shapes may favor CNC punching

- What's your budget? Plasma offers cost advantages for thick steel; laser provides value for precision work

Many successful fabrication shops maintain multiple technologies precisely because no single method handles every application optimally. When evaluating quotes, don't hesitate to ask whether the recommended technology truly fits your project—or whether an alternative might deliver better results. Understanding these trade-offs transforms you from a passive customer into an informed partner in the fabrication process.

Cost Factors and Pricing Variables Explained

Here's the uncomfortable truth most fabricators won't explain upfront: that laser cutting quote you received isn't arbitrary—it's calculated from a precise formula that factors in variables you probably didn't know existed. Understanding these cost drivers doesn't just satisfy curiosity; it gives you leverage to optimize your design, reduce expenses, and ask informed questions that signal you're not an easy mark for inflated pricing.

The biggest misconception? Assuming cost correlates primarily with material area. In reality, machine time is the single most important factor driving your custom cut metal expenses. A simple rectangle and an ornate decorative panel cut from identical sheets can have dramatically different price tags—sometimes by a factor of five or more.

Understanding Quote Variables and Pricing Factors

Every laser cutting quote follows a foundational calculation: Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin). Let's break down what each component means for your wallet.

Material Costs include not just the raw metal you're purchasing, but also the waste generated during cutting. When you order custom cut metals, shops must account for the full sheet price even if your parts only use 60% of the material. Efficient nesting—arranging parts strategically on the sheet—directly reduces this waste factor.

Variable Costs represent the machine time multiplied by the shop's hourly rate. According to industry data, typical laser cutter hourly rates range from $60 to $120, depending on equipment capability and power level. Your design determines how many minutes or hours that machine runs.

Fixed Costs cover operational overhead—rent, equipment maintenance, software licenses, and administrative expenses—allocated proportionally to your project.

Here are the primary cost drivers, ranked by their typical impact on your final quote:

- Material Thickness: The most significant variable. Doubling thickness can more than double cutting time because the laser must move much slower to penetrate completely

- Design Complexity: Intricate patterns with many curves and direction changes force the machine to slow down, extending processing time

- Pierce Count: Every time the laser starts a new cut, it must first pierce the material. A design with 100 small holes costs more than one large cutout due to cumulative piercing time

- Material Type and Grade: High-grade aluminum or stainless steel costs more than mild steel—both in raw material price and sometimes in processing time

- Order Quantity: Setup costs spread across more parts means lower per-piece pricing

- Finishing Requirements: Secondary operations like bending, deburring, or powder coating add labor and processing costs

How Design Complexity Affects Your Budget

Imagine two parts: a simple 6" × 6" square and an intricate decorative panel with the same outer dimensions but featuring 50 interior cutouts and ornate scrollwork. Both use identical material—yet the decorative panel might cost five times more. Why?

Cut Distance: The total linear distance the laser travels directly correlates with time. Longer paths equal higher costs. That decorative panel might require 10 feet of cutting versus 2 feet for the simple square.

Pierce Operations: Each interior cutout requires the laser to pierce through the material before cutting. A design with many pierces can be more expensive than one large cutout simply due to cumulative piercing time—even if total cut distance is similar.

Speed Variations: Complex geometries with tight curves and sharp corners force the cutting head to decelerate and accelerate constantly. A straight line cuts faster than a series of intricate curves because the machine maintains higher average speeds on simple paths.

Tolerance Requirements: Specifying tighter tolerances than functionally necessary is a hidden cost driver. To hold very precise dimensions, machines must run at slower, more controlled speeds. Before requesting ±0.05mm tolerances, ask yourself whether ±0.2mm would actually work for your application.

Quantity and Economy of Scale

Setup fees represent one-time costs—loading material, calibrating the machine, preparing your file—that get absorbed differently depending on order size. Order 10 parts, and that $50 setup fee adds $5 per piece. Order 100 parts, and it's only $0.50 each.

According to industry analysis, quantity discounts can reach as high as 70% for high-volume orders. The machine doesn't need to reset between identical parts, and material nesting becomes more efficient with larger quantities. If you anticipate needing parts in the future, consolidating orders often makes financial sense.

Additional Cost Factors

Beyond the core variables, several factors can push your quote higher:

- Expedited Production: Rush orders require shops to reorganize schedules and may demand overtime labor—expect premium pricing

- File Preparation: Submitting files with errors (duplicate lines, open contours, missing dimensions) means technicians must fix problems before cutting, often for additional fees

- Special Materials: Requesting metal cut to size from specialty alloys the shop doesn't stock may incur material ordering surcharges

- Shipping and Logistics: Heavy or fragile parts require special handling and packaging

Practical Budget Estimation

While exact laser cutting charges vary by provider, you can develop reasonable estimates by considering these relationships: Simple designs in thin mild steel represent your baseline cost. Each added complexity factor—thicker material, intricate patterns, reflective metals, tight tolerances—multiplies that baseline. Requesting quotes from multiple providers helps calibrate your expectations for specific project types.

The smartest approach? Before finalizing designs, ask potential fabricators which modifications would most significantly reduce your costs. Sometimes minor design adjustments—adding corner radii, consolidating small holes into slots, or accepting slightly looser tolerances—can reduce quotes by 20-30% without compromising functionality. Armed with this cost knowledge, you're prepared to understand how these precision-cut parts translate into real-world applications across industries.

Common Applications Across Industries

Now that you understand the costs—where exactly does all this precision cutting actually get used? Here's what might surprise you: custom laser cutting metal spans virtually every industry you can imagine. From the car you drive to the phone in your pocket, laser-cut components are hiding in plain sight. Understanding these applications helps you determine whether this technology fits your specific project needs—and gives you context for why certain industries dominate the fabrication landscape.

According to industry analysis, custom metal laser cutting delivers precision, speed, and versatility that meet the demands of today's most innovative sectors. Let's explore where laser cut metal actually ends up—and what that means for your project.

Automotive and Industrial Component Applications

When you open your car's hood, you're looking at dozens of laser-cut components. The automotive sector relies heavily on industrial laser cutting for everything from chassis brackets to fuel system parts. Why? Because precision matters when components must fit together flawlessly under extreme conditions.

Automotive Applications:

- Chassis Components: Structural panels, reinforcement brackets, and frame elements cut to exact specifications

- Exhaust Assemblies: Heat shields, manifold components, and custom exhaust tips requiring precise fitment

- Electric Vehicle Parts: Battery enclosures, motor mounts, and cooling system components

- Interior Elements: Dashboard brackets, seat frames, and trim mounting plates

- Suspension Parts: Control arm components, mounting brackets, and custom performance upgrades

In the automotive sector, custom metal laser cutting allows manufacturers to scale production while maintaining consistent quality, reducing waste, and improving efficiency. This makes it ideal for both mass production and aftermarket custom parts.

Industrial Equipment and Machinery:

Heavy machinery and industrial equipment require robust, accurate parts that perform reliably under demanding conditions. Laser fabrication enables manufacturers to produce:

- Gears and Fittings: Precision components for power transmission systems

- Machine Housings: Enclosures and guards protecting internal mechanisms

- Mounting Plates: Structural elements positioning motors, sensors, and control systems

- Conveyor Components: Brackets, guides, and support structures for material handling

- Agricultural Equipment: Durable parts for tractors, harvesters, and irrigation systems exposed to harsh conditions

The repeatability of laser cut metal sheets ensures that replacement parts match originals exactly—critical when equipment downtime costs thousands per hour.

Architectural, Signage, and Decorative Projects

Ever walked past a building featuring intricate metal facade panels or stunning decorative railings? Chances are, those elements came from a laser sheet metal cutter. Architects and designers increasingly turn to laser cutting for projects where aesthetics and precision intersect.

Architectural and Construction:

- Decorative Metal Panels: Facade elements featuring geometric patterns, organic designs, or custom artwork

- Structural Components: Steel brackets, connectors, and custom fixtures meeting exact specifications

- Railings and Gates: Ornate balustrades and security elements combining function with visual appeal

- Lighting Fixtures: Custom lampshades, pendant housings, and diffuser panels

- Room Dividers: Perforated screens and privacy panels with intricate cutout patterns

Laser cutting delivers clean, sharp lines that bring innovative designs to life, whether for aesthetic or functional purposes. This capability has transformed what's possible in modern architecture.

Signage and Branding:

Walk through any commercial district and you'll see laser cutter sheet metal work everywhere—from bold storefront signage to subtle wayfinding systems. Laser cutting and engraving capabilities enable:

- Channel Letter Faces: Precisely cut aluminum and stainless steel for illuminated signs

- Dimensional Logos: Brand marks with clean edges that catch light and shadow

- Wayfinding Systems: Directional signage for hospitals, airports, and commercial complexes

- Memorial Plaques: Detailed text and imagery for commemorative installations

- Trade Show Displays: Portable promotional elements demanding visual impact

Art and Creative Applications:

Artists and designers leverage laser cut sheet metal to create pieces that would be impossible—or prohibitively time-consuming—using traditional fabrication methods. From gallery sculptures to custom jewelry, the technology opens creative possibilities:

- Metal Sculptures: Large-scale art installations with intricate negative spaces

- Jewelry Components: Detailed patterns in gold, silver, and brass

- Home Decor: Wall art, candle holders, and decorative objects

- Musical Instruments: Custom components and decorative elements

Electronics, Technology, and Prototype Development

As electronics get smaller and more intricate, manufacturers depend on laser cutting to achieve the tight tolerances required. This sector represents one of the fastest-growing applications for precision laser fabrication.

Electronics and Technology:

- Heat Sinks: Precisely cut aluminum fins maximizing thermal dissipation

- Mounting Plates: Circuit board supports and component positioning elements

- Enclosures: Protective housings for sensitive electronics requiring exact ventilation patterns

- Shielding Components: EMI/RFI shields blocking electromagnetic interference

- Telecommunications Infrastructure: Components for 5G infrastructure requiring precision and durability

The non-contact cutting method ensures delicate components remain undamaged during manufacturing—critical when working with thin materials and tight tolerances.

Prototype Development and Rapid Iteration:

Perhaps nowhere does laser cutting deliver more value than in prototype development. Imagine needing to test five different bracket designs before committing to production tooling. Traditional fabrication methods might require weeks and thousands of dollars per iteration. With laser cutting, you can:

- Test Multiple Designs Simultaneously: Cut five variations in a single production run

- Iterate Rapidly: Receive parts in days rather than weeks, evaluate performance, and refine designs

- Minimize Tooling Costs: No dies or molds required—just update your CAD file

- Scale Seamlessly: Move from prototype to production using the same technology

- Reduce Development Risk: Validate designs with physical parts before committing resources

This rapid iteration capability has transformed product development cycles across industries. Engineers can validate fit, form, and function with real metal parts—not just 3D models—before investing in mass production infrastructure.

Additional Industry Applications:

- Aerospace: Lightweight brackets, structural panels, and housings from aluminum and titanium

- Medical Devices: Surgical instruments, implant components, and diagnostic equipment parts

- Renewable Energy: Solar panel frames, wind turbine brackets, and battery system enclosures

- Defense: Vehicle components, communication systems, and protective equipment

- Food and Beverage: Stainless steel processing equipment and packaging machinery components

Does your project fit these categories? If you're working on anything requiring precise metal components—whether functional brackets or decorative panels—laser cutting likely offers advantages over alternative methods. The key is matching the technology's strengths to your specific requirements. With applications spanning from artistic expression to critical safety components, understanding where your project fits helps you communicate effectively with fabricators and set appropriate expectations for quality, timeline, and cost.

Post-Processing and Finishing Options

You've got your laser-cut parts in hand—now what? Here's something fabricators rarely explain upfront: the cutting process is often just the beginning. Depending on your application, those freshly cut components may need secondary operations, surface treatments, or protective coatings before they're truly finished. Understanding these post-processing options helps you specify complete requirements from the start, avoiding delays and surprise costs down the line.

The relationship between sheet metal laser cutting quality and finishing requirements is straightforward: better edge quality from the laser means less prep work before finishing. However, even the cleanest laser-cut edges may need attention depending on your application. Let's explore what happens after the laser sheet metal cutter completes its work.

Secondary Operations and Metal Forming

Flat parts are just the starting point for many projects. Sheet metal laser cutting and bending often go hand-in-hand, transforming two-dimensional cutouts into three-dimensional assemblies. Understanding these secondary operations helps you plan complete manufacturing sequences.

Bending and Forming

Most custom cut sheet metal projects require some degree of forming. Press brakes fold flat sheets into angles, channels, and complex geometries. When designing for bending, remember that the laser-cut flat pattern must account for material stretching at bend lines—a consideration called bend allowance. Experienced fabricators can advise on optimal bend radii and sequences.

Welding and Assembly

Multiple laser-cut components often join together through welding. The clean edges produced by laser cutting of metal sheets typically weld beautifully, with minimal preparation required. However, if your parts will be welded, consider how weld zones affect overall dimensions and whether post-weld grinding is acceptable.

Deburring and Edge Finishing

Even high-quality laser cuts can leave minor imperfections. According to industry specialists, deburring removes scratches, burr, and minor imperfections leftover from the manufacturing process, preparing parts for later painting or anodizing. Common deburring methods include:

- Linear Deburring: Brushing one side to smooth scratches and remove dross—often offered free by quality fabricators

- Tumbling: Vibratory finishing for smaller parts, producing consistent edge treatment across all surfaces

- Manual Deburring: Hand finishing for parts requiring specific attention or those too large for automated processes

Keep in mind that while deburring and tumbling smooth out sharp edges, they will not make your part look perfect. For a truly finished appearance, you'll want additional surface treatments.

Surface Finishing and Protective Coatings

Surface finishes do more than improve appearance—they can dramatically enhance material properties. Metal finishes improve corrosion resistance, abrasion resistance, surface hardness, conductivity, and more. Choosing the right finish depends on your application's environmental exposure, aesthetic requirements, and budget.

Here are the primary finishing options for laser cutter sheet metal parts:

- Powder Coating: Applied electrostatically and oven-cured, powder coating lasts up to 10x longer than paint and contains no volatile organic compounds. Available in various colors and textures including matte, gloss, and wrinkle finishes

- Anodizing: Creates a durable, scratch-resistant oxide layer on aluminum through an electrochemical process. Provides excellent corrosion, heat, and electrical resistance—ideal for outdoor or electrical applications

- Plating: Deposits metal coatings like zinc or nickel onto base materials. Zinc plating enhances corrosion resistance on steel, while nickel plating improves conductivity and appearance on copper and steel

- Painting: Traditional wet application suitable for many projects. Proper surface preparation—abrasion and cleaning—ensures paint adhesion and longevity

- Passivation: Chemical treatment improving corrosion resistance on stainless steel without changing appearance

- Media Blasting: High-pressure abrasive treatment that cleans, smooths, or roughens surfaces in preparation for other finishes

Specifying Finishing Requirements

When ordering custom laser cut parts, clearly communicate your finishing needs upfront. Specify:

- Required finish type and color (if applicable)

- Which surfaces need treatment (all sides, one side only, specific areas)

- Performance requirements (outdoor exposure, food contact, electrical isolation)

- Dimensional tolerance after finishing (coatings add thickness)

Working with manufacturers offering comprehensive capabilities—from laser cutting through forming, finishing, and assembly—streamlines the journey from design to finished product. Integrated partners providing DFM (Design for Manufacturability) support can identify potential issues early, while rapid prototyping capabilities let you validate finished parts before committing to production volumes. For demanding applications like automotive components, look for partners with certifications like IATF 16949 that demonstrate quality system maturity. Companies like Shaoyi (Ningbo) Metal Technology exemplify this integrated approach, offering everything from 5-day rapid prototyping to automated mass production with comprehensive finishing options.

The bottom line? Don't treat finishing as an afterthought. Factor these requirements into your initial specifications, and you'll avoid costly rework while ensuring your parts perform exactly as intended in their final application. With finishing options understood, you're ready to evaluate potential fabrication partners and make informed decisions about who should manufacture your custom components.

Choosing the Right Custom Laser Cutting Partner

You've mastered the technology, understand costs, and know what finishing you need—but here's where many projects succeed or fail: selecting the right fabrication partner. The difference between a smooth project and a frustrating experience often comes down to asking the right questions before you commit. Yet most customers focus solely on price, overlooking factors that ultimately determine whether parts arrive on time, meet specifications, and perform as intended.

Finding quality laser cutting services near me requires more than a quick online search. The best metal laser cutting service providers distinguish themselves through capabilities, communication, certifications, and turnaround reliability—factors that become obvious only after you know what to look for.

Key Questions Before Starting Your Project

Before contacting fabricators, answer these fundamental questions about your own requirements. Your responses determine which providers can actually serve your needs—and which will waste your time.

What precision do you actually need?

This might sound obvious, but many customers over-specify tolerances, driving up costs unnecessarily. Ask yourself: Will ±0.2mm work, or does your application genuinely require ±0.1mm or tighter? Precision laser cutting services capable of ultra-tight tolerances exist, but they charge accordingly. Match your tolerance specifications to functional requirements—not aspirational ideals.

What quantity are you ordering?

Single prototypes require different capabilities than 10,000-piece production runs. Some laser cut services specialize in low-volume custom work with quick turnarounds; others optimize for high-volume efficiency. A shop perfectly suited for your 50-piece order might be the wrong choice for ongoing production needs.

What material and thickness?

Not every shop handles every material equally well. If you're working with reflective metals like copper or aluminum, confirm the provider uses fiber laser technology. For thick steel plates, verify their equipment capacity. According to industry guidance, most metal laser cutting service providers detail their material thickness specifications and acceptable sheet metal types on their websites—check before reaching out.

What's your timeline?

Standard lead times vary dramatically between providers. Some CNC laser cutting services deliver in 3-5 business days; others require 2-3 weeks. If you need rush delivery, confirm availability and understand the premium costs upfront. Planning ahead almost always saves money.

Do you need secondary operations?

If your parts require bending, welding, powder coating, or assembly, a full-service provider saves coordination headaches. Shops offering only cutting may deliver faster on simple jobs but create logistical complexity for complete assemblies.

Evaluating Service Provider Capabilities

Once you've clarified your requirements, systematically evaluate potential partners. Don't just accept the lowest quote—the cheapest option rarely delivers the best value when delays, quality issues, or communication failures enter the equation.

Use this evaluation checklist when assessing metal laser cutting services:

- Verify Equipment Capabilities: Ask what laser technology they use (CO2, fiber, or both) and confirm their machines can handle your material type and thickness requirements

- Check Quality Certifications: For demanding applications, certifications matter. IATF 16949 certification indicates automotive-grade quality management systems—a strong indicator of process discipline even for non-automotive projects

- Request References or Testimonials: Established providers should readily share client feedback. Ask for testimonials from other clients and inquire about the shop's experience with projects similar to yours

- Evaluate Communication Responsiveness: How quickly do they respond to inquiries? A provider that takes days to answer pre-sale questions will likely frustrate you during production

- Confirm Quote Turnaround Time: Professional operations provide quotes within 12-48 hours for standard projects. Extended delays may indicate capacity constraints or organizational inefficiency

- Understand Their File Review Process: Quality providers review your design files for manufacturability before cutting—catching potential issues early rather than after problems emerge

- Clarify Inspection Criteria: What quality checks occur before shipping? Professional services should articulate their inspection processes and tolerance verification methods

- Assess Additional Service Capabilities: Tube laser cutting services, bending, finishing, and assembly under one roof simplifies your supply chain and reduces coordination complexity

When Does Laser Cutting Make Sense—And When Doesn't It?

Laser cutting excels for:

- Precision parts with tight tolerances and intricate details

- Thin to medium-thickness materials (typically under 25mm)

- Prototype development requiring rapid iteration

- Low to medium production volumes with design flexibility needs

- Parts requiring clean edges with minimal post-processing

Consider alternatives when:

- Material thickness exceeds laser capabilities (plasma or waterjet may work better)

- Heat-affected zones are unacceptable (waterjet eliminates thermal effects)

- Extremely high volumes of simple shapes justify CNC punching economics

- Budget constraints on thick steel make plasma's cost advantage decisive

Quality Standards You Should Expect

Professional laser cutting service near me searches should yield providers meeting baseline quality standards:

- Dimensional Accuracy: Cuts within specified tolerances, verified through measurement

- Edge Quality: Clean cuts without excessive dross, burrs, or oxidation

- Material Traceability: Documentation confirming material grades match specifications

- Inspection Reports: Available upon request for critical applications

- Packaging Standards: Parts protected against damage during shipping

For automotive, aerospace, or medical applications, certification becomes non-negotiable. IATF 16949 certification—the automotive industry's quality management standard—demonstrates that a manufacturer maintains rigorous process controls, documented procedures, and continuous improvement practices. Providers like Shaoyi (Ningbo) Metal Technology exemplify this standard, combining IATF 16949-certified quality systems with practical advantages like 12-hour quote turnarounds and comprehensive DFM support that helps optimize designs before cutting begins.

Making Your Final Decision

The right partner balances capability, quality, communication, and cost. A slightly higher quote from a responsive provider with proven quality systems often delivers better total value than the lowest bidder who struggles with communication or consistency.

Request quotes from 2-3 qualified providers, compare not just prices but turnaround times and included services. Ask clarifying questions—professional fabricators appreciate informed customers and will respect your diligence. With the right partner selected, your custom laser cutting metal project moves from concept to reality with confidence, backed by the technology understanding and decision-making framework you've now developed.

Frequently Asked Questions About Custom Laser Cutting Metal

1. What materials can be laser cut?

Custom laser cutting handles a wide range of metals including mild steel, stainless steel, aluminum, brass, copper, and titanium. Fiber lasers excel with reflective metals like aluminum and copper, while CO2 lasers work well for thicker mild steel. Material thickness capabilities range from thin sheets up to 25mm for fiber lasers and over 100mm for high-power CO2 systems with oxygen assist. Non-metallic materials like acrylic and wood can also be processed on CO2 laser systems.

2. How much does custom laser cutting cost?

Laser cutting costs depend on several factors: material type and thickness, design complexity, pierce count, quantity ordered, and finishing requirements. Machine time is the primary cost driver, with hourly rates typically ranging from $60 to $120. Simple designs in thin mild steel represent baseline costs, while intricate patterns, thicker materials, and reflective metals increase pricing. Quantity discounts can reach up to 70% for high-volume orders as setup costs spread across more parts.

3. What is the difference between fiber laser and CO2 laser cutting?

Fiber lasers operate at a shorter wavelength (1.064 micrometers) making them ideal for reflective metals like aluminum, brass, and copper. They offer higher energy efficiency (90%+ vs 5-10% for CO2), faster cutting speeds on thin materials, and equipment lifespans exceeding 100,000 hours. CO2 lasers excel with thicker mild steel plates (10-100mm+) and handle non-metallic materials. Fiber lasers typically cost more upfront but deliver lower operating costs over time.

4. What file format is needed for laser cutting?

DXF (Drawing Exchange Format) is the universal standard accepted by nearly all fabricators. Other accepted formats include DWG, AI (Adobe Illustrator), EPS, and SVG. Before submitting, convert all text to outlines, remove duplicate or overlapping lines, ensure shapes are closed paths, and verify dimensions at 100% scale. Proper file preparation prevents delays and ensures accurate laser cut parts.

5. How do I choose a laser cutting service provider?

Evaluate providers based on equipment capabilities (CO2 vs fiber lasers), quality certifications like IATF 16949 for demanding applications, communication responsiveness, and quote turnaround time. Professional services should review files for manufacturability, articulate inspection processes, and offer references from similar projects. Consider whether you need secondary services like bending, finishing, or assembly under one roof to simplify your supply chain.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —