The Real Reason Stamped Steel Control Arms Cost Less

TL;DR

Stamped steel control arms are cheaper primarily because of their manufacturing process. Unlike cast or forged alternatives, they are made by stamping and welding sheets of steel—a method that is significantly faster, more automated, and uses less material for high-volume production. This efficiency in mass production directly translates to a lower cost for both vehicle manufacturers and consumers seeking replacements.

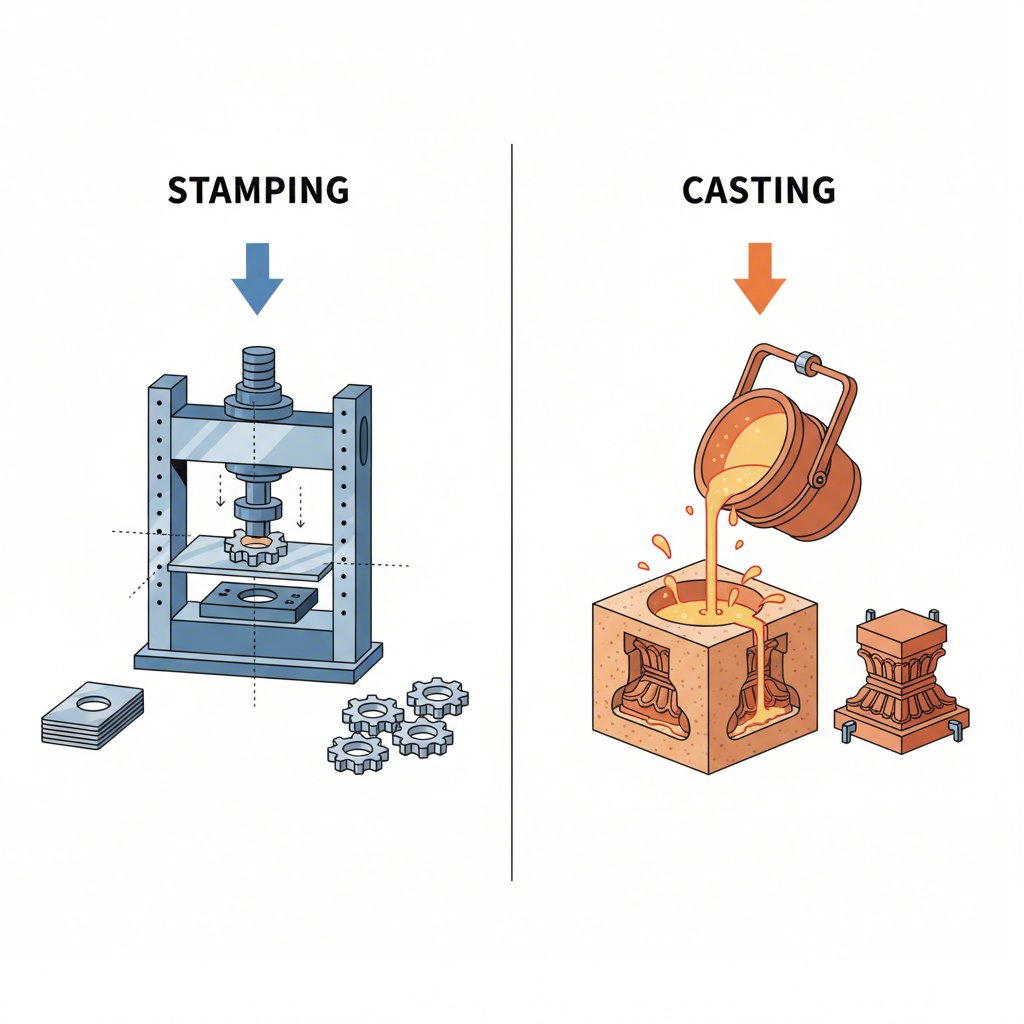

The Manufacturing Difference: Why Stamping Costs Less

The core reason for the price difference between stamped steel control arms and their cast or forged counterparts lies in how they are made. Understanding these distinct industrial processes reveals why one method is inherently more economical for mass production. Each approach creates a functional part, but the journey from raw material to finished product varies dramatically in time, complexity, and cost.

Stamped steel control arms begin as flat sheets of steel. A large hydraulic press, or stamp, cuts and forms these sheets into the required shape, creating two halves that are then welded together to form the final component. According to automotive parts specialists Skyjacker, a key identifier of a stamped steel arm is the visible weld seam where the two halves are joined. This process is highly automated and extremely fast, capable of producing thousands of identical parts with minimal human intervention. For manufacturers producing vehicles on a massive scale, this efficiency is paramount. The primary benefits are reduced labor costs and a high-speed production cycle.

In contrast, cast iron or cast aluminum control arms are made through casting. This involves pouring molten metal into a mold and allowing it to cool and solidify. The result is a single, solid piece of metal. While this creates a very strong part, the process is slower, more energy-intensive (due to melting the metal), and the molds themselves can be expensive to create and maintain. This method is better suited for producing thicker, more robust components often required for heavy-duty vehicles like trucks and SUVs. GMT Rubber notes that cast iron is preferred for these applications due to its strength and ability to cope with harsh environments.

Here's a simple breakdown of the key process differences:

- Stamped Steel: Involves cutting, pressing, and welding metal sheets. It's fast, highly automated, and ideal for high-volume, low-cost production.

- Cast Steel/Iron: Involves melting metal and pouring it into a mold. It's slower, more energy-intensive, and results in a single, solid part often used for heavy-duty applications.

The economic advantage of stamping is clear: it's a 'low cost solution,' as noted in several automotive forums, making it the go-to choice for most modern passenger cars where cost-effectiveness is a key design consideration. For automotive manufacturers who rely on precision and efficiency, specialized companies are key. For instance, those seeking comprehensive solutions from prototyping to mass production in metal stamping often turn to experts like Shaoyi (Ningbo) Metal Technology Co., Ltd., which leverages advanced automation to ensure high-quality, cost-effective components.

Performance & Durability: Stamped Steel vs. Cast and Aluminum

While cost is a major factor, the material and manufacturing process of a control arm also directly influence its performance, durability, and ideal application. Stamped steel, cast iron, and cast aluminum each present a unique set of trade-offs that engineers weigh when designing a vehicle's suspension system. Choosing the right replacement involves understanding these differences to match the part to your vehicle's needs and your driving style.

Stamped steel arms are the baseline—affordable and perfectly adequate for the daily demands of most compact cars and sedans. However, their construction from welded plates makes them more susceptible to rust, especially in wet climates or areas where road salt is common. While strong enough for standard use, they may not offer the rigidity required for heavy-duty applications or performance driving.

Cast iron control arms, as mentioned, are the heavyweights. Their solid construction provides superior strength, making them the standard choice for trucks and SUVs that handle heavy loads and rougher terrain. The trade-off is their weight; cast iron is significantly heavier than stamped steel or aluminum, which can impact ride quality and fuel efficiency. Cast aluminum offers a compelling alternative, providing strength that can rival steel but at a much lower weight. As explained by PartsAvatar, aluminum's light weight reduces unsprung mass, which improves handling and ride comfort. It's also naturally corrosion-resistant, a major advantage over steel. However, aluminum is more expensive and can be more prone to cracking upon sharp impact, whereas steel is more likely to bend.

To help you decide, here is a comparison of the different control arm materials:

| Material Type | Pros | Cons | Commonly Used On |

|---|---|---|---|

| Stamped Steel | Lowest cost, lighter than cast iron | Prone to rust, less rigid | Economy cars, standard sedans |

| Cast Iron/Steel | Highest strength, very durable | Heavy, can be susceptible to rust | Trucks, SUVs, heavy-duty vehicles |

| Cast Aluminum | Lightweight, corrosion-resistant, strong | Higher cost, can crack on impact | Performance cars, luxury vehicles |

Ultimately, the choice depends on the application. For a standard daily driver, a direct replacement with a stamped steel arm is often the most practical and economical choice. However, for a lifted truck, a performance vehicle, or for drivers in harsh climates, upgrading to a cast iron or aluminum control arm can be a worthwhile investment in durability and performance.

How to Identify Your Vehicle's Control Arms

Before ordering a replacement part, it's crucial to know exactly what type of control arms are on your vehicle. As highlighted in a guide from Maxtrac Suspension for Silverado and Sierra trucks, manufacturers sometimes used different materials on the same models within the same year, making visual identification essential. Getting it wrong can mean receiving a part with an incompatible ball joint or knuckle fitment.

Fortunately, identifying your control arms is a straightforward process you can do at home with a quick inspection. The primary identifiers are the surface finish, the presence of seams, and the material's magnetic properties. Each type has distinct visual and physical cues that make it easy to tell them apart once you know what to look for.

Follow these steps to determine which control arms your vehicle has:

- Clean the Control Arm: Use a rag and some degreaser to wipe down the control arm. Dirt and grime can hide the key features you need to see.

- Examine the Surface Finish and Color: Look closely at the arm's appearance. Stamped steel arms typically have a smooth, glossy black painted finish. Cast steel or iron arms have a rough, textured surface with a dull black finish. Cast aluminum arms will have a raw silver or gray color and a similarly textured finish.

- Look for Seams: This is a key differentiator. A stamped steel arm is made of two halves welded together, so you will see a distinct welded seam running along its edges. In contrast, cast arms are made in a mold, which leaves a thin casting line or seam, but no weld.

- Use a Magnet: This is the definitive test to distinguish steel from aluminum. A magnet will stick firmly to both stamped steel and cast steel/iron control arms. It will not stick to an aluminum control arm.

By following these simple steps, you can confidently identify your vehicle's control arms and ensure you order the correct replacement part the first time. This simple check can save you from the headache of returns and project delays.

Frequently Asked Questions

1. What is the difference between cast iron and stamped steel control arms?

The primary difference is in their manufacturing and application. Stamped steel control arms are made from pressed and welded steel sheets, making them inexpensive to produce and suitable for standard passenger cars. Cast iron control arms are made from molten iron poured into a mold, resulting in a stronger, heavier part ideal for heavy-duty vehicles like trucks and SUVs that operate in harsh environments.

2. What is the best material for control arms?

There is no single "best" material; it depends on the vehicle and its use. Aluminum is excellent for performance and luxury cars because it's lightweight and corrosion-resistant, improving handling. Cast iron is superior for trucks needing maximum strength and durability. Stamped steel is the most cost-effective solution for everyday passenger vehicles where budget is a primary concern.

3. What is a stamped steel control arm?

A stamped steel control arm is a suspension component made by stamping two pieces of sheet steel into a desired shape and then welding them together. You can typically identify them by their smooth, glossy black finish and the visible welds along their seams. They are the most common type on modern, inexpensive cars due to their low manufacturing cost.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —