CNC Machining Services Decoded: From Material Pick To Final Part

What CNC Machining Services Actually Deliver

Ever wondered how a digital design transforms into a physical component you can hold in your hand? That's exactly what CNC machining services accomplish every day across thousands of manufacturing facilities worldwide.

CNC machining is a computer-controlled manufacturing process where programmed software directs the movement of cutting tools to remove material from raw stock, creating precision parts with repeatable accuracy.

The term "CNC" stands for Computer Numerical Control - essentially, it means a computer is calling the shots instead of a human operator manually guiding each cut. This distinction matters more than you might think, and understanding it helps you make smarter decisions about your manufacturing projects.

From Digital Design to Physical Part

The journey from concept to finished component follows a straightforward path. First, engineers create a detailed 3D model using CAD (Computer Aided Design) software like AutoCAD or SolidWorks. This digital blueprint contains every dimension, tolerance, and feature specification your part requires.

Next, CAM (Computer Aided Manufacturing) software translates that 3D model into G-code - the programming language CNC machines understand. Think of G-code as a detailed set of instructions telling the machine exactly where to move, how fast to cut, and when to change tools. According to CNC Cookbook, this standardized programming language controls everything from tool motions to spindle speed and coolant activation.

Once the program loads into the machine, the operator sets up the raw material and tooling. Then machining begins - the cutting tools precisely remove material until your finished part emerges.

The Computer-Controlled Difference

Why does computer control matter so much? Consider what happens with manual machining: a skilled machinist turns handwheels to guide cutting tools across a workpiece. Their expertise determines the outcome, but human factors inevitably introduce variations.

CNC fabrication eliminates these variables. The computer-controlled servos execute identical movements every single time, whether you're making one part or one thousand. This consistency delivers several distinct advantages:

- Superior precision: High-end CNC machines achieve micron-level accuracy - tolerances as tight as ±0.001 inches (±0.025 mm)

- Continuous operation: These machines work 24/7 without fatigue, dramatically increasing production capacity

- Complex geometries: CNC turning and milling can create intricate shapes impossible to achieve manually

- Reduced material waste: Optimized toolpaths maximize raw material usage and minimize scrap

The precision of machined parts depends largely on machine quality, but even mid-range CNC equipment outperforms manual methods for most applications.

Why Precision Manufacturing Matters

You'll notice precision comes up repeatedly when discussing these services - and for good reason. Automotive components, medical implants, and aerospace parts often require tolerances that simply cannot be achieved through conventional methods.

Imagine an engine component where parts must fit together with clearances measured in thousandths of an inch. Manual machining might get you close, but CNC parts deliver the consistency needed for reliable performance across thousands of identical units.

This repeatability creates scalability that manual processes cannot match. Whether your project calls for rapid prototyping or high-volume production, the same program produces identical results every run. For manufacturers, this means predictable quality, reduced inspection requirements, and fewer rejected parts - all factors that ultimately affect your bottom line.

Core CNC Processes and When to Use Each

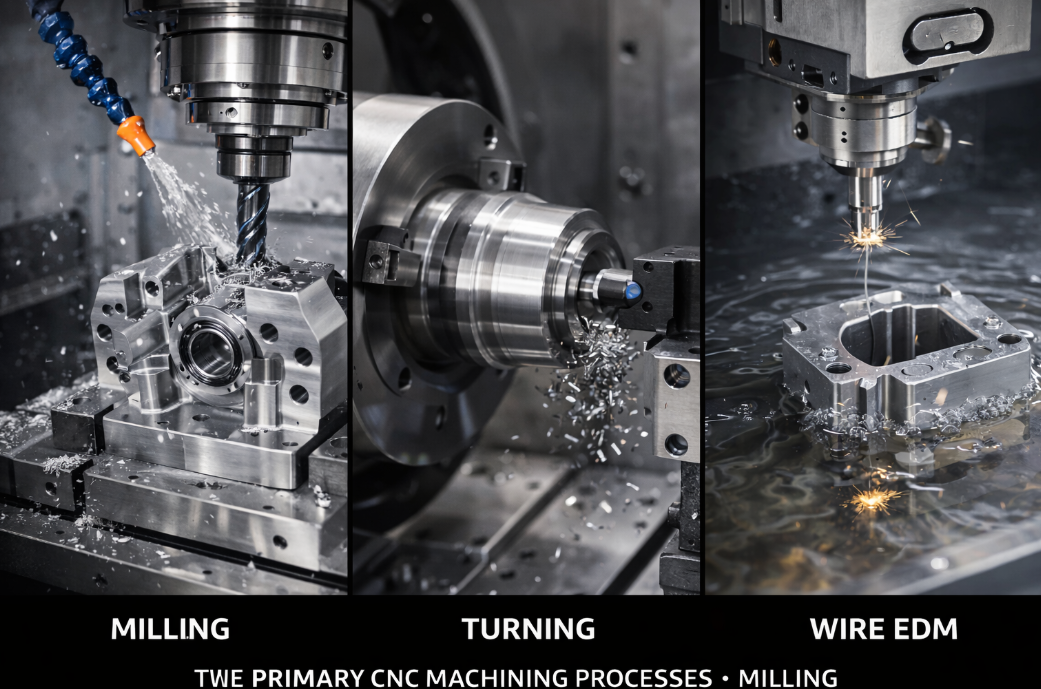

Now that you understand how computer control transforms digital designs into physical parts, let's explore the specific processes that make it happen. Three primary methods form the backbone of precision manufacturing - each with distinct strengths that determine when you should choose one over another.

CNC Milling Explained

Picture a rotating cutting tool approaching a stationary block of material. That's CNC milling in its simplest form. The spindle-mounted cutter spins at high speeds while moving across the workpiece in multiple directions, carving away material to reveal your finished part.

What makes milling so versatile? The cutting tool can approach from virtually any angle, creating complex 3D shapes, flat surfaces, pockets, and intricate patterns. Whether you need a simple bracket or a sophisticated housing with multiple features, milling handles it all.

Key characteristics of CNC milling include:

- Stationary workpiece: The material stays fixed while cutting tools move around it

- Multi-directional cutting: Tools can engage from top, sides, and various angles

- Feature flexibility: Slots, holes, contours, and 3D surfaces all possible in one setup

- Material range: Works with metals, plastics, composites, and wood

When a CNC cutting machine performs milling operations, it typically uses end mills, face mills, or ball-nose cutters depending on the geometry required. A cnc milled component might feature everything from simple drilled holes to complex sculptured surfaces - all produced in a single program.

How CNC Turning Works

CNC turning flips the script. Instead of a rotating tool approaching stationary material, the workpiece itself spins while cutting tools remain relatively fixed. This approach excels at creating cylindrical components - shafts, pins, bushings, and anything with rotational symmetry.

Think about how a potter shapes clay on a wheel. CNC turning service providers use similar principles, but with precision-ground cutting tools instead of hands. The workpiece rotates at controlled speeds while the tool moves along its length and toward its center, shaping the material into your specified profile.

According to Raycool Group, CNC turning typically operates on two primary axes - X and Z - enabling the cutting tool to move along the workpiece length and control diameter with exceptional accuracy. Modern CNC turning services often incorporate live tooling capabilities, adding milling and drilling operations without removing the part from the machine.

Swiss machining takes turning to another level. Originally developed for watchmaking, this specialized technique uses a sliding headstock and guide bushing to support the workpiece extremely close to the cutting point. The result? KMM Group reports tolerances as tight as 0.0002 inches (5 microns) on small, complex components. Swiss machines with up to 13 axes can perform multiple operations simultaneously, making them ideal for medical device components, aerospace fasteners, and precision connectors.

Understanding Multi-Axis Capabilities

Here's where things get interesting. Traditional 3-axis milling moves in three directions - side-to-side (X), front-to-back (Y), and up-down (Z). This handles most geometries, but what about parts requiring access from multiple angles?

Five-axis machining adds two rotational movements to those three linear axes. The result? Your cutting tool can approach the workpiece from virtually any direction without repositioning the part. This capability matters when you need:

- Complex contours: Turbine blades, impellers, and sculpted surfaces

- Undercuts: Features impossible to reach from straight-on approaches

- Single-setup production: All sides machined without refixturing

- Superior surface finish: Optimal tool angles throughout the cut

According to Protolabs, 5-axis indexed machining (sometimes called 3+2 machining) positions the rotational axes, locks them, then machines using standard 3-axis movements. True 5-axis continuous machining keeps all axes moving simultaneously - essential for the most complex geometries but requiring more sophisticated programming.

Wire EDM (Electrical Discharge Machining) offers something entirely different. Instead of physical cutting, a thin wire electrode creates controlled electrical discharges that erode conductive materials. The wire never touches the workpiece, eliminating cutting forces entirely. This process produces extremely precise cuts in hardened materials - perfect for dies, punches, and intricate profiles where conventional cnc cuts would struggle. When conventional methods can't achieve the required precision or material hardness presents challenges, wire EDM often provides the solution.

Understanding these process distinctions helps you communicate effectively with machine shops and select the optimal approach for your specific parts. But process selection is only half the equation - material choice plays an equally critical role in determining your project's success.

Material Selection for CNC Machined Parts

You've selected the right machining process - now comes an equally important decision that directly impacts your part's performance, cost, and lead time. Choosing the wrong material can mean components that fail under stress, cost twice as much as necessary, or take weeks longer to produce.

Material selection isn't just about picking something strong enough. You're balancing mechanical properties, machinability ratings, environmental resistance, and budget constraints all at once. Let's break down your options across three major categories.

Metals for Structural Applications

Metals remain the workhorses of precision manufacturing, offering combinations of strength, durability, and thermal properties that plastics simply can't match.

Aluminum tops the popularity charts for good reason. With a machinability rating of 90-95% compared to the brass standard, aluminum machines fast and efficiently with minimal tool wear. It's lightweight, naturally corrosion-resistant, and accepts anodizing for enhanced surface protection. You'll find aluminum in aerospace components, electronic housings, and automotive parts where weight matters.

Steel delivers superior strength when aluminum won't cut it. Mild steel machines reasonably well at around 70% machinability, producing decent surface finishes though often requiring secondary operations. Carbon steels and alloy steels offer varying hardness levels - the trade-off being that harder grades become progressively more challenging to machine. Expect longer cycle times and increased tool wear compared to aluminum.

Stainless steel presents a different challenge entirely. Its machinability drops to 30-40% because the material work hardens - it actually gets tougher as you cut it. This demands slower cutting speeds and more frequent tool changes. However, when your application requires rust resistance, biocompatibility, or food-safe surfaces, stainless steel becomes the only logical choice.

CNC bronze and brass components excel where friction, wear resistance, or electrical conductivity matter. Brass earns its position as the machinability benchmark at 100% - it cuts cleanly, produces short chips, and extends tool life significantly. When you machine bronze, you're working with a slightly lower machinability rating but gaining superior wear characteristics for bushings, bearings, and marine hardware. Bronze cnc projects are common in applications requiring low-friction sliding surfaces.

Engineering Plastics and Their Strengths

Engineering plastics offer advantages metals can't provide - chemical resistance, electrical insulation, lighter weight, and often lower material costs. But they require different machining considerations.

Delrin plastic (acetal/POM) machines exceptionally well with standard CNC tools. It's rigid, dimensionally stable, and self-lubricating - ideal for gears, rollers, and mechanical components. Unlike softer plastics, delrin doesn't deform easily under cutting pressure, producing clean edges and accurate features.

Nylon for machining applications delivers toughness and flexibility that delrin lacks. It absorbs some moisture, which can affect dimensional stability, but its impact resistance and wear properties make it valuable for bushings, slides, and wear pads. Nylon machines cleanly when you control heat buildup.

Polycarbonate brings optical clarity and exceptional impact resistance to the table. It can melt or deform if cutting speeds run too high, so machinists reduce spindle speeds compared to metals. Safety shields, optical components, and impact-resistant housings frequently specify polycarbonate.

Acrylic CNC machining produces crystal-clear parts with excellent surface finish when parameters are optimized. Acrylic machines faster than polycarbonate but proves more brittle - it can crack or chip under aggressive cutting. Display cases, lighting fixtures, and signage components commonly use acrylic.

Specialty Alloys for Demanding Environments

When standard materials can't handle extreme temperatures, corrosive chemicals, or specialized electromagnetic requirements, specialty alloys step in.

Kovar matches the thermal expansion characteristics of borosilicate glass and certain ceramics, making it essential for hermetic seals in electronics packaging. Its machinability sits well below steel, requiring careful parameter selection and specialized tooling.

Nitronic 60 offers outstanding galling resistance - it won't seize when sliding against other metals under high pressure. This makes it valuable for valve components, fasteners, and wear applications where stainless steel would fail.

Titanium combines aerospace-grade strength with remarkable lightness, but its machinability rating of just 20-25% means significantly longer cycle times and faster tool wear. The low thermal conductivity keeps heat concentrated at the cutting zone, demanding slower speeds and aggressive coolant application.

Zinc alloys provide an interesting alternative to die-casting for low-to-medium volume production. Machined zinc components offer tighter tolerances than cast parts and eliminate tooling investments, making them practical for prototypes or production runs where die-casting molds can't be justified.

| Material Type | Key Properties | Common Applications | Machinability Rating |

|---|---|---|---|

| Aluminum (6061) | Lightweight, corrosion-resistant, excellent thermal conductivity | Aerospace, electronics housings, automotive | 90-95% |

| Mild Steel | High strength, weldable, cost-effective | Structural components, machinery parts, gears | 70% |

| Stainless Steel (304) | Corrosion-resistant, biocompatible, work hardens | Medical devices, food processing, marine | 30-40% |

| Brass (C36000) | Excellent machinability, electrical conductivity, corrosion-resistant | Fittings, electrical components, decorative parts | 100% (standard) |

| Bronze | Wear-resistant, low friction, good machinability | Bushings, bearings, marine hardware | 80-90% |

| Delrin (Acetal) | Self-lubricating, dimensionally stable, rigid | Gears, rollers, mechanical components | Very High |

| Nylon | Impact-resistant, flexible, good wear properties | Bushings, slides, wear pads | High |

| Polycarbonate | Optically clear, impact-resistant, heat-sensitive | Safety shields, optical parts, housings | Medium-High |

| Titanium (Grade 5) | High strength-to-weight, heat-resistant, biocompatible | Aerospace, medical implants, performance parts | 20-25% |

| Inconel | Extreme heat resistance, corrosion-resistant | Jet engines, nuclear reactors, extreme environments | 10-15% |

Notice how machinability ratings directly correlate with production costs and lead times? A part machined from brass might cost half as much as the identical geometry in titanium - not because titanium costs more per pound, but because it takes four to five times longer to machine.

When selecting materials, consider your project's specific requirements first: What loads will the part experience? What environment will it operate in? What surface finish and tolerances do you need? Answering these questions narrows your options quickly and prevents costly material mistakes.

With your material selected, the next critical factor comes into play - understanding how design decisions and specifications translate into actual manufacturing costs.

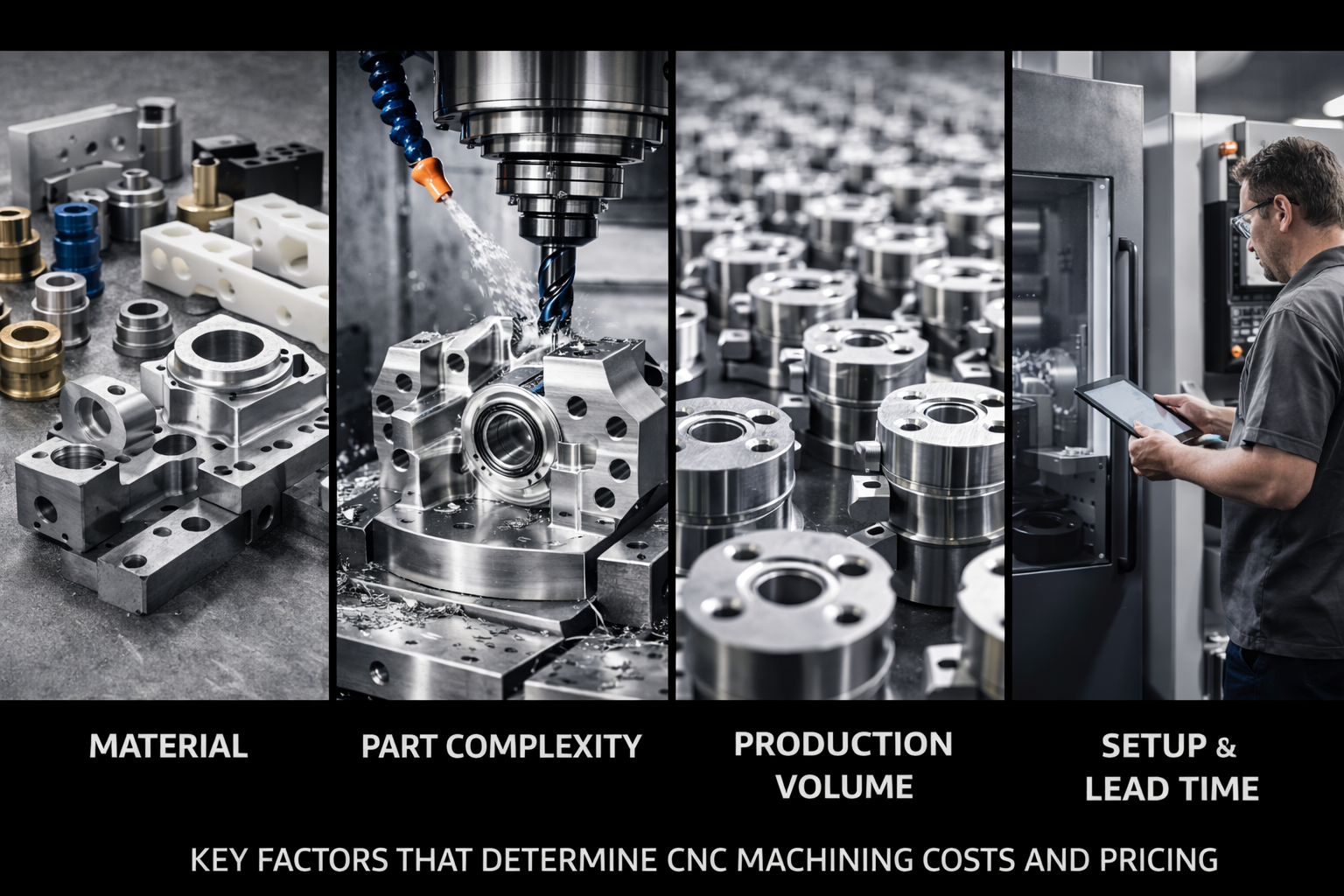

Understanding CNC Machining Cost Factors

You've selected your material and understand the machining processes available - but how does all of this translate into actual dollars? Pricing for CNC machining parts remains one of the most opaque areas in manufacturing, with quotes varying wildly between providers for seemingly identical work.

Here's the reality: CNC machining costs aren't arbitrary. They follow predictable patterns based on measurable factors. Understanding these drivers helps you make smarter design decisions, request more accurate online machining quotes, and identify where your budget actually goes.

The primary cost factors, ranked by typical impact on your final price:

- Machine time: The single largest cost driver - how long your part occupies expensive equipment

- Material costs: Raw stock pricing plus the waste factor from material removal

- Setup complexity: Number of operations, fixturing requirements, and axis configurations

- Tolerance requirements: Tighter specifications demand slower speeds and more inspection

- Surface finish specifications: Additional operations for polished or treated surfaces

- Order quantity: Volume economics that spread fixed costs across more parts

Let's examine each factor so you can see exactly where your money goes when you request a cnc quote online.

What Drives Machine Time Costs

Every CNC machine carries an hourly rate - typically ranging from $40-75 for standard 3-axis mills to $100-150+ for advanced 5-axis equipment. According to U-Need Precision Manufacturing, this rate encompasses fixed costs like machine depreciation and tool wear, plus variable costs including energy consumption and operator labor.

What determines how long your part occupies that machine? Several interconnected factors:

Material removal volume matters significantly. Machining a solid block down to a thin-walled housing removes far more material than starting with near-net-shape stock. More material removal means more cutting passes and longer cycle times.

Cutting parameters vary by material. Remember those machinability ratings from the previous section? A titanium part might require cutting speeds one-fifth as fast as aluminum - directly multiplying machine time for identical geometries.

Tool changes add time throughout production. Complex parts requiring multiple cutter sizes, drilling operations, and finishing passes accumulate minutes with each tool swap. Modern machines perform automatic tool changes in seconds, but those seconds compound across production runs.

The machinist metal cost calculation becomes straightforward once you understand this relationship: machine hourly rate multiplied by cycle time, plus setup time divided across your quantity. Simple geometry in easy-to-machine materials keeps this number low.

How Tolerances Affect Pricing

Here's where many buyers unknowingly inflate their costs. The relationship between tolerance and price isn't linear - it's exponential. According to research cited by Frigate, moving from ±0.05 mm to ±0.02 mm may raise costs by around 50%, but going further from ±0.02 mm to ±0.01 mm can multiply costs several times over.

Why does this happen? Tighter tolerances trigger a cascade of requirements:

- Slower feed rates: Machines must cut more carefully to maintain precision

- More frequent inspection: Parts require verification at multiple stages

- Better fixturing: Workholding must eliminate vibration and deflection

- Climate control: Temperature variations affect measurements at micron levels

- Higher scrap risk: Parts outside tolerance become expensive waste

So what does ±0.020 mm actually mean in practical terms? This tolerance - roughly the thickness of a human hair - represents a total allowable variation of 0.040 mm (about 0.0016 inches). For reference, standard machining typically achieves ±0.125 mm without special effort. Holding ±0.020 mm requires careful attention to tooling, temperature, and process control.

The critical question isn't "can we achieve this tolerance?" but rather "does this feature actually need it?" As one industry analysis notes: "The most expensive tolerance is often the one that doesn't add functional benefit." A European automotive supplier discovered that relaxing non-critical tolerances from ±0.01 mm to ±0.03 mm reduced their machining costs by approximately 22%.

Volume Economics Explained

Order quantity affects per-part pricing through several mechanisms that compound together.

Setup cost distribution creates the most dramatic impact. Every production run requires machine setup - loading programs, installing tooling, positioning fixtures, and running test cuts. This setup might take 30 minutes to several hours depending on complexity. Whether you're making 1 part or 1,000, that setup cost remains constant. Spread across more parts, the per-piece contribution shrinks dramatically.

Consider a real example: a part requiring 2 hours of setup time and 15 minutes of actual machining. For a single prototype, you're paying for 2.25 hours of shop time. For 100 parts, that same setup spreads across the run - effectively adding just 1.2 minutes of setup cost per part instead of 120 minutes.

Material purchasing also benefits from volume. Buying bar stock or plate in larger quantities typically earns quantity discounts. Some shops pass these savings through; others factor them into competitive volume pricing.

Process optimization becomes worthwhile at higher volumes. For a 10-piece order, a machinist uses reliable conservative parameters. For 10,000 pieces, investing time to optimize cutting speeds, reduce cycle times, and minimize tool changes pays dividends across the entire run.

The relationship between lead time and cost deserves attention too. Rush orders typically carry premiums of 25-50% or more because they disrupt scheduled production, require overtime, or bump other customers. Planning ahead and providing flexibility on delivery dates often translates directly into lower pricing.

When requesting quotes for machining parts, provide accurate quantity requirements and realistic timelines. Padding quantities "just in case" or demanding unnecessarily short lead times adds costs that could otherwise stay in your budget.

Understanding these cost drivers puts you in a stronger position when evaluating quotes and making design decisions. But there's another area where significant savings hide - optimizing your part designs specifically for manufacturability before they ever reach the machine shop.

Design Guidelines That Reduce Cost and Improve Quality

You've selected materials and understand cost factors - but here's something that can save you more money than any other decision: designing your parts correctly from the start. Poor design choices don't just increase costs; they can make parts impossible to machine or cause failures in the field.

Design for Manufacturability (DFM) isn't about limiting creativity. It's about understanding what CNC machines do well and designing accordingly. The payoff? Faster production, lower costs, and cnc machined parts that perform exactly as intended.

Here are the DFM best practices ranked by their impact on your project's success:

- Maintain adequate wall thickness - Prevents breakage and warping during machining

- Add radii to internal corners - Allows standard tooling and reduces stress concentrations

- Limit cavity and hole depths - Prevents tool deflection and breakage

- Use standard hole sizes - Enables efficient drilling with readily available bits

- Specify tolerances only where needed - Reduces machining time and inspection costs

- Avoid purely aesthetic complexity - Eliminates unnecessary machining operations

Let's explore each principle so you can apply them to your next project.

Critical Wall Thickness Guidelines

Thin walls look great on paper but create serious problems on the machine. During cutting, the workpiece experiences continuous vibration from tool contact. Thinner walls lack stiffness to resist these forces, leading to deflection, chatter marks, and dimensional inaccuracy.

According to Geomiq's design analysis, minimum recommended wall thickness is 0.8 mm for metals and 1.5 mm for plastics. However, Summit CNC recommends keeping walls greater than 0.02 inches (0.5 mm) as an absolute minimum - with thicker being better.

Wall height matters too. Tall, thin walls act like tuning forks under cutting loads. The recommended width-to-height ratio is 3:1 for unsupported walls. A wall that's 3 mm wide shouldn't exceed 9 mm in height without additional support features.

When your cnc prototyping requires thin-walled features for weight reduction, consider adding temporary support ribs that get machined away in a final pass. This maintains rigidity during primary machining operations while achieving your target specifications.

Avoiding Costly Design Errors

Certain design mistakes appear repeatedly in custom machined parts - each one adding unnecessary cost or creating manufacturing headaches.

Sharp internal corners top the list. CNC milling cutters are cylindrical, meaning they physically cannot produce perfectly sharp inside corners parallel to the tool axis. Every internal corner will have a radius equal to at least the cutting tool's radius. Design internal edges with radii 30% larger than your expected tool diameter - if using a 10 mm cutter, specify a 13 mm corner radius. This reduces tool stress and allows faster cutting speeds.

Deep pockets with small radii compound the problem. Reaching deep into a pocket requires long, thin tools that deflect easily. Industry guidelines recommend limiting pocket depths to no more than 6x the smallest corner radius. Deeper pockets require expensive long-reach tooling and dramatically slower cutting parameters.

Non-standard hole sizes waste time and money. Standard drill bits cut holes quickly and accurately. Non-standard diameters require end mills to progressively machine the opening - taking significantly longer. Whenever possible, specify standard drill sizes. For threaded holes, standard sizes also match pre-programmed thread cycles in CNC machines.

Excessive thread depth adds cost without adding strength. Most of a threaded connection's holding power comes from the first few threads. Limit thread depth to a maximum of three times the hole diameter. For blind holes, leave an unthreaded length of half the hole's diameter at the bottom to allow proper tap clearance.

Optimizing Features for Machinability

Beyond avoiding mistakes, proactive design choices make cnc polycarbonate parts, metal components, and everything in between easier to produce.

Choose chamfers over fillets for external edges. Fillets require complex 3D tool paths or specialized corner-rounding tools. Chamfers machine quickly with standard chamfer mills, reducing both programming and cycle time.

Eliminate unnecessary aesthetic features. Decorative patterns, engravings, and embossments that serve no functional purpose add machining time directly to your cost. If aesthetics matter for your application, include them - but understand the trade-off.

Apply tolerances strategically. Standard machining achieves ±0.13 mm without special effort. Specifying tighter tolerances on every dimension is a common CNC design mistake that Geomiq identifies as unnecessarily increasing time and cost. Reserve tight tolerances for mating surfaces, moving parts, and critical functional features only.

Consider surface finish requirements carefully. Default machined surfaces achieve 3.2 µm Ra roughness - smooth enough for most applications. Specifying smoother finishes increases machining time exponentially. Reserve low roughness specifications for load-bearing or sliding surfaces where they genuinely improve performance.

The bottom line? Good DFM practices reduce lead times because parts require fewer specialized tools, less programming complexity, and fewer quality concerns. When you design for manufacturability from the start, you're not compromising your part's functionality - you're ensuring it can be produced efficiently, consistently, and within budget.

Of course, different industries impose their own requirements beyond basic manufacturability. Understanding what aerospace, medical, and automotive applications demand helps you navigate certification requirements and specification standards specific to your market.

Industry-Specific CNC Machining Requirements

Designing for manufacturability gets you started - but what happens when your parts must meet aerospace safety standards, medical biocompatibility requirements, or automotive production consistency? Each industry imposes specific certifications and quality systems that go far beyond general machining capabilities.

Understanding these requirements before you engage a machine shop prevents costly surprises. A provider delivering excellent automotive components might lack the certifications needed for your medical device project. Let's examine what each major industry demands and why these standards exist.

Aerospace Machining Requirements

Aerospace manufacturing operates under some of the strictest quality requirements in any industry. When components fail at 35,000 feet, the consequences are catastrophic - which explains why aerospace cnc machining demands exceptional documentation and process control.

AS9100D certification represents the gold standard for aerospace suppliers. According to Snowline Engineering, this certification builds upon ISO 9001:2015 requirements while adding aerospace-specific controls for quality assurance, risk assessment, and continuous improvement.

What does AS9100D actually require? The standard spans ten major sections addressing:

- Leadership and planning: Management responsibilities and risk-based planning protocols

- Support systems: Personnel training, equipment calibration, and process documentation

- Operational controls: Product design, supplier management, and material traceability

- Performance evaluation: Monitoring, analysis, and management review processes

- Continuous improvement: Systematic refinement of manufacturing and quality systems

Material traceability becomes non-negotiable in aerospace applications. Every component must trace back to specific material lots, heat treatments, and processing records. When an aircraft manufacturer discovers a potential issue, they need immediate answers about which parts came from which material batches - and where those parts ended up.

ITAR compliance (International Traffic in Arms Regulations) adds another layer for defense-related aerospace work. Shops handling ITAR-controlled components must restrict access to U.S. persons and maintain specific security protocols throughout production.

Medical Device Manufacturing Standards

Medical machining carries unique responsibilities - the parts you produce may end up inside human bodies or controlling life-sustaining equipment. This reality drives exceptionally rigorous standards for precision machining services in healthcare applications.

FDA compliance through 21 CFR Part 820 establishes the Quality System Regulation governing medical device manufacturing. According to PTSMAKE's analysis, this regulation requires documented procedures ensuring every component meets predefined specifications throughout its lifecycle.

Key FDA requirements include:

- Design controls: Documented development processes with formal reviews and verification

- Device history records: Complete documentation of each unit's production history

- Corrective and preventive action (CAPA): Systematic processes for addressing quality issues

- Supplier management: Verification that all suppliers meet quality requirements

ISO 13485 certification provides the international framework for medical device quality management. Unlike general ISO 9001, this standard addresses medical-specific requirements including biocompatibility documentation, sterility controls, and traceability throughout the supply chain.

Biocompatibility determines whether materials can safely contact human tissue. The FDA categorizes testing requirements based on contact duration and type - implantable devices face far stricter requirements than external equipment housings. Materials must meet USP Class VI standards or have FDA master files documenting their safety profiles.

Precision requirements also escalate dramatically. Medical components routinely demand tolerances of ±0.0001 inches (2.54 micrometers) for implants and surgical instruments. Surface finish specifications often require Ra values between 0.1-0.4 µm - mirror-smooth surfaces that prevent bacterial adherence and tissue trauma.

Automotive Production Demands

Automotive manufacturing combines precision requirements with volume demands that most industries never experience. When you need millions of identical components delivered just-in-time, consistency becomes everything.

IATF 16949 certification represents the mandatory quality standard throughout much of the global automotive supply chain. According to the British Standards Institution, this standard incorporates ISO 9001 while adding automotive-specific requirements for continual improvement, defect prevention, and waste reduction.

What makes IATF 16949 distinctive?

- Statistical Process Control (SPC): Continuous monitoring ensuring every part meets specifications

- Advanced Product Quality Planning (APQP): Structured development processes for new components

- Production Part Approval Process (PPAP): Formal qualification before volume production begins

- Failure Mode and Effects Analysis (FMEA): Systematic risk identification and mitigation

Volume consistency presents unique challenges. A custom machine shop might produce 50 perfect prototypes, but maintaining that quality across 50,000 production parts requires process controls most general machine shops lack. Automotive suppliers must demonstrate capability indices (Cpk values) proving their processes consistently produce parts within specification.

Electronics and Specialty Applications

Electronics manufacturing introduces requirements rarely encountered in other industries - electromagnetic compatibility, thermal management, and specialized material properties.

EMI shielding (Electromagnetic Interference) demands specific materials and designs that prevent electronic components from interfering with each other or external systems. Machined housings often require conductive coatings or specialized alloys that provide electromagnetic protection.

Thermal management becomes critical as electronics pack more processing power into smaller spaces. Heat sinks, thermal interfaces, and cooling channels require precision cnc machining services capable of creating complex geometries that maximize heat dissipation.

Specialty alloys like Kovar - which matches the thermal expansion of glass and ceramics - enable hermetic seals for sensitive electronic packages. These materials demand machining expertise beyond standard capabilities.

| Industry | Key Certifications | Critical Requirements | Typical Tolerances |

|---|---|---|---|

| Aerospace | AS9100D, ITAR, Nadcap | Material traceability, documented processes, risk management | ±0.001" to ±0.0005" |

| Medical | ISO 13485, FDA 21 CFR 820 | Biocompatibility, sterility, complete documentation | ±0.0005" to ±0.0001" |

| Automotive | IATF 16949 | SPC, PPAP, high-volume consistency, just-in-time delivery | ±0.002" to ±0.0005" |

| Electronics | ISO 9001, IPC standards | EMI shielding, thermal management, specialized materials | ±0.001" to ±0.0005" |

Understanding these industry-specific requirements helps you ask the right questions when evaluating potential manufacturing partners. A shop claiming "precision cnc machining services" might excel at general work while lacking the certifications, equipment, or experience your specific application demands.

With industry requirements clarified, the next logical question becomes: how does CNC machining compare to alternative manufacturing methods, and when should you choose one approach over another?

CNC Machining Versus Alternative Manufacturing Methods

So you've identified your industry requirements and understand what certifications matter - but here's a question that trips up many engineers and procurement specialists: is CNC machining actually the right choice for your project, or would another manufacturing method serve you better?

The truth is, no single manufacturing process wins in every scenario. Metal cnc machining excels in certain applications while 3D printing, injection molding, casting, or sheet metal fabrication might deliver better results elsewhere. Making the wrong choice can cost you thousands in unnecessary expenses or months of wasted development time.

Let's compare these methods head-to-head so you can make informed decisions.

CNC vs 3D Printing Decision Points

These two technologies often compete for the same projects - but they approach manufacturing from completely opposite directions. A cnc machine for metal or plastic removes material from solid blocks, while 3D printing builds parts layer by layer from nothing.

According to Xometry's analysis, manufacturing feasibility depends heavily on part geometry. If your design includes intricate internal structures, undercuts, or organic shapes that traditional subtractive manufacturing can't reach, additive technologies become necessary.

But here's what 3D printing sacrifices: surface finish and material properties. Metal machining produces superior surfaces directly off the machine - often requiring no secondary finishing. 3D printed parts typically show layer lines and require post-processing for smooth finishes.

Material performance differs significantly too. CNC-machined components use solid stock with consistent, predictable mechanical properties. 3D printed parts can exhibit anisotropic behavior - meaning strength varies depending on print orientation. For structural applications where reliability matters, aluminum machining or steel machining typically wins.

Key decision factors include:

- Geometry complexity: Internal channels and lattice structures favor 3D printing

- Surface finish requirements: CNC delivers superior finishes without post-processing

- Material strength: Machined parts offer consistent mechanical properties

- Prototype speed: Both deliver rapid turnaround for single parts

- Production volume: CNC scales efficiently; 3D printing cost remains constant per unit

When Injection Molding Makes Sense

Injection molding enters the conversation when quantities climb into the thousands. According to Runsom's comprehensive comparison, injection molding requires expensive mold creation upfront, but per-unit costs decrease dramatically for high-volume production - typically becoming economical beyond 1,000 units.

The trade-offs become clear when you examine flexibility versus efficiency:

CNC machining advantages:

- No tooling investment required

- Design changes cost only programming time

- Material versatility including metals, engineering plastics, and exotic alloys

- Tolerances as tight as ±0.0005" achievable

- Parts delivered in days, not weeks

Injection molding advantages:

- Per-unit cost drops dramatically at high volumes

- Cycle times measured in seconds, not minutes

- Complex geometries including thin walls and undercuts

- Consistent replication across millions of parts

- Material options include specialized polymer grades and fillers

Here's the critical insight: injection molding locks you into a design. Mold modifications are costly and time-consuming. CNC machining allows design tweaks between runs with minimal impact. For products still evolving or production quantities under a few thousand, machining typically makes more sense economically.

Hybrid Manufacturing Approaches

Sometimes the smartest answer isn't choosing one method - it's combining them strategically.

Consider a complex housing requiring both precision mating surfaces and intricate internal geometry. 3D printing can create the basic form with internal channels, while subsequent CNC operations machine critical interfaces to tight tolerances. This hybrid approach captures benefits from both technologies.

Sheet metal fabrication using metal punching or sheet metal punch operations offers another comparison point. These processes excel at flat or bent geometries from sheet stock - brackets, enclosures, panels. But they can't create the three-dimensional complexity that metal machining handles easily.

Casting provides yet another alternative, particularly for complex metal geometries in moderate volumes. Sand casting, investment casting, and die casting each serve different applications. However, cast parts typically require secondary machining to achieve final tolerances on critical surfaces - bringing you back to CNC operations regardless.

| Process | Best For | Volume Range | Typical Tolerances | Lead Time |

|---|---|---|---|---|

| CNC Machining | Precision parts, prototypes, metals, low-to-medium volume | 1 - 10,000+ | ±0.001" to ±0.0005" | Days to weeks |

| 3D Printing | Complex geometries, internal features, rapid prototypes | 1 - 1,000 | ±0.005" to ±0.010" | Hours to days |

| Injection Molding | High-volume plastic parts, consistent replication | 1,000 - millions | ±0.003" to ±0.020" | Weeks (tooling) + days |

| Sheet Metal Fabrication | Enclosures, brackets, flat/bent geometries | 1 - 100,000+ | ±0.005" to ±0.030" | Days to weeks |

| Casting | Complex metal shapes, moderate volumes | 100 - 50,000 | ±0.010" to ±0.030" | Weeks to months |

The decision framework becomes clearer when you ask the right questions: What tolerances do functional features require? What volumes do you anticipate over the product lifecycle? How likely are design changes? What materials must you use?

For most precision metal components in quantities under 10,000, CNC machining delivers the optimal combination of accuracy, material choice, and flexibility. When volumes justify tooling investments or geometries demand additive approaches, those alternatives earn their place.

With manufacturing method selected, one crucial step remains: finding the right partner to execute your project successfully.

Choosing the Right CNC Machining Partner

You've determined CNC machining fits your project requirements - now comes the decision that can make or break your entire manufacturing experience. Selecting the wrong provider leads to missed deadlines, rejected parts, and endless back-and-forth that drains your time and budget. Finding the right partner transforms your supply chain into a competitive advantage.

Here's the reality: not every machine shop delivering acceptable prototypes can handle production volumes. And not every high-volume operation cares about your 50-piece development run. The key lies in matching provider capabilities to your specific needs - both current and future.

When searching for machinist shops near me or evaluating online providers, use these questions to separate genuine manufacturing partners from shops that will disappoint you.

Evaluating Technical Capabilities

Technical capability assessment goes beyond asking "what machines do you have?" You need to understand whether their equipment matches your part requirements and whether they have the expertise to use it effectively.

Key questions to ask potential providers:

- What machine types and axis configurations do you operate? - 3-axis mills handle most work, but complex geometries require 5-axis capability

- What are your maximum part size limits? - Travel limits on X, Y, and Z axes determine what fits on their machines

- What materials do you regularly machine? - Experience with your specific material matters more than general capability claims

- Do you handle secondary operations in-house? - Heat treatment, anodizing, and assembly capabilities reduce lead times and quality risks

- What CAD/CAM systems do you support? - File compatibility issues can delay projects before they even start

- What is your typical tolerance capability? - Claimed tolerances should match your requirements without requiring special handling

According to Norck's evaluation guide, the quality of output is inextricably linked to equipment quality and maintenance. A reputable shop maintains rigorous calibration schedules and can document their maintenance protocols upon request.

When looking for a prototype machine shop near me, pay attention to how they respond to technical questions. Vague answers or reluctance to discuss specifics often signal capability gaps they'd rather not reveal.

Quality Certification Essentials

Certifications tell you whether a shop has formalized quality systems - but understanding what each certification actually requires helps you evaluate their relevance to your project.

ISO 9001:2015 establishes baseline quality management requirements. It indicates documented procedures, management oversight, and continuous improvement processes. Most serious machine shops hold this certification as a minimum standard.

AS9100D adds aerospace-specific controls including risk management, material traceability, and enhanced documentation. If your parts fly, this certification becomes mandatory.

ISO 13485 addresses medical device manufacturing with requirements for biocompatibility documentation, sterility controls, and complete production records.

IATF 16949 represents the automotive industry standard, requiring Statistical Process Control (SPC) for consistent high-tolerance components. This certification ensures suppliers can maintain quality across high-volume production runs with the consistency automotive applications demand.

Providers like Shaoyi Metal Technology demonstrate how certified facilities can deliver rapid prototyping through mass production with lead times as fast as one working day. Their IATF 16949 certification ensures the SPC controls necessary for chassis assemblies, custom metal bushings, and other precision automotive components.

Beyond certifications, investigate their inspection capabilities:

- What inspection equipment do they use? - CMMs, optical comparators, surface roughness testers, and calibrated hand tools

- Do they perform in-process or only final inspection? - Catching errors early prevents costly scrap

- Can they provide inspection reports with your parts? - Documentation matters for regulated industries

- How often is inspection equipment calibrated? - Out-of-calibration equipment produces meaningless measurements

Scaling from Prototype to Production

Here's where many engineers get trapped: finding a shop that produces beautiful prototypes, then discovering they can't scale to production volumes - or vice versa.

According to Zenith Manufacturing's framework, the most dangerous transition in any project is the jump from prototype to low-volume production. A true manufacturing partner uses the prototype stage to validate the production process, not just the part itself.

Questions that reveal scalability capability:

- Do you outsource any part of the machining process? - Outsourcing introduces quality variability and communication delays

- What is your capacity for my anticipated production volumes? - Understand whether your orders fit their operation

- How do you handle the transition from prototype to production? - Look for formal processes, not ad-hoc approaches

- Do you offer inventory stocking programs? - Blanket orders and scheduled releases can streamline your supply chain

- What happens when I need design changes mid-production? - Flexibility matters during product development phases

Communication responsiveness reveals operational culture. As industry experts note, prompt and clear responses to inquiries indicate professionalism and efficiency. Ask whether you'll have dedicated project managers and direct access to technical staff when issues arise.

The cheapest quote isn't always the most economical choice. A transparent quote breaking down costs for materials, labor, tooling, and finishing helps you understand where your money goes. Hidden costs, unclear pricing, or reluctance to explain charges signal potential problems ahead.

Consider long-term partnership potential. The most valuable CNC machine shops near me aren't just vendors filling orders - they become extensions of your engineering team, understanding your needs and consistently delivering quality across multiple projects. When you find that partner, the relationship pays dividends far beyond any single transaction.

With evaluation criteria established, you're ready to take concrete steps toward bringing your project from concept to completed parts.

Moving Forward with Your CNC Machining Project

You've absorbed a significant amount of information about materials, processes, costs, and partner selection - but information without action doesn't get parts made. Whether you're holding a napkin sketch or a production-ready CAD model, there's a clear path from where you are now to finished components in your hands.

The journey looks different depending on your starting point. A product designer validating a concept needs different steps than a procurement manager scaling to production volumes. Let's map out exactly what comes next for each scenario.

Your Path Forward

Before contacting any machine shop, ensure you've answered these fundamental questions that determine project success:

- What function must this part perform? - Load requirements, environmental exposure, and mating components drive every subsequent decision

- What tolerances actually matter? - Functional surfaces need precision; non-critical features don't

- What quantities do you need now and in the future? - Initial prototypes might become 10,000-unit production runs

- What's your realistic timeline? - Rush orders cost more; planning ahead saves money

These answers shape your material choices, process selection, and which providers can realistically serve your needs. Skipping this foundation leads to wasted quotes, mismatched suppliers, and costly redesigns.

From Design to Delivery

The most successful projects follow a predictable sequence. Here's the proven approach that minimizes surprises and maximizes your chances of getting exactly what you need:

- Finalize your 3D CAD model - According to MakerVerse, projects with complete files get quoted and produced faster. Upload production-ready geometry in STEP or IGES format, removing construction planes and reference parts.

- Create technical drawings with key specifications - Include critical tolerances, thread callouts, surface finish requirements, and material specifications. Industry experts recommend providing both 3D files and 2D technical drawings to eliminate questions and speed the quoting process.

- Apply DFM principles before quoting - Review wall thicknesses, internal corner radii, and feature depths. Fixing these issues after receiving quotes wastes everyone's time.

- Request quotes from multiple qualified providers - Include all secondary operations, surface finishing, and delivery requirements upfront. Specify quantities and desired timelines clearly.

- Evaluate quotes beyond price alone - Consider certifications, communication quality, and capacity for future scaling. The lowest price often carries hidden costs in quality issues or delays.

- Approve first article inspection before production - Validate that initial parts meet your specifications before committing to full production runs.

When searching for cnc services near me or evaluating online platforms, remember that most reputable suppliers return quotes within 48 to 72 hours when files are complete. Clear file preparation eliminates back-and-forth questions that delay your timeline.

Taking Action on Your Project

Different project stages demand different actions. Here's what to prioritize based on where you stand:

If you're still in concept development: Focus on design for manufacturability before investing in detailed engineering. Consult with machining experts early - many custom cnc machining services providers offer design feedback that prevents costly mistakes. A quick conversation now saves weeks of redesign later.

If you need prototypes for validation: Prioritize speed and communication over lowest price. Look for cnc service providers who understand iterative development and can turn revisions quickly. Material selection flexibility matters here - you might test multiple options before committing.

If you're transitioning to production: Certification requirements become non-negotiable. Ensure your chosen partner holds relevant quality certifications for your industry. For automotive and precision metal applications requiring IATF 16949-certified production, Shaoyi Metal Technology's capabilities for chassis assemblies and custom metal bushings demonstrate how certified facilities bridge the gap from prototyping to volume manufacturing with consistent quality.

If you're scaling existing production: Evaluate capacity constraints and lead time commitments. Discuss blanket orders, scheduled releases, and inventory programs that smooth your supply chain. The relationship you build now determines your flexibility when demand spikes.

The information in this guide equips you to have informed conversations with potential manufacturing partners. You understand the processes, materials, cost drivers, and quality requirements that shape successful projects. Now the path forward is clear: define your requirements, prepare complete documentation, and engage qualified providers who can deliver what you need.

Your next precision component is waiting to be made. The question isn't whether CNC machining can deliver it - the question is how soon you'll take the first step.

Frequently Asked Questions About CNC Machining Services

1. What is CNC machining and how does it work?

CNC machining is a computer-controlled manufacturing process where programmed software directs cutting tools to remove material from raw stock, creating precision parts. The process starts with a 3D CAD model that gets translated into G-code instructions, which tell the machine exactly where to move, how fast to cut, and when to change tools. This automation enables repeatability, accuracy down to ±0.001 inches, and scalability that manual machining cannot match.

2. How much do CNC machining services cost?

CNC machining costs depend on several factors: machine time (the largest driver at $40-150+ per hour depending on equipment), material costs, setup complexity, tolerance requirements, surface finish specifications, and order quantity. Tighter tolerances exponentially increase costs - moving from ±0.05 mm to ±0.01 mm can multiply expenses several times. Volume orders reduce per-part costs by spreading setup time across more units, and flexible lead times typically earn better pricing.

3. What materials can be CNC machined?

CNC machines work with a wide range of materials including metals (aluminum, steel, stainless steel, brass, bronze, titanium), engineering plastics (delrin, nylon, polycarbonate, acrylic), and specialty alloys (kovar, nitronic 60, inconel). Material selection impacts cost significantly - aluminum with 90-95% machinability processes much faster than titanium at 20-25%. Each material offers different properties for strength, corrosion resistance, weight, and application suitability.

4. What is the difference between CNC milling and CNC turning?

CNC milling uses rotating cutting tools that move across a stationary workpiece, creating complex 3D shapes, pockets, and intricate patterns from multiple angles. CNC turning spins the workpiece while stationary tools shape it, excelling at cylindrical components like shafts, pins, and bushings. Milling handles diverse geometries while turning produces rotational parts more efficiently. Swiss machining extends turning capabilities to achieve tolerances as tight as 0.0002 inches on small, complex components.

5. How do I choose the right CNC machining service provider?

Evaluate providers based on technical capabilities (machine types, axis configurations, part size limits), quality certifications (ISO 9001, AS9100D for aerospace, IATF 16949 for automotive, ISO 13485 for medical), inspection equipment, and scalability from prototyping to production. Ask about their experience with your specific materials and tolerance requirements. IATF 16949-certified facilities like Shaoyi Metal Technology demonstrate how certified operations can deliver rapid prototyping through mass production with lead times as fast as one working day.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —