Custom Cut Metal Decoded: From First Measurement To Finished Part

Understanding Custom Cut Metal and Why It Matters

Imagine ordering a metal sheet that arrives ready to install—no trimming, no guesswork, no wasted material. That's exactly what custom cut metal delivers. Instead of purchasing standard-sized stock and wrestling with modifications, you receive materials precisely tailored to your project's specifications.

Custom metal cutting has become essential across industries for one simple reason: precision matters. Whether you're fabricating automotive components, constructing architectural elements, or building a backyard project, having metal cut to size eliminates costly rework and material waste. The concept is straightforward—you provide exact dimensions, and fabricators deliver parts ready for immediate use.

What Makes Metal Cutting Custom

So what separates custom cutting from grabbing a standard metal sheet off the shelf? It comes down to specifications. When you order custom cut metals, every dimension reflects your project requirements rather than arbitrary industry standards. This means your 47.25-inch panel arrives at exactly 47.25 inches—not rounded to the nearest foot.

Custom metal fabrication ensures that each component is manufactured to exact specifications, reducing the need for costly modifications and improving overall system integration. Unlike off-the-shelf components, precision-cut materials integrate seamlessly into existing systems, minimizing installation time and long-term maintenance costs.

The customization extends beyond simple dimensions. You can specify:

- Exact length, width, and thickness measurements

- Complex shapes and cutouts

- Hole patterns and edge profiles

- Tolerance requirements for critical applications

From Raw Material to Precision Part

The journey from raw metal to finished component has transformed dramatically over the decades. Early metal fabrication relied entirely on manual cutting—skilled workers using hand tools and shears to shape materials. While effective, this approach introduced significant variation between parts.

Today's precision methods tell a different story. Computer Numerical Control (CNC) technology converts digital designs into precise cutting commands, achieving tolerances as tight as ±0.0001 inches. According to Red Craft Industry, modern CNC machines can repeat the same outcomes hundreds or thousands of times with remarkable consistency.

This evolution matters whether you're an industry professional or a first-time buyer. Understanding available cutting technologies, material options, and specification requirements helps you make informed decisions—and that's exactly what this guide delivers.

Custom cutting eliminates material waste and reduces project costs by delivering exactly what you need—nothing more, nothing less.

Throughout this article, you'll learn how to navigate the complete decision-making journey: selecting appropriate cutting methods, choosing the right materials, understanding thickness specifications, specifying tolerances, and communicating effectively with suppliers. By the end, you'll approach your next custom metal project with confidence and clarity.

Metal Cutting Methods Explained

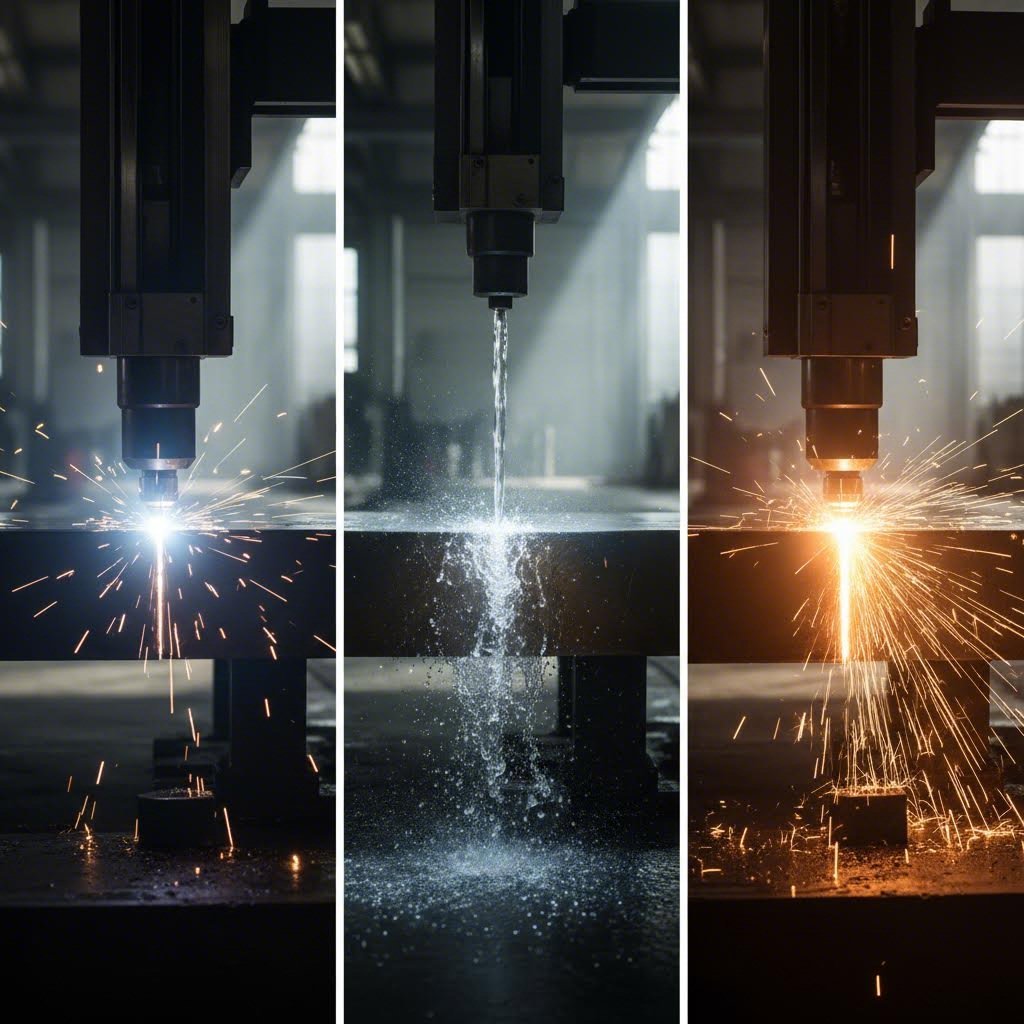

Wondering how to cut metal sheets with precision and efficiency? The answer depends entirely on your project requirements. Each cutting technology offers distinct advantages, and understanding these differences helps you select the right method for your custom cut metal project.

Modern fabrication shops typically employ several cutting technologies, each optimized for specific materials, thicknesses, and precision requirements. Let's explore the primary options available and when each makes the most sense.

Laser Cutting for Intricate Precision

When your project demands intricate designs and exceptionally clean edges, a laser cutter becomes your best ally. This technology directs a high-powered laser beam onto the metal surface, melting or vaporizing material along a digitally controlled path. The result? Cuts so precise they often require no additional finishing.

According to Zintilon, CNC laser cutting is especially suited for detailed work because the computer-controlled process ensures exact cuts with tight tolerances. The focused beam creates sharp corners and smooth edges that manual methods simply cannot match.

Key advantages of laser cutting include:

- Exceptional precision with tolerances as tight as ±0.005 inches

- Minimal heat-affected zones compared to other thermal methods

- Clean edges requiring little to no post-processing

- Ideal for thin to medium-thickness materials

- Perfect for complex shapes and small hole patterns

However, laser cutting does have limitations. It struggles with very thick materials and reflective metals like copper and brass may require specialized equipment. For electronics, medical devices, and precision parts manufacturing, though, laser technology delivers unmatched results.

Waterjet and Plasma Alternatives

What happens when laser cutting isn't the right fit? That's where waterjet and plasma technologies step in, each addressing specific challenges that lasers cannot handle effectively.

Waterjet Cutting uses high-pressure water—typically between 30,000 to 90,000 psi—mixed with an abrasive material like garnet to slice through virtually any material. The defining advantage? Zero heat generation. This makes waterjet cutting ideal for heat-sensitive materials that would warp or harden under thermal cutting methods.

According to Wurth Machinery, the waterjet market is projected to reach over $2.39 billion by 2034, reflecting growing demand for this versatile technology. Waterjet excels when cutting:

- Thick stock that exceeds laser capabilities

- Heat-sensitive alloys and tempered materials

- Composite materials and non-metals

- Applications requiring zero thermal distortion

Plasma Cutting takes a different approach, using an electrical arc and compressed gas to melt and blast through conductive metals. If you're working with steel plates over half an inch thick, plasma offers the best combination of speed and cost efficiency.

Testing by Wurth Machinery showed plasma cutting 1-inch steel approximately 3-4 times faster than waterjet, with operating costs roughly half as much per foot. For structural steel fabrication and heavy equipment manufacturing, plasma delivers exceptional value.

CNC Router CNC machining offers another option, particularly effective for non-ferrous metals like aluminum. While not typically used for cutting through thick stock, CNC routing excels at creating precise profiles and can combine cutting with bending operations in integrated manufacturing cells.

Shearing represents the most straightforward approach for straight cuts. According to Cubbison, shearing is a rapid process delivering consistency across a wide range of metal thicknesses. The trade-off? It's limited to straight-line cuts and may produce rougher edges than other methods.

Comparing Cutting Methods: A Complete Overview

Choosing the right metal cutter for your project requires weighing multiple factors. The following table compares each cutting method across the criteria that matter most:

| Cutting Method | Material Compatibility | Thickness Range | Edge Quality | Precision Tolerance | Relative Cost | Best Applications |

|---|---|---|---|---|---|---|

| Laser Cutting | Most metals; limited on highly reflective materials | Up to 1" steel; optimal under 0.5" | Excellent; minimal finishing needed | ±0.005" or tighter | Medium-High | Intricate designs, electronics, medical devices |

| Plasma Cutting | Conductive metals only | 0.5" to 2"+ steel | Good; may require deburring | ±0.015" to ±0.030" | Low-Medium | Structural steel, heavy equipment, shipbuilding |

| Waterjet Cutting | Virtually any material | Up to 12" depending on material | Excellent; no heat-affected zone | ±0.005" to ±0.010" | High | Aerospace, heat-sensitive materials, composites |

| CNC Routing | Non-ferrous metals, plastics | Up to 1" aluminum | Good; clean with proper tooling | ±0.005" to ±0.010" | Medium | Aluminum profiles, sign making, enclosures |

| Shearing | Most sheet metals | Up to 0.5" depending on equipment | Fair; may have slight distortion | ±0.015" to ±0.030" | Low | Straight cuts, high-volume blanking |

Understanding kerf—the width of material removed during cutting—also matters when specifying dimensions. Laser cutting produces the narrowest kerf (as thin as 0.006"), while plasma creates wider kerfs (up to 0.25"). This affects how you dimension your parts and calculate material usage.

With cutting methods clarified, the next critical decision involves selecting the right metal for your application. Different materials respond differently to each cutting technology, and matching material properties to project requirements ensures optimal results.

Choosing the Right Metal for Your Project

You've identified the cutting method that fits your needs—now comes an equally important decision. Which metal should you actually cut? The types of metals available for custom fabrication each bring unique characteristics to the table, and selecting the wrong material can undermine even the most precise cutting work.

Think of it this way: a perfectly cut component fails if the underlying material cannot handle your application's demands. Whether you need lightweight strength, corrosion resistance, or budget-friendly durability, understanding material properties guides you toward the right choice.

Matching Metal Properties to Project Requirements

Before diving into specific metals, consider what your project actually demands. Every application prioritizes different characteristics, and identifying these priorities simplifies your selection process considerably.

Key properties to evaluate when selecting your metal include:

- Tensile strength – How much pulling force can the material withstand before breaking?

- Corrosion resistance – Will the part be exposed to moisture, chemicals, or salt air?

- Weight – Does your application require lightweight components for mobility or fuel efficiency?

- Machinability – How easily can the material be cut, shaped, and finished?

- Cost – What's your budget, and does the application justify premium materials?

- Appearance – Will the finished component be visible, requiring aesthetic considerations?

Your answers to these questions narrow the field significantly. A marine application demands corrosion resistance above all else. An aerospace component prioritizes weight savings. A decorative railing needs visual appeal alongside durability.

Steel vs Aluminum vs Stainless

Let's examine the most commonly specified metals for custom cutting and where each excels.

Carbon Steel: The Affordable Workhorse

When budget and strength top your priority list, carbon steel delivers exceptional value. According to Impact Fab, low-carbon steel (also called mild steel) is found in every fabrication shop because it's one of the most economical choices. With high ductility and easy weldability, this material machines well and accepts most cutting methods without complications.

Carbon steel works beautifully for structural components, machine frames, and applications where the material will be painted or coated. However, it lacks inherent corrosion resistance—without protective coatings, rust becomes an inevitable concern in exposed environments.

Aluminum Sheet Metal: Lightweight Champion

When weight reduction drives your design, aluminum sheet metal becomes the obvious choice. According to Seather Technology, aluminum's density is about one-third of stainless steel's, making parts significantly easier to handle and transport.

An aluminum sheet offers more than just weight savings. The material naturally forms a protective oxide layer when exposed to air, providing excellent corrosion resistance without additional treatment. Engineers frequently specify aluminum for automotive components, aerospace applications, and any project where reducing mass improves performance or efficiency.

Keep in mind that aluminum requires expertise during welding—the oxide layer and high thermal conductivity create challenges. For cutting, however, aluminum responds well to laser, waterjet, and CNC routing methods.

Stainless Steel Sheet: Corrosion-Resistant Premium

When your application faces harsh environments, a stainless steel sheet provides the corrosion resistance carbon steel simply cannot match. The chromium content creates a self-healing protective layer that keeps the metal looking pristine for years.

But here's where material selection gets nuanced. Not all stainless steel grades perform equally, and choosing between 304 and 316 stainless steel often determines project success.

According to Geomiq, the critical difference comes down to one element: molybdenum. Grade 316 stainless steel contains 2-3% molybdenum, which dramatically improves resistance to chlorides and harsh chemicals. In salt-spray testing, 316 stainless steel demonstrated corrosion resistance lasting approximately 10 years compared to just 1 year for 304 in simulated saltwater environments.

When should you pay the 20-30% premium for 316? Consider it essential for:

- Marine and coastal applications

- Chemical processing equipment

- Medical and pharmaceutical components

- Outdoor installations in salt-belt regions

For indoor applications, kitchen equipment, and mild outdoor environments, 304 stainless provides excellent performance at lower cost.

Galvanized Steel: Outdoor Durability on a Budget

What if you need outdoor corrosion resistance without stainless steel pricing? Galvanized steel and carbon steel share the same base material, but the zinc coating provides sacrificial protection against rust. This makes galvanized steel ideal for fencing, outdoor structural components, and agricultural equipment where appearance matters less than longevity.

Brass and Copper: Specialty Applications

When comparing brass vs bronze or considering copper alloys, you're typically addressing specialized requirements. Copper's exceptional electrical conductivity makes it indispensable for electrical components and wiring applications. According to Impact Fab, copper also offers antibacterial properties valuable in medical instruments and high-touch surfaces.

Brass combines formability with corrosion resistance and an attractive golden appearance. You'll find it specified for decorative hardware, marine fittings, and components requiring low-friction properties. Both materials cut cleanly with waterjet and specialized laser equipment.

How Material Properties Affect Cutting Method Selection

Your material choice directly influences which cutting technology delivers optimal results. Reflective metals like copper and brass challenge standard laser systems—specialized equipment or alternative methods become necessary. Thick carbon steel plates favor plasma cutting for cost efficiency, while thin aluminum sheet metal responds beautifully to laser precision.

Understanding this relationship prevents costly mismatches. When you specify both material and cutting method together, you ensure the fabricator can deliver the edge quality and tolerances your project demands.

With material selection clarified, the next consideration involves thickness specifications—and understanding the gauge system that defines them.

Metal Thickness and Gauge Specifications

Here's something that trips up first-time buyers: when someone mentions "14 gauge steel," do you know exactly how thick that is? If not, you're not alone. The gauge system for measuring metal gauge thickness seems counterintuitive at first—but understanding it is essential for ordering custom cut metal that actually fits your project.

Thickness determines everything from structural integrity to which cutting methods work effectively. Get it wrong, and you'll end up with material that's too flimsy for the job or so thick your fabricator needs different equipment entirely. Let's demystify this system so you can specify exactly what you need.

Reading the Gauge System

The gauge system originated from the British wire industry before standardized measurement systems existed. According to Stepcraft, gauges were initially used to identify wire diameter during drawing processes—and the terminology stuck around for sheet metal.

Here's the critical concept: lower gauge numbers indicate thicker material. This runs opposite to intuitive thinking, where you might expect higher numbers to mean more material. Think of it this way—fewer drawing passes through the wire mill meant thicker wire, hence a lower gauge number.

To complicate matters further, the same gauge number produces different thicknesses depending on the metal type. A sheet metal gauge chart becomes essential because 14 gauge steel thickness differs from 14 gauge aluminum thickness. For example:

- 14 gauge mild steel measures 0.0747 inches (1.897 mm)

- 14 gauge aluminum measures 0.0641 inches (1.628 mm)

- 14 gauge stainless steel measures 0.0781 inches (1.984 mm)

This variation occurs because each metal has different physical properties affecting how it responds to the gauge measurement system. Always reference the appropriate chart for your specific material—assumptions lead to costly ordering mistakes.

Practical Context for Common Gauges

Understanding gauge sizes in context helps you visualize what you're actually ordering. According to MetalsCut4U, choosing the right gauge depends on structural requirements, budget constraints, and aesthetic considerations.

Here's how common gauges translate to real-world applications:

- 10 gauge steel thickness (0.1345 inches / 3.416 mm) – Heavy structural work, industrial equipment frames, trailer beds, and applications demanding maximum rigidity

- 11 gauge steel thickness (0.1196 inches / 3.038 mm) – Heavy-duty brackets, structural reinforcements, and commercial construction components

- 14 gauge steel thickness (0.0747 inches / 1.897 mm) – General fabrication work, automotive panels, equipment enclosures, and moderate structural applications

- 16 gauge thickness (0.0598 inches / 1.518 mm) – Lighter applications including HVAC ductwork, decorative panels, and interior components

- 18-22 gauge – Thin-wall enclosures, decorative elements, and applications where weight reduction matters more than heavy-duty strength

Thickness Limits by Cutting Method

Your material thickness directly determines which cutting technologies will work effectively. Each method has optimal thickness ranges—pushing beyond these limits compromises edge quality, precision, or economic viability.

According to Benchmark Abrasives, laser cutting excels on thinner gauge materials, generally under 3/4 inch, while plasma cutting handles thicker plates up to 1 inch or more with significantly faster processing speeds.

Laser Cutting Thickness Limits

Laser systems perform optimally on thin to medium stock. Most industrial fiber lasers handle steel up to about 1 inch, but edge quality and cutting speed decline noticeably beyond 0.5 inches. For precision work requiring tight tolerances and clean edges, stick to materials under 14 gauge where lasers truly shine.

Plasma Cutting Thickness Advantages

When your project involves 10 gauge steel thickness or heavier, plasma cutting becomes increasingly attractive. The technology cuts thicker plates faster and more economically than laser alternatives. However, expect a larger heat-affected zone and edges that require secondary finishing for precision applications.

Waterjet Cutting Versatility

Waterjet cutting handles the widest thickness range—from thin foils to materials 6 inches thick or more. According to Benchmark Abrasives, this "cold cutting" technique produces virtually no heat-affected zone, making it ideal for thick heat-sensitive materials where thermal distortion cannot be tolerated.

How Thickness Affects Edge Quality

Thicker materials create greater challenges for any cutting method. The kerf width—material removed during cutting—increases with thickness, affecting dimensional accuracy. Heat-based methods like laser and plasma create larger heat-affected zones on thicker stock, potentially hardening edges and requiring deburring. When specifying tight tolerances on heavy-gauge material, discuss achievable results with your fabricator before finalizing specifications.

Steel Gauge Thickness Reference Chart

The following table provides a comprehensive metal gauge thickness chart showing actual dimensions and recommended cutting methods for common gauge sizes. Use this reference when specifying your custom cut metal requirements:

| Gauge Number | Mild Steel (inches) | Mild Steel (mm) | Aluminum (inches) | Stainless Steel (inches) | Recommended Cutting Methods |

|---|---|---|---|---|---|

| 7 | 0.1793 | 4.554 | 0.1443 | — | Plasma, Waterjet |

| 8 | 0.1644 | 4.175 | 0.1285 | 0.1719 | Plasma, Waterjet |

| 10 | 0.1345 | 3.416 | 0.1019 | 0.1406 | Plasma, Waterjet, Heavy-duty Laser |

| 11 | 0.1196 | 3.038 | 0.0907 | 0.1250 | Plasma, Waterjet, Laser |

| 12 | 0.1046 | 2.656 | 0.0808 | 0.1094 | Laser, Plasma, Waterjet |

| 14 | 0.0747 | 1.897 | 0.0641 | 0.0781 | Laser (optimal), Waterjet, Plasma |

| 16 | 0.0598 | 1.518 | 0.0508 | 0.0625 | Laser (optimal), Waterjet, Shearing |

| 18 | 0.0478 | 1.214 | 0.0403 | 0.0500 | Laser, Shearing, Waterjet |

| 20 | 0.0359 | 0.911 | 0.0320 | 0.0375 | Laser, Shearing |

| 22 | 0.0299 | 0.759 | 0.0254 | 0.0313 | Laser, Shearing |

| 24 | 0.0239 | 0.607 | 0.0201 | 0.0250 | Laser, Shearing |

Notice how the recommended cutting methods shift as gauge numbers increase (and thickness decreases). Heavier gauges favor plasma and waterjet, while lighter gauges become laser and shearing territory. This relationship helps you match your thickness requirements to appropriate fabrication capabilities.

With gauge specifications understood, the next consideration involves tolerances—the acceptable deviation from your specified dimensions that determines whether parts actually fit together as designed.

Tolerances and Precision in Custom Metal Cutting

You've selected your material, determined the right gauge, and chosen a cutting method. But here's a question that separates successful projects from frustrating failures: how close to your specified dimensions does the finished part actually need to be?

This is where tolerances enter the picture—and where many first-time buyers make costly mistakes. Specify tolerances too tight, and you'll pay premium prices for precision you don't need. Specify them too loosely, and your components won't fit together properly. Understanding this balance saves both money and headaches.

What Tolerance Means for Your Parts

Tolerance refers to the acceptable deviation from your specified dimensions. When you order a part that's exactly 12.000 inches long, no cutting method delivers perfection—there's always some variation. Tolerance defines how much variation remains acceptable for your application.

Think of it this way: if your tolerance is ±0.010 inches, a 12.000-inch part measuring anywhere from 11.990 to 12.010 inches passes inspection. Parts outside this range get rejected or require rework.

According to Hypertherm, laser cutting generally achieves dimensional tolerances under 0.01 inches (0.25 mm), while X-Definition plasma systems deliver approximately 0.02 inches (0.5 mm). That difference—roughly the thickness of a business card—determines which technology suits your requirements.

Here's the critical insight: tighter isn't automatically better. Before demanding "laser quality" precision, ask yourself whether your application truly requires it. Parts heading from the cutting table directly to welding rarely need the tightest tolerances—the weld itself introduces greater variation than the cut.

Precision Standards Across Industries

Different industries demand vastly different precision levels. Aerospace components require extraordinarily tight tolerances because lives depend on perfect fit. Decorative metalwork, by contrast, tolerates more variation without compromising function or appearance.

According to Komacut, several tolerance types govern custom cut metal fabrication:

- Dimensional tolerances – Variations in length, width, and hole placement positions

- Angular tolerances – Permissible deviation from intended bend angles, typically ±0.5° to ±1°

- Thickness tolerances – Allowable variation in material thickness from specified values

- Flatness tolerances – Acceptable deviation from a perfectly flat surface

Standard laser cutting tolerances range from ±0.20 mm for high-precision work to ±0.45 mm for general applications. When your parts must interface with precision assemblies—think medical devices or electronics enclosures—specify tighter tolerances. For structural components or parts that will be welded, standard tolerances typically suffice.

Factors That Influence Achievable Precision

Multiple variables affect the precision your fabricator can realistically achieve. Understanding these factors helps you set appropriate expectations and specifications.

- Cutting method – Laser and waterjet achieve tighter tolerances than plasma or shearing

- Material type – Properties of metals vary; softer materials like aluminum may exhibit greater variation than steel

- Material thickness – Thicker stock creates greater cutting challenges and wider tolerances

- Machine calibration – Well-maintained, recently calibrated equipment delivers more consistent results

- Operator expertise – Skilled operators optimize parameters for each specific job

- Part complexity – Intricate geometries with tight corners challenge precision more than simple shapes

Part complexity deserves special attention. A simple rectangular blank holds tighter tolerances easily. Add intricate cutouts, tight radii, and multiple hole patterns, and achievable precision often loosens. Discuss complex geometries with your fabricator before finalizing specifications.

Edge Quality and Surface Considerations

Tolerance encompasses more than dimensions—edge quality matters too. Several factors affect the finished edge your parts will have.

Heat-Affected Zones (HAZ) occur with thermal cutting methods like laser and plasma. The intense heat changes metal properties adjacent to the cut, potentially hardening the edge or creating discoloration. Laser cutting minimizes HAZ due to its focused beam, while plasma creates larger affected areas.

Dross Formation—to define dross, it's the molten material that resolidifies on the underside of cuts. According to JLC CNC, dross accumulates when assist gas pressure runs too low or nozzle height is incorrect. Proper machine setup prevents dross, but some applications require post-cutting cleanup regardless.

Surface Finish varies by method and material. Laser cutting typically produces the smoothest edges, while plasma may leave visible striations requiring secondary finishing for cosmetic applications.

The Cost-Tolerance Relationship

Tighter tolerances invariably increase costs—sometimes dramatically. According to Hypertherm, unnecessarily stringent tolerances burden operations with several expense categories:

- Equipment investment – Machines capable of tighter tolerances cost significantly more; laser systems may cost hundreds of thousands more than plasma alternatives

- Inspection costs – Tighter tolerances require sophisticated measurement equipment; a Coordinate Measurement Machine (CMM) can cost up to $120,000

- Training requirements – Measuring tight tolerances demands specialized skills and higher-paid personnel

- Scrap rates – Tighter specifications mean more parts fall outside acceptable ranges

- Reduced throughput – Achieving maximum precision often requires slower cutting speeds

Consider this: some believe titanium or tungsten alloys represent the strongest metal on earth for certain applications—yet even working with the strongest metal in the world doesn't require unnecessarily tight tolerances unless function demands it. Matching tolerance specifications to actual requirements, rather than defaulting to "as tight as possible," optimizes your project economics.

When to Specify Tight Tolerances

Reserve tight tolerance specifications for applications where precision genuinely matters:

- Mating parts in precision assemblies

- Components for medical devices or aerospace applications

- Parts interfacing with CNC-machined components

- Visible edges in high-end decorative work

For structural components, parts that will be welded, or applications where paint or powder coating will cover edges, standard tolerances typically deliver identical functional results at lower cost.

With tolerances understood, the next step involves translating your requirements into clear specifications that fabricators can execute accurately—starting with proper measurement techniques and documentation practices.

How to Measure and Specify Your Order

You understand tolerances, materials, and cutting methods—but none of that knowledge matters if your measurements are wrong or your specifications confuse the fabricator. Getting custom cut sheet metal that fits your project perfectly starts long before the cutting begins. It starts with how you measure, document, and communicate your requirements.

Sounds straightforward? Many first-time buyers discover otherwise when their parts arrive slightly off-spec. Let's walk through the practices that separate successful orders from frustrating do-overs.

Measuring for Accuracy

Accurate measurements form the foundation of every successful sheet metal cut to size order. Before documenting any dimensions, ensure you're using appropriate tools and techniques.

Use Proper Measuring Instruments

A standard tape measure works for rough estimates—but custom metal fabrication demands better. According to Sheet Metal Masion, you should measure thickness using a caliper or micrometer, always at a flat, straightforward area of the sheet. For length and width dimensions, steel rules or precision tape measures provide the accuracy your project requires.

Consider these tool recommendations:

- Digital calipers – Essential for thickness verification and small feature dimensions

- Steel rules – Ideal for linear measurements with 1/64-inch or 0.5mm graduations

- Micrometers – Required when tolerances tighter than ±0.005 inches matter

- Precision squares – Verify perpendicularity of reference edges before measuring

Account for Material Removal

Here's where many orders go wrong: forgetting that cutting removes material. According to ESAB, kerf is the width of material that the cutting process removes as it cuts through the plate. A plasma cut might remove 0.150 inches or more, while laser cutting typically removes only 0.020 to 0.050 inches.

Modern CNC machines compensate for kerf automatically—the control offsets the tool path by half the kerf width. However, you need to understand this concept when designing parts that must nest together or fit precisely within an assembly. If you're providing cut-ready files, confirm with your fabricator whether kerf compensation is already applied or if they'll add it.

Double-Check Critical Dimensions

Measure twice, order once. For critical features—hole locations, mating surfaces, and interface points—verify measurements from multiple reference points. Cross-check calculations, especially when converting between metric and imperial units. A simple math error on a large order becomes an expensive lesson.

Creating Clear Cutting Specifications

Your fabricator can only produce what you clearly communicate. Ambiguous specifications lead to phone calls, delays, and potential errors. Here's how to document your requirements professionally.

File Formats for CNC Work

When submitting digital designs, file format matters. According to PTSMAKE, DXF files require cleaning up unnecessary elements, checking for overlapping lines, ensuring proper scale, and verifying all dimensions. The vector-based format ensures scalability without losing quality, making it ideal for manufacturing applications.

Recommended file formats include:

- DXF – Industry standard for 2D cutting paths; ensure geometry is clean and layers are organized

- DWG – AutoCAD native format; widely compatible with fabrication equipment

- STEP or IGES – Preferred for 3D models requiring flat pattern development

- PDF drawings – Acceptable for simple parts with clear dimensioning; not suitable for complex geometries

Before sending files, convert all text to geometry, merge connecting lines, and verify the file uses correct units. A drill chart or metal gauge thickness chart included with your documentation helps fabricators verify specifications match your intent.

Drawing Requirements and Dimension Notation

Even with digital files, include a dimensioned drawing showing critical measurements. Use standard dimension notation—clearly indicate which dimensions are critical versus reference-only. Specify datum points (reference surfaces) so fabricators measure from the same locations you did.

According to PTSMAKE, proper documentation should include material specifications, required quantities, and any special instructions. Layer management in your files significantly impacts how fabricators interpret your design—separate layers for cutting paths, bend lines, dimensions, and annotations.

Common Mistakes to Avoid

Learning from others' errors saves time and money. These mistakes appear repeatedly in custom metal orders:

- Forgetting kerf width – If you're designing parts that interlock or nest, remember that cutting removes material between them

- Specifying impossible tolerances – Demanding ±0.001 inches on plasma-cut parts wastes everyone's time; match tolerances to cutting method capabilities

- Unclear dimension references – "12 inches from the edge" means nothing without specifying which edge; use clear datum references

- Missing material specifications – "Steel" isn't a specification; indicate grade, thickness, and any surface requirements

- Ignoring bend allowances – According to Sheet Metal Masion, if bends are in your design, you must add extra material for each bend; failing to include bend allowance results in undersized finished parts

Quantity Considerations and Batch Pricing

How many parts you order affects both pricing and lead times. Fabricators typically offer tiered pricing—larger quantities reduce per-piece costs because setup time spreads across more parts. However, ordering quantities you don't need ties up capital and storage space.

Discuss batch size options with your supplier. Some fabricators offer price breaks at specific quantities (10, 25, 50, 100 pieces). Others provide volume discounts on a sliding scale. For prototype work or small runs, expect higher per-piece pricing but faster turnaround.

Step-by-Step Ordering Checklist

Before submitting your custom cut metal order, work through this checklist to ensure nothing gets missed:

- Material Selection – Specify exact material type and grade (e.g., 304 stainless steel, 6061-T6 aluminum, A36 mild steel); confirm material is appropriate for your cutting method

- Thickness Specification – Indicate gauge or decimal thickness with units; reference a gauge size chart if using gauge numbers to verify actual dimensions

- Dimension Documentation – Provide clear drawings with all critical dimensions noted; include DXF or DWG files for complex shapes; specify units (inches vs. millimeters) explicitly

- Tolerance Requirements – State required tolerances for critical dimensions; use standard tolerances where precision isn't critical to reduce costs

- Quantity and Delivery – Confirm piece count and desired delivery date; ask about batch pricing if quantities are flexible

- Finish Expectations – Specify edge quality requirements, surface finish needs, and any secondary operations (deburring, coating, etc.)

- File Verification – Check digital files for overlapping geometry, proper scaling, and clean layer organization before submission

With your specifications clearly documented and verified, you're ready to explore how custom cut metal serves different applications—from industrial manufacturing to weekend DIY projects.

Common Applications for Custom Cut Metal

Now that you understand how to specify and order custom cut metal, you might be wondering—what can you actually build with it? The applications span from massive industrial operations to weekend garage projects. Whether you're managing a steel fabrication facility or tackling your first DIY metal frame, precision-cut materials open doors that standard stock simply cannot.

Let's explore how different industries and users put custom cut metal to work, giving you ideas and context for your own projects.

Industrial and Manufacturing Applications

Manufacturing facilities represent the largest consumers of custom cut metal, and for good reason. When you're producing hundreds or thousands of identical components, starting with precisely cut blanks eliminates countless hours of secondary processing.

Automotive Manufacturing and Repair

The automotive sector depends heavily on precision metal components. According to P&D Metal Works, OEMs (Original Equipment Manufacturers) including automakers rely on custom manufactured parts that must be built to specific specifications and produced in large quantities.

Automotive applications include:

- Chassis components – Structural members requiring exact dimensions for proper assembly and safety performance

- Suspension brackets – Mounting points that must align precisely with vehicle specifications

- Structural reinforcements – Steel plates and gussets strengthening high-stress areas

- Body panels – Replacement sections for collision repair and restoration work

- Custom exhaust components – Headers, flanges, and mounting brackets for performance applications

For automotive manufacturers requiring IATF 16949-certified quality, partnering with specialized suppliers ensures precision components for chassis and suspension applications meet stringent industry standards. Companies like Shaoyi Metal Technology deliver rapid prototyping within 5 days alongside automated mass production capabilities, helping automotive supply chains maintain quality while meeting demanding timelines.

Architecture and Construction

Buildings large and small incorporate custom metal components throughout their structures. According to Schorr Metals, sturdy buildings often have metal in their structure, and some buildings are even made from metal entirely. Custom fabrication means you can get the specific metal beams, supports, and sheets in the exact dimensions you need.

Construction applications span:

- Structural brackets – Connection points between beams, columns, and trusses

- Steel plates – Base plates, gusset plates, and bearing plates for structural connections

- Architectural elements – Custom railings, stair stringers, and decorative metalwork

- Aluminum channel – Framing for curtain walls, storefronts, and glazing systems

- Security gates and fencing – Customized to specific opening dimensions and security requirements

Precision matters particularly for architectural applications where visible metalwork becomes part of the building's aesthetic. Laser-cut custom metal signs, address markers, and decorative panels add distinctive character while serving functional purposes.

Manufacturing Equipment and Machine Parts

Every manufacturing facility contains equipment that eventually needs replacement parts—and those parts often aren't available off the shelf. Custom cutting enables fabrication of:

- Machine guards and enclosures – Safety barriers sized precisely for specific equipment

- Conveyor components – Side rails, mounting brackets, and guide plates

- Tooling plates – Work-holding fixtures and jigs for production processes

- Equipment frames – Structural supports for industrial machinery

Medical and Precision Industries

According to Schorr Metals, a lot of medical equipment deals in metal, like operating tools and complex machinery. Metal surgical tools can be fabricated to very specific and precise dimensions and ordered in bulk. The medical field demands exceptionally tight tolerances, making laser cutting the preferred method for these applications.

DIY and Hobbyist Projects

You don't need an industrial operation to benefit from custom cut metal. Hobbyists, makers, and home improvement enthusiasts increasingly turn to professional cutting services for projects that demand precision beyond what hand tools can achieve.

Custom Enclosures and Electronics Projects

Building a custom computer case, amplifier chassis, or control panel? Having steel plates or aluminum cut to exact specifications eliminates hours of hand work and produces professional results. Laser cutting handles intricate ventilation patterns and precise mounting hole locations that would challenge even skilled metalworkers using manual methods.

Art and Decorative Metalwork

According to PrimeWeld, metal art projects range from simple geometric wall decorations to elaborate dragon sculptures. Custom cutting provides the precisely shaped components that artists assemble and weld into finished pieces. Popular art applications include:

- Custom metal signs with intricate lettering and designs

- Garden sculptures and yard art

- Wall-mounted decorative panels

- Furniture components combining metal frames with wood or glass

Home Improvement and Renovation

Homeowners tackling renovation projects find custom cut metal invaluable for applications where standard sizes don't fit. Think custom brackets for floating shelves, precisely sized plates for structural repairs, or metal frame components for built-in furniture. Having parts cut professionally means cleaner results and faster installation.

Automotive Restoration and Modification

According to Schorr Metals, cars that need repairs and restoration require new metal parts from the undercarriage to the interior to the exterior body. Many times, these pieces need to follow custom dimensions to fit the existing skeleton of the car. Hobbyists restoring classic vehicles or building custom hot rods regularly order:

- Floor pan patches and replacement sections

- Custom brackets and mounting plates

- Roll cage components cut to specification

- Trunk floor panels and wheel tubs

Workshop and Garage Organization

Metal fab projects for the workshop itself represent popular starter applications. Welding tables, tool storage racks, and equipment stands all benefit from precisely cut components. Starting with accurately dimensioned pieces makes assembly straightforward—corners meet properly, shelves sit level, and the finished product looks professional.

Industry Applications Summary

The following list organizes common custom cut metal applications by sector, helping you identify where your project fits:

- Automotive – Chassis components, brackets, body panels, exhaust systems, roll cage elements

- Construction – Structural brackets, base plates, railings, stairs, architectural features

- Manufacturing – Machine guards, conveyor parts, tooling fixtures, equipment frames

- Medical – Surgical instruments, equipment housings, precision components

- Landscaping – Fencing, gates, plant supports, decorative screens, edging

- Agriculture – Equipment repair parts, custom brackets, storage solutions

- Hobbyist/DIY – Enclosures, art projects, furniture, home improvement, restoration

- Signage – Custom metal signs, address markers, business identification, wayfinding

Whatever your application, the principles remain consistent: proper material selection, appropriate cutting method, clear specifications, and realistic tolerance expectations. But even perfectly cut parts often require additional processing before they're truly ready for use—which brings us to finishing and secondary operations.

Finishing and Secondary Operations

Your custom cut metal arrives precisely dimensioned—but is it actually ready to use? In many cases, the answer is no. Raw cut edges can be sharp enough to slice through gloves, rough enough to prevent proper assembly, or simply too industrial-looking for visible applications. That's where secondary operations transform a cut piece into a finished component.

Understanding these post-cutting processes helps you specify exactly what you need—and avoid paying for operations that don't add value to your particular application.

Deburring and Edge Finishing

Every cutting method leaves behind some form of edge imperfection. Laser cutting produces the cleanest edges, but even these may require attention for safety-critical applications. Plasma cutting often leaves more pronounced irregularities, while shearing can create significant burrs along the cut line.

According to Timesavers, deburring is a process that removes imperfections and sharp edges, called burrs, from machined metal products and leaves them with smooth edges. Without consistent deburring, burrs can cause longevity, safety, and functionality issues.

Why Deburring Matters

Sharp edges create real problems across multiple dimensions:

- Safety concerns – Razor-sharp burrs injure workers during handling and assembly

- Fit requirements – Raised edges prevent parts from mating properly or sitting flat

- Coating adhesion – Burrs compromise paint and powder coat coverage

- Aesthetic standards – Visible edges in finished products must look clean and professional

Common Deburring Methods

Different burr types require different removal approaches. According to Timesavers, there are two primary types of burrs—loose and fixed. Loose burrs are relatively easy to remove, while fixed burrs require more extensive deburring methods.

Here are the primary deburring approaches:

- Manual deburring – Using handheld tools to buff, sand, or scrape burrs; economical but time-consuming and labor-intensive

- Mechanical deburring – Automated machines performing grinding operations; efficient and consistent for high volumes

- Brushing – Rotating discs with metal or wire filaments scrape off burrs; fast and cost-effective for many applications

- Tumbling – Parts rotate in a chamber with abrasive media; excellent for small components and batch processing

- Thermal deburring – Heat and combustive gases vaporize burrs in hard-to-reach areas; ideal for complex geometries

Mechanical deburring offers significant advantages for production work. According to Timesavers, automated deburring is much more efficient and can be used in a wide variety of machining operations, delivering reliable, fast results while removing burrs entirely from workpiece structures.

Surface Treatments and Coatings

Beyond edge finishing, many applications require protective or decorative surface treatments. These coatings extend component life, improve appearance, and enhance performance characteristics.

According to D+M Metal Products, surface finishing is often done to protect metal parts from corrosion and wear. These processes include powder coating, anodizing, and plating—each offering distinct advantages for different applications.

Common Finishing Options

- Powder coating – A dry application process where electrostatically charged powder adheres to grounded metal, then cures in an oven to form a durable, attractive finish; available in countless colors and textures; ideal for outdoor equipment and parts requiring brilliant, fade-resistant colors

- Anodized aluminum – An electrochemical process that thickens aluminum's natural oxide layer, enhancing corrosion and wear resistance while allowing dye absorption for coloring; preferred for architectural and structural applications where protection and metallic appearance are paramount

- Galvanizing – Hot-dip or electro-galvanizing applies a zinc coating that provides sacrificial corrosion protection; cost-effective for outdoor steel components where appearance matters less than longevity

- Plating – Applying thin layers of zinc, nickel, chrome, or other metals for protection or visual appeal; chrome plating adds decorative shine while nickel provides corrosion resistance

- E-coating – Electrodeposition coating provides uniform coverage even in recessed areas; commonly used as a primer layer before topcoats

- Painting – Traditional wet paint application; less durable than powder coat but offers unlimited color matching and easier touch-up

Anodizing vs. Powder Coating

These two popular finishes serve different purposes. According to Gabrian, anodizing is ideal when you want tight dimensional margins, outstanding corrosion and wear resistance, and an attractive metallic look. A powder coat might be the solution if you're looking for vibrant colors or unique textures that will last, even when exposed to the elements.

Key differences include:

- Dimensional impact – Anodizing adds minimal thickness; powder coating adds 2-6 mils

- Appearance – Anodized finishes maintain metallic look; powder coat offers unlimited colors and textures

- Heat dissipation – Anodized surfaces dissipate heat better; important for electronics enclosures

- Cost – Powder coating typically costs less than anodizing

Maintaining Finished Surfaces

If you're wondering how to clean stainless steel or how to polish stainless steel after fabrication, the approach depends on the surface condition. For general cleaning, mild soap and water work well. Stubborn marks may require specialized stainless steel cleaners. When polishing, work with progressively finer abrasives to achieve the desired finish—but recognize that polishing removes material, so heavily polished surfaces may need re-treatment periodically.

When Secondary Operations Add Value

Not every cut part needs extensive finishing. Understanding when to specify additional operations—and when to skip them—optimizes both cost and quality.

Specify finishing when:

- Parts will be handled frequently during assembly or use

- Components will be visible in the finished product

- Corrosion resistance beyond the base metal's capability is required

- Parts must interface precisely with other components

- Safety regulations mandate smooth edges

Skip finishing when:

- Parts proceed directly to welding (welding removes any finish)

- Components will be painted on-site after installation

- Interior structural members won't be seen or touched

- Budget constraints outweigh aesthetic concerns

Specifying Finishing Requirements

When ordering custom cut metal with finishing, communicate clearly:

- Edge requirements – Specify "deburred all edges" or identify specific edges requiring attention

- Surface treatment – Indicate coating type, color (using RAL or Pantone codes), and finish texture

- Quality standards – Reference industry specifications if applicable (MIL-A-8625 for anodizing, for example)

- Masking requirements – Identify areas that must remain uncoated for welding, grounding, or assembly

According to D+M Metal Products, many fabricators send parts to trusted vendors for vibratory deburring, e-coating, plating, or powder coating services, allowing customers to receive finished products without shopping around multiple suppliers.

Lead Time and Pricing Impact

Secondary operations extend lead times—sometimes significantly. Powder coating services typically add 3-5 business days. Anodizing may require a week or more depending on the provider. Batch-processing operations like tumble deburring work more efficiently with larger quantities, potentially affecting per-piece costs.

Discuss finishing requirements upfront with your fabricator. Many offer turnkey services that simplify procurement, though costs may differ from sourcing finishing separately. For large or ongoing orders, dedicated finishing relationships often provide better pricing and more predictable scheduling.

With your parts cut, deburred, and finished according to specification, you're ready to put them to work. But before placing that order, let's pull together everything you've learned into a clear decision-making framework.

Getting Started with Your Custom Metal Project

You've absorbed a lot of information—cutting methods, material properties, gauge specifications, tolerance requirements, and finishing options. Now comes the moment that matters: translating that knowledge into a successful custom metal project. Whether you're ordering a single custom metal plate for a prototype or planning ongoing production runs, the decisions you make and the partner you choose determine your results.

Let's synthesize everything into a clear action framework and explore what separates adequate suppliers from exceptional manufacturing partners.

Making Your Custom Metal Decision

Before reaching out to fabricators, confirm you've addressed each critical decision point. Missing any of these creates delays, miscommunication, or parts that don't meet your requirements.

Material Selection

Your material choice establishes the foundation for everything else. Have you determined whether your application demands stainless steel sheet metal for corrosion resistance, aluminum for weight savings, or carbon steel for cost-effective strength? For custom cut steel applications, specify the exact grade—not just "steel." Remember that material properties directly influence which cutting methods work effectively.

Cutting Method Alignment

Match your cutting technology to material type, thickness, and precision requirements. Laser cutting delivers exceptional edge quality for thin to medium stock. Plasma handles thicker plates economically. Waterjet works when heat-affected zones cannot be tolerated. Confirming that your chosen method suits your material and thickness prevents surprises during production.

Thickness Specifications

Whether you're working with heavy 10-gauge structural plates or light 22-gauge enclosure panels, verify your thickness specification is correct. Reference gauge charts for your specific material type—remember that gauge measurements vary between steel, aluminum, and stainless. Thickness directly impacts cutting method viability and achievable tolerances.

Tolerance Requirements

Specify tolerances appropriate to your application. Demanding unnecessarily tight tolerances inflates costs without adding functional value. Reserve precision specifications for mating surfaces, critical interfaces, and applications where fit genuinely matters. Standard tolerances suffice for structural components and parts destined for welding.

Finishing Needs

Determine whether your parts require secondary operations. Will edges need deburring for safe handling? Does the application demand powder coating, anodizing, or other protective treatments? Specifying finishing requirements upfront enables accurate quoting and realistic lead time estimates.

Partnering with the Right Supplier

Your fabrication partner's capabilities directly impact project success. According to Sytech Precision, the wrong partner can stall your timeline, inflate your costs, or put compliance at risk. Evaluating potential suppliers across several dimensions helps you identify partners rather than mere vendors.

Capabilities Beyond Basic Cutting

Many fabricators offer standard laser cutting, welding, and forming services. The difference between a good and great shop comes down to comprehensive capabilities. Can your potential partner handle finishing operations internally? Do they offer assembly services? According to Sytech Precision, each additional service your fabricator can handle saves you time and money and removes the need to coordinate multiple vendors.

Look for suppliers offering:

- Multiple cutting technologies (laser, plasma, waterjet) for flexibility

- In-house deburring and edge finishing

- Powder coating or other surface treatment capabilities

- Assembly and mechanical integration services

- Design support and file optimization

Certifications That Matter

For regulated industries, certifications aren't optional—they're essential. According to Xometry, IATF 16949 certification signifies that an organization has met requirements proving its ability and commitment to limit defects in products, reducing waste and wasted effort. While general-purpose projects may not require certified suppliers, automotive, aerospace, and medical applications often demand specific quality management credentials.

Key certifications to consider:

- IATF 16949 – Essential for automotive supply chain participation

- ISO 9001 – Demonstrates standardized quality management systems

- UL certifications – Required for electrical enclosures and safety-critical components

- AS9100 – Aerospace industry quality standards

Scalability and Lead Times

Some fabricators excel at prototypes but struggle with production volumes. Others handle high-volume work efficiently but cannot accommodate small runs economically. According to Sytech Precision, larger fabrication facilities with streamlined workflows are better positioned to deliver consistent lead times, no matter the size of your order.

Ask potential suppliers about their capacity for your anticipated volumes—both current requirements and potential growth. Understand standard turnaround times and whether expedited options exist for urgent needs.

Design Collaboration and DFM Support

The best suppliers do more than execute your drawings—they improve them. According to Xometry, Design for Manufacturing (DFM) aligns design objectives with manufacturing capabilities, ensuring that prototypes are innovative and manufacturable at reasonable cost and time frames.

Partners offering robust DFM support review your designs proactively, identifying opportunities to streamline production, reduce costs, or improve durability. According to Sytech Precision, those insights can help you reduce costs, strengthen durability, and shorten turnaround times without compromising your specifications.

The right fabrication partner matches their capabilities to your specific requirements—offering the cutting technologies, certifications, turnaround times, and design support that transform your specifications into successful finished parts.

Taking Action on Your Custom Metal Project

With your decisions made and supplier criteria established, you're ready to move forward. Start by gathering complete specifications—material, thickness, dimensions, tolerances, quantities, and finishing requirements. Prepare clean digital files if submitting CAD designs. Then reach out to qualified fabricators for quotes, comparing not just price but capabilities, certifications, and communication quality.

For manufacturers requiring precision custom metal shapes in demanding applications, partnering with suppliers offering comprehensive DFM support and rapid prototyping capabilities accelerates development cycles while maintaining quality. Companies like Shaoyi Metal Technology demonstrate how 5-day rapid prototyping combined with IATF 16949-certified production and 12-hour quote turnaround transforms sheet metal fabrication from a bottleneck into a competitive advantage.

Whether you're sourcing your first custom metal plate or optimizing an established supply chain, the principles remain consistent: specify clearly, match requirements to capabilities, and partner with fabricators who understand your industry's demands. Armed with the knowledge from this guide, you're equipped to navigate the custom cut metal process with confidence—from first measurement to finished part.

Frequently Asked Questions About Custom Cut Metal

1. How much does metal cutting cost?

Metal cutting costs typically range from $0.50 to $2 per linear inch, depending on material type, thickness, and cutting method. Hourly rates generally fall between $20 and $30. Laser cutting commands higher prices for precision work, while plasma cutting offers cost-effective processing for thicker steel plates. Batch size significantly impacts per-piece pricing—larger quantities reduce setup costs spread across more parts, lowering your overall expense.

2. Will a hardware store cut metal for you?

Most hardware stores offer basic pipe cutting services but lack equipment for precision sheet metal fabrication. For custom cut metal with exact dimensions, complex shapes, or tight tolerances, specialized fabrication shops or online services like SendCutSend provide professional-grade laser, plasma, and waterjet cutting. These services accept digital design files and deliver parts cut to your precise specifications.

3. How to get a piece of metal cut?

For thin sheet metal at home, tin snips work for straight cuts. For professional results, submit your specifications to a custom metal fabrication service. Prepare accurate measurements, select your material and thickness, create dimensioned drawings or DXF files, and specify required tolerances. Online fabricators offer instant quoting—upload your design files, select materials, and receive precision-cut parts delivered within days.

4. What is the difference between laser cutting and plasma cutting for custom metal?

Laser cutting excels at intricate designs with tolerances as tight as ±0.005 inches, producing clean edges on thin to medium stock under 0.5 inches. Plasma cutting handles thicker materials more economically—processing 1-inch steel 3-4 times faster than alternatives—but produces wider kerfs and may require deburring. Choose laser for precision parts and plasma for structural steel applications.

5. What materials can be custom cut for fabrication projects?

Common custom cut metals include aluminum sheet for lightweight applications, carbon steel for affordable structural work, stainless steel (304 or 316 grades) for corrosion resistance, galvanized steel for outdoor durability, and brass or copper for decorative and electrical uses. Each material responds differently to cutting technologies—aluminum cuts cleanly with laser or CNC routing, while thick carbon steel favors plasma cutting.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —