Die Casting Gearbox Casings: A Guide to Process and Materials

TL;DR

Die cast gearbox casings are precision-engineered housings, typically manufactured from aluminum alloys, designed to protect the internal mechanisms of a transmission system. The high-pressure die casting process is favored for its ability to produce lightweight, durable, and geometrically complex parts with high dimensional accuracy, making it an essential technology for the automotive and industrial sectors.

What Are Die Cast Gearbox Casings? Function and Critical Role

A gearbox casing, or housing, is the robust outer shell that encloses and protects the critical internal components of a gearbox, such as gears, bearings, and shafts. Its primary function is threefold: to provide rigid mechanical support for the transmission system, to shield sensitive parts from harsh environmental conditions, and to create a fluid-tight seal to contain lubricants. This protective enclosure is fundamental to the performance and longevity of the entire transmission assembly.

The operational environment for many gearboxes, particularly in the automotive industry, is severe. Casings must withstand prolonged exposure to high temperatures, significant pressure variations, high humidity, and constant vibration. As detailed in a case study for an automobile gearbox shell, these components are engineered to maintain structural integrity under extreme conditions, preventing contamination from dust and moisture while ensuring internal parts remain properly aligned and lubricated.

Die casting is the preferred manufacturing method for these housings because it excels at producing parts with complex shapes and thin walls, which are characteristic of modern gearbox designs. The process allows for the integration of features like reinforcing ribs, mounting bosses, and fluid channels directly into the casting, minimizing the need for extensive secondary machining. This results in a highly optimized component that is both strong and lightweight, a crucial combination for improving vehicle efficiency and performance.

The High-Pressure Die Casting Process for Gearbox Housings

High-pressure die casting (HPDC) is the dominant manufacturing technique for producing gearbox casings due to its speed, precision, and ability to create intricate parts in high volumes. The process involves injecting molten metal into a hardened steel mold, known as a die, under immense pressure. This method ensures the metal fills every detail of the mold cavity, resulting in a net-shape part with excellent surface finish and dimensional accuracy.

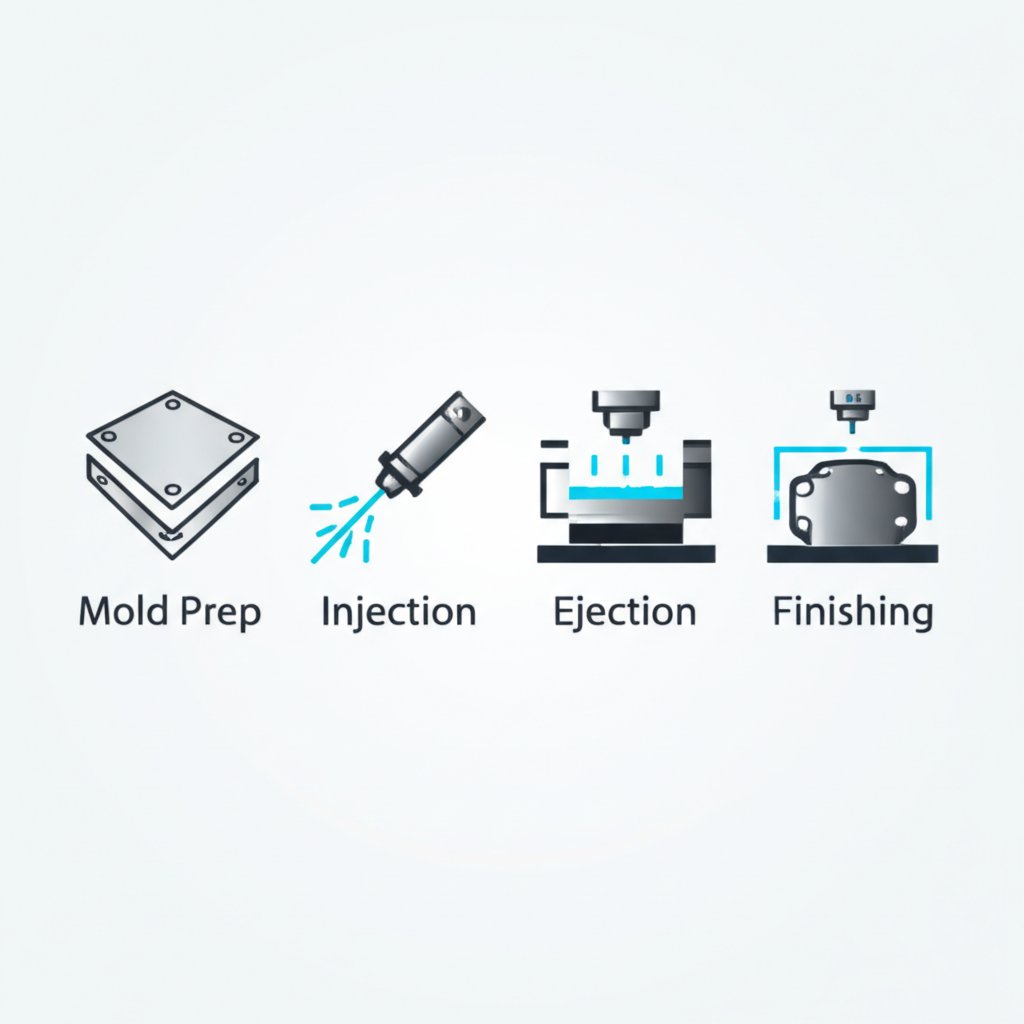

The manufacturing sequence for a die cast gearbox casing follows several controlled steps:

- Mold Preparation: The two halves of the steel die are heated to an optimal temperature and coated with a lubricant to facilitate part ejection and extend the tool's lifespan.

- Molten Alloy Injection: A precisely measured amount of molten aluminum alloy is forced into the die cavity at high speed and pressure, typically between 60 to 100 MPa.

- Cooling and Solidification: The molten metal cools rapidly within the water-cooled die, solidifying into the shape of the casing in a matter of seconds.

- Part Ejection: Once solidified, the die opens, and the casting is ejected by mechanical pins.

- Finishing: The raw casting undergoes secondary operations, such as trimming excess material (flash), shot blasting to create a uniform surface texture, and CNC machining for critical features requiring tight tolerances.

This highly automated process allows for rapid production cycles, making it more cost-effective than CNC machining for large production runs, despite the high initial investment in tooling. The precision offered by HPDC is remarkable, with manufacturers like Zetwerk achieving tolerances as tight as 0.002 inches on multi-axis gearbox housings. While die casting is ideal for high-volume parts, other advanced manufacturing methods are also vital in the automotive sector. For instance, specialists in high-performance components, such as Shaoyi (Ningbo) Metal Technology, utilize processes like hot forging to create exceptionally robust parts, demonstrating the diverse engineering solutions available for the automotive industry.

Materials of Choice: Aluminum Alloys for Optimal Performance

Aluminum alloys are the industry standard for die cast gearbox casings, prized for their exceptional combination of mechanical and thermal properties. The primary advantage of aluminum is its high strength-to-weight ratio; it offers the necessary durability to protect the gearbox while being significantly lighter than traditional materials like cast iron. This weight reduction is critical in the automotive industry for improving fuel efficiency and vehicle handling.

Beyond being lightweight, aluminum alloys provide excellent thermal conductivity, which helps dissipate the heat generated by the gearbox's internal components, extending their service life. These alloys also offer good corrosion resistance and can be cast into highly complex shapes with a smooth surface finish. As noted by suppliers like Reigstone, these features make aluminum an ideal material choice for gearbox housings that must be strong, light, and long-lasting.

Different aluminum alloys are selected based on the specific performance requirements of the application. The table below outlines some of the most common alloys used for gearbox casings and their key characteristics.

| Alloy Designation | Key Properties | Typical Applications |

|---|---|---|

| ADC12 (A383) | Excellent balance of castability, mechanical properties, and thermal conductivity. Good for complex shapes. | The most common alloy for general-purpose automotive and industrial gearbox housings. |

| A380 | High strength, good dimensional stability, and high corrosion resistance. | A widely used general-purpose alloy offering a good balance of casting and mechanical properties. |

| AlSi9Cu3 | Good thermal conductivity and resistance to hot cracking. | Often used for structural parts that operate at elevated temperatures. |

| AlSi10Mg | Suitable for heat treatment to achieve higher mechanical properties and corrosion resistance. | Ideal for high-performance applications where maximum strength and durability are required. |

The selection of the right alloy is a critical design decision that balances performance needs with manufacturing considerations. Factors like wall thickness, structural complexity, and the operational environment all influence the final choice, ensuring the gearbox casing meets its design specifications for life.

Quality Assurance and Precision in Gearbox Casing Manufacturing

For a gearbox casing to function correctly, dimensional accuracy and material integrity are non-negotiable. The slightest deviation in a bearing bore or mounting surface can lead to misalignment, premature wear, and eventual failure of the entire transmission system. Consequently, rigorous quality assurance and advanced inspection methods are integral to the manufacturing process.

Leading manufacturers employ a multi-stage quality control protocol that begins with raw material verification and extends through to final inspection. Modern metrology solutions are essential for verifying both the initial casting and the final machined features. As described by LK Metrology, techniques like 3D laser scanning provide a complete analysis of the casting's surface, creating a detailed color map that highlights any deviation from the nominal design. This allows for rapid and comprehensive first-off sample inspections, reducing what once took days to mere hours.

In addition to surface and dimensional checks, the internal integrity of the casting is often verified using non-destructive methods like X-ray inspection to detect porosity or other subsurface defects that could compromise the part's strength. Certifications such as IATF 16949 and ISO 9001 are key indicators of a manufacturer's commitment to quality, ensuring that processes are standardized and repeatable.

When evaluating a potential supplier for die cast gearbox casings, it is critical to assess their quality assurance program. Key criteria to consider include:

- Industry Certifications: Look for relevant quality management certifications like ISO 9001 or the automotive-specific IATF 16949.

- Advanced Inspection Technology: Inquire about their use of Coordinate Measuring Machines (CMMs), 3D laser scanners, and X-ray inspection capabilities.

- Material Traceability: Ensure the manufacturer has robust systems for tracing raw materials from source to finished product.

- Process Control and Monitoring: A capable supplier will continuously monitor key process parameters during die casting to ensure consistency and prevent defects.

Frequently Asked Questions

1. What material is used for gearbox casing?

The most common material for modern die cast gearbox casings is an aluminum alloy, such as ADC12 or A380. Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. Historically, cast iron was also widely used and is still found in some heavy-duty applications due to its high strength and damping properties.

2. What is gearbox casing?

A gearbox casing is a protective housing that encloses the internal components of a transmission system, including gears, shafts, and bearings. It provides structural support, protects the components from external contaminants like dust and moisture, and contains the lubricant necessary for smooth operation.

3. Is die casting cheaper than CNC?

For large production volumes, die casting is generally more cost-effective than CNC machining. While die casting involves a high initial investment for tooling (the mold), the cost per part becomes very low once production begins due to fast cycle times. CNC machining has lower setup costs but a higher cost per part, making it more suitable for prototypes and small-to-medium production runs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —