Transfer Die Stamping Automotive Components: A Technical Engineering Guide

TL;DR

Transfer die stamping is a precision metal forming process where individual blanks are separated from the metal strip before entering the press, then mechanically moved between independent die stations by fingers or rails. This “free state” allows for the production of large, deep-drawn, and intricate transfer die stamping automotive components like chassis frames and suspension arms without the restrictions of a carrier strip. While generally slower than progressive die stamping, it offers superior material efficiency and the ability to handle complex geometries that require rotation or side-piercing, making it the preferred method for structural vehicle parts.

Fundamentals: The Mechanics of Transfer Die Stamping

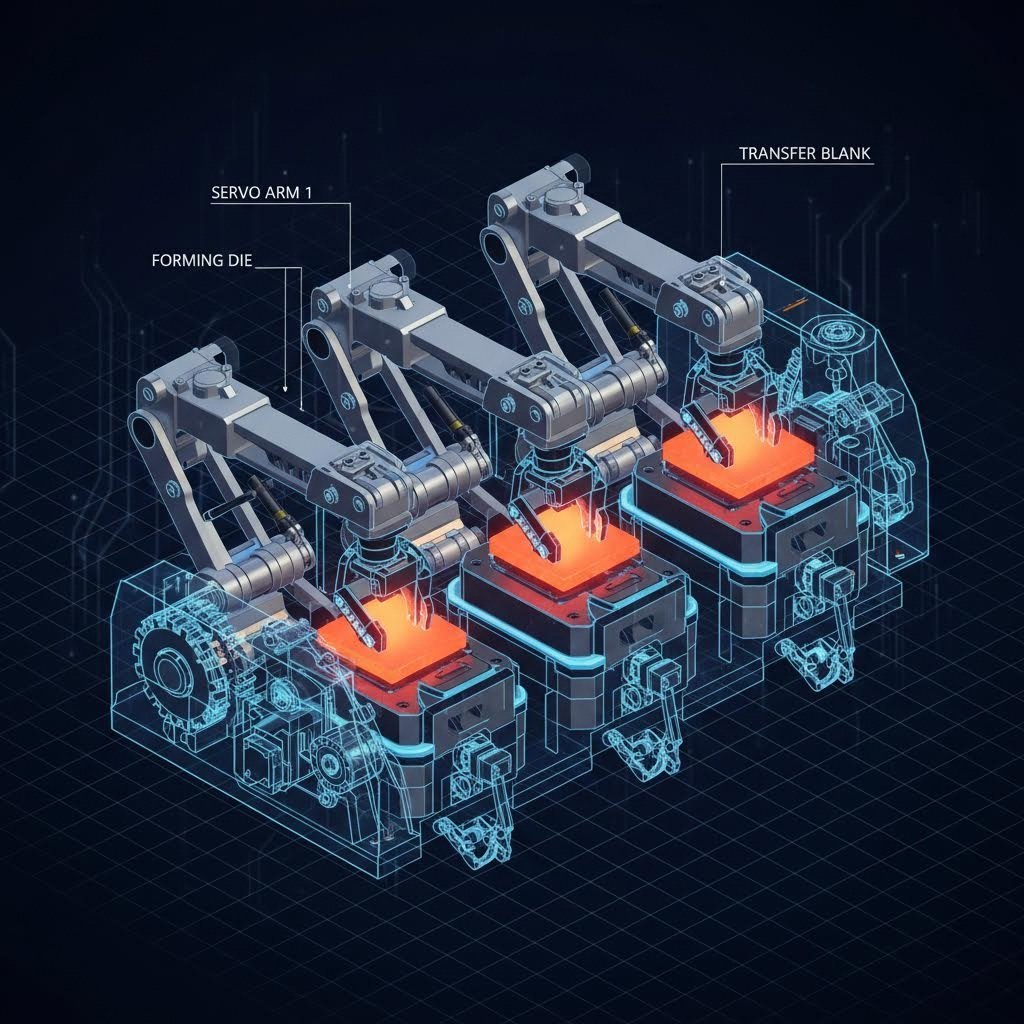

At its core, transfer die stamping differs from other methods by its handling of the workpiece. In progressive die stamping, the part remains attached to a continuous metal strip (the carrier) as it moves through stations. In contrast, transfer die stamping begins by separating the blank from the coil immediately. This separated blank is then transported from station to station using a mechanical automation system, typically consisting of servo-driven rails with grippers or fingers.

The defining engineering advantage of this process is the “free state.” Because the component is not tethered to a metal strip, it can be manipulated freely between stations. It can be rotated, tilted, or turned over to accommodate complex forming operations like reverse drawing or side-piercing that would be impossible if the part were still attached to a coil. This capability is critical for automotive manufacturing, where components often feature non-linear geometries and require tight tolerances across multiple planes.

Modern transfer presses, such as those utilized by Aranda Tooling and other industry leaders, often integrate servo technology to optimize the transfer curve. This allows for adjustable stroke profiles, enabling the press to slow down during the forming phase for better material flow and speed up during the transfer phase to maintain high output rates.

Transfer vs. Progressive Die: The Automotive Manufacturer's Dilemma

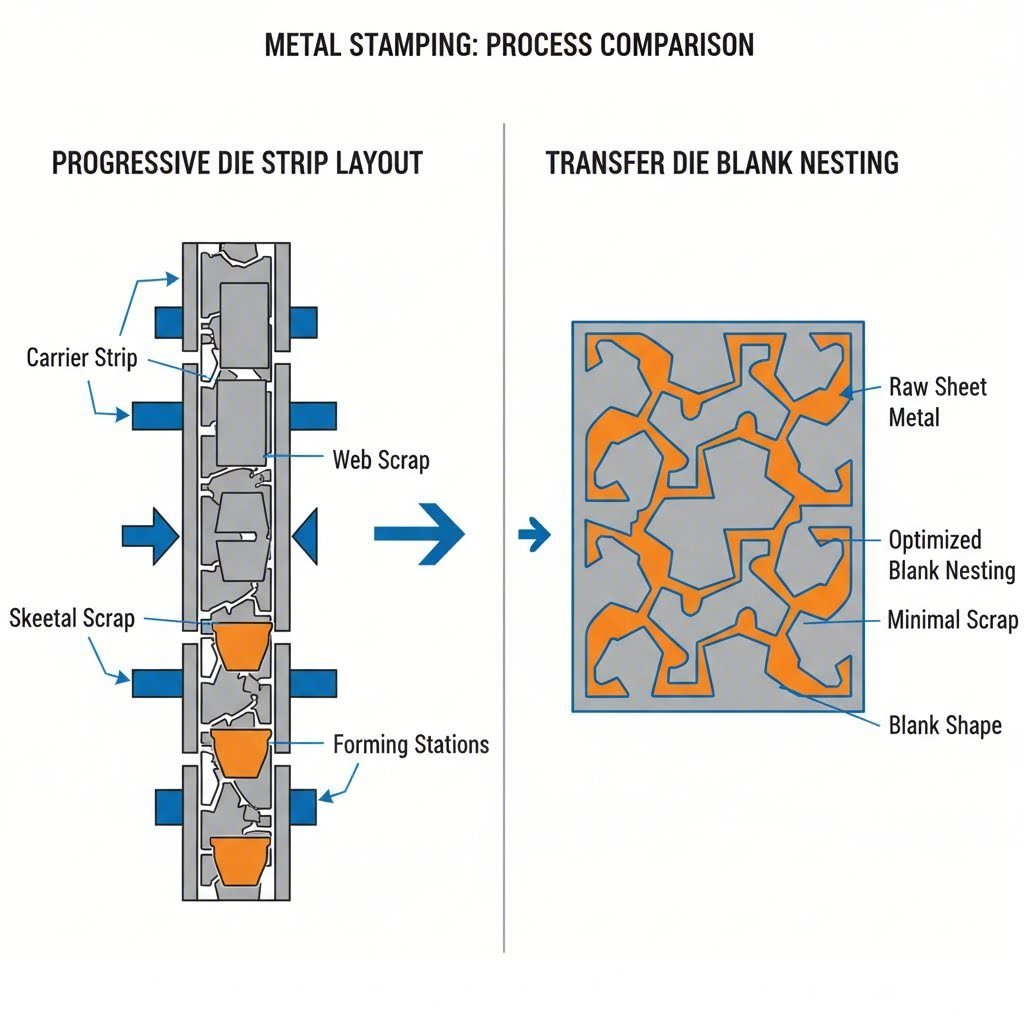

For automotive engineers and procurement managers, the choice between transfer and progressive die stamping is often the primary manufacturing decision. While progressive dies are unmatched for speed on small parts, transfer dies dominate when size and complexity increase. The following comparison highlights the operational differences critical for automotive production.

| Feature | Transfer Die Stamping | Progressive Die Stamping |

|---|---|---|

| Part Attachment | Separated blank (Free state) | Attached to carrier strip |

| Ideal Part Size | Medium to large (Frames, shells) | Small to medium (Brackets, clips) |

| Material Efficiency | High (Nesting optimization reduces scrap) | Lower (Carrier strip waste is inherent) |

| Tooling Cost | Generally lower (Simpler independent dies) | Higher (Complex single die assembly) |

| Production Speed | Moderate (15–60 SPM typically) | High (Can exceed 100+ SPM) |

| Geometric Complexity | High (Deep draws, cylindrical parts) | Medium (Limited by strip attachment) |

A key factor in this decision is material utilization. In automotive manufacturing, where raw material costs can constitute up to 70% of the part price, the ability to nest blanks efficiently is a major advantage for transfer stamping. As noted in technical analyses by Standard Die, eliminating the carrier strip allows engineers to stagger blanks (nesting) to maximize yield from the coil, a significant cost-saving strategy for high-volume runs of heavy-gauge steel or aluminum.

Key Automotive Applications & Components

Transfer die stamping is indispensable for specific categories of automotive parts where structural integrity and geometric complexity meet. The process is most frequently deployed for:

- Large Structural Components: Chassis frames, cross members, and pillars require the press tonnage and bed size typical of transfer lines. The ability to manipulate these large parts between stations ensures consistent wall thickness and strength.

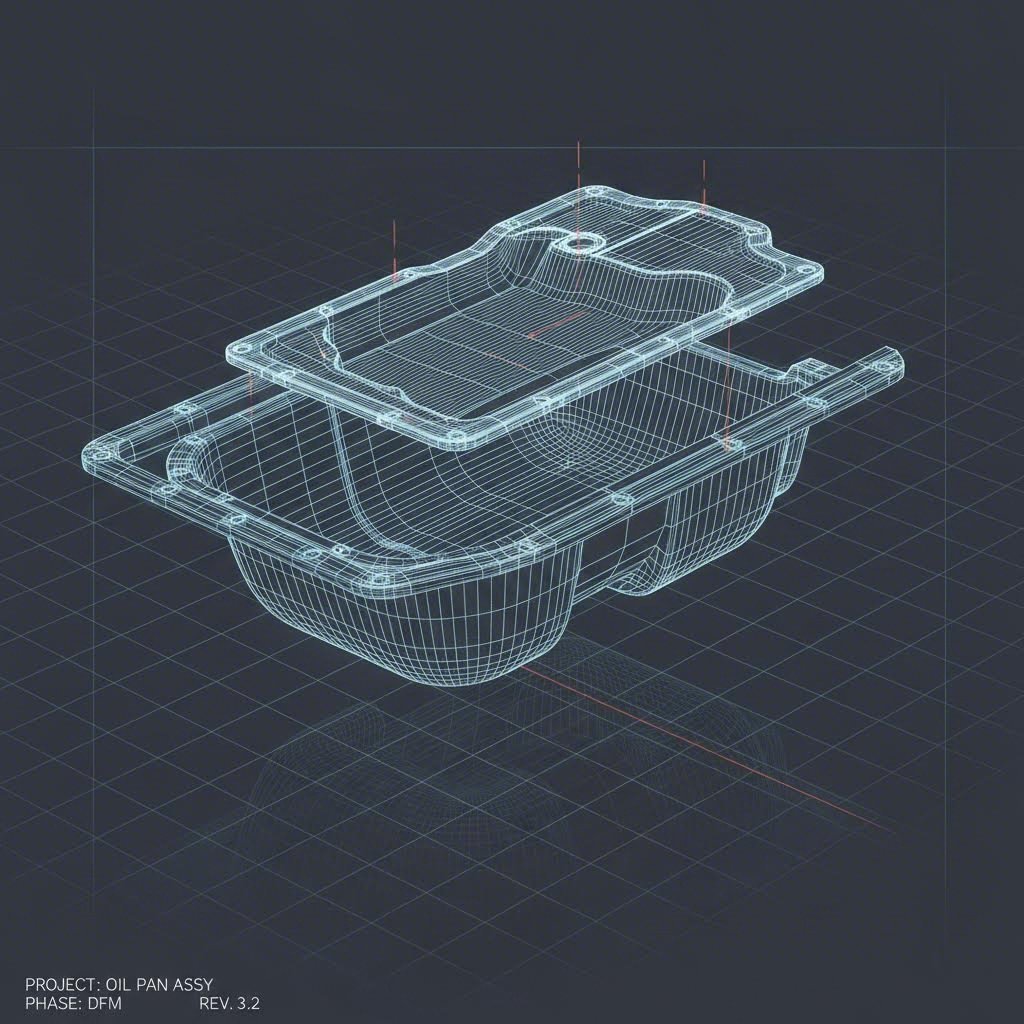

- Deep Drawn Parts: Components like oil pans, fuel tanks, and motor shells require deep drawing, where the metal is stretched significantly. The “free state” of transfer stamping allows the material to flow without the tension of a carrier strip, reducing the risk of tearing or thinning.

- Intricate Suspension Parts: Control arms and subframes often need operations on multiple axes. Transfer systems can rotate the part to perform piercing or flanging on sides that would be inaccessible in a progressive die.

For manufacturers seeking a partner capable of handling these demanding specifications, Shaoyi Metal Technology offers comprehensive automotive stamping solutions. With IATF 16949 certification and press capabilities up to 600 tons, they bridge the gap between rapid prototyping and mass production for critical components like control arms and subframes.

Technical Advantages for Automotive Production

Beyond the geometric freedom, transfer die stamping offers specific engineering benefits that align with modern automotive standards, particularly regarding lightweighting and crash safety.

Handling High-Strength Alloys

Modern vehicles increasingly rely on Advanced High-Strength Steel (AHSS) and aluminum to reduce weight while maintaining safety. These materials are less ductile and more prone to springback. Transfer dies allow for intermediate annealing or specific re-striking stations that are difficult to integrate into a progressive strip. The ability to separate the part means forces can be centered more effectively, reducing the tonnage strain on the press.

Process Flexibility and Secondary Operations

Transfer systems excel at integrating secondary operations. Because the part is accessible from all sides during transfer, processes like in-die tapping, nut insertion, or even minor assembly tasks can be included within the press cycle. According to Peterson Enterprises, this versatility often eliminates the need for downstream welding or machining steps, consolidating the manufacturing footprint and reducing total part cost.

Process Steps: From Blank to Finished Auto Part

Understanding the operational flow helps in designing parts optimized for this method. A typical transfer die line follows these sequential steps:

- Blanking: The process begins with a coil of sheet metal. A blanking die cuts the initial shape, separating it entirely from the strip. This is the distinct point of divergence from progressive stamping.

- Transfer: Mechanical fingers (grippers) or vacuum cups descend, grab the blank, and move it laterally to the first forming station.

- Forming Stations: The part moves through a series of dies. Station 1 might perform the initial draw (cupping). Station 2 might refine the shape or pierce holes. Station 3 could perform flanging or trimming.

- Output: The finished component is ejected onto a conveyor or into a bin, ready for inspection or plating.

Simulation software plays a crucial role here. As highlighted by Keysight, engineers now use “digital twins” to simulate the transfer motion and forming stresses before cutting any steel. This virtual validation ensures that the transfer fingers will not collide with the die and that the part will not split during deep drawing operations.

Strategic Fit for Automotive Supply Chains

Transfer die stamping represents the optimal middle ground for many automotive programs. It bridges the gap between the high speed of progressive dies (which struggle with deep draws and large parts) and the low speed of tandem lines (where parts are manually moved between separate presses). For components requiring structural rigidity, material efficiency, and complex forming, it remains the standard-bearer in automotive metal fabrication.

Conclusion

Selecting the right stamping process is a calculation of geometry, volume, and material cost. For transfer die stamping automotive components, the value lies in versatility. By decoupling the part from the strip, manufacturers gain the freedom to produce deeper, stronger, and more complex parts while minimizing expensive scrap. As vehicle designs continue to favor high-strength lightweight materials, the controlled precision of transfer systems will only become more critical to the automotive supply chain.

Frequently Asked Questions

1. What is the main difference between transfer die and progressive die stamping?

The primary difference is part attachment. In progressive die stamping, the part remains attached to a metal carrier strip until the final station. In transfer die stamping, the blank is cut from the strip first and then moved independently between stations. This allows transfer dies to handle larger parts and deeper draws that would deform a carrier strip.

2. Why is transfer stamping preferred for deep drawn parts?

Deep drawing requires material to flow into a die cavity. If the part is attached to a strip (as in progressive stamping), the tension from the strip restricts this flow, often causing tears or thinning. Transfer stamping leaves the part free, allowing material to flow naturally and enabling much deeper, more complex shapes like oil pans and motor housings.

3. How does transfer die stamping reduce material costs?

Transfer stamping allows for optimized “nesting” of blanks. Since the blanks are cut first, they can be staggered or arranged on the coil in a way that minimizes the web of scrap metal left behind. In contrast, progressive dies require a continuous carrier ribbon to transport the parts, which inherently generates more waste material.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —