Stamping Dies Types Decoded: Match Your Part To The Right Die

What Are Stamping Dies and Why They Matter

Ever wondered how manufacturers produce thousands of identical metal parts with perfect precision? The answer lies in a critical tool that serves as the backbone of modern metal fabrication: the stamping die.

So, what is dies in manufacturing? Simply put, stamping dies are specialized precision tools used inside stamping presses to cut, bend, and shape sheet metal into specific forms. Think of them as highly engineered molds that transform flat metal sheets into functional components through controlled force. According to The Phoenix Group, a stamping die consists of two halves placed inside a press capable of generating enough force to perform four essential functions: locating, clamping, working, and releasing.

The Foundation of Metal Forming Technology

Metal stamping dies work through a straightforward yet powerful principle. The two die halves—upper and lower—come together under tremendous pressure to impart shape onto metal material. During the working phase, these tools perform value-added operations including cutting, bending, piercing, embossing, forming, drawing, stretching, coining, and extruding.

The construction of these dies requires exceptional durability. Die shoes, which serve as the base for all other components, are typically made from cast iron or steel to resist deflection during operation. Meanwhile, the punches and die steels—the components that actually shape the material—are crafted from hardened tool steel to withstand the extreme wear these details endure during stamping metal operations.

Why Die Selection Shapes Manufacturing Success

Here's what many newcomers don't realize: choosing the right type of stamping die can make or break your production outcomes. The die you select directly impacts three critical factors:

- Production efficiency – Different die types run at vastly different speeds and require varying setup times

- Part quality – Each die category excels at specific operations and part complexities

- Manufacturing costs – Tooling investment, per-part costs, and maintenance requirements vary significantly across die types

Whether you're producing small electronic connectors or large automotive panels, understanding the various types of stamping dies available helps you match your specific part requirements to the optimal tooling solution. In the sections ahead, you'll discover progressive dies for high-volume production, transfer dies for complex large parts, compound dies for precision flat components, and specialized dies that complete the manufacturing toolkit. Each serves distinct purposes—and knowing when to use which can transform your production outcomes.

Progressive Dies for High-Volume Production

When production volumes climb into the hundreds of thousands—or even millions—of parts, one die type consistently rises to the top: the progressive die. Often called a "prog die" in shop floor conversations, this powerhouse of metal stamping has earned its reputation as the workhorse of high-volume manufacturing.

But what makes progressive metal stamping so effective? The answer lies in its ingenious sequential station design that transforms raw material into finished parts with remarkable efficiency.

How Progressive Dies Achieve Multi-Operation Efficiency

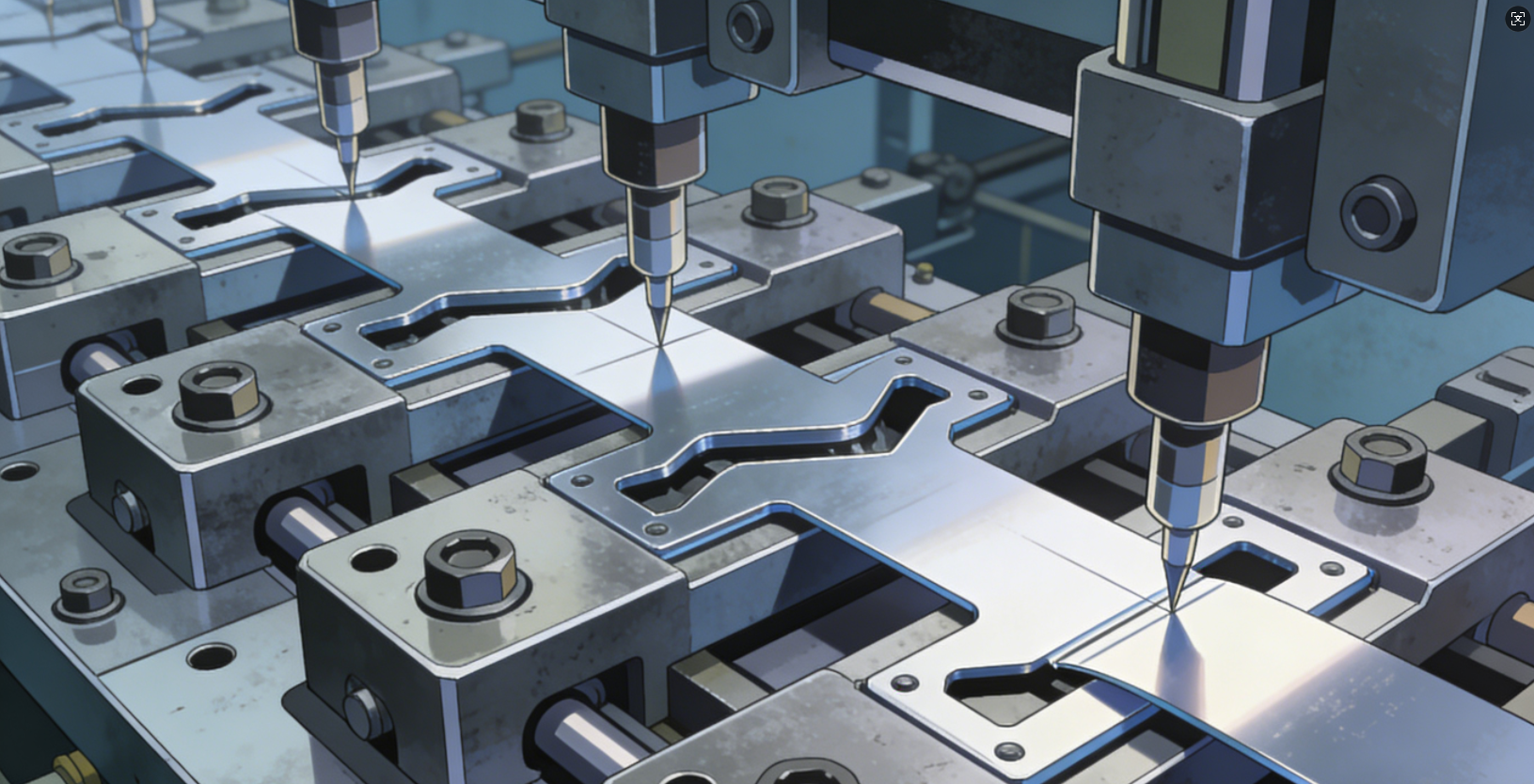

Imagine a strip of metal traveling through a series of workstations, each performing a specific operation—cutting, bending, forming, piercing—until a complete part emerges at the end. That's the progressive die stamping process in action.

According to Dayton Rogers, a progressive die contains multiple stamping stations that carry out simultaneous operations on a sheet metal strip. With each stroke of the press, the material advances to the next station while a new section enters the die. The result? Every single press cycle produces a finished component.

Here's how the mechanics work:

- Feeder mechanism – Precisely feeds the metal strip into the die, ensuring accurate alignment for each operation

- Die set – A series of dies where each station performs a specific cutting or forming operation

- Stripper – Removes the finished part cleanly from the metal strip after the final operation

- Press – Provides the controlled force needed to perform all operations, with capacities ranging from 60 to 500 tons depending on part requirements

The bypass notches in sheet metal stamping dies purpose is equally critical to this process. These strategically placed notches allow the strip to advance smoothly between stations while maintaining precise positioning. Without proper bypass notches, the material could misalign, jam, or produce defective parts.

Ideal Applications for Progressive Die Stamping

So when does progressive die and stamping make the most sense for your project? The primary advantage of a progressive press is its ability to produce complex parts at extremely high speeds with minimal labor intervention.

Progressive die stampings excel in industries where volume justifies the upfront tooling investment:

- Automotive – Brackets, clips, connectors, and electronic components produced in volumes exceeding millions annually

- Electronics – Precision terminals, lead frames, and shield components requiring tight tolerances

- Appliances – Structural components, fastening hardware, and decorative trim pieces

- Aerospace – High-precision components where consistency across large production runs is non-negotiable

The key advantages that make progressive dies the preferred choice for high-volume production include:

- Reduced labor costs – Automation minimizes manual handling between operations

- Consistent quality – Each part receives identical processing, eliminating variation

- High-speed production – Cycle times measured in fractions of seconds rather than minutes

- Complex part capability – Multiple operations combined into a single die set handle intricate geometries

As noted by Hudson Technologies, progressive die stamping is specifically designed for high-volume production, typically exceeding 50,000 pieces per year. While the setup costs run higher than simpler tooling options, the per-piece cost drops dramatically at scale—making it the economical choice when volumes warrant the investment.

Of course, progressive dies have their limitations. Parts must remain connected to the strip throughout the process, which restricts the size and depth of components that can be produced. When parts outgrow these capabilities, manufacturers turn to a different solution—transfer dies for complex large parts.

Transfer Dies for Complex Large Parts

What happens when your part design demands deep draws, intricate geometries, or dimensions too large for strip feeding? This is exactly where transfer die stamping steps in as the manufacturing solution that bridges the gap between progressive efficiency and single-station flexibility.

Unlike progressive dies that keep parts connected to a continuous strip, transfer dies work with individual blanks—separated workpieces that travel independently through multiple stations. This fundamental difference unlocks capabilities that progressive tooling simply cannot match.

When Parts Outgrow Progressive Capabilities

Imagine you need to produce an automotive body die component—a large structural panel requiring multiple deep draws and complex forming operations. Trying to keep such a part attached to a metal strip throughout processing would be impractical, if not impossible. The part's size alone would create handling challenges, and deep drawing operations require the workpiece to move freely during forming.

According to Die-Matic, transfer die stamping excels in producing complex parts with intricate features, tight tolerances, and deep draws that cannot be achieved through progressive stamping alone. The process allows manufacturers to work with thicker gauge materials while maintaining consistent pressure throughout the forming operation.

Transfer stamping becomes the preferred choice when your parts require:

- Deep draws – The separated blank can undergo significant material deformation without strip constraints

- Large dimensions – Parts too wide or long for practical strip feeding move freely between stations

- Multiple forming operations – Threading, ribs, knurls, and complex geometries become achievable

- Precise orientation control – Each blank can be repositioned and aligned at every station

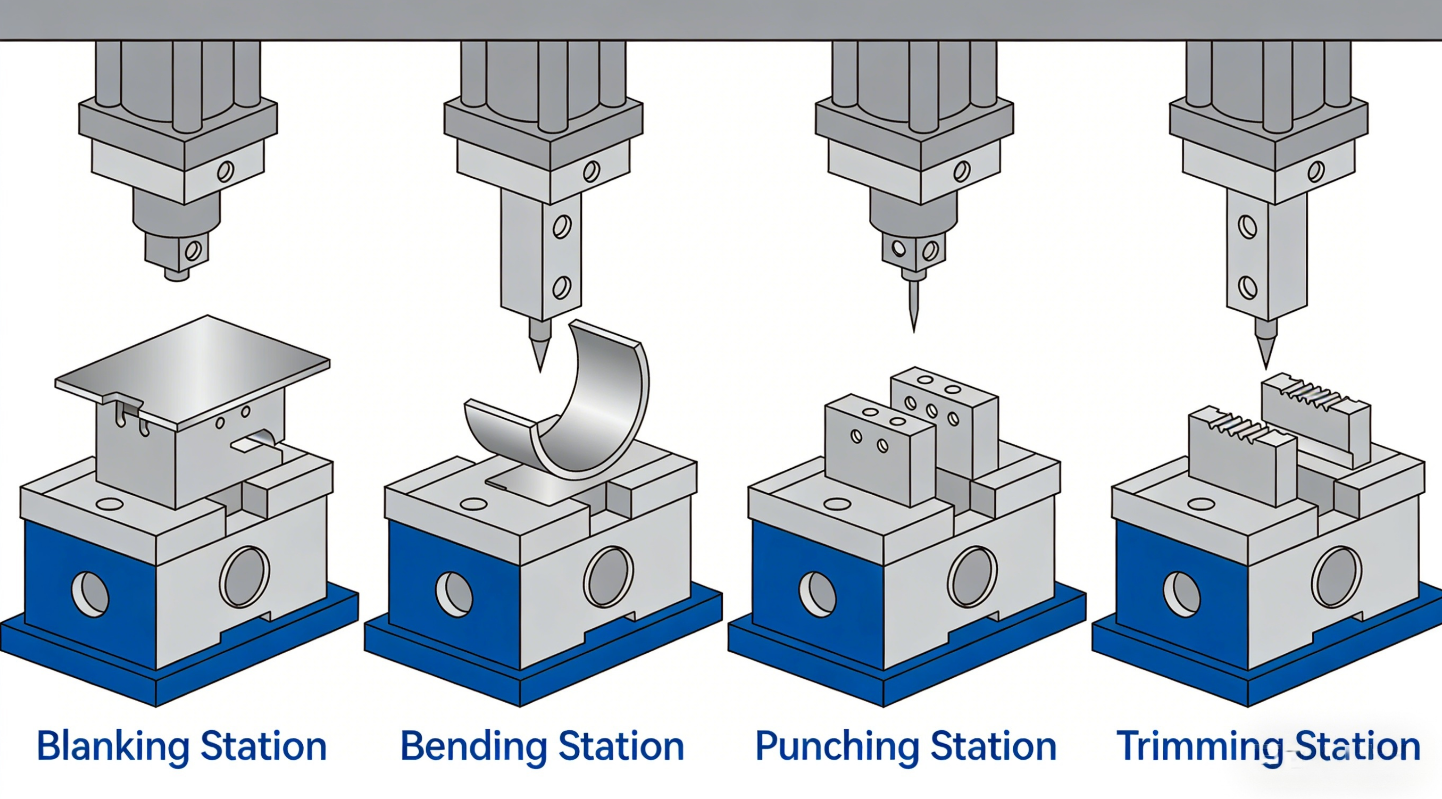

Transfer Mechanics and Station Design

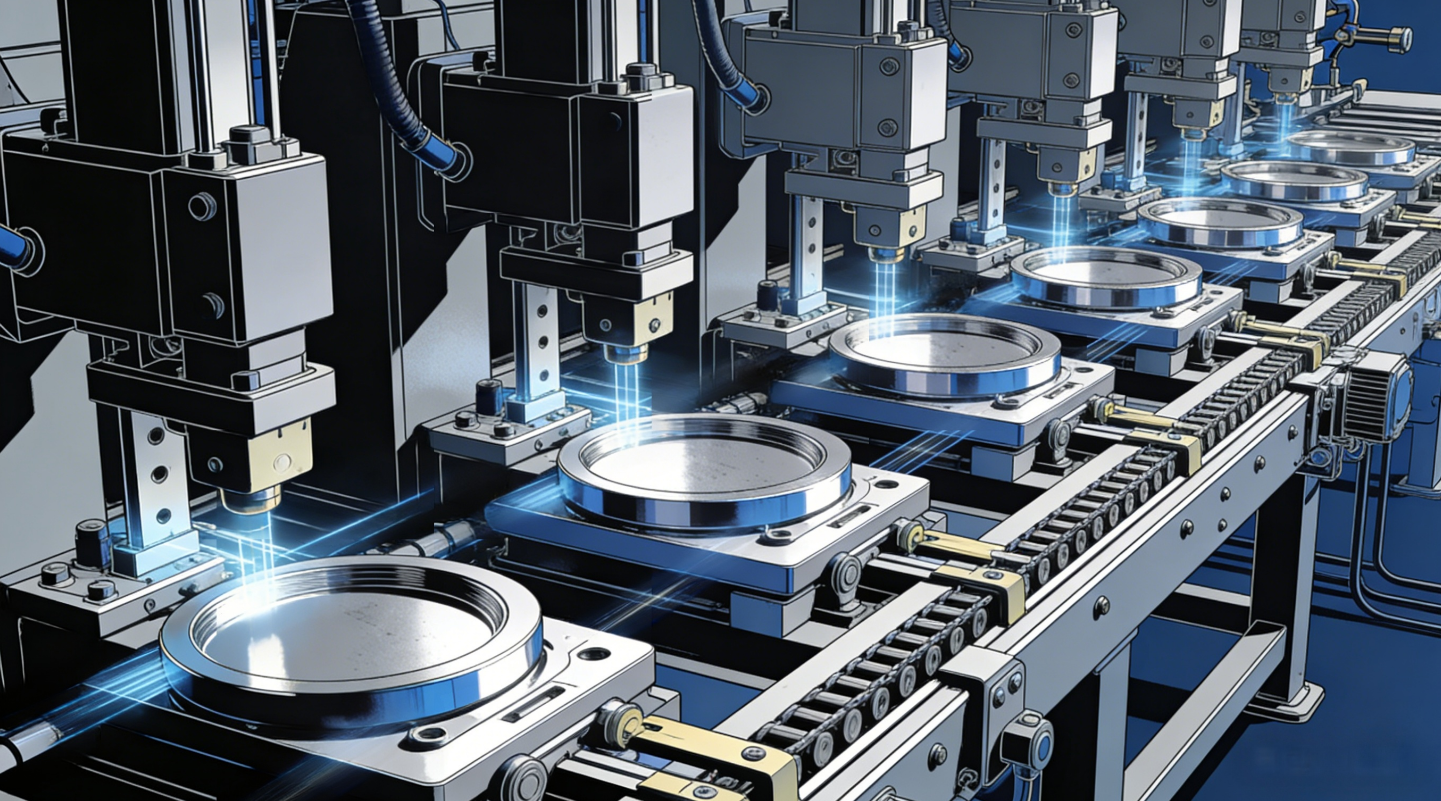

So how does the transfer process actually work? During transfer die stamping, mechanical or hydraulic transfer systems physically move partially formed blanks from one station to the next. Each station in the die set performs a dedicated function—piercing, drawing, trimming, or forming—before the transfer mechanism advances the part to its next operation.

As noted by Keats Manufacturing, the process relies on automation to transport and align workpieces to several stations, with each performing a different operation. This multi-step approach enables designs with high levels of intricacy that would be impossible with other die types.

The stop-and-go nature of transfer dies requires careful coordination between the transfer mechanism and die stations. Every blank must be accurately positioned before each operation proceeds. While this adds complexity, it also delivers exceptional control over material flow and deformation—resulting in parts with tight tolerances and dimensional accuracy.

Key Differentiators from Progressive Dies

Understanding when to choose transfer over progressive tooling comes down to recognizing their fundamental differences:

- Material handling – Transfer uses separated blanks; progressive uses connected strip material

- Part size capability – Transfer accommodates larger parts including body panels and structural components

- Deep draw capacity – Transfer excels at deep draws since the blank moves freely during forming

- Material efficiency – Transfer often utilizes less material per part, reducing scrap and lowering per-piece costs

- Setup complexity – Transfer requires longer setup times but offers greater flexibility for intricate designs

- Production speed – Progressive generally runs faster, while transfer prioritizes precision over speed

Industries that regularly rely on transfer dies include automotive manufacturing for body panels and structural components, aerospace for complex airframe parts, and heavy machinery for large-scale formed components. According to Die-Matic, more than half of stamping cost is material—so the transfer process's better material utilization helps lessen scrap and lower per-piece pricing.

While transfer die stamping involves higher operational costs due to setup complexity and skilled labor requirements, it remains the go-to solution when part complexity exceeds what progressive tooling can deliver. For simpler flat parts where multiple cutting operations must happen simultaneously with perfect alignment, manufacturers turn to yet another option—compound dies.

Compound Dies for Precision Flat Parts

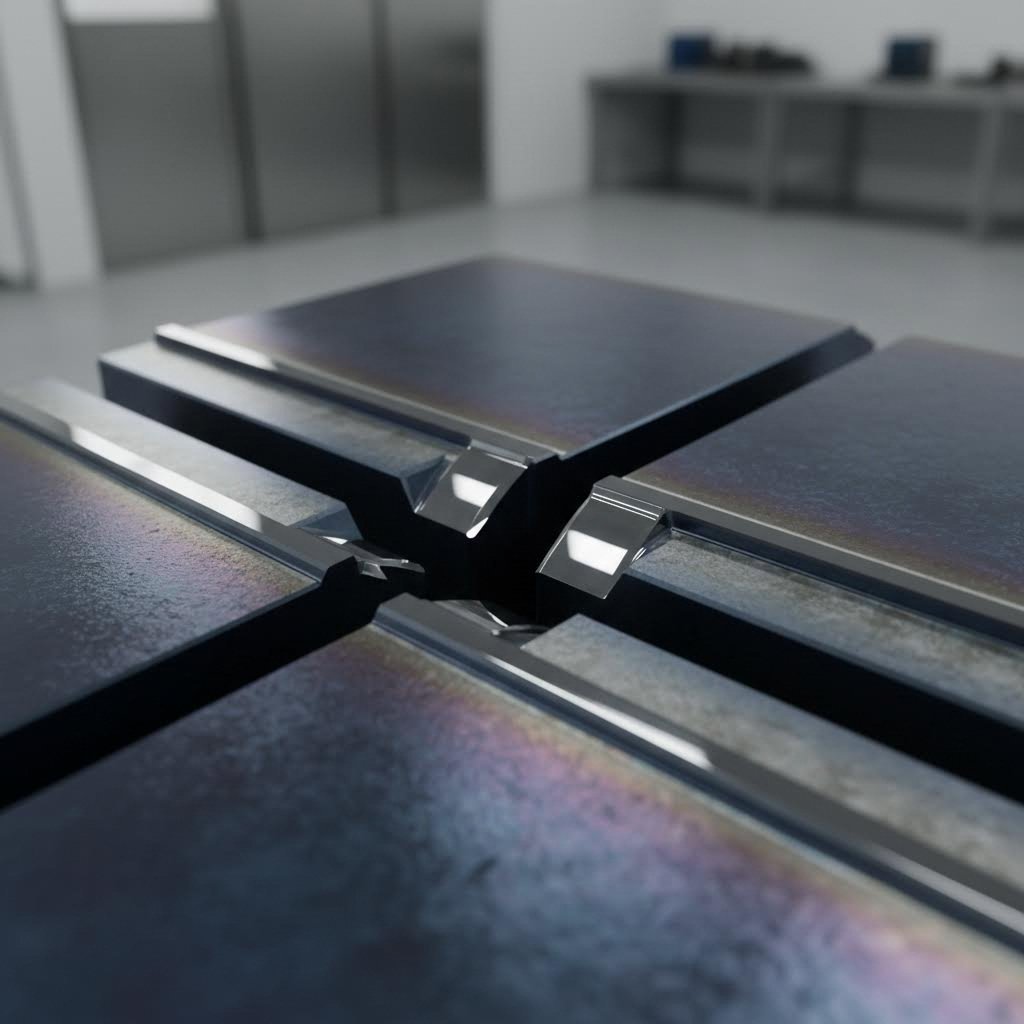

What if you need a washer with a perfectly centered hole—produced in one swift press stroke? This is where the compound die shines. Unlike progressive dies that move material through sequential stations, a compound die performs multiple cutting operations simultaneously in a single stroke, delivering exceptional precision for flat parts.

Sounds complex? The concept is actually straightforward. When your part requires multiple features that must align perfectly with each other, compound die stamping eliminates the alignment variations that can occur between separate operations.

Single-Stroke Precision for Flat Parts

Here's how compound dies work: the die performs blanking and piercing at the exact same moment. According to Alekvs, a compound die blanks and perforates a part simultaneously in the same station—typically punching holes downward while blanking the part upward, allowing slugs to fall through the die.

This simultaneous action creates a critical advantage: perfect concentricity and alignment between features. When metal punches and dies cut at the same instant, there's zero opportunity for the material to shift between operations. The result? Parts with precise geometric relationships that would be difficult to achieve through sequential stamping blanking processes.

Consider a simple washer. The outer diameter must be perfectly round, and the center hole must sit exactly in the middle. With a compound die, both cuts happen at once—guaranteeing that concentric relationship every single time.

Compound Die Applications and Limitations

While compound dies excel at what they do, understanding their boundaries helps you determine when this stamping die type fits your project. According to Master Products, compound die stamping is used to produce simple flat parts like washers, with the tooling performing multiple cuts, punches, and bends in a single stroke.

The key advantages of compound dies include:

- Perfect feature alignment – Simultaneous operations eliminate positioning errors between cuts

- Lower tooling costs – Custom tooling is less expensive to develop than complex progressive die tooling

- High repeatability – Single-die operation produces consistent results across production runs

- Efficient for simple geometries – Streamlined production for flat, relatively simple parts

However, compound dies come with inherent limitations:

- No forming capability – These dies cut material but cannot bend or form three-dimensional shapes

- Part complexity restrictions – Complex geometries require progressive or transfer dies instead

- Part removal requirements – Since parts remain in the die after stamping, a removal method is necessary

- Speed affected by part size – Larger components take longer to exit the die stamp, reducing cycle times

When to Choose Compound Versus Progressive Dies

Deciding between these two die types? Consider these factors:

- Choose compound dies when – You need flat parts with precise feature relationships, medium production volumes, simpler geometries, and lower upfront tooling investment

- Choose progressive dies when – You require complex shapes with forming operations, extremely high volumes, parts with multiple bends or three-dimensional features, and maximum production speed

As noted by Worthy Hardware, compound die stamping is more suited for smaller runs where precision is critical, while progressive die stamping is the go-to for high-volume production of complex parts.

For medium- to high-volume production of simple flat components, compound dies deliver cost-effective results with exceptional dimensional accuracy. When your parts require additional operations beyond cutting—or when you need the complete manufacturing toolkit—specialized die types round out your options.

Specialized Die Types and the Complete Framework

You've explored progressive, transfer, and compound dies—but the stamping world doesn't stop there. To truly master die selection, you need the complete picture. Beyond these "big three" categories exists a range of specialized sheet metal dies that handle unique manufacturing challenges, from prototype runs to complex forming operations.

Think of it as the "Solid Six" framework: six distinct types of dies that cover virtually every metal stamping scenario you'll encounter. Understanding this complete toolkit empowers you to match any part requirement to its optimal solution.

Beyond the Big Three Die Categories

Let's start with single-station dies—the workhorses of low-volume and prototype production. According to Custom Roll Form, single-station stamping dies are used in operations where a single element is created or a single operation is performed by each stamping press. If multiple operations are needed, the workpiece must move from press to press until completion.

Why choose single-station dies? When tooling investment must remain minimal—say, for prototype work, short production runs, or pilot projects—these dies deliver exactly what you need without the complexity. As noted by JVM Manufacturing, their straightforward design facilitates quick troubleshooting and adjustments, allowing for flexible manufacturing solutions.

The stamping tool and die landscape also includes combination dies, which merge cutting and forming in single operations. Unlike compound dies that only cut, combination dies handle both cutting and shaping—blanking, piercing, bending, and forming all within one stroke. According to Standard Die, combination dies offer multi-operation power that makes them suitable for various cutting and shaping applications, including manufacturing parts for mining equipment, electronics, and appliances.

Key benefits of combination dies include:

- Versatility – Handles both cutting and forming operations simultaneously

- Faster delivery – Multiple operations in one stroke reduce production time

- Reliable results – Consistent output across production runs

- Cost efficiency – Reduces the need for multiple separate die sets

Specialized Dies for Unique Forming Challenges

When your application demands specific metal forming operations, specialized metal forming dies step in to deliver precision results. These categories—bending dies, drawing dies, and forming dies—each excel at particular shaping tasks.

Bending dies create angular shapes by forcing material around a punch or into a die cavity. They're essential for brackets, channels, and any part requiring consistent bend angles. While conceptually different from open-die forging (which shapes material between flat dies without complete enclosure), bending dies use enclosed tooling to achieve precise, repeatable angles.

Drawing dies specialize in creating cup-shaped or box-shaped parts by pulling flat sheet metal into a die cavity. Deep drawing operations—where the depth exceeds the diameter—require dies engineered to control material flow and prevent tearing or wrinkling.

Forming dies handle complex three-dimensional shaping beyond simple bends or draws. They create ribs, embossed features, flanges, and curved surfaces that give parts their final geometry.

Here's something that surprises many newcomers: sheet metal die size varies dramatically based on application. A stamp die set for small electronic connectors might fit in your palm, while dies for automotive body panels can span 20 square feet or more. This range reflects the incredible versatility of stamping technology—from delicate precision components to massive structural parts.

The Complete Six Die Types Framework

Ready to see the complete picture? The following table presents all six die types with their characteristics and ideal applications:

| Die Type | Description | Best For | Volume Range |

|---|---|---|---|

| Progressive Die | Sequential stations perform operations as strip advances through the die | High-volume production of small to medium complex parts | 50,000+ parts annually |

| Transfer Die | Separated blanks move between stations via mechanical transfer | Large, complex parts requiring deep draws or multiple forming operations | Medium to high volume |

| Compound Die | Multiple cutting operations performed simultaneously in single stroke | Flat parts requiring precise feature alignment (washers, blanks) | Medium volume |

| Single-Station Die | One operation per press stroke; workpiece moves between presses | Prototypes, low-volume runs, simple parts | Low volume |

| Combination Die | Cutting and forming operations merged in single stroke | Parts needing both cutting and shaping in one operation | Medium to high volume |

| Specialized Forming Dies | Bending, drawing, and forming dies for specific shaping tasks | Angular bends, deep draws, complex 3D geometries | Varies by application |

Each die type occupies a specific niche in the manufacturing ecosystem. Single-station dies keep costs low when volumes don't justify complex tooling. Combination dies deliver efficiency when parts need both cutting and forming. Specialized forming dies handle the unique challenges that standard tooling can't address.

The key takeaway? No single die type works best for every situation. Your optimal choice depends on production volume, part complexity, budget constraints, and the specific operations your part requires. With this complete framework in hand, you're equipped to compare die types across the factors that matter most—which is exactly where we're headed next.

Die Type Comparison and Selection Criteria

You've explored each die type individually—but how do they stack up against each other when you're facing a real manufacturing decision? Choosing between progressive stamping dies, transfer dies, compound dies, and single-station options requires weighing multiple factors simultaneously.

Here's the challenge: most resources cover each die type in isolation. What you actually need is a side-by-side comparison that reveals which option wins under specific circumstances. Let's break down the critical performance factors that should drive your selection.

Comparing Die Types Across Key Performance Factors

When evaluating sheet metal stamping dies, five factors matter most: production volume, part complexity, tooling investment, per-part economics, and production speed. Each die type performs differently across these metrics—and understanding these trade-offs helps you make smarter tooling decisions.

| Factor | Progressive Die | Transfer Die | Compound Die | Single-Station Die |

|---|---|---|---|---|

| Volume Range | 50,000+ parts/year | 10,000–500,000 parts/year | 5,000–100,000 parts/year | Under 10,000 parts/year |

| Part Complexity | Medium to high (sequential operations) | High (deep draws, intricate features) | Low (flat parts only) | Low to medium (single operations) |

| Tooling Cost | High ($50,000–$500,000+) | High ($75,000–$400,000+) | Low to medium ($10,000–$75,000) | Low ($5,000–$30,000) |

| Per-Part Cost | Lowest at high volumes | Moderate (material savings offset setup) | Low for simple geometries | Highest (manual handling) |

| Production Speed | Fastest (100–1,500+ strokes/min) | Moderate (20–60 strokes/min) | Fast for flat parts | Slowest (manual transfer) |

| Best Applications | Automotive clips, electronic connectors, appliance components | Body panels, structural parts, deep-drawn cups | Washers, blanks, flat precision parts | Prototypes, short runs, simple brackets |

According to Worthy Hardware, the initial tooling cost for progressive die stamping can be high, but it becomes cost-effective in large-volume production due to lower per-part costs. Transfer die stamping involves higher operational costs, particularly for intricate designs and short runs, while compound die stamping proves more efficient in material usage—reducing scrap and overall costs.

Material and Volume Considerations

Your material choice significantly influences which die type delivers optimal results. Different steel stamping dies, aluminum tooling, and copper stamping setups each demand specific considerations based on material properties and thickness ranges.

Steel Stamping Dies

Steel—particularly carbon steel and stainless steel—works effectively across all die types. However, material thickness creates important constraints. According to Worthy Hardware, for progressive dies, very thick materials are unsuitable because they are difficult to flatten and feed accurately. Most precision components fall within the 0.2mm to 3mm range, though stamping can handle thicknesses from 0.05mm foils to plates exceeding 12mm.

For sheet metal stamping design involving thicker steel gauges (above 3mm), transfer dies or single-station dies typically outperform progressive options. The separated blank handling of transfer dies accommodates the rigidity of thicker materials without strip-feeding complications.

Aluminum and Copper

These softer metals present different challenges. Aluminum's tendency to gall (stick to tooling) requires careful die material selection and lubrication strategies. Progressive stamping dies handle aluminum well at higher speeds, making them ideal for high speed metal stamping applications in electronics and consumer goods.

Copper and brass—commonly used in electrical components—stamp effectively in progressive dies. According to Engineering Specialties, progressive die stamping may use a variety of metals including steel, aluminum, copper, stainless steel, and brass, with noble metals, titanium, and superalloys also viable for specialized applications.

Material Thickness Guidelines

A critical rule of thumb guides your sheet metal stamping design decisions: the diameter of any punched hole should be at least equal to the material thickness. This prevents punch breakage, especially with harder materials. As noted by Worthy Hardware, experienced manufacturers can sometimes work around this rule using heavy-duty punch and die sets made from highly durable tool steel, adjusted press speeds, and specialized lubricants.

| Material | Common Thickness Range | Best Die Types | Special Considerations |

|---|---|---|---|

| Carbon Steel | 0.3mm–6mm | All types (progressive for thinner gauges) | Thicker gauges favor transfer or single-station |

| Stainless Steel | 0.2mm–4mm | Progressive, transfer, compound | Harder grades increase tooling wear |

| Aluminum | 0.3mm–5mm | Progressive (high speed), transfer | Requires anti-galling lubrication |

| Copper/Brass | 0.1mm–3mm | Progressive, compound | Excellent for electrical components |

| Noble Metals | 0.05mm–1mm | Progressive, compound | High-precision tolerance requirements |

Tolerance and Speed Trade-offs

When precision matters, your die selection must account for achievable tolerances and how speed affects accuracy. Progressive stamping dies deliver exceptional repeatability—each part receives identical processing, eliminating operator-induced variation. For high-speed applications, this consistency proves invaluable.

However, as noted by Worthy Hardware, transfer die stamping requires a higher degree of precision in die design and maintenance to ensure consistent quality and efficient operation. The trade-off? Transfer dies often achieve tighter tolerances on complex geometries because each blank receives individual attention at every station.

Compound dies excel when feature-to-feature precision matters most. Simultaneous cutting operations guarantee perfect alignment between holes and outer profiles—a capability that sequential operations struggle to match.

For multislide stamping materials and four-slide applications—which use cam-driven slides rather than vertical presses—even thinner materials and more intricate bending operations become possible. These specialized approaches complement traditional die types for specific part geometries.

Making Your Selection Decision

With all these factors in mind, how do you actually choose? Start with volume and work backward:

- Under 5,000 parts annually? Single-station dies keep tooling costs proportional to production value

- 5,000–50,000 parts? Compound dies for flat parts; combination dies for parts needing cutting and forming

- 50,000+ parts with moderate complexity? Progressive stamping die investments pay off through per-part savings

- Large parts or deep draws at any volume? Transfer dies remain your primary option regardless of quantity

Remember: the "best" die type doesn't exist in isolation. Your optimal choice emerges from balancing volume economics, part requirements, material constraints, and timeline pressures. Understanding how die materials and construction affect long-term performance adds another layer to this decision—which we'll explore next.

Die Materials Construction and Maintenance

You've selected the right die type for your application—but here's a question that often gets overlooked: what's your die actually made of? The materials and construction of your stamping die components directly determine how long that tooling lasts, how often you'll face maintenance shutdowns, and ultimately, your total cost of ownership.

Think of it this way: two identical progressive dies running the same parts can deliver wildly different lifespans depending on their construction. One might produce 50,000 parts before needing attention; another built with superior materials might run 500,000 cycles or more. Understanding die materials transforms your tooling from an expense into a strategic investment.

Die Construction Materials and Their Impact

Metal stamping tooling relies on carefully selected materials engineered to withstand extreme pressures, repetitive stress, and constant friction. According to SteelPro Group, die steel is a high-performance material classified into cold work, hot work, and plastic mold steels—each optimized for specific operating conditions.

The most common tool steels used in stamping tooling include:

- D2 (Cold Work Tool Steel) – High carbon and chromium content delivers exceptional wear resistance. Ideal for cutting and blanking operations where abrasion resistance matters most. Hardness reaches RC 58-62.

- A2 (Air-Hardening Tool Steel) – Balances wear resistance with better toughness than D2. Offers excellent dimensional stability during heat treatment, making it suitable for precision applications.

- S7 (Shock-Resistant Tool Steel) – Engineered for high impact resistance. Choose this grade when dies face heavy shock loads during forming or drawing operations.

- H13 (Hot Work Tool Steel) – Maintains hardness at elevated temperatures. Essential for operations generating significant heat or when stamping high-strength materials.

- Powder Metallurgy (PM) Tool Steels – Advanced manufacturing creates finer, more evenly distributed carbides. According to AHSS Insights, PM tool steels retain hardness without compromising toughness—delivering up to 10x longer life than conventional grades in demanding applications.

Why does material selection matter so much? When forming Advanced High-Strength Steels, sheet metal hardness can approach the tooling hardness itself. As noted by AHSS Insights, some martensitic grades reach Rockwell C values higher than 57—meaning the material you're stamping is nearly as hard as the die shaping it.

This creates a demanding environment where inferior die materials fail rapidly. Metal stamping die sets built from conventional steels may last 50,000 cycles on mild steel but fail after just 5,000-7,000 cycles when processing high-strength grades.

Surface Treatments and Coatings That Extend Die Life

Even premium tool steels benefit from surface treatments that reduce friction, prevent galling, and dramatically extend service life. The right coating transforms good tooling into exceptional tooling.

According to AHSS Insights, common surface treatments include:

- Flame or Induction Hardening – Creates a hard surface layer while maintaining a tough core. Suitable for larger die components where through-hardening isn't practical.

- Nitriding (Gas or Plasma) – Introduces nitrogen into the surface layer, creating exceptional hardness without dimensional distortion. Ion nitriding processes faster at lower temperatures than gas nitriding.

- Physical Vapor Deposition (PVD) Coatings – Applies thin, extremely hard coatings like titanium nitride (TiN), titanium aluminum nitride (TiAlN), or chromium nitride (CrN). PVD operates at lower temperatures than CVD, avoiding die softening.

- Chemical Vapor Deposition (CVD) – Creates stronger metallurgical bonds than PVD but requires higher processing temperatures that may affect die hardness.

The performance difference is striking. A chrome-plated cutting tool failed after just 50,000 parts, while an ion-nitrided tool with chromium nitride PVD coating produced more than 1.2 million parts before replacement—a 24x improvement in tool life.

Bypass notches in sheet metal stamping dies benefit particularly from these treatments. Since bypass notches experience repeated contact with advancing strip material, surface hardening at these locations prevents premature wear that would otherwise cause feeding problems and part quality issues.

Maintenance Planning for Maximum Die Life

Even the finest stamping tooling requires systematic maintenance to achieve its full lifespan potential. According to Partzcore, the lifespan of a metal stamping die can range from thousands to millions of cycles—with proper care being the decisive factor.

Effective maintenance practices include:

- Detailed maintenance logs – Document usage, repairs, and inspections to identify patterns and refine maintenance schedules

- Regular cleaning – Remove debris and residue after each production run to prevent misalignment and maintain precision

- Alignment inspections – Check die alignment regularly to avoid uneven wear and ensure consistent part quality

- Component replacement – Replace worn punches, inserts, or cutting edges independently rather than scrapping entire die sets

- Proper lubrication – Reduce friction between die and material, minimizing wear and heat generation

Signs your tool stamp needs attention include edge deterioration (rounded or chipped cutting edges), visible cracks or fractures, inconsistent part dimensions, and unusual noise during operation. Catching these early prevents costly emergency repairs and production interruptions.

Lifespan expectations vary significantly by die type and application. Progressive dies processing mild steel might achieve 1-2 million cycles between major maintenance, while the same tooling running high-strength steel may require attention every 100,000-200,000 cycles. Transfer dies handling deep draws experience different wear patterns—with draw radii and blank holders requiring more frequent inspection than cutting stations.

The investment in quality materials and proper maintenance pays dividends over your tooling's lifetime. Premium die construction might cost 20-30% more upfront, but if it delivers 5-10x the service life, your true per-part tooling cost drops dramatically. Factor in reduced downtime, fewer emergency repairs, and more consistent part quality—and the economics become compelling.

With die materials and maintenance practices established, the question becomes: how do different industries apply these principles to meet their unique quality standards and production demands?

Industry Applications and Quality Standards

Different industries don't just use different parts—they demand entirely different approaches to precision die stamping. What works for automotive brackets won't necessarily meet the stringent requirements of medical progressive stamping, and appliance components face cost pressures that aerospace parts never encounter.

Understanding how industry-specific requirements shape die selection helps you align your manufacturing strategy with the standards your customers expect. Let's explore what sets each sector apart—and how precision die & stamping solutions adapt to meet these varied demands.

Automotive Industry Die Requirements

Automotive manufacturing operates at a scale and precision level that demands exceptional tooling performance. From structural brackets to electronic connectors, precision stamping products must meet exacting dimensional tolerances while running at production volumes that stretch into the millions.

What separates automotive-grade stamping from other industries? Certification requirements establish the baseline. According to OGS Industries, IATF 16949 certification goes beyond ISO 9001 requirements to ensure compliance with lean manufacturing, defect prevention, variance deterrence, and waste reduction. This automotive-specific standard creates a framework where quality isn't optional—it's systematically built into every process.

The benefits of working with IATF 16949-certified manufacturers include:

- Consistent quality – Monitored and measured processes maximize productivity and deliver repeatable outcomes

- Reduced product variation – Reviewed manufacturing processes ensure metal components consistently meet high-performance vehicle requirements

- Reliable supply chain – International certification establishes benchmarks for sourcing and supplier qualification

- Defect prevention – Proven processes for metal fabrication, production, and finishing minimize defects throughout production

Progressive dies dominate automotive stamping applications where volumes justify tooling investment. Electrical metal stamping for vehicle wiring harnesses, structural brackets, and electronic sensor housings all benefit from progressive die efficiency. For larger body panels and structural components, transfer dies deliver the deep-draw capabilities automotive designs require.

Manufacturers like Shaoyi combine IATF 16949 certification with advanced CAE simulation capabilities, achieving first-pass approval rates of 93%—a metric that directly translates to faster production timelines and reduced tooling iteration costs.

The Role of CAE Simulation in Modern Die Development

Imagine identifying and fixing stamping defects before cutting a single piece of steel. That's exactly what Computer-Aided Engineering (CAE) simulation delivers—and it's transforming how precision die manufacturers approach tooling development.

According to Keysight, the sheet metal forming industry faces significant challenges where defects often emerge only during the first physical trials—when corrections become both time-consuming and costly. Virtual die try-outs change this equation entirely.

CAE simulation addresses critical manufacturing challenges:

- Material selection and springback – Advanced high-strength steels and aluminum alloys exhibit high springback magnitudes that simulation predicts before production

- Process optimization – Virtual testing fine-tunes press speed, blank holder force, and lubrication without consuming physical materials

- Defect prediction – Identifies potential surface defects, wrinkles, and tears in the digital environment

- Material variation response – Models how variations in material properties within the same batch affect part quality

For automotive OEMs, simulation-validated tooling means fewer surprises during production launch. When die manufacturers leverage CAE simulation alongside rapid prototyping capabilities—with some delivering prototype parts in as little as 5 days—development timelines compress dramatically while quality improves.

Medical and Electronics Precision Standards

While automotive emphasizes volume and consistency, medical metal stamping prioritizes absolute precision and traceability. Every component must meet exacting specifications because patient safety depends on it.

According to Progressive Die and Stamping, medical progressive stamping involves feeding flat, thin metal stock through stamping machines that pierce, cut, or bend material into precision medical or dental parts. The process requires in-house die tooling designed and fabricated in controlled environments to guarantee quality and accuracy.

Medical stamping capabilities include:

- Progressive die stamping – Produces high-volume medical components with consistent quality

- Custom die tooling – Hygienic stainless steel tooling designed specifically for medical applications

- CAD engineering – Digital models ensure precision before production begins

- Prototype stamping – Tests fit, form, and function before committing to production tooling

The electronics sector shares this precision focus but adds speed requirements. Electrical metal stamping for connectors, terminals, and shield components demands tolerances measured in thousandths of an inch—while production runs at hundreds of strokes per minute. Progressive dies excel here, delivering the combination of speed and precision that electronics manufacturing requires.

Appliance and Consumer Goods Applications

Appliance manufacturing balances different priorities: cost efficiency, aesthetic quality, and functional durability. Unlike medical components where cost takes a backseat to precision, appliance stamping must optimize per-part economics while maintaining acceptable quality levels.

Progressive and combination dies handle most appliance stamping applications—structural components, decorative trim, mounting brackets, and functional hardware. The key differentiator? Tooling must deliver consistent cosmetic quality on visible surfaces while meeting functional requirements on hidden features.

Die selection for appliance applications typically follows volume-driven economics:

- High-volume decorative parts – Progressive dies with polished forming surfaces

- Structural brackets – Progressive or combination dies optimized for speed

- Large panels – Transfer dies for deep-drawn components

- Specialty hardware – Compound dies for flat precision parts

Matching Industry Requirements to Die Selection

Each industry's unique demands point toward specific die type preferences:

| Industry | Primary Die Types | Key Requirements | Critical Standards |

|---|---|---|---|

| Automotive | Progressive, Transfer | High volume, tight tolerances, defect prevention | IATF 16949, OEM specifications |

| Medical | Progressive, Compound | Absolute precision, traceability, sterile materials | FDA, ISO 13485 |

| Electronics | Progressive, Compound | Tight tolerances, high speed, miniaturization | IPC standards, RoHS compliance |

| Appliance | Progressive, Combination, Transfer | Cost efficiency, cosmetic quality, durability | UL, CSA, industry-specific |

When evaluating precision die & stamping partners, look beyond basic capabilities to industry-specific expertise. A manufacturer experienced in your sector understands the unwritten rules—the tolerance expectations that don't appear on drawings, the surface finish requirements that customers assume, and the documentation standards that procurement teams demand.

The combination of proper certification, simulation-validated tooling, and industry expertise separates adequate suppliers from strategic partners. For manufacturers ready to move forward with die selection, the next step is translating these industry requirements into a practical decision framework that guides your specific project choices.

Choosing the Right Die Type for Your Project

You've explored the full spectrum of stamping dies types—but knowledge without action leaves production decisions unresolved. How do you actually translate everything you've learned into a concrete choice for your specific project?

Here's the reality: selecting the right stamping die design isn't about finding the "best" option in absolute terms. It's about matching your unique requirements—volume, complexity, budget, and timeline—to the die type that delivers optimal results for your situation. Let's build a practical framework that guides you through this decision.

Your Die Selection Decision Framework

Forget the assumption that one die type fits all scenarios. Effective metal stamping die design starts with honest assessment of your project parameters. Work through these steps systematically, and you'll arrive at the right solution:

- Determine your annual production volume – This single factor eliminates options faster than any other. Under 5,000 parts annually? Progressive dies rarely make economic sense. Planning 500,000+ parts? Single-station dies create unnecessary labor costs.

- Assess part geometry and complexity – Flat parts with precise feature relationships point toward compound dies. Deep draws or large dimensions require transfer capabilities. Multiple sequential operations favor progressive die metal stamping.

- Evaluate material requirements – Thick gauges above 3mm often exceed progressive strip-feeding limits. High-strength steels demand tooling built from premium materials. Consider how your material choice constrains die options.

- Calculate your tooling budget – Progressive die investments range from $50,000 to $500,000+. If your total project value doesn't justify this investment, simpler tooling delivers better ROI.

- Define timeline constraints – Complex progressive dies require 12-20 weeks for development. Urgent projects may need single-station or compound dies that ship in 4-8 weeks.

- Consider secondary operations – Will parts require additional processing after stamping? Factor these costs into your per-part economics when comparing die types.

According to Zintilon, estimating annual production volume is crucial for justifying investment in different die types, while analyzing expected batch sizes and production frequencies helps determine the most efficient tooling utilization.

Busting Common Die Selection Myths

Before you finalize your decision, let's address misconceptions that lead manufacturers astray:

"Progressive dies are always the best choice for complex parts."

This assumption costs manufacturers money. Progressive dies excel at high-volume production of small to medium parts—but they're overkill for lower volumes and impossible for parts requiring deep draws. A 10,000-part annual run of complex stamping components might achieve better economics with transfer tooling despite higher per-cycle costs.

"Lower tooling cost means lower total cost."

Single-station dies cost less upfront, but manual handling between operations adds labor expense to every part. At sufficient volumes, expensive progressive tooling delivers lower per-part costs that quickly offset the initial investment.

"One die stamping machine handles everything."

Different die types often require different press specifications. Transfer dies need presses with transfer mechanisms. High-speed progressive operations demand presses rated for rapid cycling. Match your die selection to available equipment—or factor press investment into your decision.

"Precision die & stamping inc capabilities are interchangeable between suppliers."

Not all die manufacturers deliver equal results. Experience with your specific industry, material expertise, and quality certifications create meaningful differences in tooling performance and longevity.

Essential Questions for Die Manufacturers

When you're ready to engage with potential tooling partners, these questions separate capable suppliers from the rest. According to Actco Tool, asking detailed questions ensures alignment with your needs, capabilities, and expectations.

- What types of dies do you specialize in manufacturing? – Confirms their capabilities match your specific requirements—whether progressive, transfer, compound, or specialized tooling.

- What industries do you typically serve? – Experience in your sector indicates familiarity with tolerance expectations, documentation standards, and industry-specific challenges.

- Can you provide examples or case studies of similar projects? – Real-world examples demonstrate their ability to handle your specific part geometry and production requirements.

- What is your typical lead time for die manufacturing? – Lead times vary significantly by complexity. Ensure their timeline aligns with your production schedule.

- What are your capabilities regarding precision and tolerances? – Precision is non-negotiable in metal stamping die design. Verify their tolerance capabilities meet your specifications.

- Do you offer prototyping services before full-scale production? – Prototyping validates design and functionality before committing to production tooling investment.

- What is your quality control process? – Rigorous QC procedures ensure the final die meets specifications and delivers consistent production results.

- Do you provide post-production maintenance, repair, or modification services? – Ongoing support extends die life and ensures long-term production capability.

- How do you handle material selection and sourcing? – Tool steel quality directly impacts die durability and performance.

- What certifications do you hold? – IATF 16949 for automotive, ISO certifications for quality management—credentials matter for demanding applications.

Taking Action on Your Die Selection

You've built the knowledge foundation. Now it's time to move forward. Here's your action plan:

For projects still in design phase: Engage tooling partners early. According to Keysight, CAE simulation enables virtual die try-outs that identify and resolve defects before physical tooling begins—saving both time and iteration costs.

For projects ready for quoting: Prepare detailed part drawings, annual volume projections, material specifications, and tolerance requirements. Request quotes from multiple qualified suppliers to compare capabilities and pricing.

For urgent production needs: Prioritize manufacturers offering rapid prototyping capabilities. Some suppliers deliver prototype parts in as little as 5 days, allowing design validation before committing to production tooling. Manufacturers like Shaoyi combine rapid prototyping with high-volume manufacturing expertise—achieving 93% first-pass approval rates through advanced CAE simulation and IATF 16949-certified processes.

The right die type transforms your production economics. Wrong choices create ongoing costs through inefficiency, quality issues, or excessive tooling investment. By following this decision framework, asking the right questions, and partnering with qualified manufacturers, you position your stamping operations for success—whether you're producing 5,000 parts or 5 million.

Frequently Asked Questions About Stamping Dies Types

1. What are the different types of stamping dies?

The main stamping dies types include progressive dies for high-volume sequential operations, transfer dies for large complex parts with deep draws, compound dies for precision flat parts requiring simultaneous cutting, single-station dies for low-volume or prototype work, combination dies that merge cutting and forming, and specialized forming dies for bending, drawing, and shaping operations. Each type serves distinct manufacturing needs based on part complexity, production volume, and budget constraints.

2. How many types of stamping are there?

There are six primary stamping die categories known as the 'Solid Six' framework: progressive dies, transfer dies, compound dies, single-station dies, combination dies, and specialized forming dies (including bending, drawing, and forming dies). Beyond die types, stamping processes themselves include blanking, piercing, bending, drawing, embossing, coining, stretching, and curling—each performing specific metal-shaping functions.

3. What are the four types of metal stamping?

The four primary metal stamping techniques are progressive die stamping (sequential multi-station operations on strip material), transfer die stamping (separate blanks moved between stations for complex large parts), compound die stamping (simultaneous cutting operations for flat precision parts), and deep draw stamping (forming cup or box shapes from flat sheets). Production volume, part geometry, and complexity determine which method delivers optimal results for your specific application.

4. How do I choose between progressive and transfer dies?

Choose progressive dies when producing 50,000+ small-to-medium parts annually that can remain connected to strip material throughout processing. Select transfer dies when parts require deep draws, exceed strip-feeding size limits, or need individual blank handling. Progressive dies offer faster cycle times and lower per-part costs at high volumes, while transfer dies handle complex geometries and larger dimensions that progressive tooling cannot accommodate.

5. What factors affect stamping die lifespan and maintenance costs?

Die lifespan depends on tool steel grade (D2, A2, S7, H13, or powder metallurgy steels), surface treatments (nitriding, PVD coatings), material being stamped, production volume, and maintenance practices. Premium dies can produce 500,000 to over 1 million cycles when properly maintained. Regular cleaning, alignment inspections, lubrication, and timely component replacement extend die life significantly. High-strength steel stamping accelerates wear, requiring more frequent maintenance intervals.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —