Laser Cutting Of Aluminum: Fix Defects, Pick Alloys, Slash Costs

Understanding Laser Cutting of Aluminum and Its Industrial Significance

When precision meets productivity in metal fabrication, laser cutting aluminum stands apart as the go-to solution for manufacturers and hobbyists alike. But here's the catch—aluminum isn't your typical cooperative material. Its unique properties have challenged engineers for decades, pushing laser technology to evolve in remarkable ways.

So, can you laser cut aluminum? Absolutely. Can you laser cut aluminium with the same ease as steel? That's where things get interesting. Understanding these nuances separates successful projects from frustrating failures.

Why Aluminum Demands Specialized Cutting Approaches

Imagine shining a flashlight at a mirror. Most of that light bounces right back at you. Aluminum behaves similarly with laser beams. Its high reflectivity—one of the highest among industrial metals—can scatter the laser beam, potentially damaging machine optics and compromising cut quality.

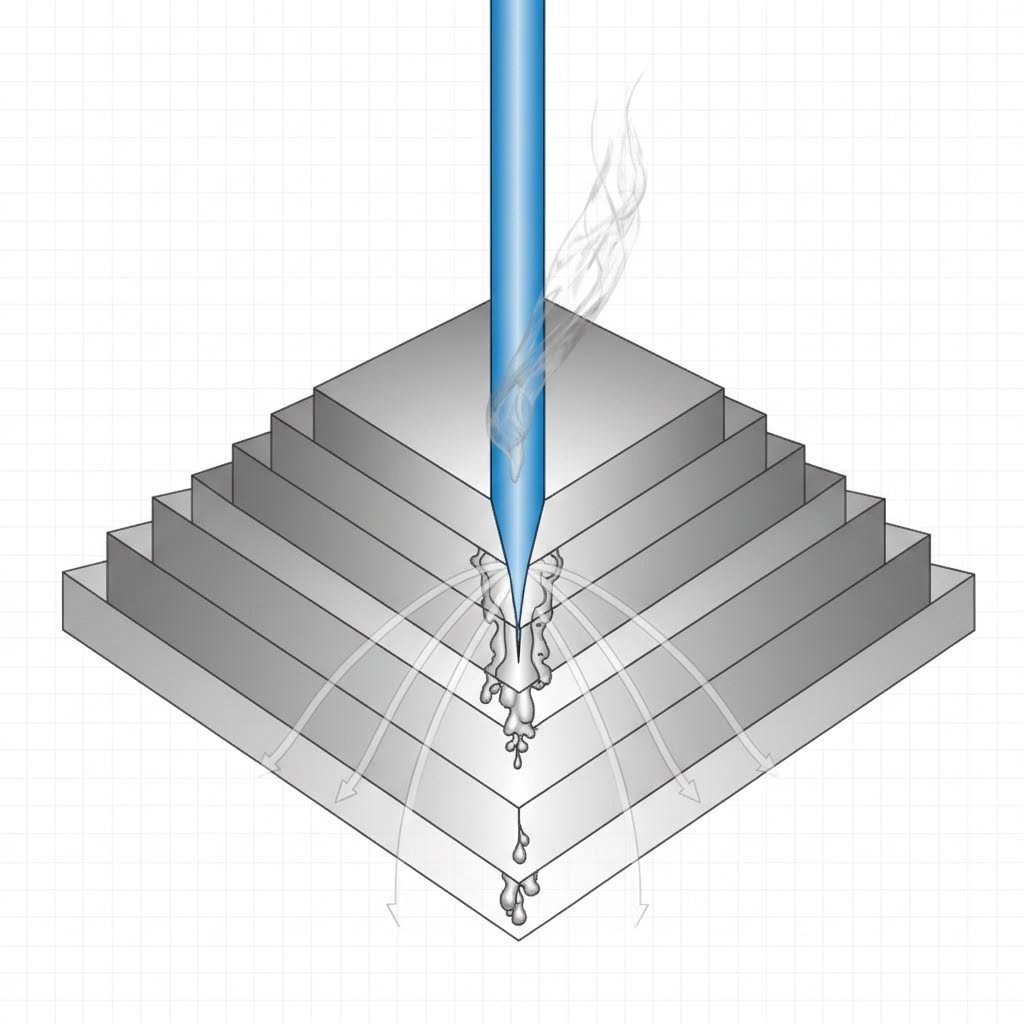

But that's only half the challenge. Aluminum's exceptional thermal conductivity means heat disperses rapidly throughout the material. While great for heat sinks, this property works against concentrated laser cutting by spreading energy away from the cut zone. The result? You'll need more power and precise parameter control than when cutting carbon steel of similar thickness.

Additionally, aluminum naturally forms an oxide layer on its surface. Though beneficial for corrosion resistance, this film can interfere with laser absorption, adding another variable to manage during aluminium laser cutting operations.

The Evolution of Laser Technology for Reflective Metals

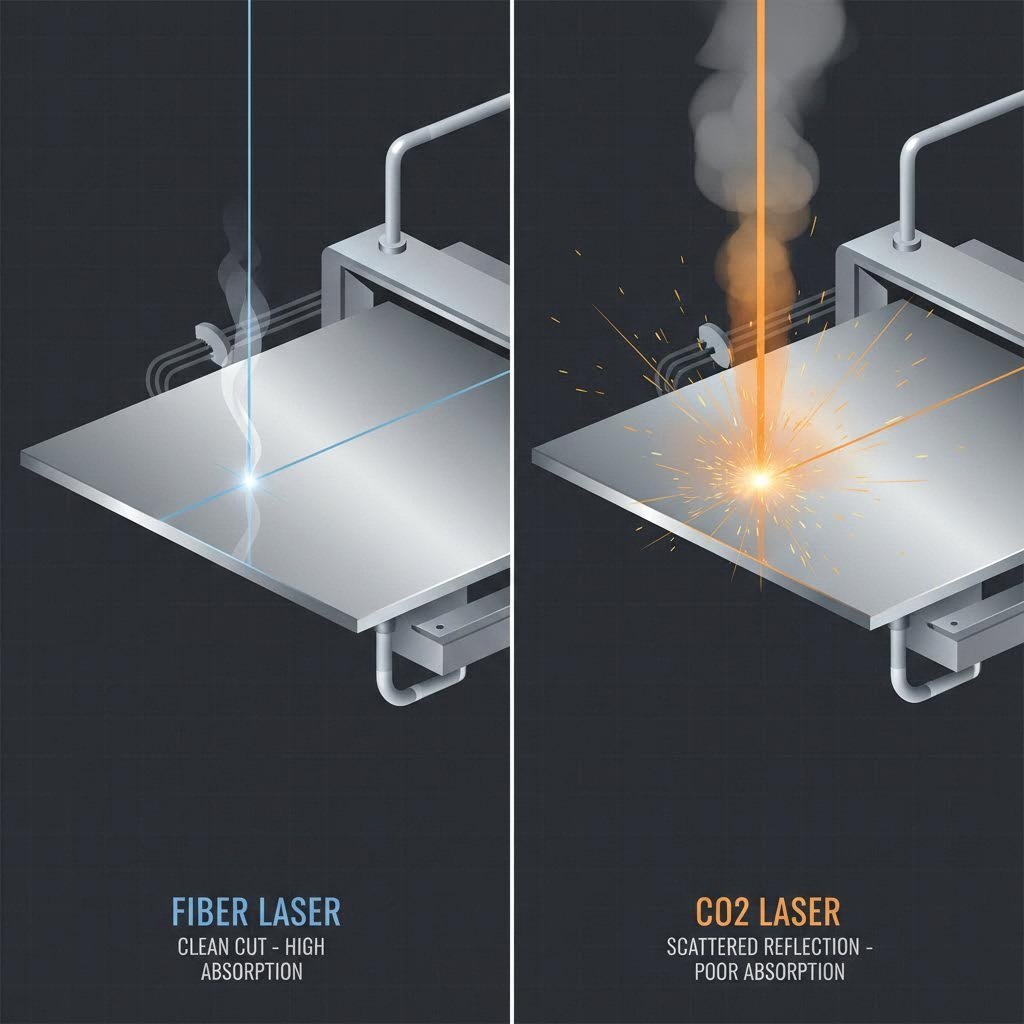

The good news? Modern laser technology has risen to meet these challenges head-on. Early CO₂ laser systems struggled significantly with aluminum's reflective nature—their 10.6-micron wavelength simply couldn't penetrate effectively. Many shops avoided aluminum laser cutting entirely due to inconsistent results and equipment damage concerns.

The game-changer arrived with fiber laser technology emerging around 2010. Operating at approximately 1.06 microns, fiber lasers offer wavelengths that aluminum absorbs far more efficiently. This technological leap transformed what was once a problematic material into a reliably laser cut aluminum option for precision fabrication.

Today's fiber laser systems deliver clean, burr-free edges on aluminum with minimal heat-affected zones—something that seemed impossible just two decades ago. Whether you're producing aerospace components, architectural panels, or custom enclosures, understanding these technological foundations helps you achieve consistent, professional results.

In the sections ahead, you'll discover exactly how to select the right laser type, match parameters to specific alloy grades, troubleshoot common defects, and optimize your cutting economics. Let's dive into the technical details that make aluminum laser cutting both predictable and profitable.

Fiber Laser vs CO2 Laser Performance for Aluminum

Picture two tools designed for the same job but engineered completely differently. That's the reality when comparing fiber lasers and CO2 lasers for aluminum cutting. While both can technically cut this reflective metal, their performance differences are dramatic—and understanding why comes down to physics.

If you're investing in fiber laser metal cutting equipment or evaluating service providers, grasping these fundamentals helps you make informed decisions. Let's break down exactly why fiber laser cutters have become the dominant choice for aluminum fabrication.

Wavelength Physics and Aluminum Absorption Rates

Here's the core principle: different laser wavelengths interact with metals differently. Think of it like radio frequencies—your car stereo can't pick up satellite signals because it's tuned to the wrong wavelength. Lasers work similarly with metals.

CO2 lasers emit light at a wavelength of 10.6 microns (10,600 nanometers). At this wavelength, aluminum reflects approximately 90-95% of the incoming laser energy. That reflected energy doesn't just disappear—it bounces back toward the laser source, potentially damaging optical components and reducing cutting efficiency.

Fiber lasers operate at approximately 1.06 microns (1,064 nanometers)—roughly one-tenth the CO2 wavelength. At this shorter wavelength, aluminum's absorption rate jumps significantly. According to industry testing data from LS Manufacturing, this improved absorption translates directly into faster cutting speeds and cleaner edge quality.

Why does wavelength matter so much? Aluminum's atomic structure interacts more efficiently with near-infrared light (fiber laser range) than far-infrared light (CO2 range). The shorter wavelength penetrates the reflective surface more effectively, delivering energy precisely where cutting occurs rather than scattering across the material.

Fiber Laser Advantages for Reflective Metal Processing

Beyond wavelength physics, fiber lasers bring several technical advantages that compound their effectiveness for fiber laser cutting aluminum:

- Superior beam quality: Fiber lasers produce extremely focused beams with excellent mode quality. This concentration enables narrower kerf widths (the material removed during cutting) and smaller heat-affected zones—critical for precision aluminum components.

- Higher power density: The tightly focused beam delivers intense energy to a tiny spot. For aluminum's high thermal conductivity, this concentrated power overcomes heat dissipation challenges that plague CO2 systems.

- Built-in back-reflection protection: Modern fiber laser for metal cutting systems incorporate sensors and protective measures specifically designed for reflective materials. This technology monitors reflected light and adjusts output to prevent equipment damage—a critical feature for high-power lasers exceeding 6kW.

- Energy efficiency: Fiber lasers achieve electro-optical conversion efficiency exceeding 30%, compared to roughly 10% for CO2 systems. This efficiency reduces operating costs significantly over the equipment's lifespan.

For manufacturers considering a desktop fiber laser or industrial-scale equipment, these advantages translate to faster processing, lower per-part costs, and consistent quality when working with aluminum alloys.

| Specification | Fiber Laser | CO2 Laser |

|---|---|---|

| Wavelength | 1.06 microns | 10.6 microns |

| Aluminum Absorption Rate | Higher (improved penetration) | 5-10% (highly reflective) |

| Typical Power Range | 1kW - 30kW+ | 1kW - 6kW |

| Electro-Optical Efficiency | 30%+ | ~10% |

| Thin Aluminum Cutting Speed | Several times faster | Baseline |

| Maintenance Requirements | Minimal (sealed beam path) | Higher (gas, mirrors, consumables) |

| Back-Reflection Protection | Standard on modern systems | Limited or unavailable |

| Best Aluminum Thickness Range | Up to 12mm+ (optimal under 10mm) | Thick plates 15mm+ (limited applications) |

When should you consider CO2 laser cut aluminum applications? Honestly, the scenarios are narrowing. Some legacy operations still use CO2 systems for extremely thick aluminum plates (15mm and above), where the longer wavelength can couple with metal plasma more effectively. However, advancing fiber laser technology continues eroding this advantage, making fibre laser cutter systems the clear choice for new equipment investments.

The bottom line? For aluminum cutting applications—particularly materials under 12mm thickness—fiber lasers deliver overwhelming advantages in efficiency, quality, and operating cost. Understanding these performance differences prepares you to select appropriate equipment or evaluate service providers effectively.

Of course, laser type represents just one variable in successful aluminum cutting. Different aluminum alloys behave uniquely under laser processing, requiring adjusted parameters and expectations based on their specific composition.

Aluminum Alloy Selection and Cutting Behavior

Ever wondered why two aluminum sheets of identical thickness cut so differently? The answer lies in their alloy composition. When you're figuring out how to cut aluminum sheets effectively, understanding alloy behavior isn't optional—it's essential for achieving consistent, high-quality results.

Aluminum alloys aren't created equal. Each series contains different alloying elements—magnesium, silicon, copper, zinc—that fundamentally change how the material responds to laser energy. These compositional differences affect thermal conductivity, melting behavior, and ultimately, your edge quality and cutting speed.

Cutting Characteristics by Aluminum Alloy Series

Let's explore the most commonly laser-cut alloys and what makes each unique:

6061 Aluminum serves as the workhorse of laser cutting aluminum sheet metal. This alloy contains magnesium and silicon, offering an excellent balance of strength, corrosion resistance, and machinability. Its predictable thermal response makes parameter optimization straightforward—a major advantage for shops processing mixed workloads. You'll find 6061 in structural components, frames, brackets, and general fabrication where reliability matters most.

5052 Aluminum excels in marine and chemical environments due to its exceptional corrosion resistance. The magnesium content (approximately 2.5%) provides moderate strength while maintaining excellent weldability. For laser cutting, 5052 typically produces clean edges with minimal dross formation. Its slightly lower thermal conductivity compared to pure aluminum means heat stays localized longer, often allowing faster cutting speeds than you might expect.

7075 Aluminum represents the aerospace standard—extremely strong but demanding to cut. The zinc-based alloy achieves tensile strengths approaching mild steel, making it ideal for aircraft components and high-stress applications. However, this strength comes with cutting challenges. According to Xometry's technical guidance, 7075 requires higher laser power and slower cutting speeds due to its hardness, and operators should expect rougher edge quality compared to softer alloys.

2024 Aluminum offers high strength through copper alloying, historically popular in aircraft structures. While excellent for fatigue resistance, 2024 presents cutting complications. The copper content can create more aggressive oxidation during cutting, and the alloy's tendency toward stress cracking demands careful heat management. Many fabricators reserve 2024 for applications where its specific mechanical properties justify the additional processing care.

Understanding how to cut aluminium sheet metal effectively means matching your approach to the specific alloy. What works perfectly for 5052 might produce unacceptable results on 7075.

Matching Laser Parameters to Alloy Properties

When cutting aluminum sheet, alloy composition directly influences your parameter selection:

- Power requirements: Higher-strength alloys like 7075 and 2024 generally need increased power to achieve clean cuts. Their denser microstructure resists melting more than softer alloys.

- Speed adjustments: Alloys with higher thermal conductivity (closer to pure aluminum) dissipate heat faster, potentially requiring slower speeds or higher power to maintain cut quality.

- Assist gas considerations: While nitrogen works universally, some alloys respond better to specific pressure settings. Higher-strength alloys often benefit from increased gas pressure to clear molten material effectively.

- Edge quality expectations: Accept that alloy choice affects achievable edge quality. Aerospace alloys like 7075 may require post-processing that 5052 or 6061 parts can skip entirely.

Based on industry experience from ABC Vietnam, the 5xxx and 6xxx series alloys consistently deliver the most reliable results when laser cut, making them preferred choices when alloy flexibility exists in your design specifications.

| Alloy | Typical Applications | Cutting Difficulty | Special Considerations |

|---|---|---|---|

| 6061 | Structural components, frames, brackets, general fabrication | Low to Moderate | Excellent all-around performance; predictable parameters; minimal post-processing needed |

| 5052 | Marine equipment, chemical tanks, fuel lines, pressure vessels | Low | Produces clean edges; lower thermal conductivity aids cutting; excellent weldability post-cut |

| 7075 | Aerospace structures, high-stress components, sporting equipment | High | Requires higher power and slower speeds; expect rougher edges; specialized parameter tuning essential |

| 2024 | Aircraft structures, fatigue-critical components, riveted assemblies | Moderate to High | Copper content increases oxidation; prone to stress effects; careful heat management required |

When learning how to cut an aluminum sheet for your specific application, start by identifying your alloy series. This single piece of information shapes your entire cutting strategy—from initial power settings to final quality expectations. Shops that skip this step often struggle with inconsistent results, blaming equipment when alloy variation is actually the culprit.

With alloy selection understood, the next critical step involves dialing in precise cutting parameters matched to your material thickness—where power, speed, and assist gas choices determine whether you achieve clean cuts or frustrating defects.

Cutting Parameters and Settings for Different Thicknesses

You've selected your alloy and chosen fiber laser technology—now comes the critical question: what settings actually produce clean, consistent cuts? This is where many operators struggle. Generic advice like "use more power for thicker material" doesn't help when you're staring at a control panel with dozens of adjustable parameters.

Whether you're running a cnc fiber laser cutting machine in a production environment or learning on a smaller sheet metal laser cutting machine, understanding parameter relationships transforms guesswork into predictable results. Let's build the comprehensive reference that actually delivers actionable guidance.

Power and Speed Settings by Thickness Range

Think of laser cutting parameters like a recipe—power, speed, and focus must work together in proper proportion. Too much power with excessive speed creates incomplete cuts. Too little speed with adequate power generates excessive heat-affected zones. Finding the balance depends primarily on material thickness.

Thin Gauge Aluminum (Under 3mm): This range represents the sweet spot for most laser cutting machine aluminum applications. A 1.5kW to 2kW fiber laser handles these thicknesses efficiently, with cutting speeds typically ranging from 5,000 to 10,000 mm/min depending on exact thickness. A 2 kw laser cutting machine can process 1mm aluminum at impressive speeds while maintaining excellent edge quality. Focus position typically sits at or slightly below the material surface (0 to -1mm focal offset).

Medium Thickness (3-6mm): As thickness increases, power requirements climb significantly. Expect to need 2kW to 4kW for consistent results in this range. According to DW Laser's thickness chart, aluminum up to 12mm requires 1.5kW to 3kW minimum—placing this middle range solidly in the 2-3kW territory. Cutting speeds drop to approximately 2,000-5,000 mm/min, and focal position moves further below the surface (-1mm to -2mm) to maintain beam focus within the thicker kerf.

Thick Gauge (6mm and Above): This territory demands serious power. For 6mm+ aluminum, 3kW to 6kW systems become necessary, with industrial applications pushing toward 10kW+ for maximum thickness capability. Industry data indicates that a 3kW fiber laser can cleanly cut aluminum up to approximately 10mm, while 6kW+ systems handle 25mm or thicker. Speeds slow considerably—often below 1,500 mm/min—and focal position requires careful optimization, typically -2mm to -3mm below the surface.

Unlike a typical steel sheet cutting machine setup, aluminum parameters require adjustments for the material's unique thermal properties. Aluminum dissipates heat faster, meaning parameters that work for steel won't translate directly.

| Thickness Range | Recommended Power | Typical Cutting Speed | Focal Position | Key Considerations |

|---|---|---|---|---|

| Under 1mm | 1kW - 1.5kW | 8,000 - 12,000 mm/min | 0 to -0.5mm | Risk of burn-through at slow speeds; maintain momentum |

| 1mm - 3mm | 1.5kW - 2kW | 5,000 - 10,000 mm/min | 0 to -1mm | Optimal range for most laser cutting machine sheet metal systems |

| 3mm - 6mm | 2kW - 4kW | 2,000 - 5,000 mm/min | -1mm to -2mm | Assist gas pressure becomes increasingly critical |

| 6mm - 10mm | 3kW - 6kW | 1,000 - 2,500 mm/min | -2mm to -3mm | Multiple piercing strategies may improve start quality |

| 10mm+ | 6kW - 12kW+ | 500 - 1,500 mm/min | -3mm or lower | Edge quality decreases; post-processing often required |

Assist Gas Selection for Optimal Edge Quality

Assist gas might seem like a secondary consideration, but it fundamentally shapes your cut quality. The gas serves multiple functions: shielding the cut zone, ejecting molten material, and preventing oxidation. Your choice between nitrogen and compressed air affects both edge appearance and operating economics.

Nitrogen: The premium choice for aluminum cutting. High-purity nitrogen (typically 99.95%+) creates oxide-free, bright silver edges that require minimal post-processing. This matters significantly for visible components or parts requiring subsequent welding or anodizing. Nitrogen cutting typically uses pressures between 10-20 bar, with thicker materials demanding higher pressures to effectively clear the kerf. The tradeoff? Nitrogen consumption represents a meaningful operating cost—often the largest consumable expense for high-volume operations.

Compressed Air: The economical alternative. Clean, dry compressed air works adequately for many laser cutting machine metal sheet applications where edge appearance isn't critical. Expect some oxidation—the edges will appear darker and slightly duller than nitrogen-cut parts. However, for internal components, prototypes, or parts receiving paint or powder coating, this visual difference rarely matters. Air cutting typically operates at 8-15 bar pressure.

Consider this practical guidance:

- Choose nitrogen when: Parts remain visible in final assembly, require welding without extensive cleaning, need anodizing with consistent color, or specifications demand oxide-free edges

- Choose compressed air when: Parts receive opaque coatings, serve internal functions, represent prototypes or test pieces, or cost optimization outweighs edge aesthetics

- Gas pressure adjustment: Increase pressure as thickness increases—thin material might cut cleanly at 10 bar, while 6mm+ aluminum often needs 18-20 bar to properly evacuate molten material

- Quality verification: When dialing in parameters, always examine both top and bottom edges—dross accumulation on the underside indicates insufficient gas pressure or excessive speed

For shops running a laser cutting machine metal sheet operation with mixed materials, having both gas options available provides maximum flexibility. Many fabricators use nitrogen for customer-facing parts and air for internal brackets and structural components—optimizing costs without sacrificing quality where it matters.

Even with perfectly optimized parameters, defects occasionally appear. Understanding what causes common problems—and how to solve them—separates professional results from frustrating inconsistency.

Troubleshooting Common Aluminum Cutting Defects

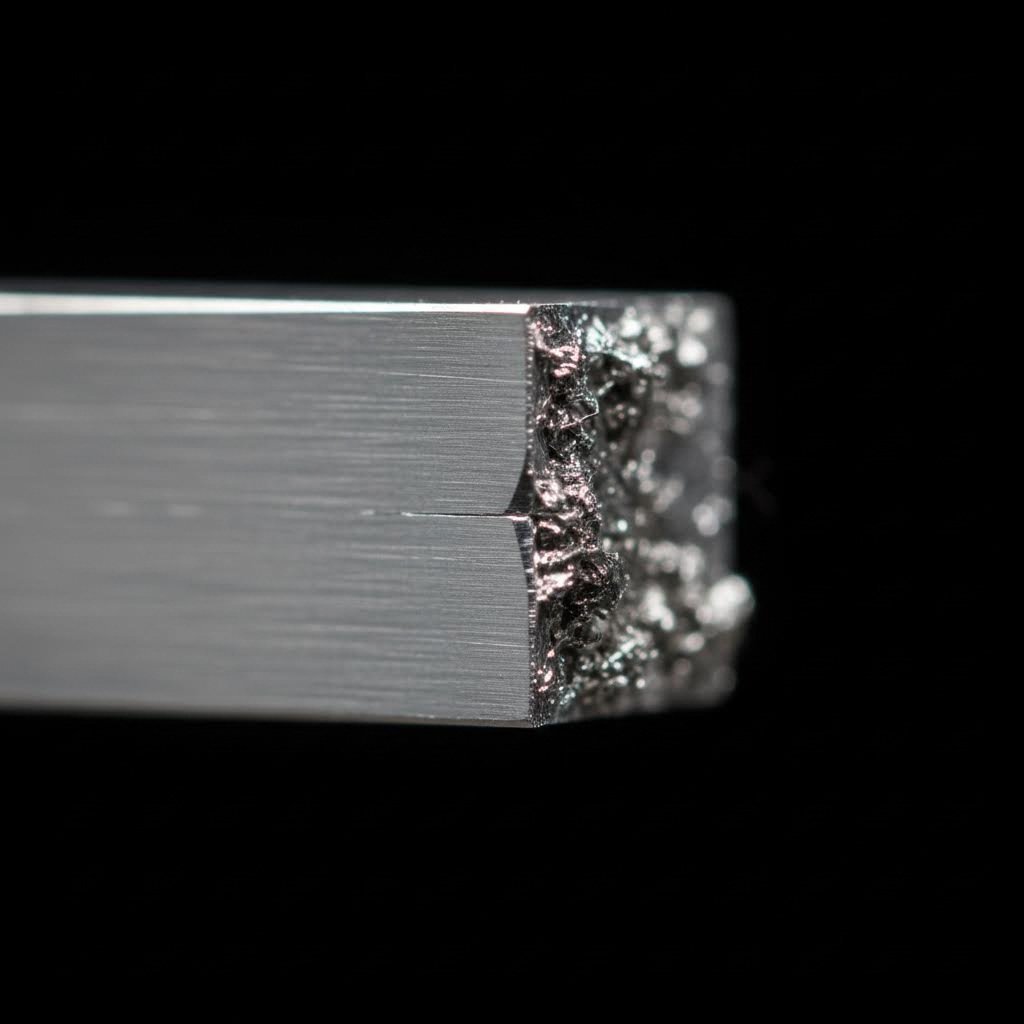

You've dialed in your parameters, selected the right alloy, and started production—then defects appear. Burrs clinging to edges. Dross fused to the underside. Rough surfaces where smooth cuts should be. Frustrating? Absolutely. But every defect tells a story, and understanding that story transforms problems into solutions.

Laser cutting of metal sheets demands precision, and aluminum amplifies every small deviation in your process. The good news? Most defects trace back to identifiable causes with proven fixes. Let's build the systematic troubleshooting approach that gets your cuts back on track.

Diagnosing Edge Quality Problems and Solutions

When laser cutting metal sheet, edge defects fall into predictable categories. Each has specific causes and targeted solutions:

-

Burr Formation

- Problem: Sharp, raised metal ridges along cut edges that require manual removal

- Causes: Cutting speed too fast for material thickness; insufficient laser power leaving material incompletely melted; assist gas pressure too low to properly eject molten material; worn or damaged nozzle creating uneven gas flow

- Solutions: Reduce cutting speed by 10-15% increments until burrs disappear; verify power settings match thickness requirements from parameter tables; increase assist gas pressure (try 2-3 bar increments); inspect and replace nozzle if worn or clogged—worn nozzles represent one of the most common causes of inconsistent cuts

-

Dross Adhesion

- Problem: Solidified molten metal adhering to the bottom edge of cuts, creating rough surfaces that interfere with assembly

- Causes: Excessive cutting speed preventing proper material ejection; gas pressure insufficient to clear molten aluminum before it resolidifies; focal position too high (above material surface); contaminated or impure assist gas

- Solutions: Slow cutting speed to allow complete material ejection; increase nitrogen pressure to 15-20 bar for thicker materials; adjust focal position 0.5-1mm lower into the material; verify gas purity meets specifications (99.95%+ for nitrogen)

-

Rough or Striated Edge Quality

- Problem: Visible vertical lines, roughness, or irregular texture on cut surfaces instead of smooth edges

- Causes: Cutting speed too slow causing excessive heat buildup; power too high for material thickness; dirty or contaminated optical components; unstable assist gas flow; mechanical vibration in cutting head or gantry

- Solutions: Increase cutting speed while monitoring for incomplete cuts; reduce power by 5-10% increments; clean all mirrors and lenses using appropriate cleaning solutions and lint-free cloths; check gas supply lines for leaks or restrictions; inspect mechanical components for loose connections or worn bearings

-

Incomplete Cuts or Intermittent Piercing Failures

- Problem: Laser fails to cut entirely through material, leaving tabs or sections attached

- Causes: Insufficient power for material thickness; cutting speed too fast; focal position incorrect (either too high or too low); material thickness variation exceeding tolerances; oxide layer buildup on material surface

- Solutions: Increase power or decrease speed; recalibrate focus using test cuts on scrap material; verify actual material thickness matches programmed parameters; pre-clean aluminum surfaces to remove heavy oxidation before cutting

-

Excessive Heat-Affected Zone (HAZ)

- Problem: Visible discoloration, warping, or material property changes extending beyond the cut edge

- Causes: Cutting speed too slow allowing heat to spread; power significantly higher than necessary; multiple passes or hesitation at corners concentrating heat; insufficient assist gas cooling

- Solutions: Optimize speed-to-power ratio—increase speed before reducing power; program corner radius rather than sharp angles to maintain momentum; use pulsed cutting mode for intricate features; increase gas flow for additional cooling effect

When troubleshooting laser metal cutting issues, change only one parameter at a time. Making multiple adjustments simultaneously makes it impossible to identify which change solved—or worsened—the problem.

Managing Reflectivity Risks During Cutting

Aluminum's reflective nature creates unique hazards beyond simple cut quality issues. Back-reflected laser energy can damage optical components, reduce cutting efficiency, and in severe cases, harm the laser source itself. Understanding these risks—and implementing proper mitigation—protects both your equipment and your results.

How Back-Reflection Damage Occurs: When laser energy strikes aluminum's highly reflective surface, a portion bounces back along the beam path. Unlike cutting steel, where most energy absorbs into the material, aluminum can reflect significant energy—especially during piercing when the beam first contacts an unmelted surface. This reflected energy travels backward through the optical system, potentially overheating lenses, damaging fiber optic cables, or reaching the laser source.

Warning Signs of Reflection Problems:

- Unexplained power drops during aluminum processing

- Optical component degradation faster than normal service intervals

- Inconsistent piercing behavior—some attempts succeed while others fail

- Machine alarms or protective shutdowns during cutting operations

- Visible damage or discoloration on protective windows or lenses

Mitigation Strategies:

- Back-reflection protection systems: Modern fiber laser systems above 6kW typically include built-in back-reflection protection that monitors reflected light and adjusts output automatically. Verify your equipment includes this feature before processing reflective materials at high power.

- Optimized piercing techniques: Ramped piercing (gradually increasing power) or pulse piercing reduces initial reflection intensity compared to full-power piercing. Many CNC controllers offer specialized piercing routines for reflective materials.

- Surface preparation: Light surface roughening, anti-reflective coatings, or simply ensuring materials are clean and free of polishing residue can reduce initial reflectivity during piercing.

- Beam delivery optimization: Proper focus position ensures maximum energy absorption at the cut point. An incorrectly focused beam spreads energy across a larger area, increasing the reflective surface interaction and back-reflection risk.

- Protective window maintenance: The protective window between the focusing lens and material serves as the first line of defense. Inspect and clean this component regularly—contamination increases absorption and heating, accelerating damage.

- Appropriate power selection: Using excessive power doesn't just waste energy—it increases reflected energy proportionally. Match power to actual thickness requirements rather than defaulting to maximum settings.

For shops regularly processing aluminum alongside steel and other metals, establishing material-specific startup procedures ensures proper protection settings engage before cutting begins. A simple checklist confirming back-reflection protection status, appropriate piercing mode selection, and protective window condition prevents costly equipment damage.

When metal laser cutting defects persist despite parameter optimization, look beyond settings to mechanical and environmental factors. Loose timing belts, contaminated optics, unstable voltage supply, and inadequate ventilation all contribute to quality problems that no amount of parameter adjustment can solve. Systematic diagnosis—addressing mechanical integrity before fine-tuning settings—saves hours of frustrating trial and error.

Once you've achieved consistent, defect-free cuts, the question becomes: what happens next? Many aluminum parts require post-processing steps that directly impact final quality and downstream operations.

Post-Processing and Surface Finishing Considerations

So you've achieved clean, consistent laser cuts—now what? Here's a reality check: not every laser-cut aluminum part arrives ready for final assembly. Understanding when secondary operations are necessary versus when your parts can proceed directly to application saves both time and budget.

The good news? Modern fiber laser technology produces significantly cleaner edges than older cutting methods. Many thin-gauge aluminum parts—particularly those cut with optimized nitrogen assist—require minimal intervention before downstream processes. However, specific applications demand additional attention.

Deburring and Edge Finishing Requirements

Even the best laser cuts can leave minor imperfections. Micro-burrs, slight edge roughness, or thermal discoloration may not affect structural performance but can impact aesthetics, handling safety, or coating adhesion.

When do you need deburring? Consider these scenarios:

- Handle-contact parts: Components that workers or end-users touch regularly benefit from smooth, burr-free edges to prevent cuts

- Precision assemblies: Parts requiring tight fits or mating surfaces need consistent edge profiles

- Pre-coating preparation: Powder coating and anodizing perform better on uniformly finished surfaces

- Visible components: Customer-facing parts often require the polished appearance that deburring provides

According to SendCutSend's finishing guide, linear deburring removes scratches, burrs, and minor imperfections from the manufacturing process—preparing parts for subsequent finishing operations. For smaller parts, ceramic tumbling offers a vibratory-abrasive process that delivers consistent results across all edges simultaneously.

When can you skip deburring? Internal structural components, prototype iterations, or parts receiving heavy post-machining often don't require this intermediate step. Evaluate each application individually rather than applying blanket policies.

Surface Treatment Preparation for Laser-Cut Parts

Laser-cut aluminum readily accepts most common surface treatments, but proper preparation ensures optimal results. Each finishing method has specific requirements:

Anodizing Preparation: Anodizing creates a durable, scratch-resistant finish by thickening aluminum's natural oxide layer through an electrochemical process. Before anodizing, parts should be deburred—imperfections become more visible through the anodized coating, not less. Note that anodized surfaces are non-conductive, which affects electrical grounding applications. Also, parts requiring welding should complete that step before anodizing—the coating interferes with weld quality.

Powder Coating Compatibility: Powder coating adheres electrostatically before oven curing, creating a finish that can last up to 10 times longer than paint. Aluminum, steel, and stainless steel are ideal candidates. Surface preparation matters—light abrasion or media blasting improves adhesion. Laser-cut edges typically provide adequate surface texture for powder coat bonding without additional roughening.

Welding Considerations: Nitrogen-cut edges weld more cleanly than air-cut parts due to minimal oxidation. For critical welds, light mechanical cleaning removes any remaining oxide layer. If your parts require both welding and surface treatment, follow this sequence: cut → deburr → weld → clean → finish (anodize or powder coat).

Laser Etching on Aluminum: Many manufacturers combine cutting with aluminum laser etching for part marking, serial numbers, or decorative elements. Laser marking can occur before or after other finishing processes, though marking after anodizing produces different visual effects than marking bare aluminum. Experiment with sequence to achieve desired aesthetics.

Here's the recommended post-processing sequence for most applications:

- Inspect cut edges for defects requiring correction

- Deburr or tumble based on part requirements and geometry

- Complete any required welding or mechanical joining

- Clean surfaces to remove oils, debris, or welding residue

- Apply media blasting if enhanced coating adhesion is needed

- Proceed with final surface treatment (anodizing, powder coating, or plating)

- Perform final inspection and quality verification

Understanding these post-processing relationships helps you quote projects accurately and set realistic timelines. A part requiring deburring, welding, and anodizing follows a fundamentally different production path than a simple cut-and-ship component.

With finishing options clarified, the next critical question for any project becomes economic: how do cutting method choices and volume decisions impact your bottom line?

Cost Analysis and Economic Considerations

Here's the question that ultimately drives every fabrication decision: what does this actually cost? Understanding laser cutting economics separates profitable projects from money-losers. Yet surprisingly, comprehensive cost analysis remains one of the most overlooked aspects of aluminum cutting—until the invoice arrives.

Whether you're evaluating in-house equipment investments or comparing service provider quotes, grasping the true cost drivers helps you make informed decisions. Let's build the framework that transforms vague estimates into accurate project budgets.

Calculating Cost Per Cut for Aluminum Projects

Laser cutting costs don't exist in isolation. Multiple factors combine to determine your actual per-part expense:

Material Thickness: This single variable influences nearly every other cost factor. Thicker aluminum requires more power, slower cutting speeds, higher gas consumption, and longer machine time. According to HGSTAR Laser's cost analysis, the main cost of laser cutting is based on cutting time—primarily determined by material thickness alongside engraving area and material type. Cutting 6mm aluminum costs significantly more per linear inch than 2mm material, even at identical complexity levels.

Part Complexity: Intricate designs with numerous small features, tight corners, and detailed cutouts require more cutting time than simple geometric shapes. The laser must decelerate for direction changes, and each pierce point adds processing time. A complex bracket with 50 holes and detailed contours might cost three times more than a simple rectangular plate of identical material weight.

Volume and Setup Efficiency: Setup time gets distributed across all parts in a production run. Cutting a single prototype absorbs the full setup cost—material loading, parameter verification, program loading—while a 500-piece run spreads that overhead across every unit. This fundamental math explains why per-part costs drop dramatically at higher volumes.

Machine Operating Costs: Operating costs for laser cutting aluminum range between $13 and $20 per hour according to industry data. This includes electrical consumption, assist gas usage, consumable wear (nozzles, lenses, protective windows), and routine maintenance allocation. Higher-power machines capable of cutting thicker material typically operate at the upper end of this range.

Assist Gas Consumption: Nitrogen—the premium choice for oxide-free edges—represents a significant consumable cost, especially for thick materials requiring high pressure and flow rates. Compressed air cutting reduces this expense substantially but produces different edge characteristics. For cost-sensitive applications where edge appearance isn't critical, air cutting can reduce consumable costs by 60-70%.

Curious about equipment investment? How much is a laser cutting machine? The range is enormous. New laser cutters cost anywhere from $1,000 to $1,000,000 USD, depending on power, automation level, and cutting bed size. Entry-level systems for thin materials start around $10,000, while production-grade metal laser cutting machines capable of processing thick aluminum begin at $100,000 and climb from there. When evaluating a laser cutting machine for sale, factor in not just purchase price but installation, training, and ongoing operating costs.

Volume Thresholds and Economic Break-Even Points

Laser cutting doesn't always represent the most economical choice. Understanding when alternatives make more sense—and when laser cutting delivers unbeatable value—helps optimize your fabrication strategy.

When Laser Cutting Wins:

- Thin to medium aluminum (under 6mm): Fiber lasers excel here, delivering fast processing with excellent edge quality

- Complex geometries: Intricate patterns, small features, and tight tolerances favor laser precision

- Mixed production: Quick setup changes between different part designs maximize flexibility

- Oxide-free edge requirements: Nitrogen-assisted cutting produces ready-to-finish edges

- Medium to high volumes: Once setup costs amortize, per-part costs become highly competitive

When Alternatives May Be More Economical:

- Very thick aluminum (12mm+): Waterjet cutting handles extreme thickness without heat effects, though slower

- Heat-sensitive applications: Waterjet's cold-cutting process eliminates thermal distortion concerns

- Simple shapes in thick material: Plasma cutting offers lower operating costs for basic geometries in conductive metals

- Ultra-low volume or one-offs: Setup costs may favor manual methods or alternative processes

According to Wurth Machinery's comparative analysis, the cost difference between technologies is substantial—a complete plasma system costs around $90,000 while a similar-sized waterjet system runs approximately $195,000. For metal fabrication shops focused primarily on aluminum and steel, the right metal cutting machine depends on your typical thickness range and precision requirements.

| Cost Factor | Laser Cutting | Waterjet Cutting | Plasma Cutting |

|---|---|---|---|

| Equipment Investment | $50,000 - $500,000+ | $100,000 - $300,000 | $50,000 - $150,000 |

| Hourly Operating Cost | $13 - $20 | $20 - $35 (abrasive costs) | $10 - $18 |

| Thin Aluminum Speed | Fastest | Slowest | Moderate |

| Thick Aluminum Capability | Good (up to 25mm with high power) | Excellent (any thickness) | Good (conductive metals only) |

| Edge Quality | Excellent (minimal post-processing) | Excellent (no heat effects) | Moderate (may require finishing) |

| Precision Tolerance | ±0.1mm typical | ±0.1-0.2mm typical | ±0.5-1mm typical |

| Best Volume Range | Medium to high | Low to medium | Medium to high |

| Heat-Affected Zone | Minimal with proper parameters | None (cold process) | Significant |

The laser cutting machine price you'll pay—whether purchasing equipment or buying cutting services—reflects these capability differences. For most aluminum fabrication scenarios involving material under 10mm, fiber laser technology delivers the optimal balance of speed, quality, and per-part economics. Thicker materials or heat-sensitive applications may justify waterjet's premium, while simple thick-plate work on budget constraints might favor plasma.

Smart fabrication strategies often combine technologies. Use laser cutting for precision components and thin-gauge work where it excels, while outsourcing occasional thick-plate or heat-sensitive jobs to waterjet specialists. This hybrid approach maximizes your equipment investment while maintaining capability flexibility.

Understanding these economic realities prepares you for informed decisions—whether you're quoting customer projects, evaluating capital equipment, or selecting service providers. But cost optimization means nothing if your operations compromise safety. Aluminum laser cutting presents specific hazards that demand proper protocols.

Safety Protocols for Aluminum Laser Cutting Operations

Cutting aluminum isn't just technically different from steel—it's fundamentally different from a safety perspective. The same reflective properties that challenge your cutting parameters create unique hazards absent when processing other metals. Understanding these aluminum-specific risks protects your team, your equipment, and your bottom line.

Whether you're operating metal laser cutters in a production environment or running a smaller laser cutter for metal in a job shop, proper safety protocols aren't optional. Let's build the comprehensive safety framework that addresses the distinct challenges of processing reflective materials.

Personal Protective Equipment for Aluminum Cutting

Eye protection tops every safety checklist—but not just any safety glasses will do. Laser wavelength matters enormously. Fiber lasers operating at 1.06 microns require different protective eyewear than CO2 systems at 10.6 microns. Using incorrect eye protection provides a false sense of security while offering no actual protection.

Consider these essential PPE requirements:

- Laser-specific safety eyewear: Select glasses rated for your exact laser wavelength and power level. Look for Optical Density (OD) ratings appropriate to your system—higher power demands higher OD protection. Never substitute generic safety glasses for laser-rated protection.

- Fire-resistant clothing: Aluminum's reflective nature can redirect laser energy unpredictably, especially during piercing. Wear natural fiber clothing (cotton) rather than synthetics that melt when exposed to heat or sparks.

- Respiratory protection: While ventilation systems handle most fume management, backup respiratory protection should be available for maintenance operations or system malfunctions.

- Heat-resistant gloves: Aluminum dissipates heat rapidly through the material—freshly cut parts can remain hot despite appearing cool. Handle with appropriate gloves until parts fully cool.

A critical point often overlooked: the metal cutting laser beam isn't the only hazard. Reflected beams, scattered radiation, and secondary emissions from the cut zone all pose risks. Ensure your workspace design contains these secondary hazards, not just the primary beam path.

Ventilation and Fume Management Requirements

Aluminum particulates present respiratory hazards distinct from steel cutting fumes. The material's lightweight nature means particles remain airborne longer, traveling further from the cut zone before settling. Proper extraction isn't just about comfort—it's about preventing long-term respiratory damage.

According to NFPA 660 guidelines, aluminum creates combustible dust that requires specific safety measures. Key considerations include:

- Dedicated fume extraction: Position extraction points close to the cutting zone—particulates captured at the source never become a breathing hazard

- Filtration requirements: HEPA filtration captures fine aluminum particles that standard filters miss. For high-volume operations, consider multi-stage filtration systems

- Dust accumulation management: Aluminum dust settling on equipment and surfaces creates fire and explosion risks. Regular cleaning protocols prevent dangerous accumulation

- Explosion protection: While welding aluminum alone may not require explosion vents, grinding operations on aluminum do require explosion vent protection per NFPA 660 requirements

Your ventilation capacity should match your production intensity. A system adequate for occasional aluminum cutting may prove insufficient during sustained high-volume operations.

Fire Prevention and Machine Safety

Aluminum's high reflectivity creates fire risks beyond typical metal cutting concerns. Misdirected laser energy can ignite nearby materials, and aluminum itself, while difficult to ignite in solid form, becomes highly combustible as fine particulates or thin foil.

Essential fire prevention measures for laser cutters for metal processing aluminum include:

- Clear work area: Remove flammable materials, debris, and unnecessary items from the cutting zone. According to FM Sheet Metal's guidelines, keeping the area clear of debris, clutter, and flammable materials is essential.

- Fire suppression accessibility: Maintain appropriate fire extinguishers within immediate reach of the operating area—not across the shop, but within seconds of the machine

- Never leave equipment unattended: Unlike some automated processes, laser cutting aluminum demands operator presence. Avoid leaving the cutter to operate unattended—reflective material behavior can change unpredictably

- Regular interior cleaning: Debris accumulation inside the machine enclosure creates ignition risks. Establish and follow regular cleaning schedules

- Back-reflection monitoring: Modern machines include sensors detecting excessive reflected energy—ensure these protective systems remain active and properly calibrated

Machine safety interlocks provide your last line of defense. Enclosure interlocks, emergency stops, and beam-off switches must function reliably. Test these systems regularly—the one time they fail shouldn't be during an actual emergency.

Finally, never look directly at the laser beam or cutting zone without appropriate protection—even brief exposure can cause permanent eye damage. Viewing windows on machine enclosures are specifically filtered for safe observation; bypass these protections at your own risk.

With comprehensive safety protocols protecting your operations, you're positioned to make informed decisions about your overall aluminum cutting strategy—including when to invest in equipment versus partnering with specialized fabrication services.

Selecting the Right Aluminum Cutting Strategy for Your Projects

You've mastered the technical fundamentals—laser types, alloy behaviors, parameter optimization, defect troubleshooting, and cost analysis. Now comes the strategic question that ties everything together: should you cut aluminum in-house, outsource to specialists, or develop a hybrid approach that leverages both?

This decision impacts more than just your immediate project. It shapes your capital allocation, workforce development, and long-term manufacturing flexibility. Let's explore the practical considerations that guide this critical choice.

Evaluating In-House vs Outsourced Cutting Decisions

When someone asks "how can I cut aluminum for my specific application?" the answer depends heavily on context. Both in-house and outsourced approaches offer distinct advantages:

When In-House Equipment Makes Sense:

- High volume, consistent work: If you're processing aluminum regularly—daily or weekly production runs—owning a laser metal cutting machine becomes cost-effective. According to GF Laser's analysis, frequent, high-volume operations often justify the capital investment

- Speed and flexibility demands: Having equipment on-site enables rapid prototyping and quick adjustments. When a customer needs modifications, you respond in hours rather than days

- Intellectual property concerns: Sensitive designs stay within your facility, reducing exposure to third-party handling

- Production control: Complete control over timelines, quality standards, and prioritization becomes possible when you own the equipment

When Outsourcing Delivers Better Value:

- Sporadic or low-volume needs: If aluminum cutting represents occasional work rather than core production, outsourcing eliminates capital tied up in underutilized equipment

- Access to specialized capabilities: Professional services often operate high-end sheet metal laser cutting systems with capabilities exceeding what your volume justifies purchasing

- Scalability without capital risk: Scale up during busy periods and down during slow times without the fixed costs of equipment ownership

- Reduced operational complexity: Skip the maintenance schedules, training requirements, and safety compliance management that equipment ownership demands

The financial reality deserves careful consideration. Current production-grade laser cutting machines from leading manufacturers cost in excess of £600,000—a significant capital commitment before factoring in installation, training, and ongoing operational expenses. For many operations, that investment only makes sense with substantial, predictable cutting volume.

Consider also the hidden costs of ownership. Nitrogen supply for oxide-free aluminum cutting requires either frequent tank deliveries or fixed tank installations for high-volume operations. Electricity consumption, consumable replacement, and skilled operator wages add to ongoing expenses that outsourcing converts into simple per-part pricing.

Building an Integrated Metal Fabrication Strategy

Here's what experienced manufacturers understand: laser cutting rarely exists in isolation. Most aluminum components require additional operations—bending, welding, hardware insertion, surface finishing, or assembly into larger systems. Viewing cutting as one step in a complete fabrication workflow opens strategic possibilities.

Many successful operations adopt hybrid approaches:

- Core work in-house, overflow outsourced: Handle regular production internally while partnering with service providers for capacity overflow during peak demand

- Standard work in-house, specialized work outsourced: Process routine parts on owned equipment while sending complex or unusual requirements to specialists with advanced capabilities

- Cutting in-house, finishing outsourced: Maintain a laser cutter for sheet metal while partnering with anodizing, powder coating, or assembly specialists

When evaluating fabrication partners for aluminum components, consider capabilities beyond cutting alone. Major aluminum fabrication cost buckets include raw material, machine time, secondary operations (cutting, drilling, bending), joining, surface finishing, and logistics. A partner offering integrated services across multiple operations often delivers better total value than managing separate vendors for each step.

For automotive and industrial applications requiring precision aluminum components, certifications matter significantly. IATF 16949 certification—the automotive quality management standard—indicates suppliers meeting rigorous process control requirements. This becomes particularly relevant for chassis, suspension, and structural components where consistency and traceability are non-negotiable.

Design for Manufacture (DFM) support represents another valuable partner capability. DFM helps reduce piece count, simplify profiles, optimize wall thickness and radii, and align specifications with process capability—cutting costs and lead times while improving yields. Partners offering DFM review before production catch costly design issues early.

For manufacturers needing precision aluminum components beyond cutting alone, Shaoyi (Ningbo) Metal Technology offers a complementary resource. Their 5-day rapid prototyping and comprehensive DFM support help optimize designs before committing to production tooling—particularly valuable when developing new aluminum components for automotive applications. With IATF 16949 certification and 12-hour quote turnaround, they provide the quality assurance and responsiveness that production-critical components demand.

Making Your Decision:

Evaluate your specific situation against these criteria:

- Volume consistency: Regular, predictable work favors equipment investment; variable demand favors outsourcing flexibility

- Capital availability: Assess whether funds are better deployed in cutting equipment or other business priorities

- Technical capability: Do you have—or can you develop—the expertise to operate and maintain laser metal cutter systems effectively?

- Complete workflow: Consider how cutting integrates with your other manufacturing operations

- Strategic direction: Does manufacturing capability align with your long-term business model, or are you better served focusing on design and assembly?

The right answer varies by organization. A precision machine shop building custom components benefits from in-house sheet metal laser cutter capability. A product company focused on design and marketing might achieve better results partnering with specialized fabricators who handle the manufacturing complexity.

Whatever path you choose, the technical knowledge you've gained throughout this guide—from fiber laser physics to alloy selection, parameter optimization to defect troubleshooting—positions you to make informed decisions and achieve consistent, professional results in your aluminum cutting operations.

Frequently Asked Questions About Laser Cutting Aluminum

1. Can I cut aluminum with a laser?

Yes, aluminum can be effectively laser cut using fiber laser technology. Unlike CO2 lasers that struggle with aluminum's high reflectivity, fiber lasers operate at a 1.06-micron wavelength that aluminum absorbs efficiently. Modern fiber laser systems include back-reflection protection to prevent equipment damage, delivering clean, burr-free edges on aluminum sheets typically ranging from 0.04 inches to over 10mm thickness with proper parameter optimization.

2. How much does it cost to laser cut aluminum?

Laser cutting aluminum typically costs $1 to $3 per inch or $75 to $150 per hour, depending on material thickness, design complexity, and production volume. Thicker materials require more power and slower speeds, increasing costs. Operating expenses range from $13 to $20 per hour including electricity, assist gas, and consumables. High-volume production significantly reduces per-part costs as setup overhead distributes across more units.

3. How powerful of a laser to cut aluminum?

Laser power requirements depend on aluminum thickness. For material under 3mm, 1.5kW to 2kW fiber lasers work effectively. Medium thickness aluminum (3-6mm) requires 2kW to 4kW power. For thicker material (6mm+), 3kW to 6kW systems become necessary, while industrial applications processing 10mm+ aluminum may require 6kW to 12kW or higher. Always match power to thickness rather than defaulting to maximum settings.

4. How thick can laser cut aluminum?

Fiber lasers can cut aluminum up to 25mm or thicker with high-power systems (6kW+). However, optimal results occur with material under 10mm where edge quality remains excellent. A 3kW fiber laser cleanly cuts aluminum up to approximately 10mm, while 6kW+ systems handle 25mm. Beyond 12mm, waterjet cutting may offer advantages for heat-sensitive applications, though advancing fiber laser technology continues expanding thickness capabilities.

5. What is the best laser type for cutting aluminum?

Fiber lasers are definitively superior to CO2 lasers for aluminum cutting. Operating at 1.06 microns versus CO2's 10.6 microns, fiber lasers achieve dramatically better absorption rates with reflective metals. They offer superior beam quality for narrower kerf widths, built-in back-reflection protection, over 30% electro-optical efficiency compared to CO2's 10%, and faster cutting speeds on thin to medium aluminum. For material under 12mm, fiber laser technology delivers overwhelming advantages.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —