Stamping Press Dies Decoded: From Raw Steel To Precision Parts

What Stamping Press Dies Are and Why They Matter

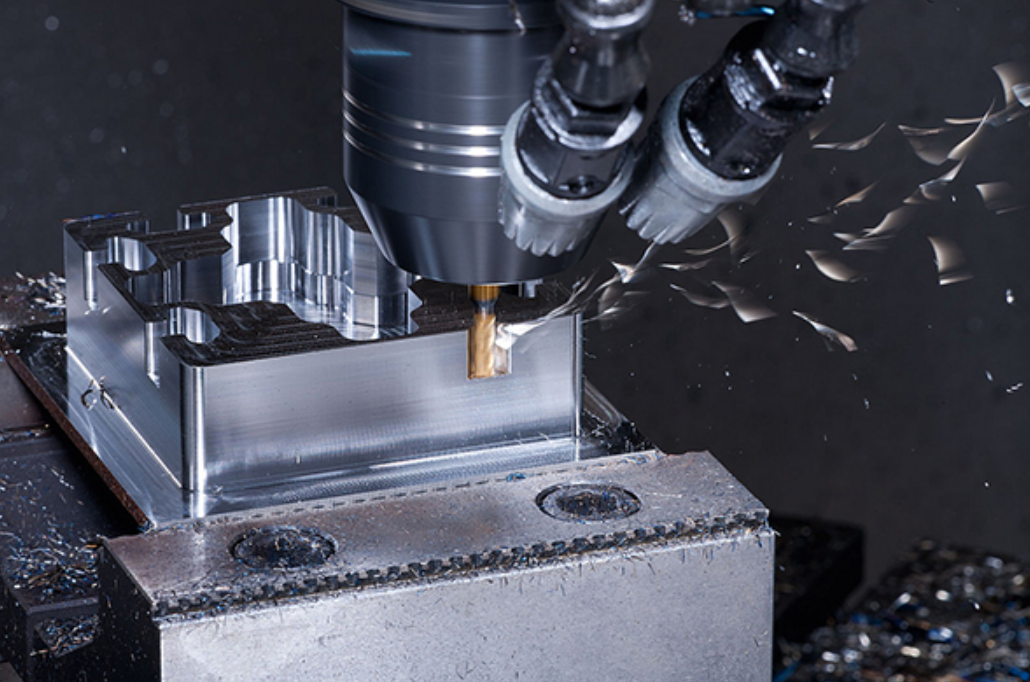

Ever wondered how a flat sheet of steel becomes a car door panel or a precision electronic component? The answer lies in one of manufacturing's most essential yet often overlooked tools: stamping press dies. Whether you're new to metal forming or looking to deepen your technical knowledge, understanding these precision-engineered tools is fundamental to grasping modern manufacturing.

A stamping press die is a special, one-of-a-kind precision tool that cuts and forms sheet metal into a desired shape or profile as the material is pressed between two mating components.

Simply put, stamping dies are the specialized tools that transform raw sheet metal into finished parts. They work in conjunction with a press that provides the necessary force to cut, bend, or shape the material. The finished product? That's called a piece part - and certain dies can produce more than one per cycle, operating at speeds up to 1,500 strokes per minute.

The Foundation of Metal Forming Operations

Metal stamping dies serve as the backbone of countless manufacturing operations across industries. From tiny components that fit in your palm for microelectronics to massive tooling measuring 20 feet square and 10 feet thick for automobile body sides, these die tools come in virtually every size imaginable.

What makes a metal die so remarkable is its dual capability. According to The Fabricator, there are many kinds of stamping dies, but they all perform two basic operations: cutting, forming, or both. Cutting operations include blanking, shearing, trimming, piercing, and notching. Forming operations encompass bending, stretching, flanging, drawing, coining, extruding, and ironing.

It's also worth noting that stamping is a cold-forming operation. No heat is intentionally introduced into the die stamp or sheet material. However, friction during cutting and forming generates heat, so stamped parts often exit the dies quite warm.

How Dies Transform Raw Sheet Metal

Imagine positioning a piece of sheet metal between two precisely machined steel sections. As the press closes, these sections move past each other with a small gap between them - called the cutting clearance. This clearance, often around 10 percent of the metal's thickness, determines how cleanly the material separates.

The transformation happens in fractions of a second. Metal stamping dies stress the material to the point of controlled failure during cutting, producing edges with distinct characteristics. Forming operations, on the other hand, deform the metal without separating it - bending it along axes, stretching it into cavities, or drawing it into three-dimensional shapes.

Throughout this article, you'll discover the complete picture of stamping dies - from the various types and their ideal applications, to the essential components that make them work, material selection criteria, design processes, and maintenance strategies that protect your tooling investment. Consider this your comprehensive guide to understanding the tools that quietly power modern manufacturing.

Types of Stamping Press Dies and Their Applications

Choosing the right die type can make or break your manufacturing project. With several distinct categories available - each designed for specific production scenarios - understanding the differences helps you match tooling to your exact requirements. Let's break down the four primary types of stamping dies and explore when each one shines.

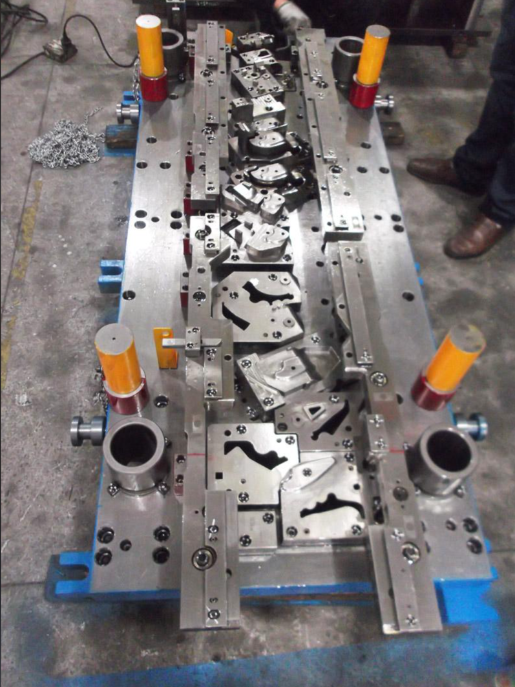

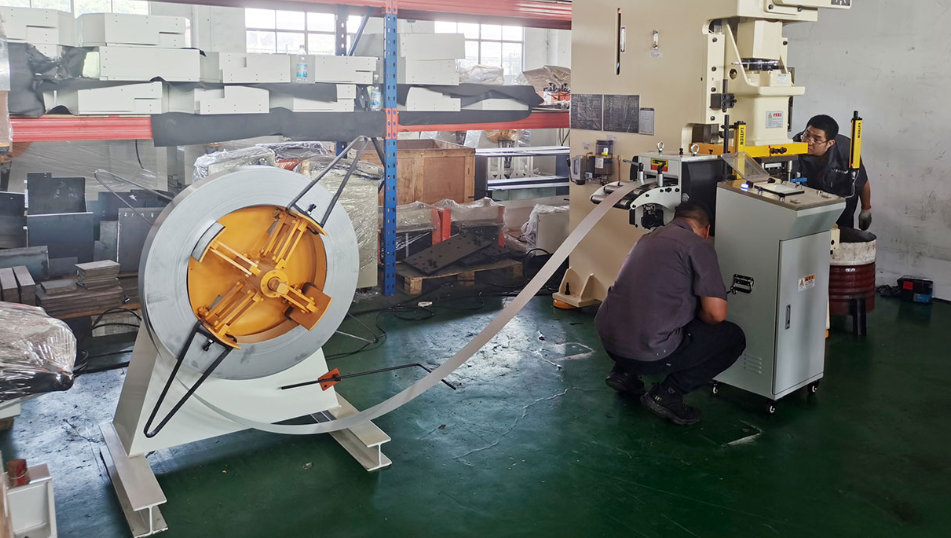

Progressive Dies for High-Volume Production

Think of progressive dies as an assembly line packed into a single tool. These die sets consist of multiple stations arranged in sequence, with each station performing a specific operation as the metal strip advances through the press. The material feeds from a coil, moves station to station with each press stroke, and exits as a finished part - all in one continuous motion.

What makes progressive dies so powerful for high-volume runs? According to Durex Inc., they're capable of producing large volumes of parts quickly while ensuring uniformity across all produced components. This makes them ideal for automotive applications like brackets and clips, as well as electronics manufacturing where intricate parts demand consistency.

The trade-off? Initial tooling costs run high. However, when you're producing thousands or millions of identical parts, the per-piece cost drops dramatically - making progressive dies the go-to choice for mass production. These punch press dies excel at creating simpler geometries at remarkable speeds, though they're less suited for highly complex designs.

Transfer Dies: Flexibility for Complex Parts

When your parts are too large or complex for progressive tooling, transfer dies step in. In this process, individual workpieces are mechanically or manually transferred from one stamping station to the next - similar to an assembly line where each station contributes a specific aspect to the final product.

Transfer die stamping offers something progressive dies can't: flexibility in part handling and orientation. As noted by Worthy Hardware, this method can incorporate various operations such as punching, bending, drawing, and trimming in a single production cycle. It's suitable for both short and long production runs, providing versatility in manufacturing scale.

The challenges? Operational costs tend to be higher due to setup complexity and the need for skilled labor. Setup time for each run can stretch longer, especially for intricate parts. But for aerospace components, heavy machinery assemblies, and large automotive panels, transfer dies deliver the precision and capability that other forming dies simply can't match.

Compound vs Combination Dies Explained

These two die press types often get confused, but they serve distinctly different purposes in manufacturing.

Compound dies perform multiple cutting operations in a single stroke. Picture blanking and piercing happening simultaneously - the die cuts the outer shape while punching internal holes all at once. This integration significantly reduces production time and enhances productivity. They're ideal for producing medium-sized, intricate components used in consumer goods and medical devices where precision matters most.

Combination dies take this further by combining cutting and forming operations in one press stroke. You might blank a shape and immediately bend or draw it - all in a single cycle. This approach works well when you need both cutting and shaping but your volumes don't justify the investment in progressive tooling.

Both types excel at material efficiency, minimizing scrap and reducing costs. However, they're limited in handling extremely complex shapes or designs that require multiple sequential operations. Think of them as press cutting dies optimized for precision rather than complexity.

Die Type Comparison at a Glance

Selecting the appropriate press dies requires weighing several factors against your specific project requirements. This comparison breaks down the key characteristics:

| Die Type | Best Application | Production Volume | Complexity Level | Typical Industries |

|---|---|---|---|---|

| Progressive Dies | High-speed production of uniform parts | High volume (thousands to millions) | Simple to moderate | Automotive, electronics, appliances |

| Transfer Dies | Large or complex assemblies requiring multiple operations | Medium to high volume | High complexity | Aerospace, heavy machinery, automotive body panels |

| Compound Dies | Flat parts requiring multiple cutting operations | Low to medium volume | Moderate (cutting only) | Medical devices, consumer goods, precision components |

| Combination Dies | Parts needing both cutting and forming in one stroke | Low to medium volume | Moderate | General manufacturing, custom components |

Matching Die Types to Your Requirements

So how do you choose? Start by answering three questions:

- What's your production volume? High-volume runs favor progressive dies despite higher upfront costs. Lower volumes may make compound or combination dies more economical.

- How complex is your part? Intricate 3D geometries with multiple operations point toward transfer dies. Simpler flat parts with precision requirements suit compound dies.

- What's your material? Different forming die configurations work better with specific metals. Steel, aluminum, and brass each require optimized die designs for best performance.

Understanding these distinctions prevents costly mismatches between tooling and production needs. The right die type delivers efficiency, quality, and cost-effectiveness - while the wrong choice leads to production headaches and budget overruns.

With die types clarified, the next step is understanding what's inside these tools - the essential components that make precision stamping possible.

Essential Die Components and How They Function

What actually happens inside a stamping press die when it transforms flat metal into precision parts? Understanding the individual components - and how they work together - separates casual observers from true manufacturing professionals. Let's pull back the curtain on the critical elements that make stamping operations possible.

Core Components That Make Dies Work

A stamping press die isn't a single monolithic tool. It's an integrated system of precision components, each serving a specific purpose in the cutting or forming process. According to Moeller Precision Tool, these parts work together like a well-orchestrated machine - and understanding each one helps you diagnose problems, optimize performance, and communicate effectively with die makers.

Here's a breakdown of the essential components you'll find in most stamping dies:

- Die Plates (Die Shoes) - These steel or aluminum plates serve as the foundation for mounting all other die components. Think of die shoes as the structural backbone - they hold punches, buttons, springs, and other elements in precise alignment. The upper and lower die shoes, when assembled with guide pins, create what's called a die set.

- Guide Pins and Bushings - These precision-ground components align the upper and lower die plates with remarkable accuracy - often within 0.0001 inches. Friction pins ride directly against bushings lined with aluminum-bronze, while ball-bearing pins glide on rotating bearings for reduced friction and faster operation.

- Die Punches - The punching tool that actually contacts and transforms the metal. Fixed within a die retainer, punches can cut holes, blank shapes, or form bends depending on their nose shape. Available in round, oblong, square, rectangular, and custom configurations.

- Die Buttons - The counterpart to punches, providing the opposite cutting edge. The clearance between punch and button - typically 5-10% of material thickness - determines cutting quality and is called the "die break."

- Stripper Plates - Spring-loaded plates that pull the metal off cutting punches after each stroke. When metal is cut, it naturally collapses around the punch shank. The stripper holds the material down flush with the lower die section, allowing punches to withdraw cleanly.

- Die Springs - High-force compression springs that provide the pressure needed to hold metal sheets in place during forming. Both mechanical coil springs and nitrogen gas springs are common, each offering different force characteristics and life expectancy.

- Retainers - Components that hold cutting and forming elements to the die shoes. Ball-lock retainers are particularly popular because they allow quick punch removal and reinstallation during maintenance.

- Heel Blocks and Wear Plates - Steel blocks that absorb side thrust generated during cutting and forming. They prevent guide pins from deflecting under one-directional force, maintaining critical alignment.

Understanding the Punch and Die Relationship

The interaction between punch and die block is where the magic happens. Imagine the punch as a precisely shaped tool descending through the die plate toward its matching cavity in the die block below. The clearance between them - that tiny gap measuring just a fraction of the material thickness - determines whether you get clean cuts or ragged edges.

During a cutting operation, the punch contacts the sheet metal first, pushing it down into the die button. The material stresses at the cutting edges until it fractures in a controlled manner. The stripper plate then holds the strip flat as the punch retracts, preventing the metal from lifting with it.

For forming operations, the relationship changes slightly. Instead of cutting through, the punch press tooling pushes material into a cavity, stretching and bending it into new shapes. Pressure pads apply downward force to control metal flow - too much pressure stops the material from moving and causes splitting; too little allows excess flow and creates wrinkles.

How Components Work Together Through the Stamping Cycle

A complete stamping cycle unfolds in fractions of a second. Here's what happens from start to finish:

Material Feeding: Coil or sheet stock enters the die, positioned precisely by automated feeders or pilot pins. These pilots - hardened pins that enter pre-punched holes - ensure accurate alignment before each stroke.

Press Activation: The ram drives the upper die shoe downward. Guide pins and bushings maintain perfect alignment between the upper and lower sections as they close. The die set configuration ensures repeatable positioning stroke after stroke.

Cutting and Forming: Punches contact the material and perform their operations - whether cutting holes, blanking shapes, or forming bends. Springs in the stripper plate compress, maintaining pressure on the workpiece throughout the stroke.

Bottom Dead Center: At full closure, all cutting and forming operations complete. The material has been transformed according to the die's design.

Retraction and Ejection: The ram reverses direction. Stripper plates push against the material while punches withdraw. Springs extend to return pressure pads to their starting positions. The finished part or strip advances for the next cycle.

Die Assembly Configurations

How these components come together determines die performance. A typical die assembly includes:

- Upper Die Assembly - Contains the punch holder, punches, stripper plate, and often the pilots. Mounts to the press ram.

- Lower Die Assembly - Houses the die block, die buttons, guides, and ejector mechanisms. Bolts to the press bed.

- Guiding System - The guide pins and bushings that align both halves with precision. Ball-bearing systems allow faster speeds with less friction and heat.

The die plate thickness depends on expected forces during operation. A coining die that compresses metal through squeezing requires much thicker shoes than a simple bending die. Material choice matters too - aluminum die shoes weigh one-third less than steel and absorb shock well, making them excellent for blanking applications.

Fastening components properly is critical. Socket head cap screws secure working components to the shoes, while dowels - precision-ground pins - locate each section in its exact position. Keys fit into milled keyways to provide additional location and heeling capability.

With this foundation of component knowledge in place, the next consideration becomes material selection - choosing the right steel grades and hardness specifications that determine how long your die will perform and how well it will maintain precision.

Die Materials and Selection Criteria

You've mastered die types and components - but here's a question that separates good tooling from great tooling: what material should your die be made from? The answer directly impacts how long your tooling lasts, the quality of every part it produces, and ultimately, your total cost of ownership. Let's decode the material selection process that many manufacturers overlook.

Tool Steel Selection for Optimal Die Performance

Tool steel forms the backbone of most steel dies used in stamping operations. But not all tool steels are created equal. According to Nifty Alloys, these specialized carbon and alloy steels contain carbide formers like chromium, vanadium, molybdenum, and tungsten - elements that deliver the hardness and wear resistance stamping demands.

For stamping applications, you'll primarily encounter cold work tool steels. Why? Because these dies operate below 200°C (400°F), focusing on surface hardness and structural integrity under heavy loads rather than heat resistance. Here are the most common grades and when to specify each:

- D2 Tool Steel - The workhorse of stamping dies. High chromium content (11-13%) delivers exceptional wear resistance. Ideal for blanking dies, stamping tools, and shear blades processing standard steel and aluminum. Hardness reaches 58-62 HRC.

- A2 Tool Steel - Air-hardening grade offering good toughness balanced with wear resistance. Excellent for dies requiring dimensional stability during heat treatment. Works well for medium-production applications.

- O1 Tool Steel - Oil-hardening grade that's easier to machine than D2. Good for lower-volume production or when complex die geometries make machinability a priority. Slightly lower wear resistance but adequate for softer materials.

- S7 Tool Steel - When impact resistance matters more than peak hardness. Specify S7 for hammer dies, punches subject to shock loading, or any application where brittle failure is unacceptable.

The critical trade-off? Wear resistance versus toughness. A steel punch hardened to maximum levels resists abrasion beautifully but may crack under impact. Conversely, tough grades absorb shock but wear faster. Matching the grade to your specific operation prevents premature failures.

When to Specify Carbide Components

Sometimes tool steel isn't enough. When you're stamping abrasive materials, running extremely high volumes, or demanding micron-level precision over millions of cycles, tungsten carbide becomes essential.

According to Retopz, tungsten carbide tools offer extreme wear resistance, long service life, and precision under high pressure and repeated operation. These steel stamping dies incorporate carbide in strategic locations rather than throughout the entire tool:

- Carbide Punches - Used in progressive stamping dies for piercing holes in sheet metal. Outlast steel punches by 10-20 times in high-abrasion applications.

- Carbide Die Inserts - Wear-resistant inserts pressed into blanking and forming die sections. Replace only the insert when worn rather than the entire die block.

- Carbide Guide Bushings - Alignment bushings for die sets that maintain precision over extended production runs.

The cost consideration? Carbide components typically run 3-5 times higher than equivalent steel parts upfront. However, when you factor in reduced downtime, fewer replacements, and consistent part quality across millions of cycles, precision dies with carbide components often deliver lower total cost of ownership.

Matching Die Material to Workpiece Material

What you're stamping matters as much as how often you're stamping. Different workpiece materials create different demands on your hardened punches and die surfaces:

- Mild Steel and Aluminum - Standard D2 or A2 tool steel performs excellently. These softer workpiece materials generate moderate wear on die surfaces.

- Stainless Steel - Highly abrasive during cutting. Specify premium D2 with maximum hardness, or upgrade to carbide inserts for high-volume applications. Steel punches wear significantly faster on stainless than mild steel.

- High-Strength Low-Alloy (HSLA) Steel - Common in automotive applications. Requires higher-grade tool steels and often carbide wear components due to increased forming forces.

- Coated Materials - Galvanized or pre-painted stock can accelerate die wear through abrasive coating particles. Consider carbide or surface treatments on cutting edges.

Remember: improper heat treatment causes more die failures than wrong material selection. Even the best D2 steel becomes useless if not hardened correctly. Always verify heat treatment procedures and hardness testing results before accepting new dies.

With material fundamentals covered, the next step explores how these materials come together in the die design and manufacturing process - the journey from concept to production-ready tooling.

Die Design and Manufacturing Process

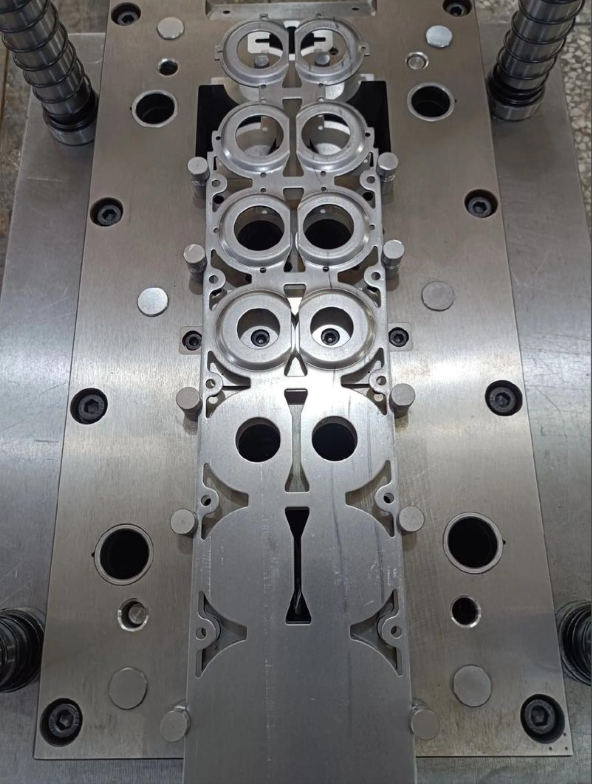

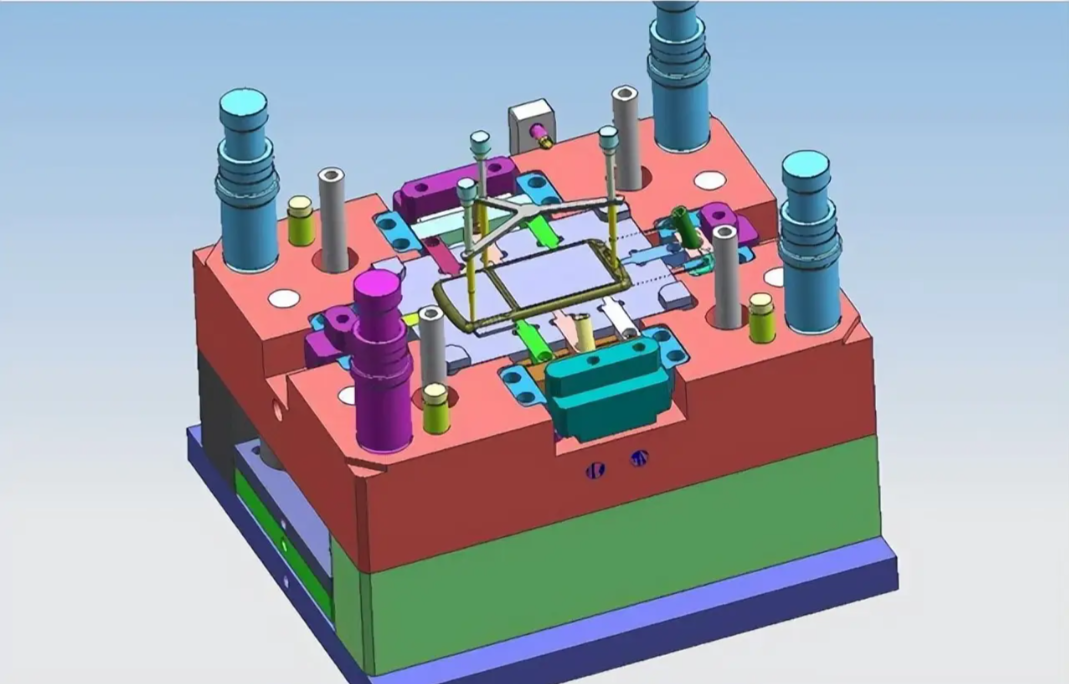

So you understand die types, components, and materials - but how does a stamping press die actually come into existence? The journey from a part drawing to production-ready tooling involves engineering expertise, advanced simulation technology, and precision manufacturing that many manufacturers never see firsthand. Let's walk through the complete die making process that transforms concepts into cutting-edge tooling.

From Concept to Production-Ready Tooling

Every successful die starts with understanding the end goal: the part itself. According to Mekalite, the precision and quality of metal stamping die design are directly proportional to the quality of the final part. The design also has a direct consequence on production costs, tool service life, and production speed.

A skilled die maker doesn't simply receive a part drawing and start cutting steel. Instead, tool and die manufacturing follows a systematic workflow that prevents costly mistakes. Here's how the typical die development process unfolds:

- Part Analysis and Feasibility Review - Engineers examine the part design to verify it can be fabricated using stamping. They check for complex patterns, sharp edges, and features that might cause cracking or wrinkling during forming. This early evaluation catches problems before they become expensive tooling mistakes.

- Process Planning and Strip Layout - The team maps out how the metal sheet will move through the die. This strip layout details every cut, bend, and form in sequence. A well-designed layout minimizes scrap material while ensuring proper material flow between stations.

- Die Face and Binder Design - Engineers model the die surfaces that will press and deform the metal. For deep drawing operations, binder surfaces control how material flows into cavities - critical for preventing wrinkles or splits.

- Structural Design of Die Parts - The blueprint for the entire die structure takes shape: die shoes, punches, die cavities, and pressure pads. Complex features often require precision components manufactured through advanced CNC processes to achieve necessary tolerances.

- Virtual Testing and Simulation - Before any steel is cut, computer software simulates the stamping process. This testing reveals potential problems like tearing, thinning, or wrinkling - allowing corrections while changes are still inexpensive.

- Final Documentation and Bill of Materials - Complete drawings with all specifications for die parts, plus a comprehensive BOM listing every component needed for construction. This documentation guides toolmakers through fabrication and serves as reference for future maintenance.

The Role of Simulation in Modern Die Design

Imagine discovering a design flaw after your die is built and installed in the press. The cost? Potentially hundreds of thousands of dollars in rework and lost production. That's why CAE simulation has become indispensable in die manufacturing.

According to Volupe, Computer-Aided Engineering solutions are the best way to ensure cost and time savings, helping solve product design and engineering problems without needing to build physical prototypes with every design change.

Modern simulation software performs Finite Element Analysis (FEA) that calculates exactly how sheet metal will behave during forming. The software predicts:

- Material stretching and thinning patterns

- Springback - how much the part will "bounce back" after forming

- Potential tearing or splitting locations

- Wrinkling tendencies in draw operations

- Required press tonnage for the operation

This virtual validation catches problems that would otherwise appear only during tryout - when the physical die meets real metal for the first time. Advanced software suites can even generate die structures and bills of materials automatically, dramatically accelerating the design phase.

Die Machining and Quality Validation

Once designs are finalized, die machining transforms engineering specifications into physical tooling. The manufacturing process for die for manufacturing applications demands exceptional precision - tolerances of ±0.001 inches are common in high-precision industries.

Key machining techniques include:

- CNC Machining - Computer-controlled mills and lathes shape die components with high accuracy. Multi-axis machines can create complex contours in single setups.

- Electrical Discharge Machining (EDM) - Creates intricate details and sharp internal corners that conventional cutting tools cannot achieve. Essential for complex punch and die cavity geometries.

- Surface Grinding - Delivers the flat, parallel surfaces critical for proper die alignment and function.

- Heat Treatment - Hardens tool steel components to specified hardness levels. Proper heat treatment determines whether a die lasts thousands or millions of cycles.

Quality control runs throughout fabrication. According to Barton Tool, common inspection techniques include visual inspection, dimensional checks, and surface roughness measurements. Coordinate measuring machines (CMM) offer high accuracy for complex geometries, while non-destructive testing methods detect internal flaws without damaging components.

Communicating Your Specifications to Die Manufacturers

Understanding the die development workflow helps you communicate more effectively with potential suppliers. When approaching a die maker with a new project, be prepared to provide:

- Part drawings with tolerances - Clear specifications for dimensions, surface finish requirements, and critical features

- Material specifications - The exact grade, thickness, and condition of sheet metal you'll be stamping

- Production volume expectations - Annual quantities and expected tool life requirements

- Quality standards - Industry certifications, inspection requirements, and acceptance criteria

- Timeline requirements - When you need prototype parts versus production tooling

The more complete your specifications, the more accurate your quotes and the fewer surprises during die tryout. Experienced die manufacturers will ask probing questions about your application - that's a good sign they're focused on delivering tooling that actually works.

With design and manufacturing fundamentals established, what happens after the die enters production? Maintaining peak performance requires understanding the maintenance strategies and troubleshooting approaches that protect your tooling investment.

Die Maintenance and Troubleshooting Strategies

Your stamping press dies represent a significant investment - but here's the uncomfortable truth: even the best-designed tooling deteriorates without proper care. The difference between dies that last for millions of cycles and those that fail prematurely often comes down to one factor: maintenance discipline. Let's explore the strategies that protect your investment and keep production running smoothly.

According to The Phoenix Group, die maintenance refers to the systematic process of inspecting, repairing, and optimizing dies used in manufacturing processes. Poor die maintenance causes quality defects during production, driving up sorting costs, increasing the likelihood of shipping defective parts to the customer, and risking expensive forced containments.

Preventive Maintenance Schedules That Protect Your Investment

Think of preventive maintenance as insurance against production disasters. Rather than waiting for something to break, you're addressing potential issues during planned downtimes. This proactive approach extends the lifespan of your die tools while maintaining consistent part quality stroke after stroke.

A structured maintenance program should include these core activities:

- Daily Visual Inspections - Check for obvious damage like chips, cracks, or excessive buildup of material on punch tools and die surfaces. Look for any misalignment or unusual wear patterns before starting each production run.

- Weekly Detailed Inspections - Use magnification to examine cutting edges, stripper plates, and guide components. Document any changes in surface texture or early signs of fatigue cracking in your die tooling.

- Monthly Comprehensive Assessments - Measure critical dimensions using precision gauges. Compare current measurements against original specifications to track gradual wear progression.

- Scheduled Sharpening Intervals - Cutting edges dull over time. Establish sharpening cycles based on material type and production volume - high-abrasion materials require more frequent attention.

- Lubrication Management - Apply appropriate lubricants to moving parts and guide components. Different operational conditions require different lubrication types - oils for general applications, greases for bearings and joints.

According to JVM Manufacturing, by sticking to a routine maintenance schedule, unexpected issues can be identified and mitigated before they become a serious and expensive problem. Regular inspections, timely sharpening, and proper lubrication ensure that tooling dies remain in top condition.

Diagnosing Common Die Problems

When parts start coming out wrong, you need to identify the root cause fast. Understanding common failure modes helps you diagnose problems before they cascade into production shutdowns. Here are the issues you'll encounter most frequently:

- Punch Wear - Cutting edges become dull or rounded, producing burrs on stamped parts. Central wearing appears as circular depressions on punch faces, typically caused by uneven force distribution. Edge chipping results from impact damage or excessive lateral forces.

- Die Block Damage - Bore scoring shows as vertical scratches in die cavities, often caused by abrasive particles or inadequate lubrication. This leads to capping and lamination issues in finished parts.

- Alignment Issues - When guide pins and bushings wear beyond tolerance, the upper and lower die sections no longer meet precisely. The result? Uneven cuts, poor forming quality, and accelerated wear on other components.

- Material Buildup - Sheet metal residue accumulates on die assembly surfaces, especially with sticky materials or inadequate lubrication. This buildup changes effective clearances and degrades part quality.

- Spring Fatigue - Stripper springs and pressure pad springs lose force over time. Weakened springs fail to hold material properly during forming, causing wrinkles or incomplete operations.

- Dimensional Changes - Die cavities gradually enlarge through wear, producing parts with reduced hardness and potential weight variation. Track these changes through regular measurement.

The relationship between maintenance and part quality is direct: as dies tool surfaces deteriorate, so does your output. According to Morse Tool, tablet weight variation often increases as die bores enlarge or punch lengths change - a principle that applies equally to metal stamping operations.

Component Replacement Timing and Inspection Protocols

Knowing when to replace versus when to repair requires balancing cost against risk. Some guidelines to follow:

- Establish Critical Wear Limits - Define maximum acceptable dimensional changes for each tooling component based on part specifications. Replace components when approaching - not exceeding - these limits.

- Track Performance Trends - Monitor ejection forces, cycle times, and part quality metrics. Sudden changes often indicate developing problems that inspection alone might miss.

- Document Everything - Maintain detailed records linking defect occurrences with tooling condition. This history helps predict future maintenance needs and guides replacement decisions.

- Consider Refurbishment - Some wear patterns can be addressed through grinding and reconditioning rather than full replacement. Evaluate each situation based on wear severity and economics.

A work order system proves invaluable here. It documents the root problem, tracks corrective steps, and provides scheduling data based on production needs and return on investment. When multiple die areas need attention, prioritize based on impact on part quality and customer requirements.

With maintenance fundamentals in place, the next consideration becomes applying these principles to demanding production environments - particularly automotive and high-volume manufacturing where precision and consistency are non-negotiable.

Automotive and High-Volume Production Applications

Understanding stamping press dies is one thing - applying that knowledge to demanding real-world scenarios is another. Nowhere are the stakes higher than in automotive manufacturing, where a single stamping die might produce millions of identical components over its lifetime. Let's explore how production volume, tolerance requirements, and industry certifications shape die selection and supplier partnerships.

Meeting Automotive Industry Standards

Automotive manufacturing isn't like other industries. The combination of extreme volumes, tight tolerances, and zero-defect expectations creates unique demands on every metal stamping die in the production line. When you're producing components for brake systems, structural reinforcements, or powertrain assemblies, failure simply isn't an option.

What separates automotive-grade stamping from general manufacturing? Consider these critical factors:

- IATF 16949 Certification - This global quality management standard, established by the International Automotive Task Force, ensures consistent quality throughout the automotive supply chain. According to Regal Metal Products, a well-built tool and die is the foundation of successful stamping operations - when built precisely, it produces consistent and repeatable parts essential for meeting these standards.

- Micrometer-Level Tolerances - According to Alicona, tolerances in precision die manufacturing often range from ±10-20 microns for general applications, while aerospace and automotive components may require ±2-5 microns. Your stamping die manufacturers must demonstrate the capability to achieve and maintain these specifications.

- Traceability Requirements - Every component must be traceable back to its source materials, manufacturing processes, and quality checks. This documentation chain protects both manufacturers and end consumers.

- Production Speed Requirements - According to Oberg Industries, automotive progressive dies support production speeds of up to 1,400 strokes per minute. Your tooling must maintain precision at these velocities while producing defect-free parts.

The variety die and stamping requirements across automotive applications span everything from tiny electrical connectors to massive body panels. Each application demands specific die and stamping configurations optimized for the component's geometry, material, and production volume.

Scaling from Prototype to Production

Here's where many manufacturers stumble: the gap between prototyping and high-volume production. A custom metal stamping dies setup that works beautifully at 100 parts per day may fail catastrophically at 10,000. Understanding this scaling challenge helps you select partners who can bridge both worlds.

The prototype-to-production journey typically follows this progression:

- Concept Validation - Soft tooling or 3D-printed dies verify part geometry and basic formability. Quick turnaround matters here - some suppliers deliver rapid prototypes in as little as 5 days.

- Design for Manufacturability Review - Engineers analyze the part design against production realities. Can progressive dies handle this geometry? Will the material flow properly at high speeds?

- Pilot Production - Small-volume runs using production-intent tooling validate process parameters before committing to full-scale manufacturing.

- Production Tooling - Hardened steel dies built for millions of cycles. This is where material selection, precision die and stamping expertise, and manufacturing capability truly matter.

CAE simulation plays a crucial role throughout this journey. Virtual testing identifies potential problems - tearing, wrinkling, springback - before cutting any steel. Companies leveraging advanced simulation often achieve first-pass approval rates exceeding 90%, dramatically reducing development time and tooling iterations.

What to Look for in an Automotive Die Partner

Selecting the right stamping die manufacturer for automotive applications requires evaluating capabilities beyond basic machining. Consider these essential qualifications:

| Capability | Why It Matters | Questions to Ask |

|---|---|---|

| IATF 16949 Certification | Demonstrates quality systems meeting OEM requirements | Is certification current? What's the scope? |

| CAE Simulation | Reduces iterations and ensures defect-free designs | What software platforms do you use? Can you share sample analyses? |

| Rapid Prototyping | Accelerates development timelines | What's your typical prototype turnaround? |

| First-Pass Approval Rate | Indicates engineering excellence and efficiency | What percentage of dies pass initial tryout? |

| Full-Service Capabilities | Simplifies supply chain and communication | Do you handle design through production? |

For manufacturers seeking a concrete example of these capabilities in action, Shaoyi's precision stamping die solutions demonstrate the integrated approach that automotive OEMs increasingly demand. Their IATF 16949 certification, advanced CAE simulation for defect-free results, and 93% first-pass approval rate exemplify the engineering excellence that distinguishes premium die and stamping partners. With rapid prototyping capabilities delivering results in as little as 5 days, they bridge the gap between concept and high-volume production that many manufacturers struggle to navigate.

The metal stamping die you select today determines your production quality for years to come. Whether you're launching new vehicle programs or optimizing existing lines, partnering with suppliers who understand automotive's unique demands protects both your investment and your reputation.

With application requirements understood, the final step is developing a systematic approach to evaluating and selecting die partners - creating the checklist that ensures your next tooling project succeeds from day one.

Selecting the Right Die Partner for Your Production Needs

You've journeyed from understanding what stamping press dies are to exploring types, components, materials, design processes, and maintenance strategies. Now comes the moment of truth: translating that knowledge into action. How do you actually specify, source, and partner with die suppliers who deliver results? Let's build the practical framework that turns your expertise into successful tooling projects.

Building Your Die Specification Checklist

Walking into supplier conversations unprepared leads to misquotes, misunderstandings, and misaligned expectations. According to Penn United Technologies, making a purchasing decision only based on quoted cost may result in overall dissatisfaction with a supplier's performance, or even in a disastrous situation. A comprehensive specification document prevents these outcomes.

Before approaching any press die manufacturer, compile these essential details:

- Part Drawings with GD&T - Complete dimensional specifications including geometric dimensioning and tolerancing for critical features. Ambiguous drawings create ambiguous quotes.

- Material Specifications - Exact grade, thickness, temper, and coating requirements for the sheet metal dies will process. Include material certifications if required.

- Production Volume Requirements - Annual quantities, batch sizes, and expected tool life. A die for press runs of 10,000 parts differs dramatically from one targeting 10 million.

- Tolerance Classifications - Identify which dimensions are critical versus general. This guides material selection and manufacturing precision levels.

- Secondary Operations - List any post-stamping requirements like deburring, plating, or assembly that might influence die design.

- Quality Standards - Specify required certifications (ISO 9001, IATF 16949), inspection methods, and acceptance criteria.

- Timeline Requirements - Distinguish between prototype needs and production tooling deadlines. Rushed timelines affect cost and sometimes capability.

- Press Specifications - Provide details about your stamping equipment including tonnage, bed size, stroke length, and press die set mounting requirements.

This documentation serves dual purposes: it helps suppliers quote accurately, and it forces you to think through requirements you might otherwise overlook. The more complete your specifications, the fewer surprises during die tryout.

Evaluating Die Manufacturing Partners

With specifications in hand, how do you evaluate potential stamper dies suppliers? According to Die-Matic, choosing the right manufacturer isn't just about price or capability - it's about long-term partnership and strategic alignment.

Use this evaluation framework when assessing custom die suppliers:

- Years of Experience - How long has the company operated? What types of components have they produced? Experience with your specific industry matters.

- Design and Build Capability - Can they design and manufacture dies in-house? A supplier who builds their own tooling understands troubleshooting and optimization far better than one who outsources.

- Process Control Systems - Are they ISO-certified? What inspection equipment do they use? Ask to see their quality management systems in action.

- Die Maintenance Programs - Do they offer ongoing maintenance services? This maximizes tool life and optimizes your total cost of ownership.

- Delivery Track Record - What's their on-time delivery percentage? If they're not officially tracking this metric, consider it a warning sign.

- Spare Tooling Approach - Do they discuss spare parts upfront? A good supplier suggests maintaining critical replacement components from the beginning.

- Engineering Support - Can they optimize your designs for manufacturability? Partners who ask detailed questions about part quality and tolerances typically over-deliver on attention to detail.

- Prototyping Capabilities - Can they produce samples before full-scale production? This validation step prevents costly production problems.

According to Metal Stamper, a company with years of experience is likely to have a deep understanding of various stamping processes, materials, and industry standards. This experience translates to better quality control, efficient processes, and the ability to handle complex projects.

Questions That Reveal True Capability

Surface-level conversations don't expose a supplier's real strengths - or weaknesses. Dig deeper with these probing questions:

- What percentage of dies achieve first-pass approval at tryout?

- Can you walk me through your simulation and validation process?

- What's your approach when unexpected issues arise during production?

- How do you handle a hydraulic press die set differently from mechanical press tooling?

- What documentation will I receive with the completed die?

- Can you provide references from customers in my industry?

Pay attention to how suppliers respond. Those who welcome detailed questions demonstrate confidence in their capabilities. Evasive answers or reluctance to discuss specifics often signal potential problems down the road.

The Partnership Approach That Delivers Results

The best die for press applications emerges from collaboration, not transaction. When evaluating suppliers, look for those who treat tooling projects as partnerships rather than purchase orders.

What does this partnership approach look like in practice? Consider capabilities like those offered through Shaoyi's engineering team, where comprehensive services span from rapid prototyping to high-volume manufacturing. Their full-service offering - including mold design, CAE simulation, and fabrication - exemplifies the type of integrated capability that simplifies sourcing while delivering cost-effective, high-quality tooling tailored to specific requirements. This single-source approach eliminates coordination headaches between multiple vendors while ensuring accountability throughout the project lifecycle.

The ideal partner offers:

- Early Engineering Involvement - Designers who engage before specifications are finalized can suggest improvements that reduce cost and improve performance.

- Transparent Communication - Regular updates throughout design, fabrication, and tryout keep projects on track and surface issues early.

- Problem-Solving Mindset - When challenges arise - and they will - partners focus on solutions rather than blame.

- Long-Term Perspective - Suppliers invested in ongoing relationships prioritize your success over short-term profit.

Optimizing Your Die Investment for Long-Term Success

Selecting the right press die is just the beginning. Maximizing your tooling investment requires ongoing attention to these factors:

- Implement Preventive Maintenance - Don't wait for failures. Schedule regular inspections, sharpening, and component replacement based on production volume.

- Document Everything - Maintain detailed records of production counts, maintenance activities, and quality metrics. This data guides future decisions.

- Plan for Spare Components - Stock critical wear items before you need them. Downtime waiting for replacement punches or springs costs more than carrying inventory.

- Review Performance Regularly - Compare actual results against specifications. Gradual drift in part dimensions signals developing problems.

- Build Supplier Relationships - The sheet metal dies experts who built your tooling understand it best. Maintain those connections for troubleshooting and future projects.

Your stamping press dies represent more than equipment - they're production assets that generate value for years when properly specified, sourced, and maintained. The knowledge you've gained through this guide positions you to make informed decisions at every stage, from initial concept through end-of-life replacement.

Whether you're launching new programs or optimizing existing production lines, the principles remain consistent: define requirements thoroughly, evaluate suppliers rigorously, and maintain tooling proactively. This disciplined approach transforms stamping operations from cost centers into competitive advantages - delivering the precision parts that drive manufacturing success.

Frequently Asked Questions About Stamping Press Dies

1. How much does a metal stamping die cost?

Metal stamping die costs range from $500 to $15,000 depending on complexity, size, and production requirements. Simple blanking dies fall on the lower end, while complex progressive dies for automotive applications can exceed this range. Factors influencing cost include die type (progressive, transfer, compound), material specifications (tool steel vs. carbide components), tolerance requirements, and expected production volume. While initial tooling investment is significant, per-piece costs often drop dramatically compared to CNC machining when producing thousands of parts.

2. What is the die in press tool?

A die in press tooling is a specialized precision tool that cuts and forms sheet metal into desired shapes. Unlike casting dies or wire drawing dies, stamping dies work with presses that provide force to transform flat metal sheets. The die consists of two mating components - the upper die assembly containing punches and the lower die assembly housing die blocks. When the press closes, these components work together to perform cutting operations (blanking, piercing, trimming) or forming operations (bending, drawing, coining) on the material.

3. What are the main types of stamping dies?

The four primary stamping die types are progressive dies, transfer dies, compound dies, and combination dies. Progressive dies contain multiple stations performing sequential operations as metal strips advance through the press - ideal for high-volume production. Transfer dies mechanically move individual workpieces between stations, handling larger or more complex parts. Compound dies perform multiple cutting operations in a single stroke, while combination dies integrate both cutting and forming in one cycle. Selection depends on production volume, part complexity, and budget constraints.

4. How long do stamping press dies last?

Stamping die lifespan varies significantly based on material selection, maintenance practices, and production conditions. High-quality tool steel dies processing mild steel or aluminum may last millions of cycles with proper care. Carbide-insert dies can extend this to tens of millions of parts when stamping abrasive materials. Key factors affecting longevity include preventive maintenance schedules, sharpening intervals, proper lubrication, and alignment checks. IATF 16949-certified manufacturers like Shaoyi implement rigorous quality systems that maximize die life while maintaining consistent part quality.

5. What should I look for in a stamping die manufacturer?

Evaluate die manufacturers based on industry certifications (ISO 9001, IATF 16949), design-to-build capabilities, CAE simulation technology, and first-pass approval rates. Request references from customers in your industry and ask about on-time delivery percentages. Look for partners offering comprehensive services from rapid prototyping to high-volume production. Engineering support during design phases, transparent communication, and ongoing maintenance programs indicate suppliers invested in long-term partnerships rather than one-time transactions.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —