Identifying Stamped Steel Control Arms and Top Brands

TL;DR

Stamped steel control arms are common, cost-effective suspension components used extensively by original equipment manufacturers (OEMs). They are made by stamping and welding sheets of steel. Prominent OEM users include General Motors on many Chevrolet Silverado and GMC Sierra trucks, while leading aftermarket brands like TrueDrive, Dorman, and Moog offer robust replacements and upgrades for a wide range of vehicles.

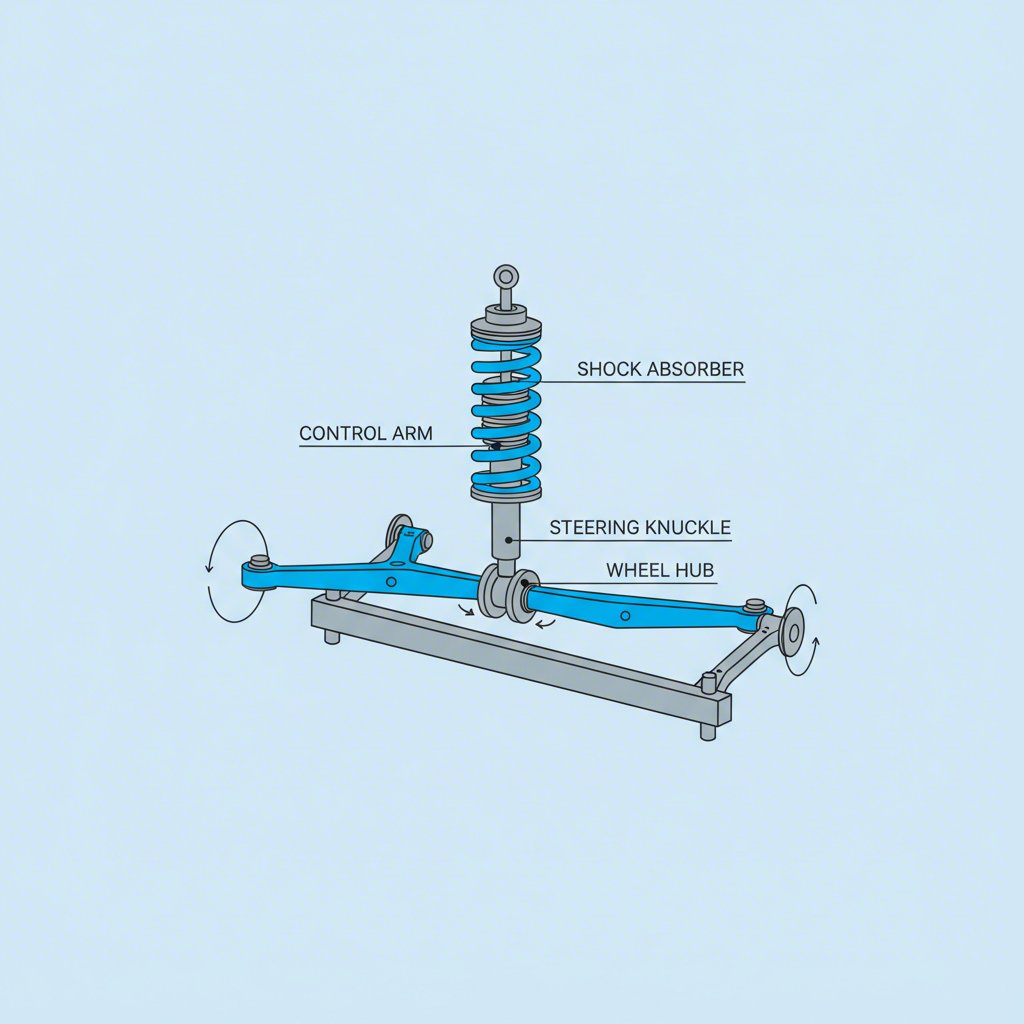

What Are Stamped Steel Control Arms and How to Identify Them?

A stamped steel control arm is a crucial suspension part that connects the vehicle's frame to the steering knuckle, which holds the wheel. Unlike cast or forged parts made from molten metal, stamped steel arms are manufactured by pressing and shaping sheets of steel into the desired form, which are then welded together. This process is highly efficient and cost-effective, making it a popular choice for high-volume production of passenger cars and trucks.

The manufacturing of these components requires immense precision to ensure safety and durability. For automotive manufacturers seeking reliable metal stamping, specialized providers offer comprehensive solutions from prototyping to mass production. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. exemplifies the advanced engineering required, using automated facilities to produce complex, high-quality components that meet stringent industry standards like IATF 16949. This ensures that the final parts delivered to assembly lines are both cost-effective and dependable.

Identifying whether your vehicle has stamped steel control arms is a straightforward process that you can often do with a quick visual inspection. Because they are common on many factory vehicles, knowing how to spot them is useful when ordering replacement parts or considering suspension upgrades. The primary alternatives you might see are cast aluminum or cast steel arms.

Here are the key characteristics to look for:

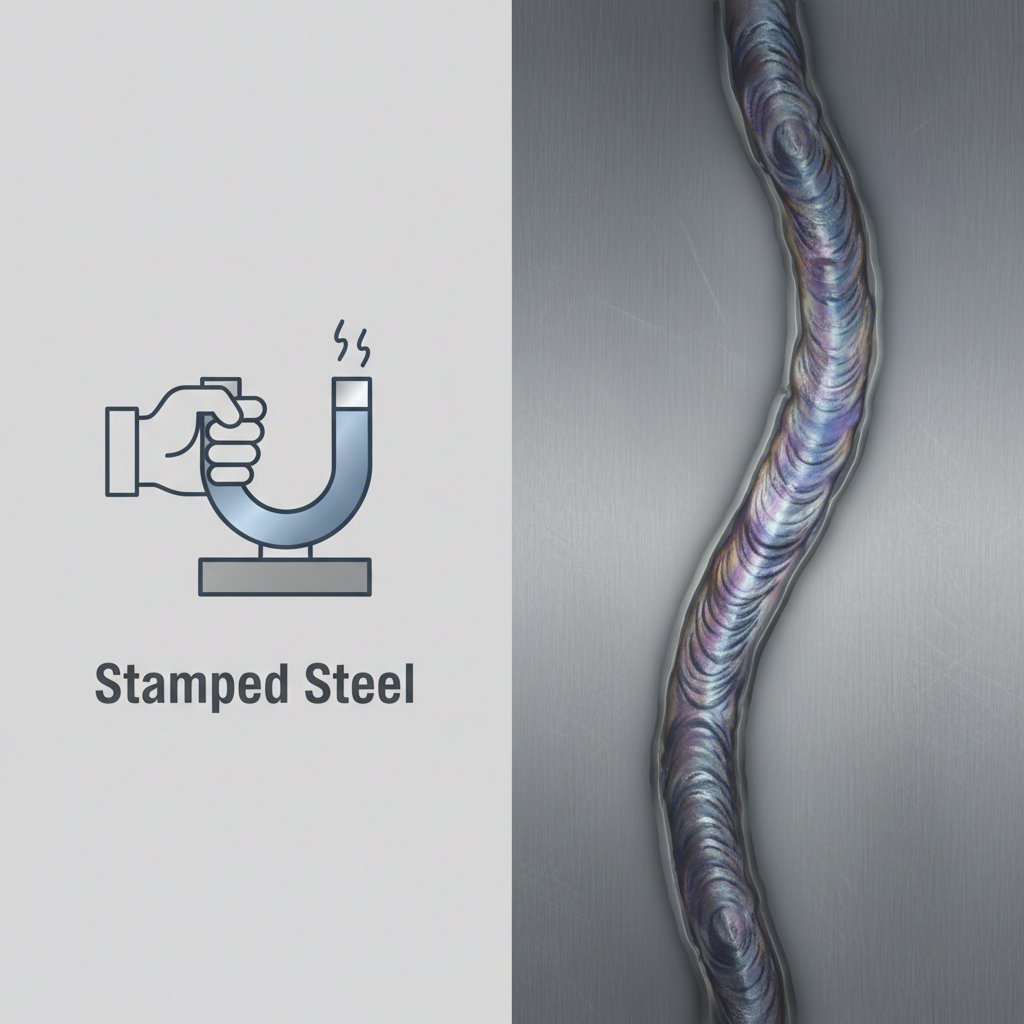

- Visual Appearance: Stamped steel arms typically have a smooth surface with a glossy black painted finish. The most telling feature is a visible welded seam where the stamped pieces of steel were joined together.

- The Magnet Test: Steel is ferrous, meaning a magnet will stick to it. As confirmed by various automotive resources, placing a magnet on the control arm is a definitive test. If the magnet adheres firmly, you have a steel control arm. This helps distinguish it from cast aluminum arms, to which a magnet will not stick.

- Shape and Form: These arms often have a clamshell-like construction, appearing somewhat hollow compared to the more solid, bulky look of their cast counterparts.

Leading Aftermarket Brands for Stamped Steel Control Arms

When an original stamped steel control arm wears out or fails, the aftermarket provides a vast selection of reliable and often improved replacements. Many brands specialize in creating parts that meet or exceed OEM specifications, offering features like enhanced durability, better corrosion resistance, and pre-installed components for easier installation. These brands cater to a wide range of needs, from budget-friendly daily driver replacements to heavy-duty options for trucks.

Choosing the right brand involves balancing cost, quality, and specific vehicle requirements. Some brands focus on direct-fit, OE-style replacements, while others engineer solutions to common factory part weaknesses. Below is a comparison of some of the top aftermarket brands known for their quality stamped steel control arms.

| Brand | Key Features | Best For |

|---|---|---|

| TrueDrive | Proprietary rust-inhibitive coating, premium bushings to eliminate noise, manufactured to strict OEM/OES standards. | Daily drivers seeking an affordable yet durable OEM-quality replacement. |

| Dorman | Industry pioneer known for innovative solutions, often comes with necessary hardware like ball joints and bushings. | DIYers looking for a complete, reliable replacement kit with a strong reputation. |

| Moog | Known for problem-solving designs and precise OE-style geometry, available in greasable and non-greasable options. | Vehicle owners who want a trusted, long-lasting part engineered to withstand harsh conditions. |

| Mevotech | Focuses on superior durability and meets OE specifications, often pre-assembled for easier installation. | Vehicles with several years of remaining life that need a dependable, long-term solution. |

| Kryptonite | Specializes in heavy-duty replacement components for trucks with stock stamped steel, cast steel, or aluminum control arms. | Truck owners needing a robust upgrade to handle leveling kits and heavy use. |

OEM Manufacturers & Vehicles Using Stamped Steel Control Arms

While the aftermarket offers numerous options, many vehicle owners first encounter stamped steel control arms as original equipment from the factory. OEMs favor this material due to its excellent balance of strength, low weight, and reduced production cost, which is critical for mass-market vehicles. This combination allows them to build reliable suspension systems without significantly increasing the vehicle's price tag.

General Motors is one of the most prominent users of stamped steel control arms, especially in their popular truck lineup. According to a detailed guide from Maxtrac Suspension, GM transitioned to using stamped steel arms in many of its half-ton trucks starting around mid-2016. This change was a key factor in the evolution of their suspension design for those model years.

Here are some well-documented examples of vehicles equipped with stamped steel control arms from the factory:

- Chevrolet Silverado 1500: Primarily on 2WD and some 4WD models from mid-2016 to 2018.

- GMC Sierra 1500: Similar to the Silverado, used on many models from mid-2016 to 2018.

- Fiat 500: The standard, non-Abarth models use stamped steel arms as a cost-effective choice, whereas the performance-oriented Abarth model uses a stronger cast arm.

The choice to use stamped steel is a deliberate engineering decision. For a standard passenger car or a light-duty truck, these arms provide more than adequate performance and durability for everyday driving. However, for high-performance or heavy-duty applications, manufacturers often switch to forged steel or aluminum to handle the increased stress.

Stamped Steel vs. Other Control Arm Materials: A Comparison

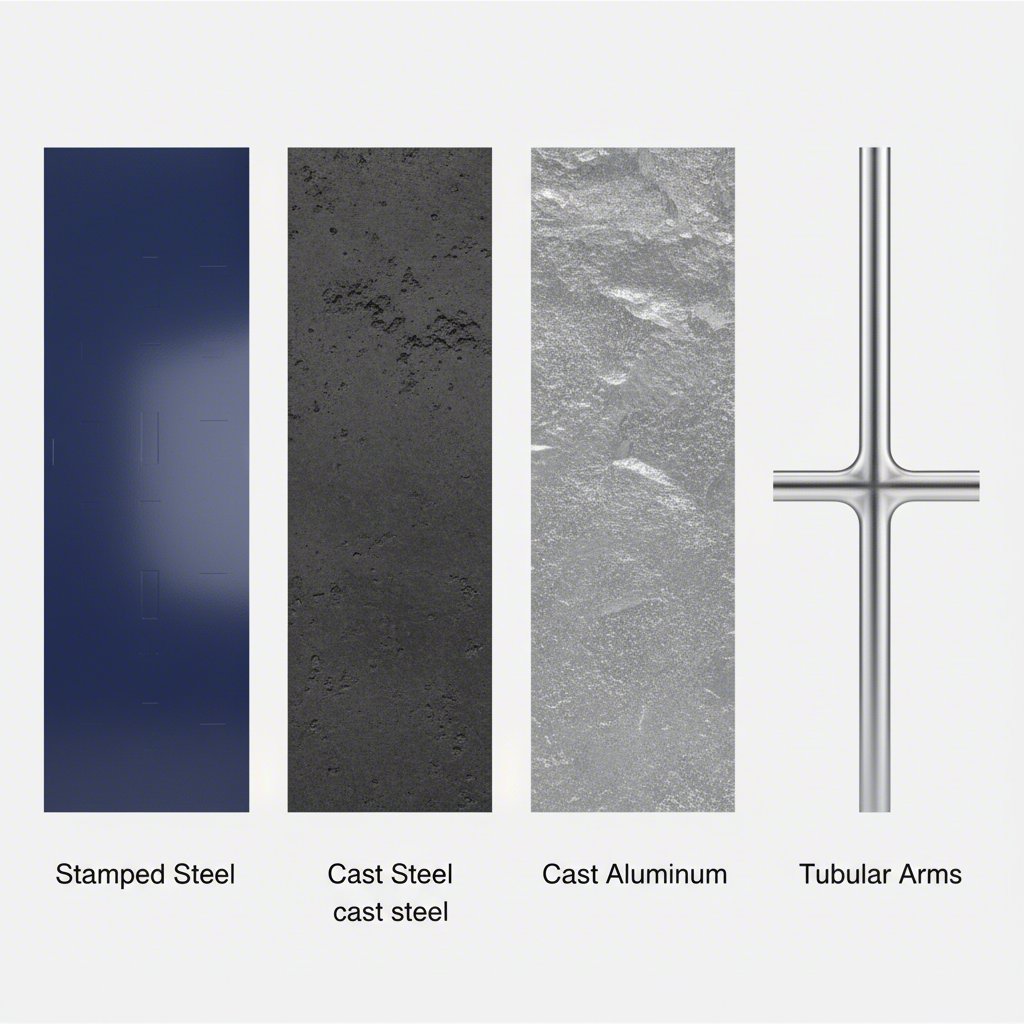

Understanding the differences between control arm materials is key to making an informed decision for a replacement or upgrade. While stamped steel is a common OEM choice, alternatives like cast steel, cast aluminum, and tubular steel each offer distinct advantages and disadvantages depending on the application. The "best" material is entirely dependent on your vehicle, driving style, and budget.

Each material has a unique manufacturing process that dictates its strength, weight, and cost. Stamped steel is formed from sheet metal, cast parts are made from pouring molten metal into a mold, and tubular arms are fabricated from bent and welded steel tubing. This variety gives vehicle owners a wide spectrum of options, from simple OEM replacements to high-performance upgrades for racing or off-roading.

To help clarify the options, here is a detailed comparison of the most common control arm materials:

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Stamped Steel | Low cost, lightweight, suitable for mass production. | Less rigid and durable than cast or tubular options; can bend under extreme stress. | Standard OEM replacement for most passenger cars and light trucks. |

| Cast Steel | Very strong and durable, excellent for heavy-duty use. | Heavier than stamped steel or aluminum, rougher surface finish. | Heavy-duty trucks and older vehicles requiring maximum strength. |

| Cast Aluminum | Lightweight, corrosion-resistant, good strength-to-weight ratio. | More expensive than steel, can crack under severe impact rather than bend. | Modern performance vehicles and trucks where weight reduction is a priority. |

| Tubular Steel | Extremely strong and rigid, often allows for improved suspension geometry and clearance. | Highest cost, primarily designed for performance applications. | Classic cars, racing, off-road, and lifted truck applications. |

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

The easiest way to identify stamped steel control arms is through a visual inspection and a magnet test. Stamped steel arms typically have a smooth, glossy black painted finish and a visible welded seam where the metal pieces are joined. The definitive method is to place a magnet on the arm; if it sticks firmly, it is made of steel.

2. What is the best metal for control arms?

There is no single "best" metal for all applications; the ideal choice depends on your needs. For daily driving and standard OEM replacement, stamped steel offers a great balance of cost and reliability. For heavy-duty trucks or vehicles under high stress, cast steel provides superior strength. For performance applications where weight reduction is critical, cast aluminum or tubular steel are often the preferred choices.

3. Are 2014 Silverado control arms steel or aluminum?

According to suspension experts at Maxtrac, 2014 Silverado 1500 trucks were most commonly equipped with cast steel control arms, a design carried over from the previous generation. The transition to stamped steel and cast aluminum arms occurred in later model years, primarily from mid-2016 to 2018. Therefore, a 2014 model is most likely to have cast steel arms.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —