How to Select a Hot Forging Auto Parts Manufacturer

TL;DR

A hot forging auto parts manufacturer specializes in shaping heated metal under extreme pressure to create exceptionally strong, durable, and precise components for vehicle systems. This process, known as closed-die forging, is critical for the automotive industry because it produces parts with superior structural integrity and reliability, essential for safety-critical applications like engines, drivetrains, and suspensions. Choosing the right partner involves verifying certifications, material expertise, and technical capabilities.

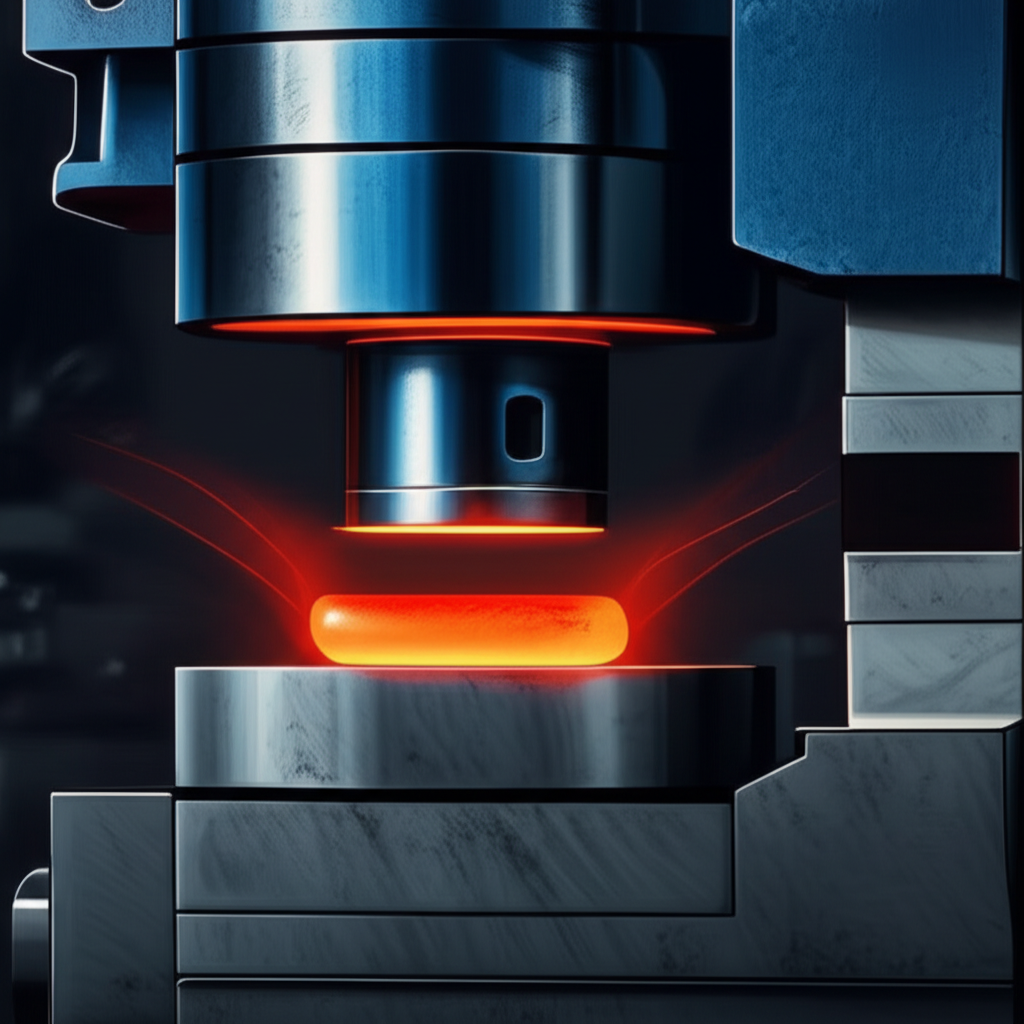

Understanding the Hot Forging Process for Automotive Components

At the heart of modern vehicle manufacturing lies the hot forging process, a method renowned for producing components with an unmatched combination of strength, durability, and precision. Specifically, closed-die hot forging is the standard for high-stress automotive applications. This technique involves heating a metal billet to a malleable temperature—without melting it—and then pressing it between two custom-made dies that contain a precise impression of the final part. The intense pressure forces the metal to conform to the shape of the die, creating a near-net-shape component.

The primary advantage of this method is its effect on the metal's internal grain structure. As detailed by experts at Cornell Forge, the compressive forces cause the metal's grain to align with the flow of the final part's shape. This metallurgical recrystallization results in a refined, uniform grain structure that enhances the component's strength, ductility, and resistance to impact and fatigue. Unlike casting, which can introduce porosity and inconsistencies, forging creates a denser, non-porous part with exceptional structural integrity.

The closed-die hot forging process generally follows three critical steps:

- Heating: The raw material, typically a steel or alloy billet, is heated in a furnace to a specific temperature where it becomes plastic and workable.

- Deformation: The heated billet is placed into the lower half of a custom die. A powerful press or hammer forces the two die halves together, shaping the metal into the desired form under immense pressure. Any excess material, known as flash, is squeezed out at the parting line of the dies and is later trimmed.

- Cooling: The newly formed part is cooled under controlled conditions to ensure it retains its enhanced properties without developing internal stresses or defects.

This meticulous process yields components with tight tolerances that often require minimal subsequent machining, reducing waste and overall production costs. It is the preferred method for manufacturing parts that must withstand extreme stress and perform reliably for the life of the vehicle.

Essential Criteria for Selecting a Hot Forging Partner

Choosing the right hot forging auto parts manufacturer is a critical business decision that directly impacts product quality, safety, and supply chain reliability. A thorough evaluation process should focus on several key areas to ensure a potential partner can meet the rigorous demands of the automotive industry. These criteria go beyond simple cost analysis and delve into the manufacturer's quality systems, technical expertise, and operational flexibility.

Certifications and Quality Standards

The most critical credential for an automotive supplier is the IATF 16949 certification. This global quality management standard is specific to the automotive sector and signifies a manufacturer's commitment to continuous improvement, defect prevention, and the reduction of variation and waste. This certification is non-negotiable for any Tier I or Tier II supplier. It ensures that processes are documented, controlled, and consistently monitored to produce parts that meet the highest safety and performance standards.

Material Expertise and Sourcing

A competent forging partner must demonstrate deep expertise in working with a range of materials, including carbon, alloy, and stainless steels. The choice of material is fundamental to the performance of the final component, whether it's a high-strength gear or a corrosion-resistant suspension part. The manufacturer should have a robust supply chain for sourcing high-quality raw materials and the metallurgical knowledge to recommend the optimal alloy for a specific application's stress, temperature, and environmental requirements.

Technical and Engineering Capabilities

Beyond certifications, a manufacturer's technical capabilities are paramount. This includes their capacity for part size and weight, the sophistication of their forging equipment (such as hydraulic presses and hammers), and their in-house tool and die manufacturing. A partner with in-house die-making capabilities can significantly reduce lead times and improve accuracy. Furthermore, inquire about their secondary services, such as CNC machining, heat treating, and finishing. An integrated provider who can deliver a production-ready part simplifies logistics and ensures quality control throughout the entire manufacturing cycle.

For businesses requiring tailored solutions, a manufacturer's ability to offer custom services is essential. For instance, providers like Shaoyi Metal Technology demonstrate this by specializing in everything from rapid prototyping for small-batch validation to full-scale mass production. Their integrated approach, which includes in-house die manufacturing and strategic logistics, ensures precision and efficiency for global supply chains, highlighting the value of a partner who can support a project from concept to completion.

Common Automotive Parts Manufactured via Hot Forging

Hot forging is the manufacturing backbone for a wide array of critical automotive components where strength and reliability cannot be compromised. The process is essential for parts in the engine, drivetrain, suspension, and chassis that are subjected to constant stress, vibration, and temperature fluctuations. The superior mechanical properties of forged parts ensure vehicle safety and longevity. Below are some common examples of automotive parts produced through hot forging.

Key forged components include:

- Engine and Drivetrain Parts: Components like connecting rods, crankshafts, camshafts, and transmission gears are forged to withstand the immense forces and high-cycle fatigue within an engine. Ring gears and drive shafts also rely on forging for their strength and durability.

- Suspension and Steering Components: Safety-critical parts such as control arms, ball joints, tie rod ends, hubs, and spindles are almost exclusively forged. Their structural integrity is essential for maintaining vehicle control and absorbing road impacts.

- Chassis and Structural Parts: Various yokes, flanges, and brackets that form the vehicle's frame and connect major assemblies are forged to provide a rigid and reliable structure. Even smaller hardware like door hinges can be forged for enhanced durability.

The table below outlines some of these parts and the primary reason forging is the preferred manufacturing method.

| Component | Primary Function | Reason for Forging |

|---|---|---|

| Connecting Rods | Connects the piston to the crankshaft | High tensile and compressive strength to handle combustion forces. |

| Control Arms | Connects the wheel hub to the vehicle frame | Excellent fatigue resistance to withstand constant road vibrations. |

| Ring Gears | Transfers power from the driveshaft to the differential | Superior wear resistance and toughness for gear-to-gear contact. |

| Tie Rod Ends | Connects the steering system to the wheels | High structural integrity to ensure precise and reliable steering control. |

| Hubs & Spindles | Mounts the wheel and supports the vehicle's weight | Exceptional load-bearing capacity and resistance to impact forces. |

Navigating the US Automotive Forging Landscape

For businesses operating within North America, sourcing from a US-based hot forging auto parts manufacturer offers significant strategic advantages. The domestic forging industry is characterized by a strong focus on quality, advanced technology, and adherence to stringent industry standards. Partnering with a domestic supplier can lead to more resilient supply chains, better communication, and greater oversight of the manufacturing process, which are critical factors in the fast-paced automotive sector.

One of the primary benefits of domestic sourcing is enhanced supply chain security. Relying on local or regional manufacturers reduces lead times and mitigates the risks associated with international shipping disruptions, tariffs, and geopolitical instability. This proximity allows for just-in-time (JIT) delivery models, which can lower inventory costs and improve production efficiency. Furthermore, working within the same regulatory environment ensures compliance with labor, safety, and environmental standards.

Leading US forging companies often distinguish themselves through innovation and a commitment to quality. As noted in an industry overview by Zetwerk, top manufacturers invest heavily in state-of-the-art equipment and processes to deliver components that meet the highest standards of precision and performance. When evaluating US-based partners, it is essential to apply the same rigorous criteria discussed earlier: confirm their IATF 16949 certification, assess their material and engineering expertise, and verify their capacity to meet your specific production volumes and technical requirements.

Making the Right Manufacturing Choice

Selecting the ideal hot forging auto parts manufacturer is a foundational step toward ensuring the quality and reliability of your final product. The decision should be guided by a comprehensive assessment of a potential partner's quality systems, technical prowess, and ability to function as a collaborative extension of your team. Prioritizing IATF 16949 certification ensures a baseline of automotive-grade quality, while a deep dive into their material expertise and engineering capabilities will reveal their suitability for your specific application.

Ultimately, the best manufacturing partnerships are built on a foundation of trust, transparency, and shared commitment to excellence. By focusing on these essential criteria, you can forge a relationship that not only delivers superior components but also strengthens your supply chain and enhances your competitive position in the market.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —