Why Stamped Steel Control Arms Compromise Car Handling

TL;DR

Stamped steel control arms are a common, cost-effective factory component that can negatively affect your vehicle's handling. Their primary drawback is a tendency to flex under cornering or acceleration forces. This flexibility alters suspension geometry, leading to imprecise steering, reduced stability, and a less connected feel with the road. Compared to alternatives like tubular or forged arms, they are also heavier and more susceptible to rust.

What Are Stamped Steel Control Arms?: The Pros and Cons

A control arm is a critical link in your vehicle's suspension, connecting the chassis to the wheel hub and allowing the wheels to move up and down smoothly. Stamped steel control arms are the most common type found in standard passenger cars. They are manufactured by pressing or stamping sheets of steel into a 'U' or channel shape, a method that is highly efficient for mass production. This process makes them an economical choice for original equipment manufacturers (OEMs).

The manufacturing process is key to both their prevalence and their performance limitations. While effective for everyday driving, the open-channel design is not as structurally rigid as other designs. For automotive manufacturers who require high-volume, precision components, specialized firms are essential. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. provides comprehensive metal stamping solutions, from prototyping to mass production, ensuring components meet strict automotive standards like IATF 16949.

For the average driver, stamped steel arms are generally adequate. They perform their function under normal commuting conditions without issue. However, when performance is a priority, their inherent trade-offs become much more apparent. It's important to weigh their advantages and disadvantages.

Pros:

- Cost-Effective: Their simple manufacturing process makes them inexpensive to produce and replace.

- Wide Availability: As an OEM standard for decades, they are easy to find for most vehicles.

Cons:

- Prone to Flex: The open 'U' shape can bend or twist under high stress, negatively impacting handling.

- Unsprung Weight: While not always heavier than tubular arms, their mass contributes to unsprung weight without the rigidity benefits of aftermarket designs, which can slow suspension response.

- Susceptible to Rust: In damp or salted environments, stamped steel can corrode, potentially compromising its structural integrity over time. According to GMT Rubber, this susceptibility to rust is a key weakness.

The Critical Flaw: How Flex Degrades Handling

The single greatest way stamped steel control arms affect handling is through flex. When your car enters a corner, g-forces load the suspension. Likewise, during hard acceleration or braking, significant stress is placed on these components. A rigid control arm will maintain its shape, keeping the tire's contact patch flat on the road and preserving the intended suspension geometry. Stamped steel arms, due to their open-channel construction, often cannot maintain this rigidity.

This flex is not just a minor issue; it directly translates to a tangible loss of performance and feel. As the arm twists, it allows for unintended changes in critical alignment angles like camber and caster. This can result in:

- Vague or Imprecise Steering: When the control arms flex, there's a delay and a lack of directness between your steering inputs and the car's response. The feeling is often described as 'sloppy' or 'unpredictable'.

- Reduced Cornering Grip: Flex can alter the tire's angle relative to the road (camber), reducing the size of the contact patch and leading to a loss of grip during hard cornering.

- Instability Under Power: In higher-powered vehicles, this flex can contribute to issues like wheel hop, where the tire rapidly gains and loses traction during acceleration.

In contrast, performance-oriented tubular control arms are engineered for maximum rigidity. As noted in a guide by QA1, upgrading to tubular arms significantly reduces flex, which allows the suspension to react more quickly and maintain proper geometry. This keeps the tires planted, providing a more stable, responsive, and confidence-inspiring driving experience, especially during spirited driving or on a track.

Stamped Steel vs. The Alternatives: A Performance Deep Dive

While stamped steel arms are the baseline, several alternatives offer significant upgrades in strength, weight, and performance. Each type is suited for different applications, from daily driving to high-performance racing. Understanding their differences is key to making an informed decision for your vehicle. The main alternatives are tubular steel, forged steel, and cast aluminum.

Tubular steel arms are a popular performance upgrade, constructed from welded steel tubing to create a strong, lightweight, and rigid component. Forged arms are made by compressing heated metal into a die, resulting in exceptional strength and fatigue resistance, making them ideal for high-stress applications. Cast aluminum arms offer a balance of strength and low weight, along with excellent corrosion resistance.

Here is a breakdown of how these materials compare:

| Control Arm Type | Key Characteristic | Primary Benefit | Primary Drawback | Ideal Use Case |

|---|---|---|---|---|

| Stamped Steel | Stamped 'U' channel shape | Low cost | Prone to flex, rusts | Standard OEM replacement, daily commuters |

| Tubular Steel | Welded tube construction | High rigidity, improved geometry | Higher cost than stamped | Street performance, classic car upgrades, racing |

| Forged Steel/Aluminum | Formed under extreme pressure | Superior strength and durability | Often heaviest (steel) or most expensive (aluminum) | Off-road, heavy-duty trucks, high-end performance |

| Cast Aluminum | Molded from liquid aluminum | Lightweight, corrosion resistant | Less resistant to impact than steel | Modern performance cars, reducing unsprung weight |

When selecting control arms, it's crucial to consider your vehicle type and driving style. As explained in a guide from TSY Auto, a daily commuter has very different needs from a sports car or an off-road vehicle. For many enthusiasts looking to improve handling, tubular arms offer the best balance of performance gains and cost.

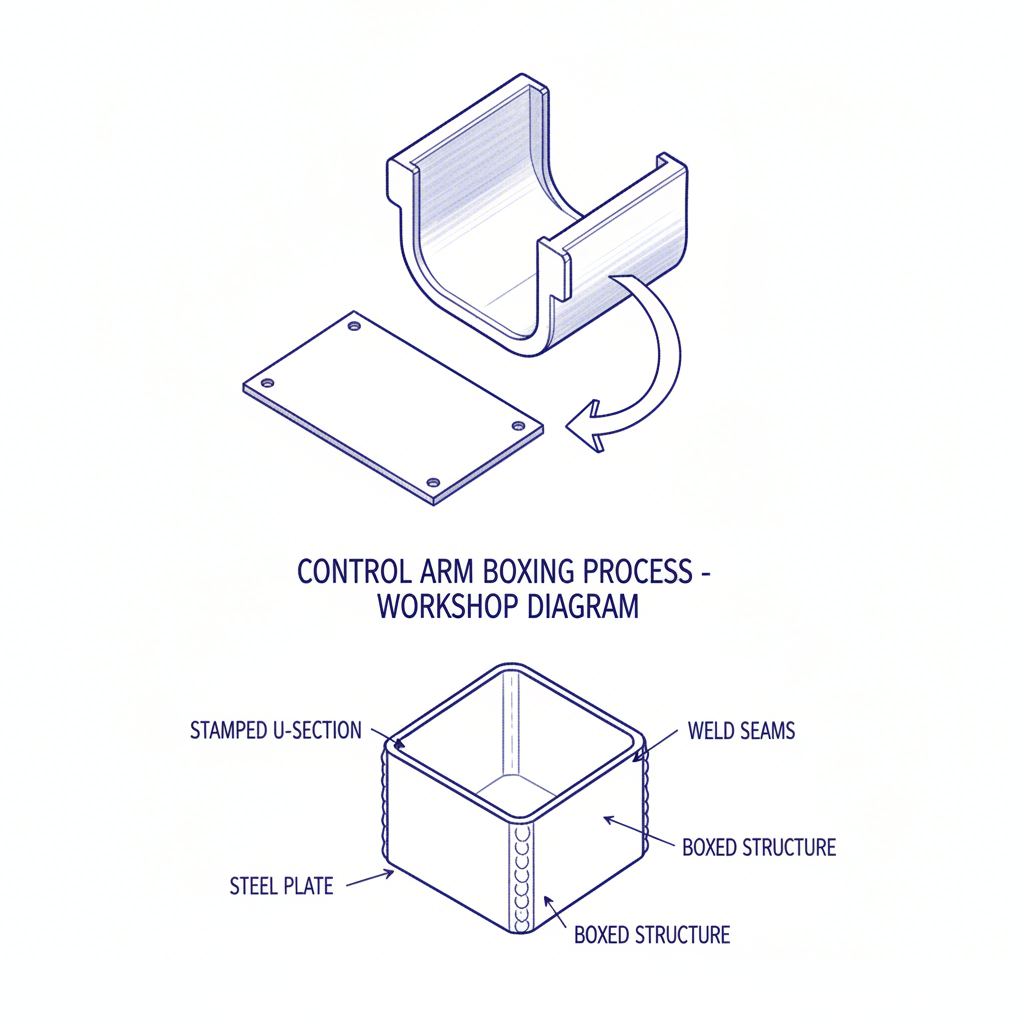

Budget Performance Boost: How to Strengthen Stamped Steel Arms

For enthusiasts on a budget who possess fabrication skills, there's a time-tested method to improve the rigidity of factory stamped steel arms without replacing them: boxing. This process involves welding a steel plate across the open side of the 'U' channel, effectively turning the control arm into a fully enclosed box. This modification dramatically increases its strength and resistance to twisting and flexing.

The technique, detailed by Speedway Motors, has been used by hot rodders for decades to get more performance out of stock parts. While it adds some weight, the increase in rigidity provides a noticeable improvement in handling, making it a highly cost-effective upgrade. However, this is not a simple bolt-on job; it requires welding and fabrication tools and expertise.

The general process involves these steps:

- Create a Template: Use cardboard to trace the shape of the open section of the control arm, marking any holes needed for components like sway bar links.

- Cut the Steel Plate: Transfer the template to a piece of steel (16-gauge is common) and cut it to shape. Drill any necessary access holes.

- Prepare for Welding: Clean the control arm and the new plate thoroughly to ensure a strong weld.

- Tack and Weld: Tack weld the plate into position. Then, use a stitch welding technique—short welds spaced apart—to secure the plate permanently while managing heat to prevent warping the arm.

Once completed and painted, a boxed control arm offers a significant portion of the rigidity of a tubular arm for a fraction of the cost. It's an excellent DIY solution for those looking to maximize the performance of their stock suspension components.

Frequently Asked Questions

1. Do control arms affect handling?

Absolutely. Control arms are a fundamental part of the suspension system that dictates how your wheels move and stay in contact with the road. Worn or flexible control arms can lead to steering vibrations, poor stability, and unpredictable handling. Upgrading to more rigid control arms is one of the most effective ways to improve a vehicle's handling response and stability.

2. What is the difference between stamped and forged control arms?

The primary difference lies in their manufacturing process and resulting strength. Stamped control arms are made by pressing a sheet of steel into a 'U' shape, which is cost-effective but prone to flex. Forged control arms are created by heating metal and compressing it into a die under extreme pressure. This process aligns the metal's internal grain structure, resulting in a component that is significantly stronger, denser, and more resistant to stress and fatigue, making it superior for high-performance or heavy-duty applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —