From Quote to Quality Part: How a CNC Machining Shop Actually Works

What Is a CNC Machining Shop and How Does It Work

Ever wondered how that perfectly machined aluminum bracket or intricate steel component actually gets made? Behind nearly every precision part you encounter - from aircraft engine components to medical implants - there's a CNC machining shop making it happen.

A CNC machining shop is a specialized manufacturing facility equipped with computer-controlled machines that cut, shape, and finish materials with exceptional accuracy. The term "CNC" stands for Computer Numerical Control, meaning these machines follow pre-programmed digital instructions rather than relying on manual operation. According to The Manufacturer, this automation enables tolerances often reaching ±0.005 mm - roughly the width of a human hair.

Think of it this way: instead of a machinist manually guiding each cut, a computer precisely controls every movement of the cutting tools. The result? Parts that are virtually identical whether you're making one prototype or ten thousand production units.

The Technology Behind Modern Precision Manufacturing

What makes a machine shop cnc-capable isn't just having the right equipment - it's the integration of several essential components working together seamlessly. When you search for cnc machine shops near me, you're looking for facilities that combine these core elements:

- CNC Machines: The workhorses of the operation - mills, lathes, routers, and grinders that execute precision cutting operations across multiple axes (X, Y, Z, and sometimes more)

- CAD/CAM Software: Computer-Aided Design (CAD) creates the digital blueprint, while Computer-Aided Manufacturing (CAM) translates that design into machine-readable G-code instructions

- Skilled Operators: Despite automation, experienced machinists remain essential for machine setup, program verification, and quality oversight

- Quality Control Systems: Inspection equipment like Coordinate Measuring Machines (CMMs), calipers, and micrometers verify that finished parts meet exact specifications

This combination allows cnc industries spanning aerospace, automotive, medical, and electronics to produce everything from simple shafts to components with complex three-dimensional geometries that would be impossible to create by hand.

From Digital Design to Physical Part

So how does a cnc precision machine actually transform a digital file into a finished component? The workflow follows a logical progression that ensures accuracy at every step:

First, an engineer creates a 3D model using CAD software like SolidWorks or Fusion 360. This digital design defines every dimension, angle, and feature of the intended part. Next, CAM software generates the toolpath - essentially a roadmap telling the machine exactly where to move, how fast to cut, and which tools to use.

Once the program is ready, an operator prepares the machine by securing the raw material (whether aluminum, steel, or engineering plastic) and installing the appropriate cutting tools. The machine then executes the programmed instructions, removing material layer by layer until the final shape emerges.

After machining, the part undergoes inspection to verify it meets all specifications. Additional finishing processes - polishing, anodizing, or surface treatments - may follow depending on application requirements.

This subtractive manufacturing process differs fundamentally from 3D printing, which builds parts by adding material. By starting with solid blocks and precisely removing what isn't needed, CNC machining delivers superior strength, tighter tolerances, and a wider range of compatible materials - making it the backbone of modern precision manufacturing.

Types of CNC Machines and Their Manufacturing Applications

Now that you understand how a CNC machining shop operates, you might be wondering: which machine actually makes your part? The answer depends entirely on what you're trying to create. Different CNC machines excel at different tasks - and choosing the wrong one can mean wasted time, higher costs, or compromised quality.

Whether you need a precision cnc turning shop for cylindrical components or a cnc milling shop for complex geometries, understanding the capabilities of each machine type helps you communicate more effectively with manufacturers and make smarter sourcing decisions.

CNC Lathes and Turning Centers

Imagine a pottery wheel spinning clay - now replace the clay with metal and add computer-controlled cutting tools. That's essentially how a CNC lathe works. The workpiece rotates at high speed while stationary cutting tools remove material to create cylindrical or round parts.

A cnc lathe shop specializes in producing components like shafts, bushings, pins, and threaded fasteners. According to CNC Masters, modern CNC lathes can produce thousands of machined parts in a single shift, making them ideal for high-volume production runs.

What makes today's turning centers particularly powerful? Live tooling capabilities. This feature allows rotating cutting tools to perform milling, drilling, and tapping operations while the part remains mounted - eliminating secondary setups and improving accuracy. A precision cnc turning shop using multi-axis lathes can create complex contours, off-center features, and even some milled details in a single operation.

Common parts produced include:

- Camshafts and crankshafts

- Hydraulic fittings and connectors

- Precision screws and fasteners

- Automotive pistons and valve stems

- Medical instrument handles

Milling Machines for Complex Geometries

While lathes spin the workpiece, CNC mills do the opposite - the cutting tool rotates while the material stays fixed (or moves along controlled axes). This fundamental difference makes milling machines incredibly versatile for producing flat surfaces, pockets, slots, and intricate three-dimensional shapes.

A cnc milling shop can tackle everything from simple brackets to complex aerospace components with internal cavities and precise surface contours. The key advantage? Multi-axis capability. Basic 3-axis mills move the cutting tool along X, Y, and Z directions. However, advanced 5-axis machines add two rotational axes, allowing the tool to approach the workpiece from virtually any angle without repositioning.

According to Zintilon, when you're making complex geometrical shapes that aren't cylindrical, CNC mills are your best choice. They excel at:

- Mold and die manufacturing

- Aerospace structural components

- Medical implants and surgical instruments

- Automotive engine blocks and transmission housings

- Custom enclosures and housings

Specialized Equipment for Unique Applications

Beyond lathes and mills, a full-service cnc turning service or machining facility may house several specialized machines designed for specific tasks:

CNC Routers: Think of these as mills optimized for larger, flatter workpieces and softer materials. They're popular for wood, plastics, composites, and sign-making applications. While less rigid than industrial mills, routers cover more ground - literally - with table sizes reaching 5 feet by 10 feet or larger.

CNC Grinders: When you need mirror-smooth finishes or ultra-tight tolerances on hardened materials, grinding is the answer. Surface grinders create precise flat surfaces, while cylindrical grinders work on round parts - achieving tolerances that cutting tools simply can't match.

EDM (Electrical Discharge Machining): For hardened tool steels or intricate internal features, wire EDM uses electrical sparks to erode material without mechanical contact. It's essential for mold-making and parts requiring sharp internal corners that conventional tools can't reach.

| Machine Type | Best Applications | Material Compatibility | Typical Tolerances |

|---|---|---|---|

| CNC Lathe | Cylindrical parts, shafts, bushings, threaded components | All metals, plastics | ±0.001" to ±0.0005" |

| CNC Mill | Complex 3D geometries, pockets, molds, housings | All metals, plastics, composites | ±0.001" to ±0.0002" |

| CNC Router | Large flat panels, signs, furniture, soft materials | Wood, plastics, aluminum, composites | ±0.005" to ±0.001" |

| CNC Grinder | Precision finishing, hardened materials, tight tolerances | Hardened steels, tool steels | ±0.0001" to ±0.00005" |

| Wire EDM | Hardened dies, intricate internal features, sharp corners | Conductive metals only | ±0.0001" to ±0.00005" |

Understanding these distinctions helps you identify the right manufacturing partner for your specific project. A shop equipped with 5-axis mills handles complex aerospace brackets differently than one specializing in high-volume turned components. The best approach? Match your part geometry and material requirements to the shop's core capabilities - a strategy we'll explore further when discussing material selection.

Materials You Can Machine from Metals to Plastics

You've identified the right machine for your project - but here's where things get interesting. The material you choose determines far more than just the look of your finished part. It affects machining time, tool wear, cost, and ultimately whether your component performs as intended in the real world.

Whether you're sourcing an aluminium cnc service for lightweight aerospace brackets or need a precision cnc machining inc partner for medical-grade titanium implants, understanding material properties helps you make smarter decisions and avoid costly mistakes.

Metals and Alloys for Structural Components

Metals remain the backbone of CNC manufacturing, and for good reason. They offer the strength, durability, and thermal resistance that critical applications demand. But not all metals machine equally - and choosing the wrong alloy can double your costs or compromise part performance.

Aluminum: Ask any cnc aluminum service provider, and they'll tell you aluminum alloys are their most-requested materials. According to WeNext, aluminum is easy to machine and cost-effective for mass production. Its excellent strength-to-weight ratio makes it ideal for aerospace, automotive, and consumer electronics. Common grades include 6061 (general purpose, good weldability) and 7075 (higher strength, comparable to some steels when heat-treated). The tradeoff? Pure aluminum lacks corrosion resistance - but anodizing creates a protective layer that solves this problem.

Steel Alloys: When your application demands serious strength, stainless steel, mild steel, alloy steel, and tool steel each serve distinct purposes. Stainless steel delivers excellent wear and corrosion resistance with great machinability - perfect for medical devices and food processing equipment. Mild steel (low carbon steel) offers economical solutions for general-purpose parts. Need higher hardness and thermal resistance? Alloy steels and tool steels handle demanding environments where other materials would fail.

Titanium: This biocompatible metal combines light weight with extreme heat resistance - without compromising strength. It's the go-to choice for medical implants, aircraft components, and high-performance jewelry. The catch? Titanium machines slowly and wears tools faster, meaning higher per-part costs.

Brass: Looking for economical parts with excellent electrical conductivity? Brass machines beautifully and works well for plumbing fittings, electronic hardware, and low-friction applications. Just remember it lacks the structural strength of steel or titanium.

Copper: Outstanding thermal and electrical conductivity make copper essential for heat exchangers, cooling systems, and electrical components. However, WeNext notes that copper is susceptible to chemical damage - keep it away from acids and ammonia solutions.

Engineering Plastics and Composites

When your design requires lightweight construction, chemical resistance, or electrical insulation, engineering plastics offer compelling alternatives to metal. Cnc manufacturing shops increasingly work with these materials as applications expand beyond traditional metal-dominated industries.

ABS (Acrylonitrile Butadiene Styrene): This common thermoplastic delivers good mechanical properties with high temperature resistance. CNC-machined ABS parts often serve as functional prototypes before committing to injection molding tooling - letting you test fit, form, and function without major investment.

PEEK (Polyether Ether Ketone): When you need plastic that can replace metal in demanding environments, PEEK delivers. Its excellent dimensional stability, chemical resistance, and impact strength make it suitable for aerospace components, medical devices, and high-temperature applications. Medical-grade PEEK is biocompatible, opening doors for implant applications.

POM (Delrin/Acetal): Need high precision with low friction? POM offers exceptional machinability, great dimensional stability, and minimal water absorption. It's perfect for gears, bearings, and precision components requiring tight tolerances.

Nylon: This versatile thermoplastic machines easily and provides excellent mechanical properties, impact strength, and chemical resistance. Nylon 6 and Nylon 66 are most common in CNC applications. One important consideration: nylon absorbs moisture, so proper storage matters.

PVC: Exceptional resistance to chemicals, corrosion, and flame makes PVC an economical choice for many industrial applications. It's affordable and readily available - a practical solution when exotic materials aren't necessary.

Matching Materials to Application Requirements

Sounds complex? It doesn't have to be. The key is focusing on what your part actually needs to do - then working backward to select materials that deliver those properties without overspending.

Consider these factors when evaluating options:

- Operating environment: Will your part face chemicals, extreme temperatures, or moisture? Materials like PEEK handle harsh conditions; nylon doesn't tolerate water well.

- Structural requirements: High-stress applications demand steel or titanium; decorative components might use brass or aluminum.

- Weight constraints: Aerospace and portable devices benefit from aluminum's strength-to-weight ratio or lightweight plastics.

- Budget realities: Titanium machines beautifully but costs significantly more than aluminum. Sometimes mild steel accomplishes the same goal at a fraction of the price.

| Material Type | Key Properties | Common Applications | Machining Considerations |

|---|---|---|---|

| Aluminum (6061, 7075) | Lightweight, corrosion resistant (anodized), excellent machinability | Aerospace brackets, automotive components, electronics enclosures | Fast cutting speeds, low tool wear, cost-effective |

| Stainless Steel (303, 304, 316) | High strength, corrosion resistant, durable | Medical devices, food processing, marine applications | Slower speeds, higher tool wear, may require coolant |

| Titanium (Grade 2, Grade 5) | Biocompatible, high strength-to-weight, heat resistant | Medical implants, aircraft components, performance parts | Slow machining, expensive tooling, higher cost per part |

| Brass (C360) | Excellent machinability, electrical conductivity, low friction | Fittings, connectors, decorative hardware | Very fast machining, produces fine chips, economical |

| PEEK | Chemical resistant, dimensionally stable, high temperature tolerance | Aerospace seals, medical components, electrical insulators | Requires sharp tools, generates heat, premium pricing |

| POM (Delrin) | Low friction, high precision, moisture resistant | Gears, bearings, precision mechanisms | Machines cleanly, holds tight tolerances, affordable |

| Nylon (6, 66) | Impact resistant, chemical resistant, good wear properties | Bushings, insulators, structural components | Absorbs moisture - control storage conditions |

The right material choice balances performance requirements against budget and timeline constraints. A reputable CNC partner will help you navigate these tradeoffs - and may suggest alternatives you haven't considered. Speaking of navigating decisions, how do you know if a shop actually delivers the quality their materials promise? That's where certifications and inspection standards come into play.

Quality Certifications and Inspection Standards to Look For

You've selected the right machine type and identified the perfect material. But here's a question that separates successful projects from costly disasters: how do you know the finished parts will actually meet your specifications?

The answer lies in quality control - and not all CNC machining shops approach it the same way. A high precision machine shop invests heavily in certifications, inspection equipment, and documented processes. Others cut corners. Understanding what to look for protects your investment and ensures consistent results, whether you're ordering ten prototypes or ten thousand production parts.

Industry Certifications That Matter

Certifications aren't just fancy logos on a website - they represent verified commitments to quality management systems that undergo rigorous third-party audits. When evaluating machine shops in new york or anywhere else, these credentials signal serious manufacturing capability:

- ISO 9001: The foundation of quality management. According to The Gateway Magazine, this globally recognized standard ensures organizations maintain robust quality systems covering customer focus, process improvement, and consistent product delivery. It applies across all industries and represents the minimum quality threshold serious buyers should expect.

- AS9100: Aerospace demands more. This certification builds on ISO 9001 by adding requirements specific to aviation, space, and defense industries - including product safety, configuration management, and verification of purchased products. If your parts fly, look for this certification.

- IATF 16949: Automotive supply chains operate under intense pressure for zero-defect production. This standard addresses automotive-specific requirements including production part approval processes, supplier quality management, and statistical techniques for process control.

- ITAR (International Traffic in Arms Regulations): Defense contractors must work with ITAR-registered facilities to handle controlled technical data and manufacture defense-related components. This isn't a quality certification per se - it's a legal requirement for certain projects.

Why do these distinctions matter? The Gateway Magazine notes that AS9100 certification requires more rigorous audits and documentation compared to ISO 9001 due to the higher scrutiny demanded by aerospace applications. Similarly, IATF 16949 enforces automotive-specific controls that general-purpose shops simply don't maintain.

Inspection and Measurement Standards

Certifications establish the framework - but inspection equipment and methods deliver actual verification. When touring a potential new york precision equipment provider or reviewing capabilities online, look for these quality control technologies:

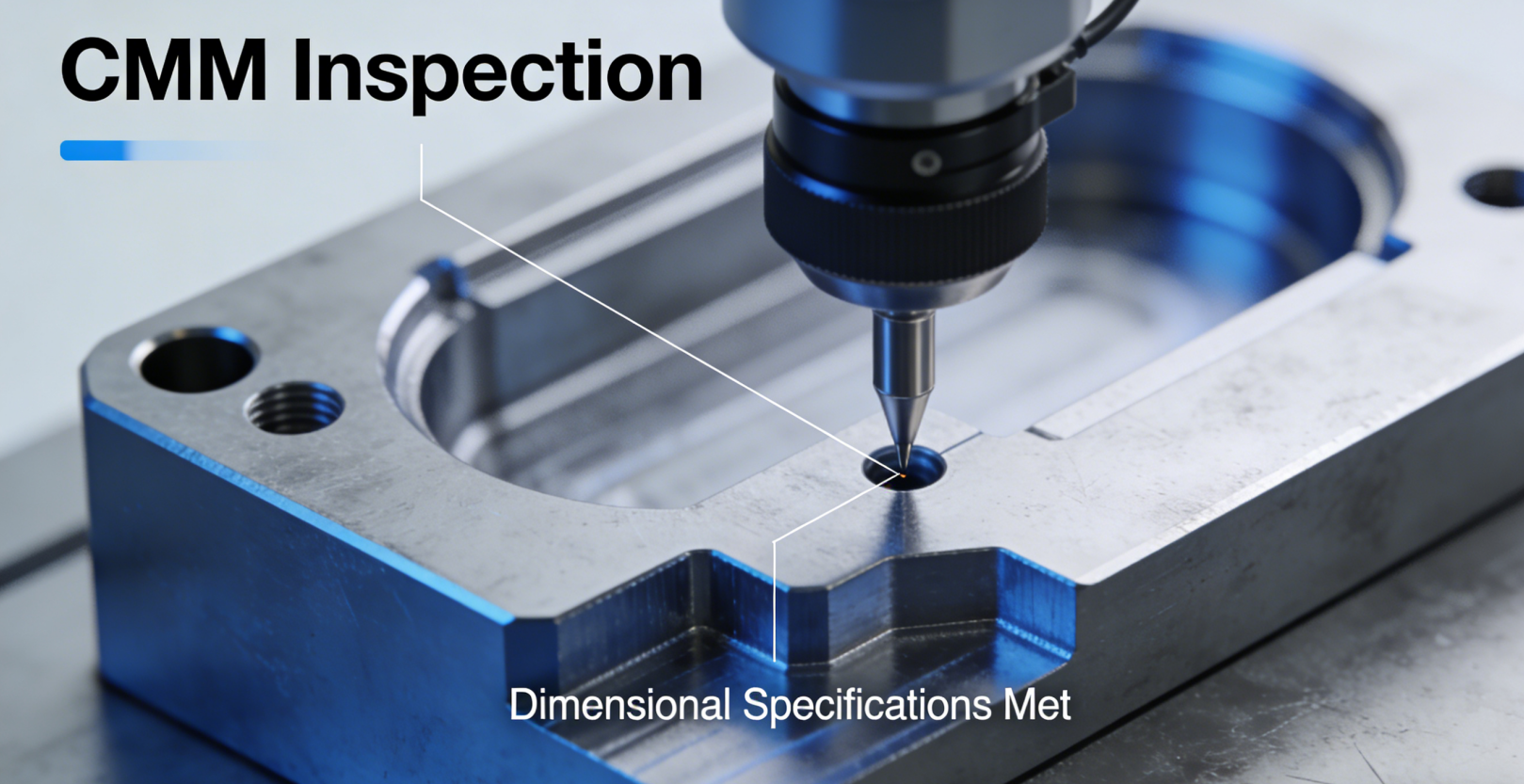

Coordinate Measuring Machines (CMM): These precision instruments use tactile probes or laser scanners to capture dimensional data with exceptional accuracy. According to FROG3D, CMMs provide precise and automated measurements for complex geometries and tight tolerances, enabling thorough 3D metrology and geometric verification. They're essential for validating critical features on complex parts.

Surface Finish Testing: Beyond dimensions, surface texture affects everything from friction behavior to fatigue life. Profilometers measure surface roughness in microinches or micrometers - ensuring machined surfaces meet specified Ra values. This matters especially for sealing surfaces, bearing interfaces, and aesthetic components.

Statistical Process Control (SPC): Here's where quality control becomes proactive rather than reactive. DataLyzer reports that when CMM data feeds directly into SPC systems, engineers can spot trends before parts go out of tolerance. Imagine a shaft measurement still within spec - but SPC reveals a gradual shift toward the upper limit. That trend signals tool wear or temperature drift. Without SPC, the change goes unnoticed until scrap or customer complaints appear.

Additional inspection methods include:

- Non-Destructive Testing (NDT): Ultrasonic testing and magnetic particle inspection assess internal material integrity without damaging parts

- Optical comparators: Project magnified part profiles against reference overlays for quick visual verification

- Hardness testing: Verify heat treatment results and material properties

- First Article Inspection (FAI): Comprehensive documentation proving the first production part meets all drawing requirements

Why Quality Control Protects Your Investment

Quality control isn't an expense - it's insurance against far costlier problems downstream. Consider what happens when defective parts escape detection: assembly line shutdowns, warranty claims, product recalls, or worse.

FROG3D emphasizes that early detection of defects through CNC machining quality control can prevent scrap and rework, leading to significant reductions in production costs. But the benefits extend beyond cost savings:

- Verification of accuracy: Confirm that machined parts meet specified dimensions, tolerances, and surface finishes before they ship

- Customer satisfaction: Consistently deliver products that meet or exceed expectations, building long-term supplier relationships

- Process improvement: Inspection data reveals opportunities for optimization - reducing variation and improving efficiency over time

- Traceability: Documented quality records support warranty claims, regulatory compliance, and root cause analysis when issues arise

Companies linking CMM and SPC systems reported reductions in manual entry time by up to 80% and improved reaction speed by 60%. That real-time visibility transforms quality control from a gate-keeping function into a continuous improvement engine.

The bottom line? When comparing potential manufacturing partners, dig deeper than quoted prices. Ask about certifications, inspection capabilities, and how they handle nonconforming parts. A shop with robust quality systems may cost slightly more per part - but delivers dramatically lower total cost when you factor in rejected parts, rework, and project delays. Understanding these quality foundations sets you up for the next critical decision: whether your project calls for prototyping or full production runs.

Prototyping Versus Production Runs and When to Choose Each

You've verified a shop's quality credentials - now comes a decision that can make or break your project budget: should you start with prototypes or jump straight to production? Get this wrong, and you'll either waste money on expensive tooling for a flawed design or struggle with prototype tools that can't handle the volumes you need.

The good news? Understanding the economics behind each approach helps you make confident decisions. According to BEC Group, rapid prototyping prioritizes speed and flexibility, getting you functional parts quickly so you can test, iterate, and refine your design. Full production tooling takes the opposite view - it's designed for efficiency, longevity, and consistent quality across thousands or millions of parts.

When Rapid Prototyping Saves Time and Money

Imagine investing $50,000 in production tooling, only to discover a fundamental design flaw during assembly. That's an expensive lesson many companies learn the hard way. Custom cnc work during the prototype phase catches these issues when fixes cost hundreds - not tens of thousands.

Prototyping shines when you're still learning about your product. Consider this approach when you need to:

- Validate design concepts before committing to expensive tooling

- Test fit, form, and function with physical parts rather than simulations

- Present tangible samples to stakeholders or investors

- Iterate quickly based on testing feedback

- Confirm manufacturability before scaling up

According to Zintilon, rapid prototyping slashes costs by enabling swift design iterations. CNC machining helps create parts quickly without investing in costly tooling for initial prototypes. This allows for quick testing and design adjustments, minimizing expensive rework later in production.

The financial math is straightforward: discovering a design flaw with a $5,000 prototype tool beats finding the same issue after investing $50,000 in production tooling. That's why startups and established manufacturers alike use prototyping to de-risk their development process.

Scaling from First Article to Full Production

So when does skipping prototypes make sense? Sometimes prototyping represents unnecessary delay rather than prudent caution. If your design is genuinely finalized and you're confident about market demand, investing directly in production tooling can significantly accelerate your route to market.

This works best when:

- Your design has been thoroughly tested through previous iterations

- You have confirmed orders or strong market validation

- Time to market is critical for competitive reasons

- The product is an evolution of existing proven designs

Here's what changes between prototype and production runs. Zintilon notes that setup costs - machine setup, tool changes, and fixture preparation - get spread across a very small number of units during prototyping (often 1-20), leading to high per-unit fixed costs. The same expensive setup cost, when spread across 1,000 units, becomes very affordable per unit.

Custom machine shops working on production runs also optimize differently. Prototypes may use general-purpose fixturing and less-optimized tool paths since the focus is functional validation. Production runs feature meticulously optimized tool paths for speed and efficiency, specialized dedicated fixturing, and standardized procedures that minimize variations.

Economic Breakpoints for Different Quantities

Where exactly do the economics shift? According to Qoblex research, batch production becomes more cost-effective than job shop manufacturing when order quantities exceed 50 units due to shared setup costs across identical items. The economic break-even analysis reveals batch production becomes advantageous when monthly volumes fall between 500-5,000 units for most consumer goods.

Several factors influence your specific breakpoint:

- Setup cost distribution: A $500 setup divided by 10 parts adds $50 per unit; divided by 1,000 parts, it's only $0.50

- Material purchasing power: Bulk material purchases result in 10-30% discounts compared to small prototype quantities

- Process optimization: Production runs allow operators to develop efficiency through repetition, reducing cycle times

- Quality control methods: Prototypes often need 100% inspection; production can use statistical sampling that reduces inspection time and cost

- Tool wear economics: Spreading tooling costs across larger quantities dramatically reduces per-part expenses

The choice isn't always binary. Modern industrial machine shops near me and across the globe increasingly offer progressive tooling development - starting with rapid prototype tools, then upgrading specific components as confidence grows. This hybrid approach lets you validate designs quickly while building toward production capability.

Consider total project costs rather than just initial tooling investment. Factor in design changes, potential delays, and lost market opportunities alongside obvious tooling expenses. A slightly higher upfront investment in proper prototyping often delivers the lowest total cost when you account for avoided mistakes and optimized production processes downstream.

With your prototyping-versus-production strategy mapped out, the next step is ensuring you can communicate your requirements effectively. That means preparing the right files and specifications to get accurate quotes from potential manufacturing partners.

How to Prepare Your Files and Get Accurate Quotes

You've identified your prototyping needs and selected materials - but here's where many projects stall: the quote request. Submit incomplete files, and you'll wait days for clarification requests. Provide the wrong format, and the shop can't even open your design. Getting this step right accelerates your timeline and ensures pricing reflects what you actually need.

According to JLCCNC, accuracy starts at the file level. CNC machines follow instructions down to the fraction of a millimeter, so if your CAD data is incomplete, in the wrong format, or overly complex, you can end up with costly delays and unexpected revisions. Whether you're working with a cnc machining new york provider or sourcing globally, these preparation standards remain consistent.

Essential File Formats and Drawing Standards

Not all CAD formats work for CNC machining. The shop needs geometry data that their CAM software can interpret accurately - and mesh-based formats designed for 3D printing simply won't cut it.

Best formats for CNC machining:

- STEP (.step/.stp): The industry standard. STEP files preserve solid model geometry, surface data, and feature relationships. Most shops prefer this format because it imports cleanly across different CAM systems.

- IGES (.igs/.iges): An older but widely compatible format. Use IGES when STEP isn't available, though some complex surface data may translate less precisely.

- Parasolid (.x_t/.x_b): Native to SolidWorks and some other CAD systems. Many machine shops accept Parasolid files directly.

- Native CAD files: Some shops accept SolidWorks, Fusion 360, or Inventor files directly - but confirm compatibility before assuming.

Formats to avoid: STL and OBJ files work for 3D printing but break smooth curves into tiny triangles. This creates problems for CNC toolpath generation where precise curve definitions matter. According to JLCCNC, mesh-based formats simply don't work for CNC because they lose the mathematical accuracy that defines manufacturable geometry.

Beyond 3D models, you'll need technical drawings. A PDF dimensional drawing with GD&T (Geometric Dimensioning and Tolerancing) communicates what the 3D model cannot: which dimensions are critical, what tolerances apply, surface finish requirements, and material specifications. Think of the 3D file as showing shape - the drawing tells the shop what matters most.

Communicating Tolerances and Critical Dimensions

Here's a common mistake: applying unnecessarily tight tolerances across entire parts. According to HM Making, many engineers apply ±0.01 mm tolerances to non-functional features, which contradicts good design for manufacturability practice. Tight tolerances affect tool selection, inspection time, and machining speed - driving up costs without improving function.

Instead, prioritize only the dimensions that matter. Ask yourself:

- Which surfaces mate with other components?

- Where do fits and clearances need precise control?

- What features are purely cosmetic or non-critical?

Apply tight tolerances (±0.025 mm or tighter) only to functional interfaces. Let everything else default to standard machining tolerances (typically ±0.1 mm for non-critical features). This approach aligns with established manufacturing principles and dramatically reduces per-part costs.

When documenting tolerances, use proper GD&T symbols rather than vague notes. Clear callouts for position, perpendicularity, flatness, and surface finish eliminate ambiguity. If a machine shop queens ny or anywhere else has to guess your intent, you'll get either conservative (expensive) pricing or parts that don't meet your actual needs.

Information That Speeds Up Your Quote

Want faster, more accurate quotes? Provide everything the shop needs upfront. According to HM Making, the most common reason RFQs stall is incomplete documentation. Missing tolerances, undefined threads, absent surface finish requirements, and inconsistent dimensions create uncertainty that forces suppliers to pause and request clarification.

Follow this step-by-step checklist before submitting your quote request:

- Export your 3D model in STEP format (preferred) or IGES. Verify the file opens correctly before sending.

- Create a PDF drawing with all critical dimensions, GD&T callouts, and tolerance specifications clearly marked.

- Specify the exact material - not just "aluminum" but "6061-T6" or "7075-T651." Include any required material certifications.

- Define surface finish requirements using Ra values (e.g., Ra 1.6 μm) for critical surfaces. Note any post-machining treatments like anodizing or plating.

- Document thread specifications completely - thread size, pitch, class of fit, and depth for blind holes.

- State your quantity requirements - prototype quantities, pilot run volumes, and projected production needs.

- Include delivery timeline expectations - when you need parts and whether expedited options should be quoted.

- Note any inspection requirements - FAI reports, CMM data, material certifications, or specific quality documentation.

- Add revision history - ensure the shop knows they're quoting your latest design version.

Missing any of these elements? Expect delays. A cnc new york provider - or any professional shop - will pause quoting until they have complete information. That back-and-forth can add days to your timeline.

Complete RFQ packages include STEP files, PDF drawings with GD&T, material and surface finish details, quantities, delivery expectations, and notes for assembly or secondary operations. Incomplete packages lacking tolerances, material specs, or quantity information force suppliers to pause and request clarification.

The effort you invest upfront pays dividends throughout your project. Clean files, clear tolerances, and complete specifications don't just accelerate quotes - they reduce manufacturing errors and ensure the parts you receive match your design intent. With your documentation prepared, the next consideration is understanding how these specifications translate into actual pricing.

Understanding CNC Machining Costs and Pricing Factors

You've prepared your files and submitted a quote request - now comes the moment of truth. When that pricing comes back, will it make sense? Or will you find yourself staring at numbers wondering where the money actually goes?

Here's what most buyers don't realize: CNC machining costs follow a predictable formula. According to RapidDirect, the equation breaks down simply: Total Cost = Material Cost + (Machining Time × Machine Rate) + Setup Cost + Finishing Cost. Understanding each component helps you spot opportunities to optimize pricing without sacrificing quality - whether you're working with a machine shop brooklyn ny provider or sourcing from across the country.

Material and Machine Time Calculations

Two factors dominate most CNC quotes: what you're cutting and how long the machine runs.

Material costs go beyond simple per-pound pricing. According to U-Need, the total cost is composed of factors such as grade and availability of the raw material and the machining properties. A part designed around standard stock sizes wastes less material than one requiring oversized billets. Exotic alloys like titanium or Inconel command premium prices - but even within common materials, availability matters. Aluminum 6061 typically costs less than 7075 because it's more readily available.

Want to reduce material costs? Design parts that fit standard bar or plate dimensions. Odd shapes force shops to purchase larger blanks, and CNC machining - as a subtractive process - can waste 30% to 70% of the original blank volume depending on part complexity.

Machine time is where complexity really hits your wallet. Every minute the spindle runs costs money - and different machines have vastly different hourly rates. According to Geomiq, 5-axis CNC machines are more expensive to run than 3-axis counterparts due to higher equipment costs, specialized tooling, and the skill required to operate them.

Machine rates typically range from:

- 3-axis CNC mills: $40-75 per hour

- CNC lathes: $35-65 per hour

- 5-axis mills: $75-150 per hour

- Wire EDM: $50-100 per hour

The same part machined on a 3-axis mill versus a 5-axis machine can see dramatically different pricing - sometimes 2-3x higher for the advanced equipment. Choose machinery that matches your actual requirements rather than defaulting to maximum capability.

How Complexity Affects Your Bottom Line

Ever wonder why two parts of similar size quote at wildly different prices? Complexity is usually the culprit.

According to RapidDirect, design complexity is the strongest driver of machining time, and machining time is typically the largest portion of CNC cost. Features that spike your quote include:

- Deep pockets and cavities: Require multiple passes with progressively smaller tools

- Thin walls: Force slower cutting speeds to prevent deflection and vibration

- Tight internal corners: Small-radius end mills cut slowly and wear faster

- Undercuts: Often require 5-axis machining or specialized tooling

- Tight tolerances: Demand slower feeds, careful measurement, and sometimes multiple finishing passes

Tolerances deserve special attention. Geomiq notes that achieving tight tolerances requires meticulous attention to detail, increasing machining time and effort. The default tolerance of ±0.127 mm is already quite accurate and sufficient for most applications. Tighter specifications - ±0.025 mm or below - require slower cutting, careful temperature control, and comprehensive inspection. Each step adds cost.

Similarly, surface finish requirements scale in expense. The standard 3.2 μm Ra finish comes included. According to Geomiq, smoother finishes of 1.6 μm, 0.8 μm, and 0.4 μm Ra cost an additional 2.5%, 5%, and up to 15% above the base price, respectively - with the smoothest requiring post-machining polishing.

Volume Discounts and Setup Cost Distribution

Here's where quantity changes everything. A machine shop in queens ny - or anywhere else - incurs significant fixed costs before cutting a single chip: CAM programming, fixture preparation, tool setup, and first-article verification. These expenses remain constant whether you order one part or one thousand.

According to RapidDirect, a $300 setup fee adds $300 to a 1-piece order but only $3 per part in a 100-piece batch. The math is dramatic: prototypes are expensive precisely because setup costs concentrate on few units.

Real-world pricing demonstrates this clearly. Geomiq reports that a part costing £134 for one unit drops to £38 per unit at 10 pieces and £13 per unit at 100 pieces - representing 70% and 90% cost reductions respectively.

Beyond setup distribution, larger orders unlock additional savings:

- Material bulk discounts: Purchasing larger quantities reduces per-unit material costs by 10-30%

- Process optimization: Operators develop efficiency through repetition, reducing cycle times

- Reduced inspection overhead: Statistical sampling replaces 100% inspection at higher volumes

- Tooling amortization: Specialized cutters and fixtures spread across more parts

| Cost Factor | Impact Level | How to Optimize |

|---|---|---|

| Material Selection | High | Choose machinable materials (aluminum, brass) over difficult alloys; design around standard stock sizes |

| Part Complexity | High | Simplify geometry; avoid deep pockets, thin walls, and unnecessary features; increase internal corner radii |

| Tolerances | High | Apply tight tolerances only to functional features; use standard ±0.127 mm elsewhere |

| Machine Type | Medium-High | Design for 3-axis machining when possible; avoid features requiring 5-axis unless functionally necessary |

| Order Quantity | High | Batch orders to spread setup costs; consider 50-100 minimum quantities for best per-unit pricing |

| Surface Finish | Medium | Specify standard 3.2 μm Ra for non-critical surfaces; reserve fine finishes for visible or functional areas |

| Post-Processing | Medium | Limit finishing to functional requirements; anodizing and plating add 15-40% to base machining cost |

| Setup Complexity | Medium | Design parts machinable in single setups; avoid features requiring custom fixtures or multiple repositioning |

Understanding these cost drivers empowers you to make informed tradeoffs. Sometimes paying more for 5-axis capability saves money overall by eliminating secondary operations. Other times, a minor design tweak cuts machining time in half. The key is knowing which levers to pull - and working with manufacturing partners who can suggest optimizations you haven't considered. Speaking of partnerships, CNC machining rarely stands alone. The next consideration is how complementary services can enhance your project outcomes.

Complementary Services That Enhance CNC Machining Projects

CNC machining delivers exceptional precision - but it's rarely the only manufacturing process your project needs. Imagine machining a beautiful aluminum housing, only to realize you need sheet metal brackets, laser-cut panels, or rapid prototypes to complete the assembly. Suddenly, you're coordinating with three different vendors, managing multiple timelines, and watching lead times stretch.

The reality? Most successful products combine multiple manufacturing technologies. According to Microrelleus, modern manufacturing facilities use different technologies to ensure each project is delivered with the appropriate and most efficient solution to reach its purpose. Understanding how complementary services work alongside CNC machining helps you streamline production and reduce overall project complexity.

Laser Cutting and Sheet Metal Integration

When your design calls for flat components, enclosures, or brackets made from sheet material, laser cutting becomes an essential companion to CNC machining. While mills and lathes excel at three-dimensional geometries from solid blocks, lasers cut intricate two-dimensional profiles from sheet stock with remarkable speed and accuracy.

Think about a typical electronics enclosure project. The machined housing might require CNC milling for complex mounting features and threaded bosses - but the cover panel, ventilation grilles, and mounting brackets are better suited for laser cutting. Combining both processes often delivers faster turnaround and lower costs than forcing everything through one technology.

Laser cutting capabilities you might encounter include:

- CO2 lasers: Versatile cutting for metals, plastics, wood, and composites - common in general fabrication shops

- Fiber lasers: Superior speed and edge quality on thin metals, particularly stainless steel and aluminum

- Femtosecond and nanosecond lasers: According to Microrelleus, femtosecond lasers deliver absolutely burr-free engraving with high-quality surface finishing and excellent tolerances over any 3D shape - ideal for micro-engraving and surface functionalization

Beyond cutting, many facilities integrate bending, welding, and finishing into their sheet metal operations. This means your laser-cut brackets can be bent to shape, welded into assemblies, and powder-coated - all before shipping alongside your CNC-machined components.

When 3D Printing Complements CNC Machining

Here's a question worth considering: why choose between 3D printing and CNC machining when you can leverage both? According to AMFG, the CNC machining industry has seen remarkable growth, with its market value already exceeding $81 billion - and projections indicate this sector will surpass the $126 billion mark by 2028. Yet 3D printing continues capturing headlines. The smart approach? Combine them strategically.

The technologies serve different purposes brilliantly:

- Rapid iteration: AMFG reports that creating prototypes using CAD files through 3D printing is much faster than producing tools for injection molding - letting you test and refine designs before committing to CNC production

- Design flexibility: 3D printing enables geometric freedom impossible with subtractive methods - internal lattices, organic shapes, and consolidated assemblies

- Cost-effective prototyping: Print early-stage prototypes cheaply, then machine final versions from production-intent materials

- Hybrid finishing: Print complex near-net shapes, then CNC machine critical surfaces to tight tolerances

Why does this combination work so well? Precision requirements tell the story. According to AMFG, current 3D printers can print parts with tolerances of around 0.1 mm, while CNC machines achieve accuracy of 0.025 mm. For many applications, printed parts need secondary machining to meet functional requirements - particularly mating surfaces, bearing bores, and threaded features.

The workflow makes practical sense: engineers create CAD files for 3D printing, make improvements based on physical testing, then machine the refined design for production. BAE Systems exemplifies this approach, 3D printing 30% of the parts for its new Tempest fighter jet to reduce production costs and lead times.

Complete Manufacturing Solutions Under One Roof

Coordinating multiple vendors creates headaches you probably don't need. Misaligned timelines, communication gaps, and finger-pointing when problems arise - these issues multiply with each additional supplier in your chain. Facilities offering integrated manufacturing capabilities eliminate much of this friction.

According to Microrelleus, comprehensive manufacturing facilities complement CNC milling with die-sinking EDM - manufacturing engraved electrodes and proceeding with EDM for aluminum stamping tools, mold cavities, or other applications. This integration extends to SLS 3D printers, wire cut EDM, hole-drilling EDM, lathes, and grinders.

EDM (Electrical Discharge Machining) deserves special attention. When your design features hardened tool steels, intricate internal geometries, or sharp internal corners that conventional cutting tools can't reach, EDM becomes essential. Wire EDM cuts complex profiles using electrical sparks rather than mechanical contact - perfect for dies, molds, and precision components where cutting forces would distort the workpiece.

Complementary services and their ideal applications:

- Die-sinking EDM: Complex mold cavities, hardened materials, intricate internal features requiring non-contact machining

- Wire EDM: Precision profiles in hard materials, stamping dies, components with sharp internal corners

- CNC grinding: Ultra-tight tolerances on hardened surfaces, bearing races, gauge blocks

- 3D printing (SLS/SLA): Rapid prototypes, design validation, complex geometries before production commitment

- Laser cutting: Sheet metal components, flat profiles, high-volume panel production

- Heat treatment: Hardening, tempering, stress relief for machined components

- Surface finishing: Anodizing, plating, powder coating, polishing

For automotive supply chains, this integration proves particularly valuable. Certified facilities like Shaoyi Metal Technology offer comprehensive solutions spanning complex chassis assemblies to custom metal bushings - addressing the full spectrum of automotive component requirements from prototyping through mass production. This approach eliminates supplier coordination headaches while maintaining consistent quality standards across interconnected components.

The quality control advantages compound when services consolidate under one roof. According to Microrelleus, integrated facilities employ confocal and focus variation microscopes, optical microscopes, and profile projectors for quality verification - ensuring inspection standards remain consistent whether components came from CNC mills, EDM, or laser systems.

The fusion of 3D printing and CNC machining represents a dynamic approach that holds great promise for manufacturing - offering advantages in speed, cost reduction, tolerance accuracy, and high-volume production.

Consider total project requirements when evaluating potential manufacturing partners. A shop offering only CNC machining might deliver excellent parts - but if your assembly requires laser-cut brackets, EDM-processed features, and surface finishing, you'll spend significant time coordinating additional vendors. Facilities offering integrated solutions reduce this coordination burden while often improving quality through unified process control. With these complementary capabilities in mind, the final consideration becomes selecting the right manufacturing partner for your specific project needs.

Choosing the Right CNC Machining Partner for Your Project

You've mapped out your manufacturing requirements, prepared your files, and understand cost drivers - but here's the decision that ultimately determines project success: which CNC machining shop actually deserves your business? Get this wrong, and you'll face missed deadlines, quality issues, and frustrating communication breakdowns. Get it right, and you gain a manufacturing partner who anticipates problems before they occur.

According to CNC Solutions, selecting a suitable CNC machining facility requires careful consideration of precision capabilities, quality control measures, communication responsiveness, and industry experience. Whether you're searching for a machine shop nyc provider or evaluating cnc machine companies near me across the country, these evaluation criteria remain universally applicable.

Matching Shop Capabilities to Your Requirements

Not every shop handles every job equally well. A facility specializing in high-volume automotive components may struggle with one-off aerospace prototypes - and vice versa. The key? Match your specific requirements to demonstrated capabilities.

Start with equipment alignment. Does the shop possess the machinery your part actually requires? According to CNC Solutions, advanced machinery and software play a crucial role in ensuring efficiency while producing high-quality machine parts at speed. A forward-thinking provider continuously invests in equipment upgrades to stay competitive and meet evolving customer demands.

Consider these equipment-related questions:

- Machine types: Does the shop have 5-axis mills if your design requires them? Multi-axis lathes with live tooling for complex turned parts?

- Capacity and size limits: Can their machines accommodate your part dimensions and weights?

- Material experience: According to CNC Solutions, shops typically handle a wide range of materials - aluminum, steel, plastics, composites, ceramics - but experience with your specific material ensures optimal results

- Tolerance capabilities: Can they consistently achieve the precision your design demands?

Certifications serve as reliable capability indicators. IATF 16949 certification, for instance, signals automotive-grade quality systems with rigorous process controls. Facilities like Shaoyi Metal Technology demonstrate how transparent capability presentation - detailing equipment, certifications, and production capacity - helps buyers quickly assess fit. Their combination of IATF 16949 certification and Statistical Process Control (SPC) exemplifies the quality framework serious manufacturing partners maintain.

Evaluating Experience and Track Record

Equipment matters - but experience operating that equipment on projects similar to yours matters more. According to CNC Solutions, a shop with long-standing experience has likely perfected its techniques and implemented effective methods that generate superior CNC machined parts. Shops specializing in specific areas such as aerospace or automotive components offer valuable insights and tailored solutions.

How do you verify experience claims? Past client testimonials provide honest insight into collaboration success. You can often find these on company websites or third-party platforms like Google Reviews. Don't hesitate to request references from clients with projects similar to yours - speaking directly reveals firsthand information about working relationships.

The longevity of a CNC machining shop indicates reliability and industry reputation. According to CNC Solutions, a well-established company demonstrates stability and commitment to delivering consistent quality over time while adapting to new technologies and market demands.

Look for these experience indicators:

- Industry-specific expertise: Aerospace, automotive, medical, and defense sectors each have unique requirements

- Portfolio examples: Can they show parts similar to yours in complexity and material?

- Problem-solving track record: How have they handled challenging projects or unexpected issues?

- Technology adoption: Do they invest in automation, new equipment, and process improvements?

The Value of Responsive Communication

Technical capability means nothing if you can't get answers when you need them. According to CNC Solutions, clear communication between you and your chosen CNC machining shop is critical throughout your project's duration. Assess their responsiveness to inquiries - this indicates customer service skills that foster collaboration during production phases.

Why does communication matter so much? Design changes, material availability issues, and inspection questions arise throughout manufacturing. Timely communication prevents delays and additional costs. If problems surface during production, do you want to wait three days for a response - or get real-time updates that allow immediate course correction?

Evaluate communication quality from initial contact:

- Quote turnaround: How quickly do they respond to RFQ submissions?

- Question handling: Do they provide thorough answers or brush off technical inquiries?

- Proactive updates: Will they notify you of potential issues before they become problems?

- Communication channels: Do they offer regular email updates, real-time messaging, or project portals?

Geographic considerations intersect with communication. Machine shops in syracuse ny, nyccnc-area facilities, or providers anywhere nearby offer certain advantages: easier site visits, faster shipping, and overlapping business hours. However, don't let proximity override capability - a responsive distant shop often outperforms an unresponsive local one.

Lead time reliability also reflects communication culture. According to CNC Solutions, the ability of a machine shop to meet deadlines significantly impacts project success. Facilities demonstrating one-day lead times for urgent requirements - like Shaoyi Metal Technology's rapid prototyping capabilities - signal the operational agility and communication infrastructure needed to handle time-sensitive projects.

Your Complete Evaluation Checklist

Before committing to any manufacturing partner, work through this systematic assessment:

- Verify certifications: Confirm ISO 9001 as a baseline; look for AS9100 (aerospace), IATF 16949 (automotive), or ITAR registration (defense) based on your industry requirements

- Assess equipment capabilities: Ensure they have appropriate machine types, sizes, and accuracy levels for your specific parts

- Confirm material experience: Ask specifically about your materials - including any challenges they've encountered and how they address them

- Request references: Speak with clients who've completed similar projects; ask about quality consistency, communication, and problem resolution

- Evaluate quality systems: Look for CMM inspection, Statistical Process Control (SPC), and documented quality procedures beyond basic certification

- Test communication responsiveness: Note how quickly and thoroughly they respond to your initial inquiries - this previews your ongoing experience

- Review lead time capabilities: Understand their typical turnaround and flexibility for expedited orders

- Examine scalability: Can they handle your prototype needs today and production volumes tomorrow?

- Confirm pricing transparency: Do they provide detailed cost breakdowns or just bottom-line quotes?

- Assess complementary services: Consider whether integrated finishing, assembly, or secondary operations reduce coordination burden

According to the Machine Shop Directory, comprehensive supplier assessment frameworks have prevented over $50 million in supplier-related losses. Their 47-point checklist emphasizes that any critical evaluation item marked as fail should disqualify the supplier - protecting your investment from preventable failures.

Building Long-Term Manufacturing Partnerships

The best supplier relationships transcend individual projects. When you find a CNC machining partner who consistently delivers quality, communicates proactively, and understands your applications, that relationship becomes a competitive advantage.

Long-term partnerships offer tangible benefits:

- Institutional knowledge: Your partner learns your standards, preferences, and common requirements - reducing errors and setup time

- Priority scheduling: Established customers often receive preferential treatment during capacity crunches

- Collaborative problem-solving: Trusted partners suggest improvements rather than just executing drawings

- Stable pricing: Ongoing relationships reduce the pricing volatility that comes with constantly switching suppliers

How do you nurture these relationships? Communicate clearly, pay on time, and provide feedback - both positive and constructive. Share your roadmap so partners can anticipate future needs. Treat your manufacturing partners as extensions of your own team rather than interchangeable vendors.

According to CNC Solutions, a reputable shop will stand behind its work by offering guarantees or warranties on quality - including material certifications, dimensional inspection reports, or replacement policies if defects are found. These commitments signal the confidence that comes from proven processes and the partnership mindset that enables long-term collaboration.

The right CNC machining partner combines technical capability, quality systems, responsive communication, and scalable capacity - delivering not just parts, but manufacturing confidence that accelerates your entire product development cycle.

The evaluation criteria outlined here apply whether you're assessing your first potential supplier or auditing an existing relationship. Markets evolve, technologies advance, and your own requirements change over time. Periodic reassessment ensures your manufacturing partnerships continue serving your needs - transforming supplier management from a procurement headache into a genuine competitive advantage.

Frequently Asked Questions About CNC Machining Shops

1. What does CNC machine shop mean?

A CNC machine shop is a specialized manufacturing facility equipped with computer-controlled machines that cut, shape, and finish materials with exceptional accuracy. These shops use Computer Numerical Control technology where pre-programmed digital instructions guide the machines rather than manual operation. Core components include CNC machines (mills, lathes, routers), CAD/CAM software for design and toolpath generation, skilled operators for setup and oversight, and quality control systems like CMMs for verification. This automation enables tolerances as tight as ±0.005 mm, making CNC shops essential for producing precision parts across aerospace, automotive, medical, and electronics industries.

2. What is the hourly rate for a CNC machine?

CNC machine hourly rates vary significantly based on equipment type and complexity. Typical ranges include: 3-axis CNC mills at $40-75 per hour, CNC lathes at $35-65 per hour, 5-axis mills at $75-150 per hour, and Wire EDM at $50-100 per hour. The same part machined on different equipment can see dramatically different pricing - sometimes 2-3x higher for advanced 5-axis machines due to higher equipment costs, specialized tooling, and operator skill requirements. Choosing machinery that matches your actual requirements rather than defaulting to maximum capability helps optimize costs.

3. How much does CNC machining cost?

CNC machining costs follow a formula: Total Cost = Material Cost + (Machining Time × Machine Rate) + Setup Cost + Finishing Cost. Key factors include material selection (exotic alloys cost more), part complexity (deep pockets, thin walls, tight tolerances increase time), and order quantity. Setup costs of $300-500 add significantly to single-piece orders but become negligible at volume. A part costing $134 for one unit might drop to $38 per unit at 10 pieces and $13 at 100 pieces. IATF 16949-certified facilities like Shaoyi Metal Technology offer competitive pricing with rapid prototyping to production scalability.

4. What certifications should I look for in a CNC machining shop?

Essential certifications depend on your industry: ISO 9001 serves as the quality management baseline for all industries. AS9100 is required for aerospace applications, adding requirements for product safety and configuration management. IATF 16949 addresses automotive supply chain needs with zero-defect production standards and Statistical Process Control. ITAR registration is legally required for defense-related components. Beyond certifications, look for inspection capabilities including CMM measurement, surface finish testing, and documented first article inspection processes. These credentials represent verified commitments to quality systems that undergo rigorous third-party audits.

5. How do I prepare files for getting accurate CNC machining quotes?

Submit STEP files (preferred) or IGES format for 3D models - avoid mesh-based STL files that lose mathematical accuracy. Include PDF drawings with GD&T callouts specifying critical dimensions, tolerances, and surface finish requirements using Ra values. Document the exact material grade (e.g., '6061-T6' not just 'aluminum'), complete thread specifications, quantity requirements, delivery timeline, and any inspection documentation needs. Apply tight tolerances only to functional features while letting non-critical dimensions default to standard tolerances. Complete RFQ packages prevent delays from clarification requests and ensure pricing reflects your actual requirements.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —