Metal Cutting Services Decoded: From Raw Steel To Precision Parts

Understanding Metal Cutting Services and Their Industrial Role

Ever wondered how a massive steel beam transforms into perfectly sized components for a skyscraper? Or how intricate aerospace parts emerge from solid aluminum blocks? The answer lies in metal cutting services—a cornerstone of modern manufacturing that bridges the gap between raw materials and finished products.

At its core, metal cutting is a manufacturing process where larger pieces of material are separated into smaller, precisely shaped parts. These operations utilize various mechanical and thermal methods to transform stock metal into usable components. From towering construction projects in metal fabrication New York operations to delicate prototype work, these services power virtually every industry that relies on metal components.

What Metal Cutting Services Actually Deliver

When you engage professional cutting providers, you're accessing more than just equipment. You're tapping into expertise that turns your design concepts into tangible parts. These services typically encompass:

- Material separation: Dividing larger stock into manageable sections using sawing, laser, plasma, or waterjet technologies

- Precision shaping: Creating complex geometries and exact dimensions from flat sheets or solid bars

- Volume flexibility: Handling everything from single prototype pieces to high-volume production runs

- Material expertise: Working with diverse metals including aluminum, stainless steel, brass, copper, and specialty alloys

Whether you're exploring metal cutting NYC options for a local project or sourcing laser cutting New York specialists for architectural metalwork, providers deliver these capabilities through specialized equipment and trained technicians.

Why Precision Cutting Matters for Your Project

Imagine ordering components that don't fit together during assembly. Or parts that require extensive rework before they're usable. Precision isn't just a nice-to-have—it's the difference between project success and costly delays.

The right cutting method depends on several interconnected factors:

- Material type: Different metals respond differently to thermal versus mechanical cutting

- Thickness requirements: Some methods excel with thin sheets while others handle thick plates

- Tolerance specifications: Tighter tolerances typically require more advanced cutting technologies

- Project scale: Prototype quantities demand different approaches than mass production

Throughout this guide, you'll discover how to navigate these decisions confidently. Consider this your comprehensive buyer's resource—designed to educate rather than sell, helping you make informed choices about your next fabrication project.

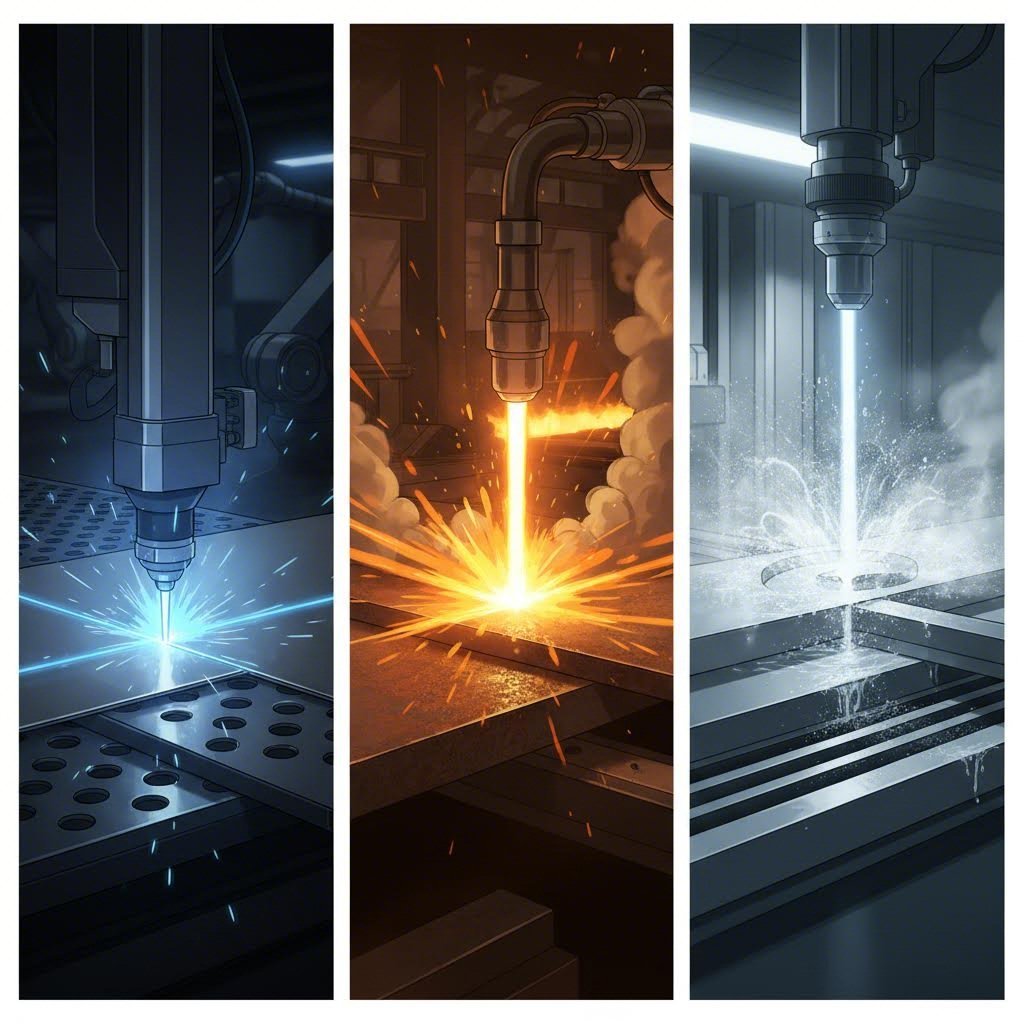

Comparing Laser Cutting Plasma and Waterjet Methods

So you've got a project requiring precision metal parts—but which cutting technology should you choose? Picking the wrong method can cost thousands in wasted material, extended timelines, and subpar results. Let's break down today's primary cutting technologies so you can match the right solution to your specific needs.

Laser Cutting Technology Explained

When precision matters most, laser cutting often takes center stage. This technology uses an intense, focused beam of light—either CO2 or fiber laser—to cut through metal with surgical accuracy. The concentrated energy melts or vaporizes material along a narrow path, creating exceptionally clean edges.

What makes laser cutting stand out? According to industry specifications from Hypertherm, laser systems can hold cut part dimensional tolerances under 0.01" (0.25 mm). For context, that's about the thickness of a standard business card—remarkable precision that eliminates most post-processing needs.

Laser cutting NYC providers and laser cutting Brooklyn shops frequently serve industries where this precision level isn't optional. Electronics manufacturers, medical device companies, and precision parts producers rely on laser technology for:

- Intricate patterns and complex geometries

- Small holes and fine details

- Thin materials requiring clean, burr-free edges

- High-volume production with consistent quality

However, lasers do have limitations. They struggle with extremely thick materials and reflective metals like copper and brass can present challenges. When your project involves thick steel plates or non-metallic materials, other technologies may serve you better.

Mechanical Sawing and Plasma Alternatives

Sounds complex? Let's simplify. Beyond laser technology, three other cutting methods dominate the market—each with distinct strengths.

Plasma cutting uses an electrical arc combined with compressed gas to melt and blast through conductive metals. If you're working with steel plates over half an inch thick, plasma delivers the best balance of speed and cost efficiency. According to testing conducted by Wurth Machinery, plasma systems cut 1-inch steel approximately 3-4 times faster than waterjet, with operating costs roughly half as much per foot. X-Definition plasma systems can achieve tolerances around 0.02" (0.5 mm)—less precise than laser but perfectly acceptable for structural applications headed to welding bays.

Waterjet cutting takes a completely different approach, using high-pressure water mixed with abrasive particles to slice through virtually any material. No heat means no warping, no hardening, and no heat-affected zones. The waterjet market is projected to exceed $2.39 billion by 2034, reflecting growing demand for this versatile technology. When cutting heat-sensitive alloys, composites, stone, or glass, waterjet is often the only viable option.

Mechanical sawing includes two primary categories that fabrication shops commonly use:

- Cold saws: These deliver cleaner, more precise cuts using resharpenable blades that can be sharpened 30-40 times before replacement. The cutting process transfers heat to chips rather than the workpiece, keeping materials cool and preventing distortion. Cold saws excel at smaller-capacity jobs requiring smooth, burr-free edges.

- Band saws: These feature a continuous rotating blade ideal for cutting large or stacked workpieces. While they sacrifice some precision—often leaving burrs on cut edges—band saws handle high-volume cutting efficiently across various materials. Their straightforward operation requires minimal expertise compared to other methods.

Whether you're searching for a laser cutter NYC specialist or evaluating mechanical sawing options, understanding these trade-offs helps you communicate effectively with providers.

Quick Comparison: Cutting Methods at a Glance

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Sawing |

|---|---|---|---|---|

| Precision Tolerance | Under 0.01" (0.25 mm) | ~0.02" (0.5 mm) | 0.003" - 0.005" (0.08 - 0.13 mm) | Varies; cold saws more precise than band saws |

| Material Compatibility | Most metals; challenges with highly reflective materials | Conductive metals only (steel, aluminum, copper) | Virtually any material including non-metals | Ferrous and non-ferrous metals |

| Thickness Capacity | Best for thin to medium sheets | Excellent for thick plates (1"+ steel) | Up to 12" in some materials | Varies by equipment; band saws handle larger stock |

| Edge Quality | Exceptionally clean; minimal finishing needed | Good; may require light deburring | Smooth; no heat-affected zone | Cold saws: clean; Band saws: often require deburring |

| Cutting Speed | Fast on thin materials | Very fast on thick conductive metals | Slower than plasma and laser | Cold saws faster; band saws slower but versatile |

| Typical Applications | Electronics, medical devices, precision parts | Structural steel, heavy equipment, shipbuilding | Aerospace, stone/glass, heat-sensitive materials | General fabrication, bar stock, structural sections |

Choosing Based on Your Project Requirements

When does precision really matter? Consider this: if your cut parts are heading straight to a welding bay where weld tolerances far exceed dimensional specifications, paying premium prices for laser-tight tolerances may burden your project with unnecessary costs.

Here's a practical decision framework:

- Choose laser when you need intricate shapes, small holes, or the cleanest possible edges on thin to medium materials

- Choose plasma when cutting thick conductive metals and prioritizing speed and cost over ultra-tight tolerances

- Choose waterjet when heat distortion must be avoided or when working with non-metallic materials

- Choose mechanical sawing for straight cuts on bar stock, structural sections, or when bundle cutting large volumes

Many successful fabrication shops eventually incorporate multiple technologies, starting with the system that addresses their most common projects. Understanding these trade-offs between speed, cost, and quality positions you to ask the right questions when evaluating providers—and to recognize when a shop's capabilities truly match your project demands.

Material Compatibility and Thickness Limitations

Now that you understand the cutting technologies available, here's the next critical question: which method works best with your specific material? Different metals behave uniquely under cutting processes, and matching the wrong technology to your material can result in warped parts, rough edges, or damaged equipment.

Let's explore the most common materials processed through professional cutting services and the considerations that determine optimal results.

Steel Grades and Their Cutting Requirements

Steel remains the backbone of fabrication projects—but not all steel cuts the same way. Understanding the differences between steel grades helps you communicate effectively with providers and anticipate potential challenges.

Carbon Steel (Mild Steel)

This workhorse material is the easiest to cut across virtually all technologies. Carbon steel responds well to laser, plasma, waterjet, and mechanical sawing methods. Key considerations include:

- Mill scale on the surface provides slightly better traction during cutting, reducing slippage on CNC tables

- Plasma cutting excels for plates thicker than 1/4-inch, with speeds reaching 200+ inches per minute on medium thicknesses

- Laser cutting delivers clean edges on sheets up to about 3/4-inch thick

- Minimal heat-affected zone concerns compared to stainless grades

Stainless Steel (304, 316, and Other Grades)

Stainless steel demands more careful consideration due to its corrosion-resistant properties that can be compromised by improper cutting. According to cutting specialists at Red-D-Arc, maintaining relatively high travel speeds is crucial when cutting stainless steel to prevent excessive heat-affected zones (HAZ).

- 304 stainless: The most common grade responds well to all cutting methods but requires attention to heat management

- 316 stainless: Contains molybdenum for enhanced corrosion resistance; cutting too slowly can compromise these properties

- Austenitic grades: Particularly sensitive to heat—slow cutting speeds may cause the material to lose corrosion resistance or mechanical properties

- Thickness classification: Materials thinner than 8 gauge are considered sheet metal and require adjusted cutting parameters to prevent warping

When precision matters for stainless projects, laser cutting Brooklyn NY providers often recommend fiber lasers, which handle reflective surfaces better than older CO2 systems.

Aluminum Alloys and Specialty Metal Considerations

Aluminum presents unique challenges that require specialized knowledge and equipment. As research from TWI Global explains, all metals are reflective to CO2 laser beams until a certain power density threshold is reached—and aluminum is significantly more reflective than carbon or stainless steel.

The Reflectivity Challenge

Here's what makes aluminum tricky: when a laser beam contacts a reflective molten pool, it can transmit back through the beam delivery optics and into the laser itself, potentially causing significant damage. Most modern equipment includes a back reflection protection system that detects hazardous reflections and automatically stops the laser before damage occurs.

- Pure aluminum is harder to process than alloyed versions—alloying elements reduce reflectivity

- 5000 series alloys are more forgiving than pure aluminum for laser cutting

- Always verify with providers that their equipment is specifically designed for aluminum processing

Aluminum Alloy Categories

- 1000 series (pure aluminum): Most reflective; waterjet often preferred over laser

- 5000 series: Magnesium alloy; better laser compatibility than pure grades

- 6000 series: Silicon and magnesium alloy; widely used and reasonably laser-friendly

- 7000 series: Zinc alloy for aerospace applications; requires careful heat management

Copper, Brass, and Specialty Metals

These materials share aluminum's reflectivity concerns but often with additional complications:

- Copper: Extremely reflective; waterjet or plasma typically preferred for thicker sections

- Brass: Requires back reflection protection systems similar to aluminum; check with providers before processing

- Titanium: Responds well to laser and waterjet; plasma possible but edge quality suffers

- Inconel and nickel alloys: Heat-resistant materials that often favor waterjet to avoid thermal distortion

Thickness Limitations by Cutting Method

Understanding thickness capabilities helps you quickly determine which cutting technology fits your project:

| Material | Laser Cutting | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Carbon Steel | Up to 1" (optimal under 3/4") | Up to 2"+ at production speeds | Up to 12" in some applications |

| Stainless Steel | Up to 3/4" (thinner preferred) | Up to 1.5" with proper gas selection | Up to 8" depending on grade |

| Aluminum | Up to 1/2" with proper equipment | Up to 1" with argon-hydrogen gas | Up to 8" with no heat concerns |

| Copper/Brass | Limited; reflectivity concerns | Up to 3/4" for conductive grades | Up to 6" (preferred method) |

Matching Materials to Methods: Practical Guidance

When you're ready to request quotes, use these material-method pairings as starting points:

- Thin stainless sheets (under 1/4"): Laser cutting delivers clean edges with minimal HAZ when travel speeds stay high

- Thick carbon steel plates (over 1"): Plasma cutting offers the best speed-to-cost ratio; consider argon-hydrogen gas mixtures for improved quality

- Aluminum parts requiring precision: Fiber laser systems handle reflectivity better than CO2; waterjet eliminates heat concerns entirely

- Mixed-material projects: Waterjet handles virtually everything, making it ideal when a single setup must process diverse materials

With material compatibility clarified, you're ready to navigate the next critical step—understanding exactly what providers need from you to transform your designs into finished parts.

The Metal Cutting Process From Design to Delivery

You've selected your cutting method and confirmed your material compatibility—now what? Many first-time buyers find the actual ordering process mysterious. What files do providers need? How do you communicate specifications clearly? What happens between submitting your design and receiving finished parts?

Let's demystify the complete customer journey from initial concept to delivered components.

Preparing Your Design Files for Cutting

Your design files are the foundation of every successful cutting project. Submit the wrong format or overlook critical details, and you'll face delays, requotes, or parts that don't match your expectations.

Accepted File Formats

Most metal cutting providers accept these standard formats:

- DXF (Drawing Exchange Format): The industry standard for 2D cutting operations; virtually every provider accepts this format

- DWG (AutoCAD Drawing): Native AutoCAD files work well, though some shops prefer DXF for cleaner data transfer

- STEP files: Ideal for 3D models and complex assemblies; providers extract 2D profiles for flat cutting

- AI (Adobe Illustrator): Common for artistic or decorative metalwork; requires conversion to vector outlines

According to laser cutting guidelines from SendCutSend, if you've converted your file from a raster image (like a JPEG or PNG), always verify dimensions before submission. Printing your design at 100% scale can help confirm that measurements and proportions are correct.

Critical Design Considerations

Before submitting files, check these common issues that cause problems:

- Text conversion: Any text in your design must be converted to outlines or shapes. Hover over text elements—if they're still editable as text, they need conversion. In Illustrator, this is called "converting to outlines"; in CAD software, look for "explode" or "expand" commands.

- Minimum feature sizes: Holes and cutouts smaller than the material thickness often cannot be cut accurately. Circles that are too small will be flagged during review.

- Floating cutouts: Interior pieces that aren't connected to the main part will fall away during cutting. Add bridging tabs if you need to retain these sections, or submit them as separate designs.

- Bend allowances: If your flat parts will be bent after cutting, account for the K-factor—the ratio that determines how material stretches during bending. As Geomiq's sheet metal design guide explains, K-factor values typically range from 0.25 to 0.50 depending on material type and bend radius.

What Specifications Providers Need From You

Beyond your design file, providers need clear specifications to generate accurate quotes and deliver parts that meet your requirements. Unclear communication is the leading cause of order issues.

Essential Information to Provide

- Material type and grade: Don't just say "stainless steel"—specify 304, 316, or the exact grade required

- Material thickness: Include units (inches or millimeters) to avoid confusion

- Quantity needed: Different volumes often qualify for different pricing tiers

- Tolerance requirements: Standard tolerances work for most applications; tighter specifications increase cost and lead time

- Surface finish requirements: Note if you need specific finishes or if mill finish is acceptable

- Delivery timeline: Rush orders cost more but are often available

Tolerance Communication Tips

When communicating tolerance requirements, be specific about which dimensions are critical. Blanket tight tolerances across all features significantly increase costs. Instead, identify the dimensions that matter most—perhaps hole locations for assembly alignment or edge straightness for welding fit-up—and allow standard tolerances elsewhere.

The Complete Customer Journey: Step by Step

Understanding each stage of the process helps you anticipate timelines and prepare appropriately:

- Design Preparation: Create or refine your design files following the format and specification guidelines above. Verify all dimensions, convert text to outlines, and confirm that your design is manufacturable.

- File Submission: Upload your files through the provider's portal or email them with complete specifications. Include all relevant notes about materials, tolerances, quantities, and any special requirements.

- Quote Review: Providers analyze your files, check for manufacturability issues, and return a detailed quote. Review carefully—this is your opportunity to catch errors or request modifications before production begins.

- Material Selection Confirmation: Confirm the exact material grade, thickness, and finish. Some providers offer material substitutions that may reduce cost or lead time while meeting your requirements.

- Production: Once you approve the quote and confirm materials, your order enters the production queue. Complex jobs or tight tolerances may require additional setup time.

- Quality Inspection: Reputable providers inspect finished parts against your specifications. This may include dimensional verification, visual inspection, and documentation for certified applications.

- Delivery: Parts are packaged appropriately for the material and quantity, then shipped or prepared for pickup according to your timeline requirements.

Common Mistakes to Avoid

Learning from others' errors saves time and money. Watch out for these frequent pitfalls:

- Assuming providers will "figure it out": Ambiguous specifications lead to parts that don't match your vision—communicate clearly upfront

- Ignoring Design for Manufacturing (DFM) feedback: When providers suggest modifications, they're often preventing problems you haven't anticipated

- Ordering exact quantities: Build in a small buffer for assembly losses or damaged pieces, especially for high-volume orders

- Skipping prototype runs: For new designs, ordering a small test batch before full production catches issues before they become expensive

As fabrication workflow experts at OmegaCube note, no two custom jobs are the same—and the better you communicate your unique requirements, the smoother your project will proceed from quote to delivery.

With your design files prepared and specifications clearly communicated, understanding the quality standards that separate professional providers from the rest becomes your next advantage.

Quality Certifications and Precision Standards Explained

You've prepared your design files and selected your cutting method—but how do you know whether a provider can actually deliver consistent quality? This is where certifications and precision standards become your safeguard against costly mistakes and unreliable results.

Quality certifications aren't just fancy logos on a website. They represent verified systems that ensure every part leaving a facility meets documented standards. Understanding what these certifications mean—and when they matter for your specific project—helps you evaluate providers with confidence.

What ISO 9001 Certification Means for Your Project

When you see "ISO 9001 certified" on a fabricator's credentials, what exactly are you getting? According to LYAH Machining's comprehensive guide, ISO 9001:2015 defines requirements for a Quality Management System (QMS)—a structured approach to planning, controlling, measuring, and continuously improving operations.

For metal cutting services, this certification translates into tangible benefits:

- Repeatable processes: Every order follows documented procedures, reducing variation between batches

- Traceability: Materials, machine settings, and inspection results are recorded and retrievable

- Continuous improvement: The 2015 revision added risk-based thinking and leadership accountability, meaning certified shops actively identify and address potential quality issues

- Customer focus: Systems are designed around meeting your specifications, not just internal convenience

Imagine you're ordering 500 identical brackets over several months. Without standardized systems, each batch might vary slightly based on which operator ran the machine or what material happened to be in stock. ISO 9001 certification means the shop has documented procedures ensuring consistency regardless of who's working that day.

Look for providers whose ISO 9001 certification specifically covers their cutting operations—not just administrative functions. Request their certificate and verify it includes the manufacturing processes relevant to your project.

The certification also requires regular third-party audits, typically annually, ensuring that quality systems remain active rather than gathering dust in a filing cabinet.

IATF 16949: The Automotive Industry Standard

If your parts are destined for automotive applications, standard ISO 9001 certification may not be enough. The IATF 16949 standard builds on ISO 9001 with additional requirements specific to automotive supply chains.

Published by the International Automotive Task Force in 2016, this certification focuses on:

- Defect prevention: Proactive systems to catch problems before they reach your assembly line

- Variation reduction: Statistical process controls that minimize part-to-part differences

- Waste elimination: Lean manufacturing principles embedded in daily operations

- Product safety: Enhanced requirements for components that could affect vehicle safety

Most major automotive OEMs mandate IATF 16949 certification for their suppliers. If you're developing components for chassis, suspension, structural assemblies, or any safety-related applications, working with an IATF 16949-certified provider isn't optional—it's a requirement for entering the automotive supply chain.

IATF 16949 certification demonstrates a provider's commitment to automotive-grade quality management. For chassis and structural components where failure isn't an option, this certification should be non-negotiable.

Understanding Tolerance Specifications

Certifications verify that systems exist—but tolerances define what "acceptable" actually means for your parts. Tolerance specifications establish the permissible limits of variation in physical dimensions, ensuring features are produced within acceptable ranges for their intended application.

According to Xometry's tolerance guide, international standards like ISO 2768 and ISO 286 provide general tolerances that apply by default, streamlining the design process when high precision isn't required for every dimension.

Key Tolerance Terminology

- Nominal dimension: The intended design measurement (e.g., a 50mm hole)

- Tolerance: The acceptable range of deviation (e.g., ±0.15mm)

- IT grades: International Tolerance grades ranging from IT1 (extremely precise) to IT18 (very loose)

Common Tolerance Standards

| Standard | Application | Typical Use Cases |

|---|---|---|

| ISO 2768-m (Medium) | General tolerances for machined parts | Standard fabrication, non-critical dimensions |

| ISO 2768-f (Fine) | Tighter general tolerances | Precision assemblies, closer-fit requirements |

| ISO 286 IT6-IT8 | Specific feature tolerances | Bearing fits, shaft-hole relationships |

For a practical example: a part with a 50mm nominal dimension under ISO 2768-f (Fine) allows deviation of ±0.15mm. Under ISO 2768-m (Medium), that same dimension permits ±0.30mm deviation. The tighter tolerance costs more but may be essential for proper fit.

When Tighter Tolerances Matter—and When They Don't

Here's where many buyers overspend: specifying tight tolerances across all dimensions when only a few features actually require precision. Every dimension held to tighter specifications increases cost through slower cutting speeds, additional inspection time, and higher rejection rates.

Situations Requiring Tighter Tolerances:

- Mating surfaces where parts must fit together precisely

- Hole locations for fastener alignment in multi-part assemblies

- Bearing seats or shaft fits with specific clearance requirements

- Components for automated assembly where robots expect exact positioning

Situations Where Standard Tolerances Suffice:

- Outer edges that won't interface with other components

- Decorative features where visual appearance matters more than exact dimensions

- Parts heading to welding operations where weld tolerances exceed cutting precision

- Structural components where strength matters more than dimensional perfection

Identify your critical-to-function dimensions and specify tight tolerances only where they genuinely impact performance. Allow standard tolerances elsewhere to optimize cost without sacrificing quality where it matters.

When communicating with providers, clearly mark which dimensions require precision and which can follow general tolerances. This approach demonstrates manufacturing knowledge and often results in better pricing—because you're not asking for unnecessary precision that drives up costs.

With quality standards clarified, understanding how different industries leverage these cutting capabilities reveals the full scope of what's possible for your specific application.

Industry Applications From Aerospace to Custom Projects

Ever wonder how the same cutting technologies serve both a neighborhood fabrication shop creating custom railings and a defense contractor manufacturing flight-critical aircraft components? The versatility of metal cutting spans an enormous range of applications—each with unique requirements, tolerances, and volume expectations.

Understanding how different industries leverage these services helps you contextualize your own project needs and communicate more effectively with providers. Whether you're developing aerospace prototypes or ordering architectural metalwork, knowing what's standard in your sector prevents both under-specification and costly over-engineering.

Automotive and Aerospace Applications

These two industries represent the most demanding applications for precision cutting—where component failure isn't just inconvenient, it's potentially catastrophic.

Aerospace Manufacturing

According to Modus Advanced's analysis of aerospace manufacturing, the complexity of modern aerospace systems requires components with increasingly tight tolerances, specialized materials, and complex geometries. Traditional manufacturing approaches often fall short when dealing with these demanding specifications.

What makes aerospace cutting unique?

- Material diversity: Titanium alloys, Inconel, aluminum-lithium alloys, and other exotic materials require specialized cutting parameters

- Weight optimization: Every gram matters in flight applications, driving demand for precise pocket cuts and lightening holes

- Traceability requirements: Complete documentation from raw material certification through final inspection

- AS9100 certification: The aerospace equivalent of ISO 9001, adding configuration management, risk management, and product safety requirements

- ITAR compliance: Defense-related aerospace components require facilities with proper security protocols and personnel clearances

Aerospace projects typically involve lower volumes but higher precision. A prototype run might consist of just 5-10 parts, while production quantities for aircraft components often remain in the hundreds rather than thousands—making rapid prototyping capabilities essential for development cycles.

Automotive Manufacturing

The automotive sector presents a different challenge: achieving aerospace-adjacent precision at volumes measured in thousands or millions. As Endura Steel's automotive fabrication analysis explains, metal fabrication forms the backbone of vehicle manufacturing—from chassis frameworks to body panels.

Critical automotive cutting applications include:

- Chassis components: Structural frames requiring precise cuts for welding fit-up and dimensional accuracy

- Suspension brackets: High-stress mounting points where tolerance affects vehicle handling and safety

- Structural reinforcements: Crash protection components manufactured to exacting specifications

- Body panel blanks: Large-format cuts that feed into stamping and forming operations

- Exhaust system components: Tubes and flanges requiring clean edges for welding integrity

The automotive industry's shift toward lightweight materials—particularly aluminum and high-strength steel—has increased demands on cutting precision. According to Endura Steel, manufacturers are increasingly turning to these materials to improve fuel economy and reduce emissions while maintaining safety standards.

Construction and Custom Fabrication Uses

Beyond high-volume manufacturing, metal cutting services support an enormous range of construction, architectural, and custom fabrication projects. Think about the variety you encounter daily—just as diverse as searching for pho near me reveals countless restaurant options, the applications for precision cutting span virtually every built environment you encounter.

Architectural Metalwork

Modern architecture increasingly features exposed metal elements where cutting precision directly impacts visual quality:

- Decorative screens and panels: Laser-cut patterns for building facades, privacy screens, and interior dividers

- Staircase components: Stringers, brackets, and decorative elements requiring consistent dimensions across multiple pieces

- Custom signage: Letters, logos, and dimensional graphics cut from various metals

- Railing systems: Posts, brackets, and connection plates for residential and commercial installations

- Furniture components: Table bases, shelf brackets, and decorative elements for custom furnishings

Architectural projects often prioritize edge quality and visual consistency over extreme dimensional precision. A plasma-cut decorative screen may tolerate ±1mm dimensional variation but demands clean, consistent edges that don't require extensive finishing.

Industrial Equipment Manufacturing

Equipment manufacturers rely on metal cutting for everything from machine frames to specialized tooling:

- Machine bases and frames: Heavy plate cutting for equipment foundations

- Mounting brackets: Standardized components produced in medium volumes

- Guard panels: Safety enclosures requiring precise cutouts for controls and visibility

- Conveyor components: Wear plates, guides, and structural elements

- Custom tooling: Jigs, fixtures, and production aids specific to manufacturing operations

Volume Requirements: Prototypes vs. Mass Production

How volume affects your cutting project is something many buyers underestimate. The difference between ordering 5 parts and 5,000 parts isn't just about pricing—it often determines which cutting method makes economic sense.

According to EABEL's manufacturing analysis, the biggest cost factor in sheet metal manufacturing is tooling amortization. The crossover point where mass production becomes more economical than prototyping methods typically occurs between a few dozen to a few hundred parts, depending on material and complexity.

Prototype and Low-Volume Considerations

- Rapid prototyping: Laser and waterjet cutting support quick design iterations without tooling investment

- Design flexibility: Changes can be implemented within days rather than weeks

- DFM validation: Testing manufacturability before committing to production tooling

- Bridge production: Soft tooling or prototype methods can fill demand while production tooling is developed

Mass Production Considerations

- Tooling investment: Dedicated dies and fixtures become economical at higher volumes

- Process consistency: Hardened tooling and automated processes deliver extremely consistent tolerances

- Unit cost reduction: Per-part pricing drops significantly as tooling costs are amortized

- Lead time stability: Established production runs offer predictable delivery schedules

Many successful product launches follow a hybrid path: start with rapid prototyping for design validation, move to soft tooling for mid-volume runs, and scale into full production as demand and design stability increase. This approach minimizes risk while maintaining flexibility during development.

Matching Industry Needs to Cutting Capabilities

Different applications demand different priorities:

| Industry | Primary Concerns | Typical Volumes | Preferred Methods |

|---|---|---|---|

| Aerospace | Precision, traceability, exotic materials | Low to medium | Laser, waterjet |

| Automotive | Consistency, volume capacity, cost efficiency | High | Laser, plasma, stamping |

| Construction | Speed, cost, structural integrity | Medium | Plasma, mechanical sawing |

| Architectural | Edge quality, visual consistency | Low to medium | Laser, waterjet |

| Industrial Equipment | Durability, dimensional accuracy | Medium | Plasma, laser |

Whether you're developing mission-critical aerospace components or custom architectural elements, understanding these industry-specific requirements helps you communicate effectively with providers and ensures your project receives appropriate attention to the factors that matter most.

Once your parts emerge from cutting operations, the question becomes: what finishing steps transform raw-cut components into professional, assembly-ready parts?

Post-Cutting Finishing and Edge Treatment Options

Your parts just came off the cutting table—now what? Raw-cut edges often carry burrs, sharp corners, or surface imperfections that can compromise assembly, create safety hazards, or simply look unprofessional. Understanding your finishing options helps you specify exactly what you need and avoid paying for processes that don't add value to your application.

According to Westway Machinery's deburring guide, finishing and deburring machines are designed to remove imperfections that remain attached to workpieces after they've been modified by another machine. These undesirable raised edges—commonly called burrs—fall into categories based on how they formed and what's required to remove them.

Deburring and Edge Treatment Options

Burrs form from various factors including material type and thickness, blade clearance, and the pressure exerted during cutting. Even the cleanest laser cut may leave microscopic irregularities that matter for certain applications.

Common Deburring Methods

- Belt sanding: Uses abrasive belts to remove burrs and smooth edges; ideal for consistent results across flat surfaces

- Disc sanding: Targets specific areas with rotating abrasive discs; useful for complex geometries

- Brush finishing: Employs rotating wire or abrasive brushes to reach intricate features and break sharp edges

- Tumbling: Parts rotate with abrasive media in a drum; economical for high volumes of small parts

- Manual hand finishing: Skilled operators use files, grinders, or hand tools for precision work or low volumes

As SendCutSend's edge quality analysis explains, edge quality varies by cutting process, material, and thickness. Thinner materials typically produce cleaner edges right off the machine but are more sensitive to changes in cutting conditions. Thicker materials require parameter adjustments that can affect surface quality.

Edge Rounding Options

Beyond removing burrs, many applications require deliberate edge treatment:

- Edge breaking: Removes the sharp 90-degree corner without creating a visible radius

- Edge rounding: Creates a measurable radius along cut edges, typically 0.5mm to 2mm

- Chamfering: Cuts an angled face along the edge, often specified as 45 degrees

Edge treatment matters significantly for parts that will be handled, painted, or powder coated. Sharp edges reject coating adhesion and create safety risks during assembly. Just as you might comparison shop—scanning options like you would hannaford locations for the best grocery deals—evaluating edge treatment options ensures you get the right finish for your application without overspending.

Surface Finishing for Professional Results

Surface finishing extends beyond edge treatment to address the entire part face. Your requirements depend heavily on the part's end use.

Finishing Options by Application Type

- Welding preparation: Light deburring ensures proper fit-up; heavy finishing wastes time since weld grinding follows anyway

- Painted or powder-coated parts: Smooth surfaces with broken edges ensure coating adhesion and consistent appearance

- Visible architectural elements: Grain-consistent brushed finishes or polished surfaces for aesthetic applications

- Food-grade equipment: Smooth, crevice-free surfaces meeting sanitary requirements

- Functional machinery components: Focus on dimensional accuracy over cosmetic appearance

When Additional Finishing Is Necessary

- Parts will be handled by workers or end users (safety requirement)

- Components interface with electrical wiring or sensitive equipment

- Coating or painting is planned (adhesion and appearance)

- Assembly requires sliding fits between parts

- Aesthetics matter for visible installations

When Cut Edges Are Acceptable As-Is

- Parts proceed directly to welding operations

- Edges will be enclosed or inaccessible in final assembly

- Structural applications where appearance is irrelevant

- Cost constraints outweigh cosmetic concerns

Specify finishing requirements upfront during quoting—adding processes after production creates delays and added costs that could have been avoided with clear initial communication.

For shops considering automation, Westway notes that automated deburring delivers consistent quality, higher productivity, cost savings over manual methods, improved safety, and enhanced production capacity. Whether you're ordering from a full-service fabricator or selecting finishing equipment for your own operations, understanding these options ensures your parts meet their intended purpose—from functional machine components to customer-facing architectural elements.

With finishing requirements clarified, the final step is selecting a provider whose capabilities, certifications, and responsiveness match your project demands.

Selecting the Right Metal Cutting Service Provider

You've navigated cutting methods, material compatibility, quality standards, and finishing options—now comes the decision that ties everything together: choosing the right provider. This choice determines whether your project proceeds smoothly or becomes a frustrating exercise in miscommunication, delays, and quality issues.

Think of selecting a fabrication partner like choosing where to eat when you're craving something specific. Searching for an acai bowl in a steakhouse district won't yield great results—you need a provider whose core capabilities align with your actual needs. The same principle applies to metal cutting: matching your project requirements to a provider's genuine strengths prevents disappointment and wasted resources.

Key Questions to Ask Potential Providers

Before requesting quotes, prepare a list of questions that reveal whether a provider can genuinely deliver what you need. According to Topline Welding's provider selection guide, not all metal cutting and bending services are created equal—evaluating potential providers requires examining their equipment, technology, experience, and expertise.

Essential Questions to Ask:

- What certifications do you hold? Request copies of ISO 9001, IATF 16949 (for automotive applications), or AS9100 (for aerospace) certificates and verify they cover manufacturing operations—not just administrative functions.

- What equipment do you operate? Cutting-edge machinery often translates to higher precision and faster turnaround times. Ask about laser wattage, bed sizes, and automation capabilities.

- What materials do you regularly process? Providers experienced with your specific material—whether it's 316 stainless, 6061 aluminum, or exotic alloys—will anticipate challenges and optimize parameters accordingly.

- What tolerances can you consistently hold? Get specific numbers, not general claims. Ask for capability studies or sample parts demonstrating their precision on materials similar to yours.

- Do you offer Design for Manufacturing (DFM) support? As Approved Sheet Metal explains, precision sheet metal shops know the ins and outs of their machines—they can advise on material choices, bend radii, and design modifications that improve manufacturability.

- What is your typical quote turnaround time? Responsiveness during quoting often indicates responsiveness throughout the project. Providers offering same-day or next-day quotes demonstrate organized operations and customer focus.

- Can you share examples of similar projects? Case studies or sample parts from comparable applications reveal real-world capability better than marketing claims.

Evaluating Turnaround Time and Capabilities

Time is often critical in project execution. Discuss the provider's estimated turnaround time and ensure it aligns with your project timeline. But turnaround involves more than just cutting speed—it encompasses the entire workflow from quote to delivery.

Turnaround Components to Evaluate:

- Quote responsiveness: How quickly can you get pricing? Some providers deliver quotes within hours—for example, Shaoyi (Ningbo) Metal Technology offers 12-hour quote turnaround, enabling faster decision-making and project planning.

- Prototype lead times: For product development, rapid prototyping capabilities accelerate design iterations. Look for providers offering 5-day rapid prototyping or similar expedited services for initial samples.

- Production scheduling: Understand their current capacity and how your order fits into their queue. Ask about rush order options and associated costs.

- Quality inspection time: Thorough inspection takes time but prevents problems downstream. Clarify what's included in quoted lead times.

Rapid prototyping capabilities deserve special attention if you're developing new products. The ability to receive physical samples within days rather than weeks fundamentally changes how you can approach design validation. You can test fit, function, and appearance with real parts, catch issues early, and iterate quickly before committing to production tooling.

Provider Evaluation Checklist

Use this comprehensive checklist when comparing potential providers:

| Evaluation Criteria | What to Look For | Red Flags |

|---|---|---|

| Certifications | ISO 9001 for general quality; IATF 16949 for automotive; AS9100 for aerospace | Claims without documentation; certifications covering only non-manufacturing functions |

| Equipment Capabilities | Modern machinery; multiple cutting technologies; automation for consistency | Outdated equipment; single-technology dependence; no investment in upgrades |

| Material Expertise | Demonstrated experience with your specific materials; documented parameters | Hesitation about material questions; no examples of similar work |

| Turnaround Times | Clear lead time commitments; expedited options available; quote responsiveness under 24 hours | Vague timing promises; inability to provide rush services; slow quote response |

| Quote Responsiveness | Same-day or 12-hour turnaround; detailed breakdowns; proactive communication | Multi-day quote delays; incomplete pricing; unresponsive to follow-up questions |

| DFM Support | Proactive design feedback; material recommendations; manufacturability guidance | No input on designs; "we'll cut whatever you send" attitude |

| Volume Flexibility | Handles prototypes through mass production; scales with your needs | Minimum order quantities that don't fit your requirements; no prototype capability |

Why DFM Support Matters More Than You Think

Design for Manufacturing support separates order-takers from true partners. As industry experts note, getting your CAD models to a precision sheet metal shop early allows them to advise on material choices, identify potential issues, and suggest modifications that improve both quality and cost.

What comprehensive DFM support looks like:

- Proactive feedback: Providers review your designs and suggest improvements before quoting—not after problems appear in production

- Material recommendations: Guidance on when a different thickness or grade might perform better or cost less

- Tolerance optimization: Identifying which dimensions truly need tight tolerances versus where standard precision suffices

- Process selection: Recommending the optimal cutting method for your specific requirements

- Assembly considerations: Advice on tab placement, bend sequences, and features that simplify downstream operations

Providers like Shaoyi demonstrate this approach through comprehensive DFM support combined with IATF 16949-certified quality systems—particularly valuable for automotive chassis, suspension, and structural components where manufacturing optimization directly impacts performance and safety.

Evaluating Customer Service and Communication

Technical capability means little if you can't communicate effectively with your provider. According to Topline Welding, a strong customer service team can make a significant difference in your overall experience—responsive communication, willingness to address concerns, and proactive problem-solving are hallmarks of excellent customer support.

Communication Quality Indicators:

- Response time to initial inquiries

- Clarity and completeness of quotes

- Willingness to explain technical concepts

- Proactive updates during production

- Accessibility of technical staff for questions

- Problem resolution approach when issues arise

Reading reviews or testimonials from previous clients provides insights into the level of service you can expect. Look for consistent positive feedback regarding communication and problem resolution—not just product quality.

Making Your Final Decision

After gathering information from multiple providers, weigh your priorities:

- For prototype development: Prioritize rapid turnaround, DFM support, and flexibility over lowest price

- For production volumes: Focus on consistency, capacity, and total cost including quality failures

- For automotive applications: IATF 16949 certification is non-negotiable; verify it covers your specific component types

- For complex materials: Documented experience with your specific alloys matters more than general capabilities

The best provider isn't always the cheapest or fastest—it's the one whose capabilities, communication style, and quality systems best match your specific project requirements.

Remember that choosing a metal cutting partner is often the beginning of an ongoing relationship. The effort you invest in selection pays dividends across multiple projects as you develop shared understanding, streamlined communication, and mutual trust. When you find a provider who consistently delivers quality parts on time with responsive communication, you've found a competitive advantage worth protecting.

Frequently Asked Questions About Metal Cutting Services

1. How much does metal cutting cost?

Metal cutting costs vary based on material type, thickness, cutting method, and complexity. Sheet metal cutting typically ranges from $0.50 to $2 per linear inch, while hourly rates fall between $20 and $30. Laser cutting offers premium precision at higher costs, while plasma cutting provides economical solutions for thicker materials. For accurate pricing, submit your design files with complete specifications including material grade, thickness, quantity, and tolerance requirements to receive detailed quotes within 12-24 hours from quality providers.

2. What is the difference between laser cutting and plasma cutting?

Laser cutting uses focused light beams to achieve tolerances under 0.01 inches with exceptionally clean edges, ideal for thin to medium materials and intricate patterns. Plasma cutting employs electrical arcs with compressed gas, cutting 1-inch steel 3-4 times faster than waterjet at roughly half the operating cost per foot. Choose laser for precision electronics or medical devices; select plasma for structural steel, heavy equipment, or thick conductive metals where speed and cost efficiency matter more than ultra-tight tolerances.

3. Will a hardware store cut metal for you?

While hardware stores like Ace Hardware offer basic pipe cutting services, they lack the equipment for precision metal fabrication. Professional metal cutting providers offer laser, plasma, waterjet, and mechanical sawing technologies capable of processing complex designs with tight tolerances. For custom components, intricate patterns, or specific material grades like 304 stainless or aerospace-grade aluminum, partner with ISO-certified fabrication shops that provide DFM support, quality inspection, and consistent results across production volumes.

4. What file formats do metal cutting services accept?

Most metal cutting providers accept DXF files as the industry standard for 2D cutting operations, along with DWG (AutoCAD) files and STEP files for 3D models. Adobe Illustrator files work for decorative metalwork but require conversion to vector outlines. Before submission, convert all text to outlines, verify dimensions at 100% scale, and ensure minimum feature sizes exceed material thickness. Include complete specifications covering material grade, thickness, quantity, tolerances, and delivery timeline for accurate quoting.

5. What certifications should I look for in a metal cutting provider?

ISO 9001 certification ensures documented quality management systems with repeatable processes and traceability. For automotive applications, IATF 16949 certification is essential, providing defect prevention, variation reduction, and product safety requirements demanded by major OEMs. Aerospace projects require AS9100 certification with configuration management and ITAR compliance for defense-related components. Request certificate copies and verify they cover manufacturing operations specifically, not just administrative functions, to ensure genuine quality assurance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —