Coil Spring Vs Nitrogen Spring: Which One Is Bleeding Your Budget?

The Spring Selection Dilemma in Modern Stamping Operations

Every stamped part that leaves your production line carries the fingerprint of one critical decision: which spring technology powers your die. Whether you're running high-volume automotive panels or precision-formed components, the choice between coil vs spring alternatives—specifically traditional metal coils versus nitrogen gas systems—directly impacts your bottom line, part quality, and operational efficiency.

Here's the uncomfortable truth: selecting the wrong spring system doesn't just cause minor inconveniences. It triggers a cascade of problems that bleed your budget through multiple channels you might not immediately recognize.

Why Your Spring Selection Impacts Every Stamped Part

Imagine running a progressive die at 60 strokes per minute. That's 3,600 compression cycles every hour, each one demanding precise force delivery to strip parts cleanly and maintain dimensional accuracy. When your spring technology fails to deliver consistent force throughout its stroke, you'll notice the consequences almost immediately:

- Parts sticking in the die, causing micro-delays that accumulate into significant downtime

- Inconsistent material flow leading to dimensional variations and scrap rates climbing

- Premature wear on punch and die surfaces from uneven stripping forces

- Unexpected spring failures halting production at the worst possible moments

So, what is a gas spring, and how does it compare to the traditional coiled steel wire approach? At their core, both technologies serve the same purpose—storing and releasing energy to perform work in your tooling. Yet they accomplish this goal through fundamentally different mechanisms, each with distinct advantages depending on your specific application requirements.

The Hidden Costs of Choosing the Wrong Spring Technology

The spring vs coil debate isn't about crowning a universal winner. It's about matching technology to application. Choosing based solely on initial purchase price—or worse, simply defaulting to "what we've always used"—often creates hidden costs that dwarf any upfront savings.

Consider the stamping operation that selects coil springs purely for their lower price point, only to discover their space constraints require undersized springs that fatigue prematurely. Or the shop that invests in premium nitrogen systems for every application, including low-volume prototype work where simpler technology would suffice.

In this comprehensive comparison, we'll cut through manufacturer marketing claims to examine both technologies objectively. You'll discover exactly when each spring type delivers optimal value, how to calculate true cost of ownership, and which specific applications favor one technology over the other. No sales pitch—just practical engineering guidance you can apply to your next die design decision.

How We Evaluated Coil and Nitrogen Spring Performance

Before diving into product-by-product analysis, you need to understand how we're measuring success. A fair comparison between compression gas springs and compression coil springs requires a consistent evaluation framework—one that reflects real-world tooling demands rather than laboratory ideals.

Think of it this way: you wouldn't compare two stamping presses by looking only at tonnage ratings. You'd examine stroke speed, shut height, bed accuracy, and dozens of other factors. Spring technology deserves the same rigorous, multi-dimensional assessment.

Five Critical Factors for Spring Technology Evaluation

Our comparison centers on five criteria that die professionals consistently identify as make-or-break factors in spring selection. These aren't abstract engineering metrics—they're the practical considerations that determine whether your tooling runs smoothly or becomes a maintenance nightmare.

- Force Consistency: How stable is the force output throughout the compression stroke? Does the spring deliver predictable stripping power at every position?

- Space Efficiency: What force-to-footprint ratio does each technology offer? Can you achieve required tonnage within your die envelope constraints?

- Maintenance Requirements: What ongoing attention does each spring type demand? How do inspection intervals and replacement schedules compare?

- Total Cost of Ownership: Beyond initial purchase price, what are the lifetime costs including replacements, downtime, and quality impacts?

- Application-Specific Performance: How does each technology perform under your specific conditions—cycle rates, temperatures, contamination exposure?

Each criterion carries different weight depending on your operation. A high-volume automotive stamper might prioritize force consistency above all else, while a job shop running diverse short runs might value maintenance simplicity more heavily.

Understanding Force Delivery Mechanisms

Here's where the fundamental physics difference between these technologies becomes critical. Understanding how each spring generates and delivers force helps you predict performance in your specific application.

For nitrogen gas springs, force calculation follows the principle F=PA—force equals pressure multiplied by piston area. This means a gas spring delivers relatively constant force throughout its stroke because gas pressure remains largely stable during compression. You'll notice the force curve stays nearly flat, providing predictable stripping power whether the spring is at 10% compression or 90% compression.

Compression coil springs behave differently. Their force output follows Hooke's Law, where force increases proportionally with deflection. The K-factor (spring rate) and progression rate determine how dramatically force climbs as the spring compresses. A standard coil spring might deliver 500 pounds at initial contact but 800 pounds at full compression—a 60% increase that directly affects how your die performs at different points in the stroke.

Why does this matter for your tooling? Consider a stripping application where consistent force prevents part distortion. The rising force characteristic of coil springs means you're either undersizing for the initial stroke or oversizing for full compression. Nitrogen technology eliminates this compromise, but at higher cost and added complexity.

With this evaluation framework established, let's examine each spring technology in detail—starting with the traditional workhorse that still dominates countless stamping operations worldwide.

Metal Coil Springs for Reliable Force Delivery

Walk into any stamping facility, and you'll find them everywhere—those familiar spirals of steel wire quietly doing their job in die after die. The metal coil spring has earned its reputation as the dependable workhorse of the tooling world, and for good reason. But what exactly makes this seemingly simple technology tick, and where does it truly excel?

Understanding what is spring coil technology at a fundamental level helps you recognize both its strengths and limitations. Let's break down the mechanics, applications, and honest assessment of where coil spring metal solutions deliver—and where they fall short.

How Metal Coil Springs Store and Release Energy

Picture a length of high-carbon steel wire wound into a precise helical shape. That's your coil spring in its simplest form. But the magic happens in the physics of compression.

When you compress a metal coil spring, you're actually twisting the wire along its entire length. Each coil rotates slightly as the spring shortens, storing mechanical energy in the form of torsional stress within the wire itself. Release that compression, and the stored energy pushes back—delivering the force that strips parts, holds workpieces, or performs whatever work your die requires.

Here's where things get interesting for die designers. Unlike gas-based systems, what is coiled spring force behavior follows a linear progression. The more you compress, the harder the spring pushes back. This relationship—governed by the spring's rate constant—means force increases predictably throughout the stroke.

Consider a spring with a 100 lb/inch rate. At 0.5 inches of compression, you get 50 pounds of force. At 1.5 inches, that climbs to 150 pounds. This progressive force characteristic works perfectly for some applications while creating challenges in others.

The wire diameter, coil diameter, number of active coils, and material properties all influence how a spring performs. Heavier wire and fewer coils create stiffer springs with higher force output but shorter stroke capability. Lighter wire with more coils delivers gentler force curves but requires more physical space.

Best Applications for Traditional Coil Technology

So when does traditional coil spring technology make the most sense? The answer often comes down to matching the spring's characteristics to your specific operational requirements.

Standard blanking operations represent the sweet spot for coil springs. When you're punching parts from sheet metal and need reliable stripping force without extreme precision requirements, coil springs deliver predictable performance at an attractive price point. The progressive force curve actually helps here—lighter initial contact force reduces marking on finished parts, while higher force at full compression ensures positive stripping.

Forming operations with generous die envelopes also favor coil technology. When space isn't at a premium, you can size springs appropriately without the cost premium of compact alternatives. Many forming dies have operated reliably for decades using nothing but well-selected coil springs.

Prototype and low-volume production work benefits from coil spring simplicity. Quick availability, easy replacement, and zero pressure monitoring requirements mean less complexity during development phases when designs frequently change.

Pros

- Lower Initial Investment: Coil springs typically cost a fraction of equivalent-force nitrogen alternatives, making them budget-friendly for standard applications

- Zero Sealing Concerns: No pressurized gas means no seals to degrade, leak, or fail unexpectedly during production

- Infinite Shelf Life: Store coil springs for years without degradation—they're ready when you need them without pressure checks or maintenance

- Simple Replacement: Any maintenance technician can swap a coil spring in minutes without specialized tools or safety procedures

- Predictable Force Progression: Linear force curves are easily calculated and consistent from spring to spring

- Wide Availability: Standard sizes ship quickly from numerous suppliers, reducing lead time concerns

Cons

- Larger Footprint Required: Achieving high force output demands physically larger springs, consuming valuable die real estate

- Force Variation Through Stroke: The 30-60% force increase from preload to full compression complicates applications requiring consistent stripping pressure

- Fatigue Life Limitations: After millions of cycles, wire fatigue can cause sudden failure—often without warning signs

- Height Requirements: Adequate free length plus solid height plus working stroke often exceeds available shut height in compact dies

- Set and Creep Over Time: Heavily loaded springs may lose free length gradually, reducing preload force over extended service

The reality is straightforward: metal coil springs remain the right choice for a significant percentage of stamping applications. Their simplicity, reliability, and cost-effectiveness make them impossible to ignore—especially when die space allows proper sizing and force progression doesn't create quality issues.

However, when your application demands consistent force throughout the stroke, or when space constraints make adequate coil sizing impossible, you'll need to explore the alternative technology designed specifically to address those limitations.

Nitrogen Gas Springs for Consistent Compact Force

Now imagine a completely different approach to force delivery. Instead of twisted steel wire, picture a precision-machined cylinder filled with pressurized nitrogen gas—a sealed powerhouse that fits in your palm yet delivers forces that would require a coil spring the size of your forearm. That's the fundamental appeal of nitrogen spring technology, and it's why nitrogen die springs have become essential components in demanding stamping applications worldwide.

But before you rush to replace every coil spring in your tool room, you need to understand exactly how this technology works, where it excels, and what trade-offs come with that compact power delivery.

The Science Behind Nitrogen Gas Spring Technology

Think of a nitrogen spring as a sophisticated piston-cylinder assembly. A hardened steel piston rod extends from a precision-bored cylinder body, with the internal chamber charged with nitrogen gas at pressures typically ranging from 150 to 2,500 psi—sometimes even higher for specialty units.

Here's where the physics gets interesting. When you compress the piston rod into the cylinder, you're reducing the volume available for the gas inside. According to the ideal gas laws, this pressure increase is relatively modest compared to the dramatic force changes you'd see with coil springs. The result? A force curve that stays remarkably flat throughout the compression stroke.

The force calculation follows the straightforward F=PA principle—force equals pressure multiplied by piston area. A nitrogen die spring with a 1-inch diameter piston operating at 1,000 psi delivers approximately 785 pounds of force. Compress that spring 50% of its stroke, and the force might increase only 10-15%, not the 60% or more you'd see with coil technology.

Multiple sealing elements keep the pressurized gas contained. High-performance polymer seals, backup rings, and precision surface finishes on the piston rod work together to maintain charge pressure over millions of cycles. Modern car gas springs routinely achieve cycle lives exceeding 2 million operations when properly applied and maintained.

The nitrogen gas itself offers advantages over air or other gases. Nitrogen is inert, non-corrosive, and maintains consistent properties across operating temperature ranges. It also eliminates moisture-related issues that could cause internal corrosion or ice formation in extreme cold conditions.

When Compact Force Delivery Matters Most

Why would you pay a premium for nitrogen technology? The answer becomes crystal clear in applications where space and force consistency directly impact part quality or die design feasibility.

Consider a progressive die for automotive structural components. The die design requires 2,000 pounds of stripping force, but available space measures just 3 inches in diameter and 6 inches tall. A coil spring delivering that force would require far more real estate than available. A single nitrogen spring fits the envelope perfectly while delivering consistent stripping pressure throughout the stroke.

High-precision forming operations benefit enormously from flat force curves. When you're forming complex geometries where material flow depends on consistent pressure, the progressive force increase of coil springs can cause dimensional variations. Nitrogen technology maintains the same forming pressure whether you're at 10% compression or 80% compression.

Deep-draw applications present another compelling case. As the punch descends into the die, material flows over the draw radius under controlled pressure. Consistent blank holder force—exactly what nitrogen springs deliver—produces more uniform material thinning and fewer quality defects.

Pros

- Near-Constant Force Output: Force variation typically stays within 10-15% throughout the stroke, eliminating the progressive force challenges of coil technology

- Exceptional Force-to-Size Ratio: Deliver forces impossible to achieve with coil springs in the same footprint—often 3-5 times the force per unit volume

- Reduced Die Height Requirements: Shorter overall length compared to equivalent-force coil springs frees valuable shut height for other design elements

- Adjustable Pressure Options: Many designs allow field recharging to fine-tune force output for specific applications without replacing the unit

- Predictable Performance: Consistent force delivery simplifies die tryout and reduces part-to-part variation

- Long Cycle Life: Quality nitrogen springs routinely exceed 2 million cycles with proper application

Cons

- Higher Initial Investment: Expect to pay 5-10 times more per unit compared to equivalent coil springs—a significant consideration for budget-conscious operations

- Seal Degradation Over Time: All sealing systems eventually wear, requiring replacement or recharging to maintain performance

- Temperature Sensitivity: Force output varies with operating temperature—cold environments reduce pressure while hot conditions increase it, potentially by 15-20%

- Pressure Monitoring Required: Unlike coil springs that visually show wear, nitrogen springs need periodic pressure checks to verify charge status

- Specialized Replacement Procedures: Recharging or rebuilding requires proper equipment and trained personnel—not a quick toolroom swap

- Contamination Vulnerability: Stamping debris can damage exposed piston rods, accelerating seal wear and causing premature failure

Automotive gas springs have become standard equipment in many high-volume stamping operations precisely because the benefits outweigh the costs when applications demand their unique capabilities. The premium price pays for itself through reduced die maintenance, improved part consistency, and design flexibility impossible to achieve otherwise.

However, the either/or choice between coil and nitrogen technology isn't always necessary. Some of the most effective die designs strategically combine both technologies, leveraging the strengths of each while minimizing their respective limitations. That hybrid approach opens possibilities worth exploring for your next tooling project.

Hybrid Spring Systems Combining Both Technologies

What if the best solution isn't choosing one technology over the other—but strategically deploying both? This hybrid approach represents a gap in most spring selection discussions, yet experienced die designers have quietly used mixed systems for years to optimize performance while controlling costs.

Think about it: why limit yourself to a single tool when your toolbox could hold two? Understanding what is a spring coil's strengths alongside nitrogen technology's advantages lets you position each where it performs best. The result often outperforms either technology used alone.

Strategic Placement of Mixed Spring Systems

Picture a progressive die with six stations. Stations one through four handle standard blanking and piercing operations—straightforward stripping requirements where coil springs perform admirably at a fraction of nitrogen costs. But station five involves a deep-draw operation demanding consistent blank holder pressure, while station six requires compact high-force stripping in a tight envelope.

This scenario screams for a hybrid solution. You'd install conventional coil springs at the first four stations, then deploy nitrogen technology specifically at stations five and six where its unique characteristics justify the investment.

Common hybrid configurations include:

- Perimeter coil with central nitrogen: Coil springs handle general stripping around the die perimeter while nitrogen springs manage high-force requirements at specific punch locations

- Primary coil with nitrogen assist: Coil springs provide baseline stripping force while smaller nitrogen units add localized pressure where part geometry demands it

- Station-specific allocation: Different spring types assigned to individual stations based on each operation's unique requirements

- Redundant backup systems: Nitrogen springs handling critical operations with coil springs positioned as secondary support

The spring to fall force transition between technologies requires careful calculation. You'll need to account for the different force curves—nitrogen's flat delivery versus coil's progressive increase—ensuring total force at any stroke position meets your requirements without overloading the die or understressing critical areas.

Balancing Force Requirements Across Die Stations

Mixing spring types introduces engineering considerations you wouldn't face with single-technology systems. Force balancing stands as the primary challenge—and the key to successful hybrid implementation.

Consider stroke synchronization first. Coil springs compress linearly with force increase, while nitrogen springs maintain near-constant force through their stroke. When both types work in the same die, they compress at different rates under equal load distribution. This can create uneven stripping if not properly accounted for during design.

The solution involves careful preload calculations:

- Calculate the force contribution from each spring type at every point in the stroke

- Verify that combined forces remain balanced across the die face throughout compression

- Adjust spring quantities or specifications to achieve synchronized force delivery

- Test actual performance during die tryout and fine-tune as needed

Maintenance scheduling differences also demand attention. Your coil springs might run indefinitely with only visual inspections, while nitrogen units require periodic pressure checks—perhaps every 500,000 cycles. Smart shops schedule nitrogen spring inspections during planned die maintenance windows, checking charge pressure and rod condition without adding separate downtime events.

When does hybrid complexity justify itself over simpler single-technology approaches? Generally, when your die meets two or more of these criteria:

- Multiple stations with distinctly different force or space requirements

- Budget constraints that preclude full nitrogen implementation

- Specific operations demanding consistent force that coil springs cannot provide

- Existing dies being upgraded where partial conversion makes more sense than complete replacement

- High-volume production where optimized performance at critical stations drives measurable quality improvements

If you're sourcing components from a gas springs shop for a hybrid system, communicate your mixed-technology approach clearly. Suppliers can recommend nitrogen specifications that complement your existing coil spring setup, ensuring force curves and stroke characteristics work together rather than against each other.

The hybrid approach demands more upfront engineering effort, but the payoff comes through optimized performance at controlled cost. You're not compromising by choosing the "cheaper" option everywhere or overspending on premium technology where it isn't needed. Instead, you're engineering a solution precisely matched to your application's actual requirements.

With single-technology and hybrid approaches now understood, how do the technical specifications actually stack up in a direct comparison? The next section delivers the detailed specification table you'll reference repeatedly when making spring selection decisions.

Technical Specifications Comparison Table

You've heard the claims from both sides. Now it's time to see the numbers side by side—no marketing spin, just the technical specifications that matter when you're standing at the die design table making real decisions. This comparison table gives you the reference data competitors either bury in footnotes or skip entirely.

Bookmark this section. You'll come back to it repeatedly when evaluating spring options for specific applications.

| Specification | Nitrogen Gas Springs | Metal Coil Springs |

|---|---|---|

| Force Range | 50 lbs to 50,000+ lbs per unit | 5 lbs to 5,000 lbs per unit (typical) |

| Stroke Length Options | 0.5" to 12" standard; custom available | Limited by coil geometry; typically 25-35% of free length |

| Force Variation Through Stroke | 10-15% increase from preload to full compression | 50-100% increase depending on deflection percentage |

| Space Requirements (Force/Volume) | 400s to 1200 lbs per cubic inch typical | 50-150 lbs per cubic inch typical |

| Operating Temperature Range | -4°F to 176°F (-20°C to 80°C) standard | -40°F to 410°F (-40°C to 210°C) for standard steel |

| Expected Cycle Life | 1-3 million cycles before service required | 500,000 to 2 million cycles before fatigue concerns |

| Maintenance Intervals | Pressure check every 250,000-500,000 cycles | Visual inspection only; no scheduled maintenance |

| Primary Failure Mode | Seal degradation causing pressure loss | Wire fatigue causing sudden fracture |

| Failure Warning Signs | Gradual force reduction; visible oil seepage | Often none; sudden breakage common |

| Contamination Resistance | Vulnerable; debris damages exposed rod surfaces | Excellent; enclosed wire tolerates dirty environments |

| Field Adjustability | Rechargeable to modify force output | Fixed; requires physical replacement to change force |

Force-to-Size Ratio Comparison

Here's where nitrogen technology truly separates itself from the pack. When your die design demands maximum force from minimum space, the numbers tell a compelling story.

A typical nitrogen spring measuring 2 inches in diameter and 6 inches long can deliver 2,000 to 4,000 pounds of force—that's roughly 400 to over 1200 lbs per cubic inch of envelope space. Achieving the same force from coil springs? You'd need a package three to five times larger, assuming the geometry even permits it.

Consider a practical example: you need 1,500 pounds of stripping force in a pocket measuring 2.5 inches diameter by 4 inches deep. A single nitrogen spring handles this easily with room to spare. Coil spring alternatives simply cannot deliver that force in that footprint—you'd need to redesign the die or accept inadequate stripping performance.

This force density advantage extends across the size range. Compact nitrogen units deliver forces in the 400s of pounds from packages smaller than a C-battery. Larger industrial units push into the 10,000+ pound range while remaining practical for die installation. Coil springs approaching these force levels become unwieldy—think coffee-can-sized units that dominate die real estate.

However, when space isn't constrained, coil springs close the gap on value. A die with generous shut height and open pockets can accommodate properly sized coil springs at a fraction of nitrogen costs. The force-to-size advantage matters only when you're actually space-limited.

Lifecycle and Maintenance Requirements

The maintenance story differs dramatically between these technologies—and understanding those differences affects both your operating costs and your production reliability.

Nitrogen springs demand scheduled attention. Every 250,000 to 500,000 cycles, someone needs to check charge pressure and inspect rod surfaces for damage. Seals gradually wear regardless of operating conditions, eventually requiring rebuild service or unit replacement. Most manufacturers rate their springs for 1-3 million cycles before major service, but that assumes proper application and clean operating environments.

Coil springs take a simpler approach: install them and forget them until they break. No pressure checks, no seal inspections, no specialized equipment required. Visual inspection during routine die maintenance catches obvious problems like set (permanent shortening) or surface damage. When a coil spring fails, replacement takes minutes with basic hand tools.

But here's the catch—coil spring failures often arrive without warning. One cycle the spring works fine; the next cycle it's in two pieces. This sudden failure mode can cause collateral die damage or part quality issues before operators recognize the problem. Nitrogen springs typically degrade gradually, giving maintenance windows to address declining performance before catastrophic failure.

Environmental factors shift the reliability equation:

- Contaminated environments: Stamping generates debris—slugs, lubricant mist, metal particles. Coil springs shrug off this contamination while nitrogen spring piston rods suffer accelerated seal wear from abrasive particles. Protective boots help but add complexity.

- Temperature extremes: Cold environments below 410°F favor coil springs, which maintain consistent performance. Nitrogen springs lose pressure in cold conditions, reducing available force by 10-20% in unheated facilities during winter months.

- High-cycle applications: At 60+ strokes per minute, nitrogen springs accumulate maintenance intervals quickly. A die running three shifts might require pressure checks monthly rather than annually.

Smart maintenance strategies account for these realities. Many operations schedule nitrogen spring inspections during planned die preventive maintenance, checking pressure and rod condition without adding separate downtime. This integrated approach captures the benefits of both technologies while managing their respective maintenance demands.

With technical specifications and maintenance requirements clearly mapped, one critical question remains: what do these differences actually cost you over the life of your tooling? The total cost analysis coming next reveals whether premium spring technology pays for itself—or bleeds your budget unnecessarily.

Total Cost of Ownership Analysis

Here's the question that separates savvy tooling managers from those bleeding budget unnecessarily: what does each spring technology actually cost over its entire service life? Initial purchase price tells only a fraction of the story—and often the least important fraction.

Think about it this way. You wouldn't evaluate a stamping press based solely on the invoice price while ignoring energy consumption, maintenance contracts, and productivity differences. Spring technology deserves the same comprehensive financial lens. The true cost comparison requires examining every dollar that flows through your operation because of that spring selection decision.

Calculating True Spring Investment Returns

Let's break down the complete cost picture into categories that actually matter for your bottom line. Each element contributes to total ownership cost—some obviously, others in ways you might not immediately recognize.

| Cost Category | Nitrogen Gas Springs | Metal Coil Springs |

|---|---|---|

| Initial Purchase (per equivalent force) | 5-10x higher than coil alternatives | Baseline cost reference |

| Replacement Frequency | Every 1-3 million cycles; rebuild option available | Every 500,000-2 million cycles; full replacement required |

| Scheduled Maintenance Labor | Pressure checks every 250,000-500,000 cycles | Visual inspection only during routine die service |

| Unplanned Downtime Risk | Lower—gradual degradation provides warning | Higher—sudden fracture common without warning |

| Part Quality Impact | Consistent force reduces scrap and rework | Progressive force may cause dimensional variation |

| Die Maintenance Frequency | Reduced—consistent stripping minimizes punch/die wear | Standard—variable force accelerates localized wear |

| Spare Parts Inventory | Higher unit cost; fewer spares needed | Lower unit cost; larger inventory typically required |

The numbers shift dramatically depending on your production volume. Consider a die running 500,000 cycles annually versus one running 5 million cycles. That tenfold difference in cycle accumulation transforms the cost equation entirely.

For the low-volume die, coil springs might require replacement once every two to four years—inexpensive units swapped during scheduled maintenance windows with minimal impact. The nitrogen alternative costs five to ten times more upfront and still requires periodic pressure checks, adding labor costs without corresponding benefits.

Now flip to high-volume production. That 5-million-cycle annual pace burns through coil springs at alarming rates. You're replacing springs multiple times yearly, each replacement consuming maintenance labor and risking production interruption. Sudden coil failures during production runs cascade into scrap parts, die damage inspection, and unplanned downtime measured in hours rather than minutes.

When Premium Springs Pay for Themselves

The crossover point—where nitrogen technology's higher purchase price delivers lower total cost—depends on several factors specific to your operation. Understanding these drivers helps you identify which applications justify premium investment.

Production volume stands as the primary determinant. High-cycle applications accumulate the maintenance and replacement costs where nitrogen springs demonstrate their value. When you're running three shifts at 40+ strokes per minute, those cycles add up fast. A die producing 3 million parts annually reaches nitrogen spring service intervals in months rather than years—but coil springs might fail multiple times in that same period.

Part quality sensitivity amplifies the calculation. If your application tolerates modest dimensional variation, coil spring force progression creates no meaningful cost. But when you're stamping precision components where every tenth of a millimeter matters, the scrap and rework costs from inconsistent stripping force quickly eclipse any spring purchase savings. Early afternoon quality reviews revealing out-of-spec parts trace back to force variation issues that nitrogen technology eliminates.

Consider these scenarios where nitrogen springs typically deliver positive ROI:

- Automotive structural components: High volumes, tight tolerances, and significant scrap costs make consistent force delivery essential

- Deep-draw operations: Uniform blank holder pressure prevents material thinning variations that cause rejection

- Progressive dies exceeding 1 million annual cycles: Replacement frequency tips the economic balance toward longer-lasting technology

- Space-constrained designs: When coil springs simply cannot fit, nitrogen becomes necessary regardless of cost preference

- Critical path production: When die downtime directly halts customer shipments, reliability premium pays for itself

Conversely, coil springs maintain clear economic advantage in these situations:

- Prototype and development work: Low cycle counts never approach nitrogen spring payback thresholds

- Job shop environments: Diverse short runs favor simple, inexpensive, readily available spring technology

- Non-critical stripping applications: When force consistency doesn't affect part quality, why pay for it?

- Operations below 500,000 annual cycles: The math rarely favors premium springs at these volumes

- Budget-constrained new die builds: Sometimes the immediate availability of affordable coil springs beats waiting for nitrogen unit lead times

One often-overlooked factor: die maintenance intervals. Consistent stripping force from nitrogen springs reduces the hammering effect on punch and die surfaces that occurs when coil springs deliver varying force through the stroke. Early fall of punch edge sharpness—premature dulling requiring regrinding—often traces to inconsistent stripping dynamics. Over a die's lifetime, reduced sharpening frequency and extended component life contribute meaningfully to total cost calculations.

The productivity equation also deserves attention. Nitrogen springs' gradual degradation pattern allows planned replacement during scheduled maintenance windows. Coil springs' sudden failure mode forces unplanned stops—often at the worst possible moments. That production interruption cost varies dramatically by operation, but for high-volume stampers running just-in-time delivery schedules, a single unexpected two-hour die repair can cost more than the price difference between spring technologies.

Smart operations don't apply blanket spring policies across all dies. They evaluate each application individually, matching technology to requirements. That evaluation process—and the framework for making confident decisions—comes into focus with a structured selection methodology.

Decision Framework for Your Application

You've absorbed the technical specifications, cost comparisons, and performance characteristics. Now comes the moment of truth: translating that knowledge into a confident selection decision for your specific application. This framework transforms everything you've learned into a practical decision-making tool you can apply immediately.

Think of this section as your spring selection roadmap. Whether you're specifying springs for a new die build or evaluating whether existing tooling deserves an upgrade, these criteria guide you toward the right choice—not the cheapest or most expensive, but the optimal match for your actual requirements.

Your Spring Selection Checklist

Before committing to either technology, work through each criterion systematically. Skipping steps leads to the costly mismatches we've discussed throughout this comparison. Grab your die prints and production data—you'll need them.

- Required Force Magnitude: What total stripping or blank holder force does your application demand? Calculate the force needed at full compression, not just initial contact. If you need forces exceeding 2,000-3,000 pounds per spring location, nitrogen technology often becomes necessary simply because equivalent coil springs won't fit available space.

- Available Space Envelope: Measure the actual pocket dimensions in your die—diameter and depth available for spring installation. Compare these measurements against force requirements. When the force-to-space ratio exceeds what coil springs can deliver (roughly 150 lbs per cubic inch), nitrogen becomes your practical option.

- Stroke Requirements: How much spring travel does your application need? Coil springs typically deliver 25-35% of free length as working stroke. Nitrogen springs offer more flexibility, with stroke lengths up to 50% or more of body length. Deep-draw and high-lift applications often favor nitrogen for stroke capability alone.

- Cycle Volume Expectations: Estimate annual production cycles realistically. Dies running under 500,000 cycles annually rarely justify nitrogen investment unless space or force consistency drives the decision. Above 2 million annual cycles, nitrogen's longer service life begins offsetting higher purchase costs.

- Budget Constraints: Be honest about available tooling budget. Nitrogen springs cost 5-10 times more per unit. Can your project absorb that premium, or does fiscal reality demand coil spring simplicity? Sometimes the right answer is "coil now, nitrogen later" when budget allows.

- Maintenance Capabilities: Does your facility have equipment and trained personnel for nitrogen spring pressure checks and recharging? If not, factor in outsourced service costs or recognize that coil springs' zero-maintenance simplicity carries real operational value.

- Force Consistency Requirements: Does your part quality depend on consistent force throughout the stroke? Applications involving precision forming, deep drawing, or sensitive materials benefit from nitrogen's flat force curve. Standard blanking and piercing typically tolerate coil spring force progression without quality impact.

- Environmental Conditions: Consider your stamping environment honestly. Heavy contamination from slugs and lubricant favors coil springs' sealed-wire construction. Temperature extremes below freezing affect nitrogen spring output. Clean, climate-controlled facilities favor either technology equally.

Score each criterion honestly. When four or more factors favor nitrogen technology, the premium investment typically pays off. When most factors point toward coil springs, don't let marketing pressure push you toward unnecessary expense.

Matching Spring Technology to Application Requirements

Common misconceptions lead to poor spring selection more often than lack of technical knowledge. Let's clear up the confusion that trips up even experienced die professionals.

Misconception #1: Nitrogen springs are always better. They're not. They're better for specific applications—high force in compact spaces, consistent force delivery, high-cycle production. For standard blanking dies with generous space and moderate production volumes, nitrogen springs represent unnecessary expense without corresponding benefit.

Misconception #2: Coil springs are outdated technology. Hardly. Coil springs remain the right choice for the majority of stamping applications worldwide. Their simplicity, reliability, and cost-effectiveness make them impossible to dismiss. "Outdated" implies inferior—coil springs are simply different, not lesser.

Misconception #3: Converting to nitrogen springs eliminates maintenance. Wrong. Nitrogen springs require scheduled maintenance that coil springs don't—pressure checks, seal inspections, and eventual rebuilds or replacement. You're trading one maintenance profile for another, not eliminating maintenance entirely.

Misconception #4: You must choose one technology for the entire die. As we explored in the hybrid systems section, mixing technologies often delivers optimal results. Don't let either/or thinking limit your design options.

When considering partial versus full conversion from coil to nitrogen springs, start with your highest-impact locations. Identify the specific spring positions causing quality issues, experiencing frequent failures, or limiting die performance. Converting those critical locations first delivers the most immediate benefit while containing investment.

Full conversion makes sense when:

- Space constraints affect multiple spring locations throughout the die

- Consistent force requirements span all stripping or forming operations

- Standardizing on one technology simplifies maintenance planning

- Production volumes justify premium investment across all positions

Partial conversion proves more practical when:

- Only one or two stations demand nitrogen technology's unique capabilities

- Budget constraints limit total investment

- Existing coil springs perform adequately at most positions

- You're testing nitrogen technology before broader commitment

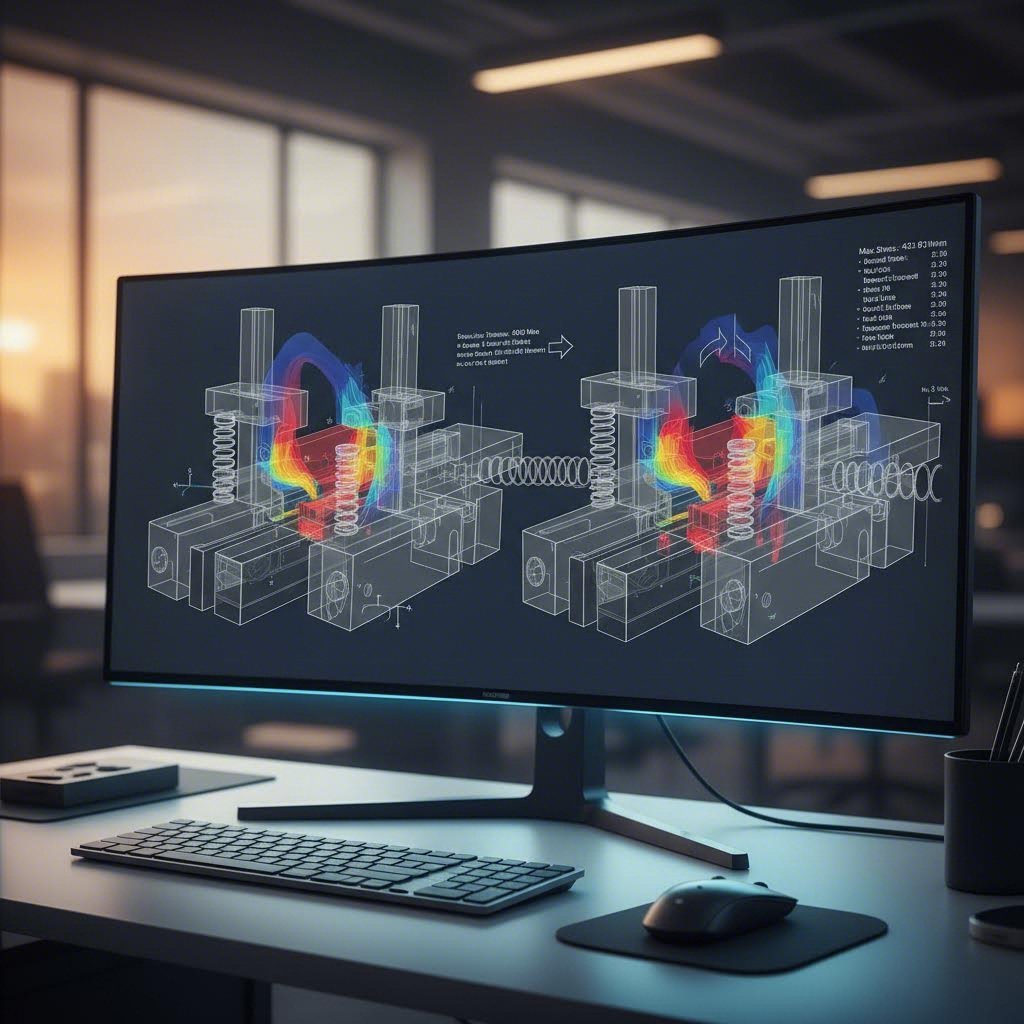

For stamping operations requiring precision spring integration, die design software with advanced CAE simulation capabilities can validate spring configurations before cutting steel. Engineers can model force distribution across multiple spring locations, verify stroke synchronization between mixed spring types, and predict performance under production conditions. This simulation-driven approach—available through IATF 16949-certified tooling suppliers like Shaoyi—eliminates trial-and-error spring selection and ensures defect-free results from the first production run.

Document your selection rationale. When the next die project arrives with similar requirements, you'll have a reference point rather than starting from scratch. Over time, your organization builds institutional knowledge about which applications favor each technology—knowledge that streamlines future decisions and prevents repeating costly mistakes.

With your decision framework established and misconceptions cleared away, the final step is translating analysis into action. The recommendations that follow provide specific guidance based on common application categories, giving you a clear path forward for your spring selection decisions.

Final Recommendations and Next Steps

You've worked through the technical specifications, cost analyses, and decision frameworks. Now it's time to translate all that knowledge into concrete action. These recommendations cut through complexity to give you clear guidance based on your specific application category—no hedging, no maybe-it-depends qualifiers.

Remember: the goal isn't selecting the "best" spring technology in abstract terms. It's matching the right technology to your actual requirements. Here's how that breaks down across the most common stamping scenarios.

Recommendations by Application Type

Based on everything we've examined—force characteristics, space requirements, cycle life, maintenance demands, and total cost of ownership—here are ranked recommendations for each major application category:

-

High-Volume Automotive Stamping (2+ million annual cycles)

Recommended: Nitrogen gas springs as primary technology

The math works decisively in nitrogen's favor at these volumes. Consistent stripping force reduces scrap rates on precision structural components. Longer service life between replacements minimizes production interruptions. The premium purchase price amortizes across millions of cycles, often delivering lower total cost than coil alternatives requiring multiple replacements. Consider hybrid systems only where specific stations genuinely don't require nitrogen's capabilities. -

Precision Forming Operations (tight tolerances, complex geometries)

Recommended: Nitrogen gas springs for critical forming stations

When dimensional accuracy depends on consistent blank holder pressure or uniform stripping force, nitrogen technology eliminates the variable that coil springs introduce. Deep-draw applications, progressive forming sequences, and any operation where force variation translates directly to part variation benefit from flat force curves. The quality improvement often justifies the investment regardless of production volume. -

Standard Blanking Applications (moderate volumes, generous die space)

Recommended: Metal coil springs as primary technology

This is coil spring territory. Standard blanking operations tolerate—even benefit from—progressive force characteristics. Lower initial contact force minimizes part marking while full-compression force ensures positive stripping. When your die envelope accommodates properly sized coil springs, their simplicity and cost-effectiveness make them the clear choice. Save nitrogen investment for applications that actually need it. -

Prototype and Low-Volume Work (under 250,000 annual cycles)

Recommended: Metal coil springs exclusively

Nitrogen springs never reach payback thresholds at these volumes. Quick coil spring availability supports rapid die development cycles. Zero maintenance requirements mean less tracking and scheduling during already-complex prototype phases. When designs change—and they will during development—inexpensive coil springs absorb those iterations without budget pain.

Your Next Steps for Spring Optimization

Knowledge without action changes nothing. Here's your practical roadmap for implementing what you've learned:

For your next new die project: Apply the selection checklist from the decision framework section before finalizing spring specifications. Document your rationale so future engineers understand why specific technologies were chosen for each location. This prevents the "we've always done it this way" trap that leads to suboptimal selections.

For existing dies with spring-related issues: Identify which specific spring locations cause problems—quality defects, frequent failures, or inadequate force. Evaluate whether targeted nitrogen conversion at those locations solves the issue without full die conversion expense. Often, converting two or three critical positions transforms die performance.

For operations standardizing spring technology: Resist the temptation to mandate one technology across all applications. The evidence clearly shows that context determines optimal choice. Instead, develop selection guidelines that match technology to application requirements—guidelines your engineering team can apply consistently.

Spring technology continues evolving. Manufacturers are developing nitrogen springs with improved seal materials that extend service life in contaminated environments. Smart springs with integrated pressure sensors enable predictive maintenance rather than calendar-based checks. Hybrid designs that combine gas and mechanical elements promise new performance envelopes. Staying connected with technology developments ensures your operations benefit from improvements as they become available.

Perhaps most importantly, partner with tooling suppliers who genuinely understand both spring technologies and their application-specific trade-offs. Working with certified die suppliers who understand spring force requirements—teams that can simulate spring performance during die design, validate configurations before production, and optimize force distribution across complex progressive dies—ensures your spring selection decisions translate into real-world results. Shaoyi's engineering team, for example, delivers precision die solutions with 93% first-pass approval rates, leveraging advanced CAE simulation to get spring integration right from rapid prototyping through high-volume manufacturing.

The coil spring vs nitrogen spring decision ultimately comes down to honest assessment of your specific requirements—not marketing claims, not habit, not budget panic. Apply the frameworks in this guide, match technology to application, and your spring selection stops bleeding your budget and starts contributing to your competitive advantage.

Your stamped parts carry the fingerprint of every tooling decision you make. Make the spring selection count.

Frequently Asked Questions About Coil Springs vs Nitrogen Springs

1. What is the difference between a gas spring and a coil spring?

A coil spring stores energy through elastic deformation of wound metal wire, with force increasing progressively as you compress it. A gas spring (nitrogen spring) stores energy by compressing pressurized nitrogen gas in a sealed cylinder, delivering near-constant force throughout its stroke. This fundamental difference means nitrogen springs provide consistent force regardless of compression position, while coil springs can increase force by 50-100% from preload to full compression.

2. What are the disadvantages of coil springs?

Coil springs require larger footprints to achieve equivalent force compared to nitrogen alternatives. They experience significant force variation through the stroke (50-100% increase), which can cause quality issues in precision applications. Coil springs are also susceptible to fatigue failure after millions of cycles, often breaking suddenly without warning signs. Additionally, they may experience permanent set over extended service, reducing preload force.

3. Can nitrogen springs replace all coil springs?

No, nitrogen springs cannot universally replace coil springs. While nitrogen springs excel in high-volume applications requiring consistent force or compact spaces, coil springs remain the better choice for standard blanking operations, prototype work, low-volume production, and budget-constrained projects. The optimal approach often involves hybrid systems that strategically deploy each technology where it performs best.

4. How do I choose between coil springs and nitrogen springs for my stamping die?

Evaluate your application against these criteria: required force magnitude, available space envelope, annual cycle volume, force consistency requirements, and budget constraints. Choose nitrogen springs when you need high force in compact spaces, consistent force throughout the stroke, or run 2+ million annual cycles. Select coil springs for standard blanking, prototype work, operations under 500,000 annual cycles, or when generous die space is available.

5. What is the total cost of ownership difference between coil and nitrogen springs?

Nitrogen springs cost 5-10 times more initially but often deliver lower total cost in high-volume applications through reduced replacement frequency, fewer unplanned downtime events, and improved part quality. Coil springs maintain clear economic advantage for low-volume work under 500,000 annual cycles, prototype development, and non-critical stripping applications where their simplicity and lower purchase price outweigh any performance differences.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —