Machining Service Decoded: From Raw Metal To Precision Parts

What Machining Service Really Means for Modern Manufacturing

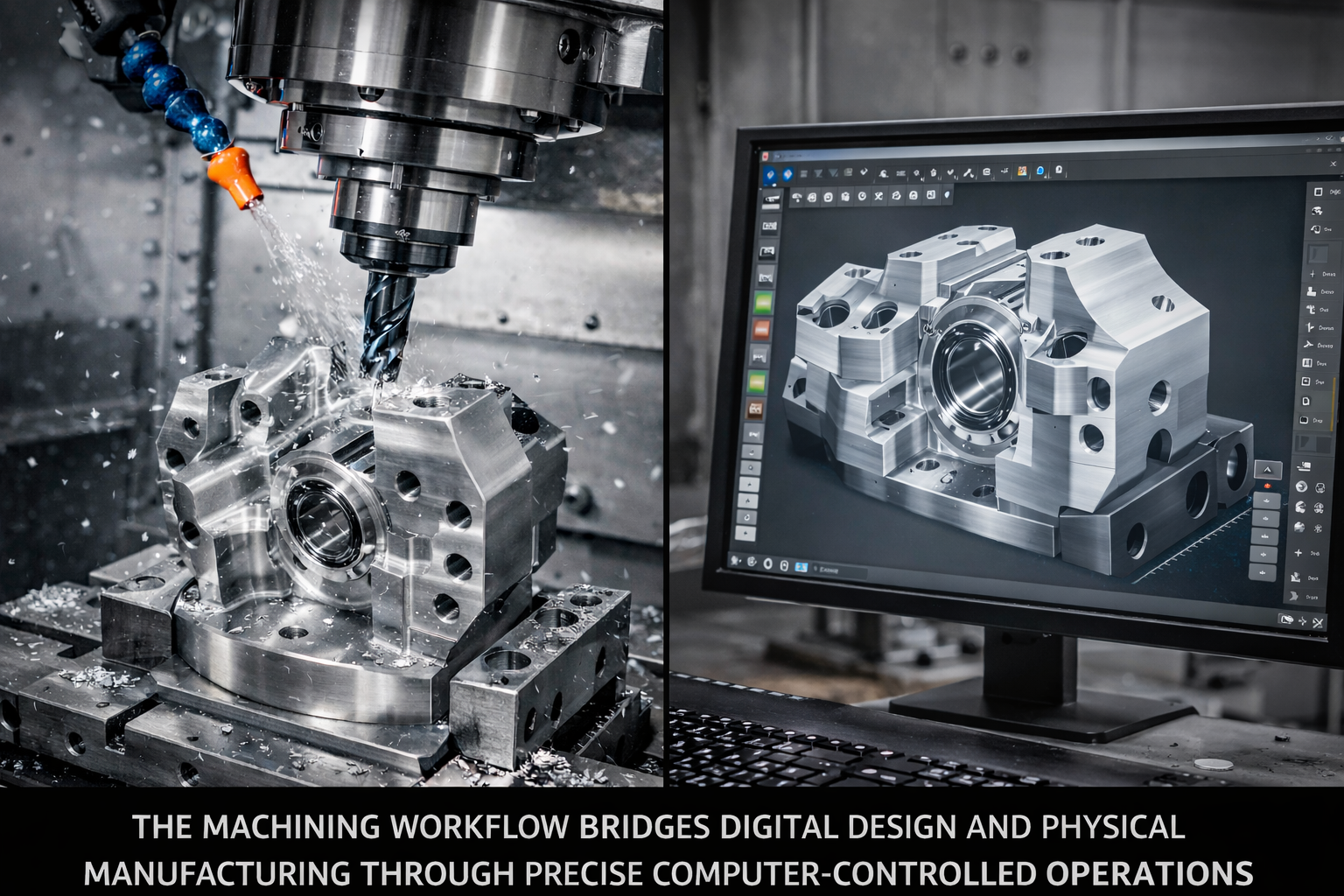

Imagine starting with a solid block of aluminum and ending up with a perfectly shaped aerospace component, accurate to within the width of a human hair. That's the power of modern machining at work. Whether you're an engineer sourcing parts or a business owner exploring manufacturing options, understanding this process opens the door to smarter decisions and better products.

Precision machining services utilize computer-controlled machines to remove material from solid blocks, creating components with exceptionally tight tolerances - often within 0.005 inches or less - that meet exact design specifications.

From Raw Material to Precision Part

At its core, a machining service transforms raw materials into finished components through controlled material removal. The process begins with a stock piece - a block, bar, or cylinder of metal or plastic - and systematically carves away everything that isn't part of the final design. Think of it like sculpture, but with computer-guided precision instead of a chisel.

This approach, known as subtractive manufacturing, stands in contrast to additive methods like 3D printing, where parts are built layer by layer. Metal machining through subtractive processes remains the gold standard when you need components that can withstand real-world stress, heat, and repeated use.

The Subtractive Manufacturing Advantage

Why does removing material beat adding it for so many applications? The answer lies in material integrity. When you machine a part from a solid block, you're working with material that has consistent internal properties throughout. There are no layer lines, no weak points between deposited layers, and no concerns about internal porosity.

This matters enormously for:

- Structural components that must bear loads without failure

- Moving parts requiring smooth surfaces and precise fit

- High-temperature applications where material consistency prevents warping

- Medical and aerospace parts where safety margins are non-negotiable

The result? Precision CNC machining delivers parts you can trust in critical applications, from automotive brake systems to surgical instruments.

Why Computer Control Changed Everything

Before CNC (Computer Numerical Control) technology, skilled machinists manually guided every cut. This approach demanded years of training, limited production speed, and introduced human variability between parts. Today's CNC fabrication has transformed the equation entirely.

Modern CNC machines follow programmed instructions with unwavering consistency. As noted by industry experts, CNC machining is superior in producing highly complex and precise parts because it can follow intricate designs with minimal error. The machine doesn't get tired on the third shift, doesn't have off days, and replicates the same exact movements whether it's making the first part or the thousandth.

The process works like this: designers create a 3D model using CAD software, that model gets converted into machine-readable G-code and M-code instructions, and the CNC machine executes those commands with precision. G-codes control tool movements and cutting paths, while M-codes handle auxiliary functions like coolant flow and tool changes.

This digital foundation means CNC machining services can deliver:

- Tolerances as tight as ±0.005 inches (roughly twice the width of a human hair)

- Identical parts across production runs of any size

- Complex geometries that would be impossible to produce manually

- Faster turnaround from design to finished component

Whether you need a single prototype or thousands of production parts, this technology-driven approach has become the backbone of modern manufacturing - and understanding it is your first step toward leveraging its full potential.

Understanding Different CNC Machining Processes

Now that you understand what machining services accomplish, the next question becomes: which process fits your project? Not all CNC operations are created equal. Each technique excels at specific geometries, materials, and precision requirements. Choosing the wrong process can mean higher costs, longer lead times, or parts that don't meet specifications. Let's break down the options so you can match the right method to your needs.

Milling Operations and Multi-Axis Capabilities

CNC machining milling uses rotating cutting tools to remove material from a workpiece secured to a table. Imagine a high-speed drill that can move in multiple directions, carving out pockets, slots, contours, and complex 3D surfaces. The number of axes determines what geometries are possible.

3-Axis Milling moves the cutting tool along X, Y, and Z axes - left-right, forward-back, and up-down. This handles most flat surfaces, pockets, and simple contours efficiently. It's the workhorse for straightforward parts and offers the lowest machine time costs.

4-Axis Milling adds rotation around one horizontal axis, allowing the CNC cutting machine to reach features on multiple sides of a part without manual repositioning. This reduces setup time and improves accuracy for parts with features on more than one face.

5 axis CNC machining services represent the pinnacle of milling capability. With simultaneous movement along five axes, these machines can approach the workpiece from virtually any angle. Complex aerospace components, turbine blades, and intricate medical implants become feasible in a single setup. While machine time costs more, the elimination of multiple setups often makes 5-axis the economical choice for complex geometries.

When should you specify multi-axis milling? Consider it when your part has:

- Compound angles or sculptured surfaces

- Features on multiple faces that require tight positional relationships

- Undercuts or deep cavities with restricted tool access

- Thin walls that might deflect under repeated setups

Turning Services for Cylindrical Components

While milling rotates the tool, CNC turning rotates the workpiece. The cutting tool remains stationary or moves along defined paths, shaping the spinning material. This makes turning ideal for any part with rotational symmetry - shafts, bushings, fittings, and cylindrical housings.

A standard CNC turning service handles operations like facing, boring, threading, grooving, and taper cutting. Modern turning centers often include live tooling, which adds milling capabilities to create features like flats, cross-holes, and keyways without moving the part to a second machine.

For extremely small or highly complex turned parts, swiss machining offers unmatched precision. Swiss-type lathes use a sliding headstock and guide bushing that supports the workpiece close to the cutting action. This minimizes deflection and enables exceptionally tight tolerances on long, slender components. Watch components, medical pins, and electronic connectors frequently rely on swiss machining for their demanding specifications.

CNC turning services typically deliver faster cycle times than milling for round parts. If your component is fundamentally cylindrical, turning will almost always be more economical than trying to mill it from a rectangular block.

Specialized Processes for Complex Geometries

Some manufacturing challenges require processes beyond conventional milling and turning. Here's when to consider specialized techniques:

Electrical Discharge Machining (EDM) uses electrical sparks to erode material, making it perfect for hardened steels and exotic alloys that would destroy conventional cutting tools. EDM excels at sharp internal corners, deep narrow slots, and intricate die cavities. Wire EDM cuts complex profiles with exceptional accuracy, while sinker EDM creates detailed cavity shapes.

Grinding achieves the finest surface finishes and tightest tolerances available. When you need surface roughness below Ra 0.4 micrometers or dimensional accuracy within 0.0001 inches, grinding becomes essential. It's commonly applied after heat treatment to restore precision that thermal processes might have affected.

Drilling and Boring create and refine holes. While basic drilling happens on any milling machine, dedicated drilling operations optimize speed for parts requiring many holes. Boring refines existing holes to precise diameters and positions, critical for bearing fits and alignment features.

| Process Type | Best Applications | Typical Tolerances | Material Compatibility | Relative Cost |

|---|---|---|---|---|

| 3-Axis Milling | Flat surfaces, pockets, simple contours | ±0.005" (0.127mm) | All machinable metals and plastics | Low |

| 4-Axis Milling | Multi-face features, indexed parts | ±0.003" (0.076mm) | All machinable metals and plastics | Medium |

| 5-Axis Milling | Complex 3D surfaces, undercuts, aerospace parts | ±0.002" (0.050mm) | All machinable metals and plastics | High |

| CNC Turning | Cylindrical parts, shafts, fittings | ±0.005" (0.127mm) | All machinable metals and plastics | Low to Medium |

| Swiss Machining | Small precision parts, medical components | ±0.0005" (0.013mm) | Most metals, some plastics | Medium to High |

| EDM | Hardened materials, sharp corners, dies | ±0.0005" (0.013mm) | Conductive materials only | High |

| Grinding | Ultra-fine finishes, critical tolerances | ±0.0001" (0.003mm) | Hardened metals, ceramics | High |

Selecting the right process starts with understanding your part's geometry. Cylindrical? Start with CNC turning. Complex multi-face features? Consider 5-axis milling. Hardened steel with intricate details? EDM might be your answer. Most machining service providers will recommend the optimal approach during design review, but understanding these distinctions helps you communicate effectively and evaluate their recommendations.

With process selection clarified, the next critical decision involves choosing the right material for your application - a choice that directly impacts both part performance and manufacturing cost.

Material Selection Guide for CNC Machined Parts

You've identified the right machining process for your part geometry. Now comes an equally critical decision: what material should that part be made from? The wrong choice here can result in components that fail in service, cost far more than necessary, or prove impossible to machine efficiently. The right choice balances mechanical requirements, environmental exposure, weight constraints, and budget - all while remaining practical to manufacture.

Think of material selection as a puzzle with multiple interconnected pieces. A marine valve component needs corrosion resistance above all else. An aerospace bracket demands strength-to-weight ratio. A food processing gear requires FDA compliance and wear resistance. Each application points toward specific material families, and within those families, particular grades optimize performance for your exact needs.

Metals and Their Machining Characteristics

Metals remain the backbone of precision machining, offering combinations of strength, durability, and thermal performance that plastics simply cannot match. Understanding the key categories helps you navigate the options effectively.

Aluminum Alloys

When weight matters and strength requirements are moderate, aluminum alloys deliver exceptional value. They machine faster than steel, reducing production costs, and offer natural corrosion resistance for many environments.

- 6061-T6: The general-purpose workhorse. Good strength, excellent machinability, weldable. Ideal for structural components, fixtures, and housings.

- 7075-T6: Near-steel strength at one-third the weight. Preferred for aerospace and high-stress applications. Costs more and machines slightly slower than 6061.

- 2024: Superior fatigue resistance. Common in aircraft structures where cyclic loading is a concern.

Stainless Steels

When corrosion resistance combines with strength requirements, stainless steel machining becomes essential. These alloys contain chromium that forms a protective oxide layer, but this same property makes them more challenging to cut.

- 304 Stainless: The most common grade. Excellent corrosion resistance, good formability. Used in food equipment, medical devices, and architectural applications.

- 316 Stainless: Enhanced resistance to chlorides and marine environments. Slightly more expensive but essential for coastal or chemical exposure.

- 17-4 PH: Heat-treatable for high strength. Combines corrosion resistance with mechanical properties approaching tool steel.

Carbon and Alloy Steels

For maximum strength and hardness at the lowest material cost, carbon steels remain unmatched. They require protective coatings or plating in corrosive environments but excel where strength-to-cost ratio drives the decision.

- 1018 Steel: Low carbon, easily machined and welded. Ideal for shafts, pins, and structural parts that will be plated or painted.

- 4140 Steel: Heat-treatable alloy steel with excellent strength. Common for gears, axles, and high-stress mechanical components.

- A2/D2 Tool Steel: Extreme hardness and wear resistance. Used for dies, punches, and cutting tools themselves.

Bronze and Brass

These copper alloys bring unique properties that steel and aluminum cannot replicate. CNC machining bronze produces parts with exceptional wear resistance, low friction, and natural antimicrobial properties.

According to industry specialists, bronze's composition - primarily copper and tin - provides outstanding wear resistance and strength, making it ideal for gears, bearings, and components requiring continuous mechanical contact. Machining bronze allows for smooth cutting with reduced risk of galling, resulting in excellent surface finishes.

- C932 Bearing Bronze: The go-to choice for bushings and bearings. Self-lubricating properties extend component life in rotating applications.

- Aluminum Bronze: Combines corrosion resistance with high strength. Preferred for marine hardware, valves, and pump components.

- Brass 360: The most machinable metal available. Excellent for decorative parts, electrical components, and fittings where appearance matters.

Engineering Plastics for Precision Parts

Not every application demands metal. Engineering plastics offer compelling advantages: lighter weight, natural lubricity, electrical insulation, and chemical resistance that outperforms many metals. Modern CNC plastic machining produces components with precision rivaling metal parts.

Acetal (Delrin)

Delrin plastic has become synonymous with precision plastic components. This delrin material offers exceptional dimensional stability, low friction, and resistance to moisture absorption - properties that make it ideal for gears, bearings, and sliding components.

- Excellent machinability with tight tolerance capability

- Self-lubricating surface reduces wear

- Resists fuels, solvents, and many chemicals

- Available in FDA-compliant grades for food contact

Nylon (Polyamide)

When you need strength and impact resistance in a plastic, nylon for machining delivers. Machinable nylon grades handle demanding mechanical applications while remaining significantly lighter than metal alternatives. Machining nylon requires attention to its moisture absorption characteristics, as parts can change dimensions slightly in humid environments.

- Nylon 6/6: Highest strength and stiffness. Best for structural applications.

- Cast Nylon: Available in large blocks for big parts. Slightly better machinability than extruded grades.

- Oil-Filled Nylon: Embedded lubricant extends wear life in bearing applications.

Polycarbonate

Need optical clarity combined with impact resistance? CNC polycarbonate machining creates transparent components that won't shatter under stress. Safety shields, sight glasses, and protective covers frequently rely on this material.

- Virtually unbreakable - 250 times stronger than glass

- Maintains clarity after machining with proper techniques

- Temperature range from -40°F to 240°F

- Can be tinted or coated for specific applications

Acrylic (PMMA)

When optical clarity matters most and impact resistance is secondary, acrylic machines beautifully and polishes to a crystal-clear finish. Display cases, light guides, and decorative components often specify this material.

High-Performance Plastics

For extreme environments, specialty plastics push the boundaries:

- PEEK: Continuous service to 480°F, excellent chemical resistance, and strength approaching some metals. Expensive but irreplaceable for demanding applications.

- PTFE (Teflon): Lowest friction coefficient of any solid material. Challenging to machine but essential for seals and chemical handling.

- UHMW: Extreme wear and abrasion resistance. Self-lubricating and FDA compliant for food handling.

Matching Material Properties to Application Requirements

How do you navigate these options for your specific project? Start by identifying the non-negotiable requirements, then optimize for secondary factors.

Strength Requirements

If your part must withstand significant loads, metals generally outperform plastics. Within metals, the progression typically runs: aluminum < brass < carbon steel < stainless steel < alloy steel < titanium. Higher strength usually means higher material cost and slower machining, so specify only what your application truly demands.

Corrosion Resistance

Environmental exposure drives many material decisions. For mild indoor environments, carbon steel with proper coating works fine. Outdoor exposure calls for aluminum, stainless steel, or plastics. Marine and chemical environments demand 316 stainless, aluminum bronze, or specialized plastics like PEEK or PTFE.

Weight Constraints

When every gram matters - aerospace, portable equipment, or moving components that affect energy consumption - material density becomes critical. Plastics are lightest, followed by aluminum, then titanium, then steel. Often, aluminum at slightly thicker sections beats heavier materials while maintaining acceptable strength.

Cost Considerations

Material cost combines raw material price with machining time. A "cheap" material that machines slowly may cost more in finished part price than an "expensive" material that cuts quickly. Brass and aluminum machine fastest among metals. Stainless steel and titanium machine slowest. Among plastics, acetal and nylon machine efficiently, while PEEK requires careful technique and consumes more time.

Temperature Exposure

Operating temperature limits narrow options quickly. Most plastics fail above 200-250°F, though PEEK extends to 480°F. Aluminum weakens significantly above 300°F. Steel maintains properties to much higher temperatures. If heat is part of your environment, start by eliminating materials that won't survive.

Still uncertain? Most machining service providers maintain material specialists who can recommend optimal choices for your application. Providing them with complete information about operating conditions, loads, and environmental exposure enables better recommendations than simply requesting "stainless steel" or "aluminum."

With material selection complete, understanding the machining workflow from design submission to finished part helps set realistic expectations for timing and identifies opportunities to streamline your project.

The Complete CNC Machining Workflow Explained

You've selected your process and material. Now what actually happens when you submit an order? For many customers, the machining service workflow remains a black box - designs go in, parts come out, and everything in between feels mysterious. Understanding each stage helps you set realistic expectations, identify potential delays before they happen, and communicate more effectively with your manufacturing partner.

The journey from CAD file to finished component follows a logical sequence. Each phase builds on the previous one, and knowing what happens at each step empowers you to prepare better documentation upfront and ask informed questions throughout production.

- Design File Submission: You provide 3D CAD files (STEP, IGES, or native formats) along with 2D drawings specifying tolerances, surface finishes, and critical dimensions.

- Design Review and DFM Feedback: Engineers analyze your files for manufacturability, flagging potential issues and suggesting optimizations.

- Material Procurement: Raw stock is ordered or pulled from inventory based on your specifications.

- Machine Setup and Programming: CAM programmers generate toolpaths and G-code while operators prepare machines and tooling.

- Machining Operations: CNC machines execute programmed instructions to create your parts.

- Quality Inspection: Finished parts undergo dimensional verification against specifications.

- Finishing Operations: Secondary processes like anodizing, plating, or polishing are applied as required.

- Packaging and Shipping: Parts are protected and dispatched to your facility.

Design Submission and Engineering Review

The process begins the moment you upload your files. But what exactly should those files include? Complete documentation accelerates every subsequent phase, while missing information creates delays and potential misunderstandings.

Your submission should include:

- 3D CAD model: STEP format offers universal compatibility. Include native files if complex features might not translate perfectly.

- 2D drawing: Callout critical tolerances, surface finishes, and any features requiring special attention. Don't assume the 3D model communicates everything.

- Material specification: Beyond just "aluminum," specify the exact alloy and temper (e.g., 6061-T6).

- Quantity requirements: Both immediate needs and projected annual volumes help optimize pricing and process selection.

- Application context: What will the part do? This information helps engineers make appropriate DFM recommendations.

During design review, engineers examine your files against manufacturing realities. According to industry workflow documentation, this CAD-to-CAM translation process identifies potential issues before they become expensive problems on the shop floor. Common DFM feedback includes recommendations for wall thickness adjustments, internal corner radii modifications, or tolerance relaxation where tight specs add cost without functional benefit.

Expect design review to take one to three business days for standard parts, potentially longer for complex assemblies or tight-tolerance CNC machining parts requiring detailed analysis.

From Programming to First Article

Once design review concludes and you approve the quotation, production preparation begins. This phase transforms your digital design into physical reality through careful planning and machine preparation.

CAM programming generates the G-code instructions that control machine movements. Programmers select appropriate cutting tools, determine optimal feeds and speeds, and plan efficient toolpaths that balance cycle time against surface quality. For complex custom machined parts, this programming stage may require several hours of skilled engineering time.

Simultaneously, material procurement occurs. Common materials like 6061 aluminum or 304 stainless steel typically ship from suppliers within one to two days. Specialty alloys or unusual sizes may require longer lead times - sometimes weeks for exotic materials.

Machine setup involves:

- Installing appropriate cutting tools in the tool magazine

- Securing raw material in fixtures or vises

- Establishing coordinate systems and work offsets

- Loading and verifying the CNC program

- Running test cuts to confirm tool lengths and positions

The first article - your initial machined parts - receives extra attention. Operators monitor cutting conditions closely, pausing to verify dimensions at critical points. This first-piece inspection catches any programming errors or setup issues before they propagate through an entire batch.

For straightforward components, expect three to five days from order confirmation to first article completion. Complex geometries, tight tolerances, or specialty materials extend this timeline accordingly. CNC machine parts requiring multiple operations or setups naturally take longer than single-setup designs.

Quality Verification and Final Delivery

Machining operations complete the subtractive work, but your parts aren't ready for shipment yet. Quality verification confirms that every dimension, tolerance, and surface finish meets your specifications.

Inspection methods vary based on part complexity and industry requirements:

- Manual measurement: Calipers, micrometers, and height gauges verify basic dimensions quickly and economically.

- Coordinate Measuring Machines (CMM): For tight tolerances and complex geometries, CMM inspection provides comprehensive dimensional verification with documented reports.

- Surface roughness testing: Profilometers measure Ra values to confirm finish specifications.

- Visual inspection: Trained inspectors check for cosmetic defects, burrs, and workmanship quality.

Failed inspections trigger corrective action. Minor issues might be remedied through additional machining or hand finishing. Significant deviations require scrapping affected parts and producing replacements - another reason why thorough design review and first article inspection matter so much.

Finishing operations follow successful inspection. Common secondary processes include:

- Deburring and edge breaking

- Anodizing or chemical conversion coating for aluminum

- Plating (zinc, nickel, chrome) for steel parts

- Polishing or bead blasting for specific surface textures

- Heat treatment for hardness requirements

These finishing steps add time - typically two to five additional days depending on process complexity and whether work is performed in-house or sent to specialty vendors.

Finally, careful packaging protects your investment during transit. Precision machining parts often receive individual wrapping, foam cushioning, or custom packaging to prevent damage. Shipping options range from ground freight for standard timelines to expedited air service when speed matters most.

Total lead time from order to delivery? For typical machined parts in common materials with standard tolerances, expect two to three weeks. Rush services can compress this to under a week for simple parts, while complex assemblies with special finishes might require four to six weeks or longer.

Understanding this workflow reveals where you can accelerate timelines - complete documentation, readily available materials, relaxed tolerances where appropriate - and where delays typically originate. With realistic expectations set, the next step is ensuring your design maximizes manufacturability while minimizing unnecessary costs.

Design Guidelines That Reduce Cost and Lead Time

You understand the workflow. You've selected your material. But here's a reality many engineers discover too late: design decisions made before you ever contact a machining service can lock in 50% or more of your final part cost. The good news? Small adjustments to your CAD model - often taking just minutes - can dramatically reduce both price and production time without sacrificing functionality.

Think of design for manufacturability (DFM) as speaking the language of CNC machines. These machines excel at certain geometries and struggle with others. When your design aligns with machining capabilities, everything flows smoothly. When it fights against them, costs multiply and lead times stretch.

Critical Dimensions That Affect Machinability

Certain dimensional relationships directly determine how efficiently a CNC cut can be executed. Understanding these relationships helps you design parts that machines can produce quickly and accurately.

Wall Thickness

Thin walls present one of the most common manufacturability challenges. When walls become too thin, they deflect under cutting forces, vibrate during machining, and risk breaking entirely. According to DFM best practices from Summit CNC, all wall thicknesses should remain greater than 0.02 inches - and thicker is always better from a machining perspective.

For metals, aim for minimum wall thickness of 0.030" (0.76mm) whenever possible. Plastics require even more material - at least 0.060" (1.5mm) - because they deflect more readily under tool pressure. Small CNC machining operations on thin-walled parts often require reduced cutting speeds and lighter passes, directly increasing cycle time and cost.

Internal Corner Radii

Here's a geometric reality that surprises many designers: CNC milling parts cannot have perfectly sharp internal corners. Rotating end mills leave a radius equal to their diameter. Requesting sharper corners than standard tooling allows forces the use of smaller tools, longer reach cutters, and dramatically increased machining time.

The recommendation? Design internal corner radii of at least 0.0625" (1.6mm) - or better yet, 0.125" (3.2mm) when your design permits. This allows use of standard tooling running at optimal speeds. When sharp internal corners are functionally required, consider EDM as an alternative process, but expect significantly higher costs.

Pocket and Cavity Depths

Deep pockets create tool access problems. The deeper a cavity relative to the tool diameter required, the more likely you'll need specialized long-reach tooling that costs more and runs slower. Industry guidelines suggest limiting pocket depths to no greater than 6x the smallest corner radius in that pocket.

For example, if your pocket has 0.125" corner radii, keep the depth under 0.75". Exceeding this ratio doesn't make machining impossible - it just makes it more expensive and time-consuming as operators switch to specialized cutters prone to vibration and breakage.

Hole Depth-to-Diameter Ratios

Standard twist drills work efficiently up to depth-to-diameter ratios of about 4:1. A 0.250" diameter hole can be drilled to 1" depth without special consideration. Beyond this ratio, specialized drills, peck-drilling cycles, and increased caution become necessary.

For deep holes (10:1 ratio or greater), gun drilling or EDM may be required - processes that add significant cost. When possible, design holes no deeper than necessary and consider through-holes instead of blind holes, which are faster to produce and easier to inspect.

| Design Feature | Recommended Specification | Why It Matters | Cost Impact |

|---|---|---|---|

| Minimum Wall Thickness | Metals: ≥0.030" (0.76mm) Plastics: ≥0.060" (1.5mm) |

Prevents deflection, vibration, and breakage during CNC cuts | Thin walls add 20-40% to machining time |

| Internal Corner Radii | ≥0.0625" (1.6mm), preferably ≥0.125" | Matches standard tooling; avoids long-reach cutters | Sharp corners can double machining time |

| Pocket Depth | ≤6x smallest corner radius | Allows standard tools; reduces vibration and tool breakage | Deep pockets add 30-50% to cycle time |

| Hole Depth-to-Diameter | ≤4:1 for standard drilling | Standard drills work efficiently; no peck cycles needed | Deep holes may require 2-3x drilling time |

| Thread Depth | ≤3x nominal diameter | Standard taps reach easily; full thread engagement achieved | Excessive depth adds setup and risk |

| Undercuts | Avoid when possible; use standard T-slot dimensions | Requires special tooling and additional operations | Each undercut adds $25-100+ per part |

Avoiding Common Design Mistakes

Some design decisions seem logical on screen but create headaches on the shop floor. Recognizing these patterns before submitting your files saves revision cycles and prevents budget surprises.

Over-Specifying Tolerances

This might be the most expensive mistake in CNC machining materials selection and design. According to tolerance cost analysis from industry experts, tight tolerances increase costs exponentially - ±0.005" precision costs roughly 2x standard rates, while ±0.001" costs 4x more. Ultra-tight ±0.0001" tolerances can inflate costs by 10-24x.

The real question to ask: what happens if this dimension varies by ±0.05mm? If the answer is "nothing critical," standard tolerances serve you better. Reserve tight tolerances for:

- Mating surfaces where fit matters

- Bearing seats and shaft interfaces

- Sealing surfaces for O-rings or gaskets

- Features affecting critical function or safety

For everything else - external surfaces, non-functional features, cosmetic areas - standard tolerances of ±0.005" (±0.127mm) work perfectly and cost far less.

Designing Features That Fight Tool Access

CNC plastic machining and metal machining alike require physical tool access to every feature. Sounds obvious, but designs regularly arrive with features that tools simply cannot reach - or can only reach with expensive specialized setups.

Common access problems include:

- Deep narrow slots where tool diameter exceeds slot width

- Features hidden behind walls or projections

- Internal cavities with no tool entry path

- Text or engravings in recessed areas

Before finalizing your design, mentally trace a cutting tool path to every feature. If you can't visualize tool access, machining will be difficult or impossible without creative fixturing that adds cost.

Specifying Fillets Instead of Chamfers

External edges often need some form of break - either a fillet (rounded) or chamfer (angled). From a machining perspective, chamfers win on cost and speed. As DFM guidelines note, machining a fillet requires complex 3D tool paths or specialty corner-rounding tools, while chamfers are easily produced with standard chamfer mills.

Unless your application specifically requires rounded edges - for ergonomics, aerodynamics, or stress concentration reduction - specify chamfers and reduce machining time.

Adding Complexity for Aesthetics

That decorative pattern looked great in CAD. But every additional feature requires additional machining time. Complex aesthetic elements - intricate textures, non-functional curves, detailed engravings - add cost without improving function.

When optimizing for production, design for functionality first. Consider whether intricate geometries are truly critical to your part's end-use application, or whether simpler alternatives achieve the same purpose.

Optimizing Your Design for Production

Beyond avoiding mistakes, proactive design choices accelerate production and reduce costs. These optimizations require minimal design effort but yield significant manufacturing benefits.

Minimize Setups

Each time a part must be repositioned in the machine - flipped, rotated, or re-fixtured - adds setup time and introduces potential positional errors between features. Designs that can be completed in a single setup cost less and achieve better accuracy than those requiring multiple orientations.

Review your design with setup reduction in mind:

- Can features on opposite faces be accessed from one side with through-holes?

- Are multi-face features truly necessary, or can they be consolidated?

- Would a slight geometry change eliminate a flip operation?

Use Standard Tool Sizes

Holes at 0.250", 0.375", or 0.500" diameter? Standard drills are inexpensive and immediately available. Holes at 0.237" or 0.489"? Custom reamers or boring operations add time and cost.

Similarly, specifying standard thread sizes (10-32, 1/4-20, M6x1.0) allows use of readily available taps and inserts. Non-standard threads require special tooling that may need ordering.

Specify Material Form Strategically

The shape of your raw material affects how much machining is required. A part designed to fit efficiently within standard bar, plate, or rod stock dimensions wastes less material and machines faster than one requiring oversized blocks with extensive rough cutting.

Communicate with your machining service about available stock sizes before finalizing external dimensions. Sometimes adding 0.050" to a dimension allows use of next-size-down stock, reducing material cost and rough machining time.

Consider Prototype Versus Production Tolerances

During prototyping, you're validating design concepts - not producing final products. Starting with relaxed tolerances reduces prototype costs by 40-60% according to industry analysis. You can always tighten specific dimensions later if testing proves it necessary.

This iterative approach - prototype with standard tolerances, test, then tighten only what testing reveals as critical - delivers better results at lower total cost than over-specifying from the start.

Design optimization doesn't mean compromising your part's functionality. It means communicating your requirements in ways that align with manufacturing capabilities. When tolerances, features, and geometries match what CNC machines do well, everybody wins: you get better parts faster at lower cost.

With your design optimized for manufacturability, understanding exactly what tolerances and surface finishes are achievable - and what they cost - becomes the next critical knowledge gap to fill.

Tolerances and Surface Finishes Demystified

You've designed your part with manufacturability in mind. But how precise can a machining service actually make it? And what surface quality should you expect? These questions matter enormously - specify too loosely and parts won't function correctly; specify too tightly and costs skyrocket without adding real value.

Understanding tolerances and surface finishes transforms you from someone who simply accepts what's quoted to someone who makes informed decisions about precision requirements. Let's decode these specifications so you can communicate exactly what your application demands - nothing more, nothing less.

Standard Versus Tight Tolerance Requirements

Every dimension on a machined part has some acceptable range of variation. This is the tolerance - the difference between the largest and smallest acceptable measurement. No manufacturing process produces perfect parts, but CNC machining comes remarkably close.

Standard Tolerances represent what machines achieve under normal operating conditions without special measures. For most precision machining companies, this means:

- Linear dimensions: ±0.005" (±0.127mm)

- Hole diameters: ±0.005" (±0.127mm)

- Angular features: ±0.5°

According to industry specifications from Factorem, these standard tolerances accommodate inherent variations in material properties, tool wear, thermal expansion, and machine positioning without requiring special techniques or extended cycle times.

Tight Tolerances demand additional care - slower cutting speeds, more frequent measurements, temperature-controlled environments, and specialized equipment. Precision machining parts requiring tight tolerances typically specify:

- Precision grade: ±0.001" to ±0.002" (±0.025mm to ±0.050mm)

- High precision: ±0.0005" (±0.013mm)

- Ultra-precision: ±0.0001" (±0.003mm) - requires grinding or specialized equipment

When do you actually need tight tolerances? Focus on functional requirements:

- Press-fit assemblies where interference must be precisely controlled

- Bearing seats requiring specific clearance or interference

- Sealing surfaces where gaps cause leakage

- Mating components that must align perfectly

For CNC turning parts like shafts and bushings, bearing fits typically demand tight tolerances on diameter and concentricity. Similarly, stainless steel machining for valve components often requires precision on sealing surfaces while allowing standard tolerances elsewhere.

| Tolerance Grade | Typical Range | Common Applications | Cost Multiplier |

|---|---|---|---|

| Standard | ±0.005" (±0.127mm) | Non-critical dimensions, housings, brackets, covers | 1.0x (baseline) |

| Precision | ±0.002" (±0.050mm) | CNC milled parts with mating features, bearing housings | 1.5-2.0x |

| High Precision | ±0.0005" (±0.013mm) | CNC milled parts for aerospace, medical implants, optical mounts | 3.0-4.0x |

| Ultra-Precision | ±0.0001" (±0.003mm) | Gauge blocks, critical inspection fixtures, semiconductor | 8.0-24.0x |

Surface Finish Options and Applications

While tolerances control dimensions, surface finish describes texture - the microscopic peaks and valleys left by cutting tools. According to the ASME standards documented by GD&T Basics, surface finish comprises three elements: roughness (fine irregularities), waviness (broader spacing variations), and lay (directional pattern from machining).

The most commonly specified parameter is Ra (average roughness) - the arithmetic average of surface height deviations from the mean line, measured in micro-inches (μin) or micrometers (μm). Lower Ra values mean smoother surfaces.

Typical Ra Values Achievable by Process:

- Standard milling: 63-125 μin (1.6-3.2 μm)

- Fine milling: 32-63 μin (0.8-1.6 μm)

- Standard turning: 63-125 μin (1.6-3.2 μm)

- Fine turning: 16-32 μin (0.4-0.8 μm)

- Grinding: 8-32 μin (0.2-0.8 μm)

- Polishing: 2-8 μin (0.05-0.2 μm)

What finish does your application actually need? Consider these guidelines:

- Cosmetic/non-contact surfaces: 125 μin (3.2 μm) - standard as-machined finish is perfectly acceptable

- General mechanical contact: 63 μin (1.6 μm) - adequate for most sliding or rolling contact

- Sealing surfaces: 32 μin (0.8 μm) - required for O-ring grooves and gasket faces

- Bearing surfaces: 16-32 μin (0.4-0.8 μm) - critical for proper lubrication and wear life

- Optical or decorative: 8 μin (0.2 μm) or better - requires secondary polishing operations

International specifications often use Rz (mean roughness depth) instead of Ra. As a rough conversion, Rz values typically run 4-7 times higher than Ra for the same surface, though this relationship varies with surface uniformity.

Balancing Precision with Production Economics

Here's the uncomfortable truth: tighter tolerances invariably mean higher costs. As tolerance specialists note, the relationship is driven by several factors:

- Slower machining speeds to reduce tool deflection and thermal effects

- More frequent inspection during and after production

- Higher scrap rates as acceptable ranges narrow

- Specialized equipment for ultra-precision requirements

- Climate-controlled environments for critical measurements

The most cost-effective approach? Apply tight tolerances selectively. Review your design and ask: what actually fails if this dimension varies by the standard tolerance? For precision machining parts where function truly demands accuracy, specify it without hesitation. For everything else, standard tolerances deliver equivalent performance at dramatically lower cost.

Verification Methods Matter Too

How do machining services confirm your tolerances are met? The answer depends on what you've specified:

- Standard tolerances: Calipers, micrometers, and go/no-go gauges provide quick, economical verification

- Precision tolerances: Coordinate Measuring Machines (CMMs) generate comprehensive dimensional reports with documented traceability

- Surface finish: Profilometers measure Ra values directly, providing objective verification

- GD&T callouts: Specialized fixtures and CMM programming verify complex geometric relationships

For critical applications, request inspection documentation with your parts. Most precision machining companies provide dimensional reports showing actual measured values compared to specifications - documentation that becomes essential for quality traceability in regulated industries.

Understanding what's achievable - and what it costs - puts you in control of the precision versus economics tradeoff. With tolerances and finishes specified appropriately, the next question becomes: is CNC machining even the right process for your application, or would alternative manufacturing methods serve you better?

CNC Machining Versus Alternative Manufacturing Methods

You've mastered tolerances, optimized your design, and selected the perfect material. But here's a question worth asking before committing to any machining service: is CNC machining actually the right manufacturing method for your project? Sometimes the answer is a resounding yes. Other times, alternative processes deliver better results at lower cost.

This isn't about declaring one method superior to another. Each manufacturing approach has a sweet spot - specific combinations of quantity, complexity, precision, and budget where it outperforms all alternatives. Understanding these sweet spots helps you make smarter decisions and avoid expensive mismatches between process and project requirements.

When Additive Manufacturing Makes More Sense

3D printing has evolved from a rapid prototyping novelty into a legitimate manufacturing option for specific applications. But when should you choose additive over subtractive?

According to comparative analysis from Ultimaker, 3D printing excels at producing complex geometries and internal structures that would be challenging or impossible to achieve through traditional manufacturing methods. Think lattice structures for weight reduction, internal cooling channels, or organic shapes that follow stress paths rather than machining constraints.

Choose 3D printing when:

- Quantity is very low (1-10 parts) - no setup costs make small batches economical

- Geometry is highly complex - internal features, undercuts, and organic shapes print easily

- Speed matters most - rapid cnc prototyping alternatives can deliver overnight

- Material properties are secondary - when strength and precision aren't critical

Choose CNC machining instead when:

- Material properties matter - machined parts maintain full material strength without layer lines

- Precision is critical - CNC achieves tolerances of ±0.025mm versus ±0.1mm to ±0.5mm for most 3D printing

- Surface finish counts - machined surfaces reach 0.8 μm Ra versus 15 μm for printed parts

- Quantities exceed 10-20 parts - CNC becomes more cost-effective at moderate volumes

For cnc prototype development, the decision often comes down to purpose. Need a visual model to check ergonomics or proportions? 3D printing delivers faster and cheaper. Need functional validation under real loads? CNC machining prototyping provides parts with production-representative properties.

Many successful product development programs use both methods strategically. Early concept prototypes might be printed for speed and economy, while later functional prototypes are machined to validate actual performance. Prototype machining services bridge this gap, offering rapid turnaround on machined parts when functional testing demands real-material properties.

Injection Molding Versus Machining Economics

The machining versus molding decision fundamentally comes down to quantity. As cost analysis from Cubein explains, injection molding wins at affordable production for many parts, while CNC machining is easier for prototyping and manufacturing small batches.

Here's why: injection molding requires significant upfront tooling investment - anywhere from $2,000 for simple aluminum molds to $100,000 or more for complex multi-cavity steel tools. Once that mold exists, each part costs pennies to produce. CNC machining requires no tooling but costs more per part regardless of quantity.

The crossover point varies by part complexity, but general guidelines suggest:

- Under 100 parts: CNC machining almost always wins economically

- 100-500 parts: Evaluate both options carefully; complexity determines the winner

- 500-10,000 parts: Low-volume injection molding becomes increasingly attractive

- 10,000+ parts: Injection molding dominates on cost per part

But economics aren't everything. Consider these additional factors:

Timeline: CNC prototype machining delivers parts in days. Injection mold tooling requires 4-8 weeks before first parts arrive. If speed to market matters, machining buys you time.

Design flexibility: Changing a CNC program takes hours. Modifying an injection mold costs thousands and takes weeks. During product development when designs evolve rapidly, cnc machining prototyping preserves flexibility.

Material options: CNC machines metals, engineering plastics, and composites with equal ease. Injection molding works primarily with thermoplastics, limiting material choices.

Precision: CNC machining achieves tighter tolerances than injection molding (±0.005" versus ±0.020" typically). For precision components, machining may be necessary regardless of quantity.

Smart manufacturers often use both processes across a product lifecycle. Prototype machining services validate designs quickly, then production transitions to injection molding once volumes justify tooling investment and design stability is confirmed.

Choosing the Right Process for Your Project

Beyond 3D printing and injection molding, other manufacturing methods compete with CNC machining for specific applications. Die casting offers high-volume metal part production. Sheet metal fabrication excels at enclosures and brackets. Each has distinct advantages worth considering.

| Manufacturing Method | Best Quantity Range | Precision Level | Material Options | Lead Time | Cost Structure |

|---|---|---|---|---|---|

| CNC Machining | 1-10,000 parts | ±0.001" to ±0.005" | All metals, plastics, composites | Days to weeks | No tooling; moderate per-part |

| 3D Printing | 1-100 parts | ±0.004" to ±0.020" | Plastics, some metals, resins | Hours to days | No tooling; higher per-part |

| Injection Molding | 500-1,000,000+ parts | ±0.005" to ±0.020" | Thermoplastics primarily | Weeks (tooling) + days | High tooling; very low per-part |

| Die Casting | 1,000-500,000+ parts | ±0.010" to ±0.030" | Aluminum, zinc, magnesium alloys | Weeks (tooling) + days | High tooling; low per-part |

| Sheet Metal Fabrication | 1-50,000 parts | ±0.005" to ±0.015" | Sheet metals (steel, aluminum, etc.) | Days to weeks | Low tooling; varies by complexity |

Use this decision framework to select your optimal process:

- Define your quantity requirements - both immediate needs and projected lifetime volumes. Low quantities favor CNC; high volumes favor tooled processes.

- Assess precision requirements - if tolerances under ±0.005" are critical, CNC machining or grinding may be your only options.

- Consider material constraints - specific alloys, engineering plastics, or composite materials often dictate process selection.

- Evaluate timeline pressures - prototype machining services deliver in days; tooled processes require weeks of preparation.

- Calculate total project economics - include tooling amortization, per-part costs, quality costs, and time-to-market value.

For cnc prototyping applications, the answer is usually straightforward: machining provides the fastest path from design to functional hardware with production-representative materials. For production, the calculation becomes more nuanced, balancing setup investments against per-part economics.

The best manufacturing partners help you navigate these decisions. They'll recommend CNC machining when it's genuinely optimal and suggest alternatives when other processes better serve your goals. This honest consultation - rather than pushing every project toward their preferred equipment - marks the difference between vendors and true manufacturing partners.

With process selection clarified, the next consideration becomes industry-specific: what certifications and quality standards does your application demand, and how do you verify that a machining service meets those requirements?

Industry Certifications and Quality Standards

You've selected the right manufacturing process for your project. But here's a question that separates adequate suppliers from exceptional ones: does your machining service hold the certifications your industry demands? In regulated sectors like aerospace, medical, and automotive, certifications aren't optional paperwork - they're mandatory proof that a manufacturer can consistently deliver parts meeting the strictest quality requirements.

Think of certifications as a manufacturer's quality DNA. They document proven systems for controlling processes, tracing materials, inspecting parts, and correcting problems before they reach customers. When you source from certified machine shop services, you're not just buying parts - you're buying into a verified quality infrastructure that protects your products and your reputation.

Automotive Industry Standards and IATF 16949

The automotive industry operates on razor-thin margins with zero tolerance for defects that could trigger recalls or endanger drivers. IATF 16949 certification represents the global quality management standard specifically developed for automotive production and relevant service part organizations.

According to industry analysis, automotive supply chains require strict adherence to IATF 16949 standards, with third-party audits now standard practice among global OEMs. Non-compliant suppliers risk exclusion from strategic supply chains entirely.

What IATF 16949 requires:

- Statistical Process Control (SPC): Real-time monitoring of critical dimensions during production, not just final inspection

- Advanced Product Quality Planning (APQP): Structured methodology for launching new parts with validated processes

- Production Part Approval Process (PPAP): Documented evidence that production processes can consistently manufacture parts meeting specifications

- Measurement System Analysis (MSA): Verified inspection equipment and methods capable of detecting required variations

- Continuous improvement culture: Documented corrective actions and preventive measures for any quality deviations

For precision cnc machining services supplying automotive components, IATF 16949 certification signals capability to handle the industry's demanding requirements. Manufacturers like Shaoyi Metal Technology demonstrate this commitment through their IATF 16949 certification and implementation of Statistical Process Control across their precision automotive component production, including complex chassis assemblies and high-tolerance parts.

When should you require IATF 16949? Any component destined for automotive applications - whether engine parts, chassis assemblies, or interior mechanisms - benefits from suppliers holding this certification. The discipline it enforces translates directly into consistent quality and reliable delivery.

Aerospace and Defense Compliance Requirements

If automotive standards are demanding, aerospace cnc machining requirements are unforgiving. When components operate at 40,000 feet or in combat conditions, failure modes that might cause inconvenience elsewhere become catastrophic. AS9100 certification builds on ISO 9001 foundations with aerospace-specific requirements that address these elevated stakes.

AS9100 mandates capabilities beyond general machining services:

- Configuration management: Rigorous control ensuring parts exactly match approved design revisions

- Risk management: Formal assessment and mitigation of technical, schedule, and quality risks

- First Article Inspection (FAI): Comprehensive dimensional verification of initial production parts per AS9102 requirements

- Foreign Object Debris (FOD) prevention: Programs preventing contamination that could cause in-flight failures

- Special process controls: Qualified procedures for heat treatment, plating, and non-destructive testing

- Counterfeit parts prevention: Documented material traceability from mill certification through finished component

As noted in certification guidance from industry experts, being an AS9100 and ISO-certified machine shop allows manufacturers to provide the highest quality parts for all customers - the discipline transfers even to non-aerospace work.

Traceability takes on special significance in aerospace. According to quality management specialists, traceability guarantees are given through registration of lots, origin of materials, services and parts, manufacturing date, and other relevant information from the production process. For aerospace components, this means every part can be traced back to specific material heat lots, machine operators, and inspection records - documentation that becomes critical if questions arise years after delivery.

Medical Device Manufacturing Protocols

Medical machining operates under its own regulatory framework centered on ISO 13485 and FDA oversight. When machined components become surgical instruments, implants, or diagnostic equipment, the stakes involve patient safety and regulatory approval for entire medical devices.

ISO 13485 certification addresses medical device-specific requirements:

- Design and development controls: Documented validation that designs meet intended use requirements

- Risk management per ISO 14971: Systematic identification and mitigation of hazards throughout product lifecycle

- Sterile product controls: When applicable, validated cleaning and packaging processes

- Biocompatibility considerations: Material selection and processing compatible with patient contact

- Complaint handling systems: Formal procedures for investigating and addressing quality issues

- Regulatory reporting: Documentation supporting FDA 510(k) or international regulatory submissions

According to market analysis, the global medical device market is growing at 5.5% CAGR, with CNC machining indispensable for producing implants, surgical instruments, and diagnostic equipment. CNC precision enables compliance with ISO 13485 and FDA standards that govern this expanding sector.

For general machining services seeking to enter medical markets, the certification journey requires significant investment in documentation systems, validated processes, and ongoing compliance maintenance. But for buyers, working with ISO 13485-certified suppliers dramatically simplifies regulatory submissions and reduces risk of supply chain disruptions from quality failures.

Certification Requirements by Industry:

- Automotive: IATF 16949 (quality management), VDA 6.3 (process audits), CQI standards (special processes)

- Aerospace: AS9100 (quality management), Nadcap (special processes), ITAR compliance (defense articles)

- Medical: ISO 13485 (quality management), FDA registration, cleanroom capabilities where required

- Electronics: ISO 9001 (quality management), IPC standards (workmanship), ESD controls

- General Industrial: ISO 9001 (quality management baseline)

How do you verify a supplier's certification claims? Legitimate certifications come from accredited registrars and include certificate numbers that can be verified. Ask for copies of current certificates and confirm validity with the issuing body if certifications are critical to your application. Expired or fabricated certifications - unfortunately not unheard of - expose your products to significant quality and regulatory risk.

Beyond certifications, understanding what drives machining costs empowers you to optimize pricing without sacrificing quality - the subject we'll explore next.

Understanding Machining Service Pricing Factors

You've selected your process, optimized your design, and verified supplier certifications. Now comes the question every buyer asks: what will this actually cost? Unlike commodity products with fixed price tags, machining service pricing varies dramatically based on dozens of interrelated factors. Understanding what drives these variations transforms you from someone who simply accepts quotes to someone who can strategically reduce costs while maintaining quality.

Here's the reality: two seemingly similar parts can differ in price by 300% or more based on design decisions, material choices, and quantity requirements. The difference between an expensive part and an economical one often comes down to knowledge - knowing which factors inflate costs and which optimizations deliver savings without compromising function.

What Drives Machining Costs

Every machine shop quote reflects a combination of cost elements, each contributing to the final cnc machining price. According to industry pricing analysis, understanding these components helps you identify where savings are possible:

- Machine Time: The single largest cost driver for most parts. CNC machines represent significant capital investments, and shops charge hourly rates ranging from $35-40 per hour for 3-axis milling to $75-120 per hour for multi-axis operations. Every minute your part spends under the spindle adds directly to cost.

- Material Costs: Raw stock prices vary enormously - aluminum runs $5-10 per pound, steel $8-16, stainless steel higher still, and titanium or specialty alloys can reach $25-50 or more. The machinist metal cost also includes the blank size required, not just what ends up in your finished part.

- Setup and Programming: Before any cutting begins, CAM programmers must generate toolpaths and operators must fixture your part. This non-recurring engineering (NRE) cost can range from $50-200 for simple parts to $500+ for complex geometries requiring custom fixtures.

- Tolerance Requirements: Tighter tolerances demand slower speeds, more frequent inspection, and higher scrap rates. Moving from ±0.005" to ±0.001" can double machining time on critical features.

- Complexity and Geometry: Deep pockets, thin walls, and tight internal corners require specialized tooling, slower feeds, and careful technique - all adding time and cost.

- Finishing Operations: Anodizing, plating, polishing, and other secondary processes add $2-20+ per part depending on requirements.

- Quality and Inspection: CMM inspection reports, first article documentation, and material certifications require time and expertise beyond basic production.

As TMC Technologies explains, the formula for estimating costs breaks down as: Estimated Cost = (Material Cost + Setup Cost) + (Machining Time × Hourly Rate) + Finishing Cost. This framework helps you understand where your money goes and where optimization efforts yield the greatest returns.

Material Machinability Matters

Not all materials machine equally. Harder materials require slower cutting speeds and wear through tooling faster - both adding cost. According to industry guidelines, machinability ratings help predict relative expenses:

- Excellent machinability (lowest cost): Brass 360, aluminum 6061, free-machining steels like 12L14

- Good machinability: Most aluminum alloys, bronze, carbon steels

- Moderate machinability: Stainless steels (304, 316), alloy steels

- Challenging (highest cost): Titanium, Inconel, hardened tool steels

Choosing aluminum over stainless steel - when your application permits - can reduce machining time by 40-60%, delivering substantial savings on machine time charges.

How Quantity Affects Per-Part Pricing

One of the most powerful cost levers available to buyers is order quantity. The economics work dramatically in favor of larger batches, though the relationship isn't always intuitive.

Why single parts cost more:

Every production run requires setup - programming, fixturing, tool loading, and first-article verification. Whether you order one part or one hundred, these costs remain nearly constant. For a single prototype, that entire setup investment lands on one part. Order ten parts, and setup cost per unit drops by 90%.

According to cost optimization research from Fictiv, setup time makes up a large portion of machining bills at the prototyping stage and should be minimized as much as possible. Their recommendation: order more than one of each part so your unit cost is lower, but not so many that you're making unneeded parts.

Quantity price breaks typically follow this pattern:

- 1-5 parts: Highest per-unit cost; setup dominates pricing

- 10-25 parts: 20-40% reduction as setup amortizes across more units

- 50-100 parts: 40-60% reduction; production efficiencies emerge

- 250+ parts: 60-80% reduction; batch optimization and reduced handling per part

For small parts manufacturing or custom machine projects, this quantity effect is even more pronounced. The setup time for a small precision component might exceed actual machining time - making quantity the dominant pricing variable.

Strategic quantity planning:

If you anticipate needing parts over time, consider ordering your projected annual quantity in one batch rather than multiple small orders. Many buyers order prototypes in quantities of 5-10 rather than single units, gaining better unit pricing while having spares for testing variations or replacing damaged samples.

Getting Accurate Quotes Efficiently

The quality of your quote request directly affects the accuracy of pricing you receive. Incomplete information forces suppliers to make assumptions - usually conservative ones that inflate quoted prices to cover uncertainty.

For the most accurate online machining quotes, provide:

- Complete 3D CAD files: STEP format ensures universal compatibility

- 2D drawings with tolerances: GD&T callouts remove ambiguity about precision requirements

- Specific material grade: "6061-T6 aluminum" rather than just "aluminum"

- Surface finish requirements: Ra values or finish descriptions

- Quantity needed: Both immediate order and projected annual usage

- Required delivery date: Expedite fees can add 25-50% or more

- Finishing requirements: Anodizing, plating, or other secondary operations

- Quality documentation needs: Inspection reports, certifications, PPAP requirements

Modern cnc quote online platforms can process well-documented requests and return pricing within hours. Missing information, conversely, triggers manual review cycles that delay response and often result in higher quotes to cover unstated requirements.

How to reduce your machine shop quote:

Beyond providing complete documentation, strategic choices during design and specification phases yield the greatest cost reductions:

- Relax non-critical tolerances: Standard ±0.005" tolerances cost far less than precision grades

- Choose machinable materials: Aluminum and brass machine faster than stainless or titanium

- Minimize setups: Design features accessible from fewer orientations

- Avoid deep pockets and thin walls: Standard geometries machine faster

- Use standard hole sizes: Common drill sizes avoid custom tooling

- Consolidate finishing: One finish type rather than multiple surface treatments

- Plan for reasonable lead times: Rush orders carry premium pricing

According to industry specialists, customers can save up to 30% on CNC machining costs by opting for batch production and implementing design optimization strategies. The savings compound when multiple optimization approaches combine.

Understanding quote variations between suppliers:

Requesting quotes from multiple machine shop services often yields surprisingly different prices. This variation reflects genuine differences in:

- Equipment capabilities and hourly rates

- Material sourcing costs and relationships

- Overhead structures and profit margin requirements

- Experience with your specific part type

- Current capacity utilization

The lowest quote isn't always the best value. Consider supplier capabilities, quality systems, communication responsiveness, and delivery reliability alongside price. A slightly higher quote from a supplier with proven quality and on-time delivery often delivers better total value than the cheapest option with uncertain execution.

Armed with this pricing knowledge, you're prepared to evaluate machining service providers based on factors that truly matter for your project - the focus of our final section.

Selecting the Right Machining Service Partner

You've mastered the technical fundamentals - processes, materials, tolerances, and pricing factors. Now comes the decision that determines whether all that knowledge translates into successful parts: choosing the right manufacturing partner. This choice extends far beyond comparing quotes. The machining service you select becomes an extension of your engineering team, directly impacting product quality, development timelines, and ultimately your competitive position.

Whether you're searching for a cnc machine shop near me or evaluating global suppliers, the same evaluation criteria apply. The difference between a frustrating manufacturing experience and a seamless one often comes down to asking the right questions before placing your first order.

Evaluating Technical Capabilities and Equipment

Start your evaluation with a fundamental question: can this provider actually make your parts? Sounds obvious, but capability mismatches cause more project failures than any other factor.

According to industry guidance from 3ERP, a CNC machining service is only as effective as the tools at its disposal. Whether it's lathes, mills, or routers, the variety and quality of machinery can make or break your project. Different types of CNC machines cater to different kinds of tasks.

Key equipment questions to ask:

- Machine types and axis counts: 3-axis milling handles simple geometries; complex parts may require 4-axis or 5-axis capabilities

- Work envelope sizes: Can their machines accommodate your part dimensions?

- Turning capabilities: For cylindrical components, do they offer CNC lathes or swiss-type machines?

- Secondary equipment: EDM, grinding, and other specialized processes for challenging features

- Inspection equipment: CMM capabilities for verifying tight tolerances

Beyond equipment lists, evaluate technical expertise. As PEKO Precision notes, the OEM evaluation team must look at the strategies the shop uses to run parts. Different volumes, setups, cycle times and flow all can seriously affect the price, quality and lead time of an order. A shop with the right machines but poor process optimization delivers inferior results compared to one that maximizes their equipment capabilities.

When evaluating machining shops near me or distant suppliers, request examples of similar parts they've produced. Past projects reveal their true capabilities better than equipment lists alone.

Quality Systems That Protect Your Investment

Technical capability gets parts made. Quality systems ensure those parts consistently meet specifications. This distinction becomes critical when your products depend on reliable component performance.

According to Modus Advanced's manufacturing guidance, quality in custom manufacturing isn't just about meeting specifications - it's about building robust systems that consistently deliver excellence. Look beyond basic certifications to understand their quality philosophy.

Signs of a strong quality culture include:

- Documented inspection procedures: Written protocols for dimensional verification at each production stage

- Statistical process control: Real-time monitoring of critical dimensions during production

- Corrective action systems: Formal procedures for investigating and preventing quality issues

- Calibrated equipment: Regularly verified measuring instruments with traceability documentation

- Material traceability: Ability to trace every part back to specific material lots and production records

When machinist shops near me or any prospective supplier claim quality excellence, ask for evidence. Request sample inspection reports, review their quality manual, and inquire about their defect rates and corrective action history. Genuine quality-focused suppliers welcome these questions.

- Verify certifications match your industry requirements - ISO 9001 minimum; IATF 16949 for automotive; AS9100 for aerospace; ISO 13485 for medical

- Request sample inspection documentation - quality of reports reveals inspection rigor

- Ask about in-process versus final inspection - catching issues during production prevents costly scrap

- Evaluate measurement capabilities - CMM equipment for tight tolerances; surface finish testers for critical surfaces

- Review material certification procedures - traceability from mill certs through finished parts

- Understand corrective action processes - how they handle and prevent quality escapes

- Assess communication responsiveness - quick responses to technical questions indicate engaged engineering support

- Check delivery performance history - on-time delivery reflects overall operational discipline

- Evaluate technical consultation capabilities - DFM feedback quality shows engineering depth

- Confirm scalability from prototype to production - seamless transition protects your development timeline

Scaling from Prototype to Production

Here's a scenario that frustrates countless engineering teams: your prototype supplier delivers excellent parts, but they can't handle production volumes. Or your production source requires minimum orders too large for prototype quantities. Finding a partner that handles both ends of the spectrum eliminates painful supplier transitions.

According to manufacturing partnership experts, a truly valuable custom manufacturing partner can support your product from initial concept through production scaling. This requires diverse manufacturing capabilities and a willingness to work with varying volume requirements.

Evaluate scalability by examining:

- Minimum order quantities: Will they produce single prototypes, or do they require batch minimums?

- Production capacity: Can they scale to thousands of parts when your product succeeds?

- Lead time flexibility: Rapid turnaround for prototypes; reliable scheduling for production

- Process consistency: Same quality at 10 parts as at 10,000 parts

- Pricing transparency: Clear volume break points so you can plan manufacturing economics

Manufacturers demonstrating this seamless scaling capability provide significant advantages. Shaoyi Metal Technology exemplifies this approach, offering precision CNC machining services that scale from rapid prototyping to mass production with lead times as fast as one working day. Their high-tolerance component capabilities and proven automotive industry expertise - backed by IATF 16949 certification and Statistical Process Control - demonstrate how the right partner eliminates the prototype-to-production gap that stalls so many product development programs.

Communication and responsiveness matter equally:

As 3ERP emphasizes, communication is the backbone of any successful partnership. An effective communication process means the service provider can promptly address your queries, update you on progress, and quickly rectify any issues that may arise.

During your evaluation, note response times to your inquiries. Suppliers who take days to return emails during the quoting phase rarely improve after receiving your order. Look for transparent communication channels and proactive updates rather than having to chase for status information.

Finding the right machining service partner - whether you're searching for a cnc shop near me or evaluating global options - requires balancing technical capabilities, quality systems, and operational flexibility. The investment in thorough evaluation pays dividends throughout your product lifecycle, transforming manufacturing from a source of problems into a competitive advantage.

When you find a partner combining technical excellence with quality discipline and scalability, you've found more than a supplier. You've found a manufacturing relationship that accelerates your success from first prototype through production ramp-up and beyond.

Frequently Asked Questions About Machining Services

1. What is the hourly rate for a CNC machine?

CNC machining rates vary significantly based on machine complexity and capability. Standard 3-axis milling typically costs $35-40 per hour, while advanced multi-axis operations range from $75-120 per hour. Factors affecting rates include machine type, operator expertise, facility location, and required precision levels. For automotive-grade precision work with IATF 16949 certification and Statistical Process Control, specialized providers like Shaoyi Metal Technology offer competitive rates with lead times as fast as one working day for high-tolerance components.

2. What is machining work?

Machining is a subtractive manufacturing process where material is systematically removed from a solid block to create precision parts. Using computer-controlled equipment, CNC machines follow programmed instructions to cut, drill, mill, or turn raw materials like metals and plastics into finished components. This process achieves tight tolerances often within 0.005 inches, making it essential for aerospace, automotive, medical, and industrial applications requiring exact specifications and consistent quality.

3. How is machining cost calculated?

Machining costs combine several factors: material cost (varying from $5-50+ per pound depending on alloy), setup and programming charges ($50-500+), machine time at hourly rates ($35-120/hour), tolerance requirements (tight tolerances can double costs), and finishing operations ($2-20+ per part). The formula is: Estimated Cost = (Material Cost + Setup Cost) + (Machining Time × Hourly Rate) + Finishing Cost. Quantity significantly impacts per-unit pricing, with batch orders of 50+ parts often reducing costs by 40-60%.