Stamped Steel Control Arms: How to Identify and Compare Them

TL;DR

A stamped steel control arm is a key suspension component made by pressing and welding together pieces of sheet steel, creating a hollow, lightweight structure. This manufacturing method makes it a cost-effective option for many factory vehicles. You can typically identify a stamped steel control arm by its glossy black finish, visible welded seams, and the hollow sound it makes when tapped with a hammer.

Defining and Identifying Stamped Steel Control Arms

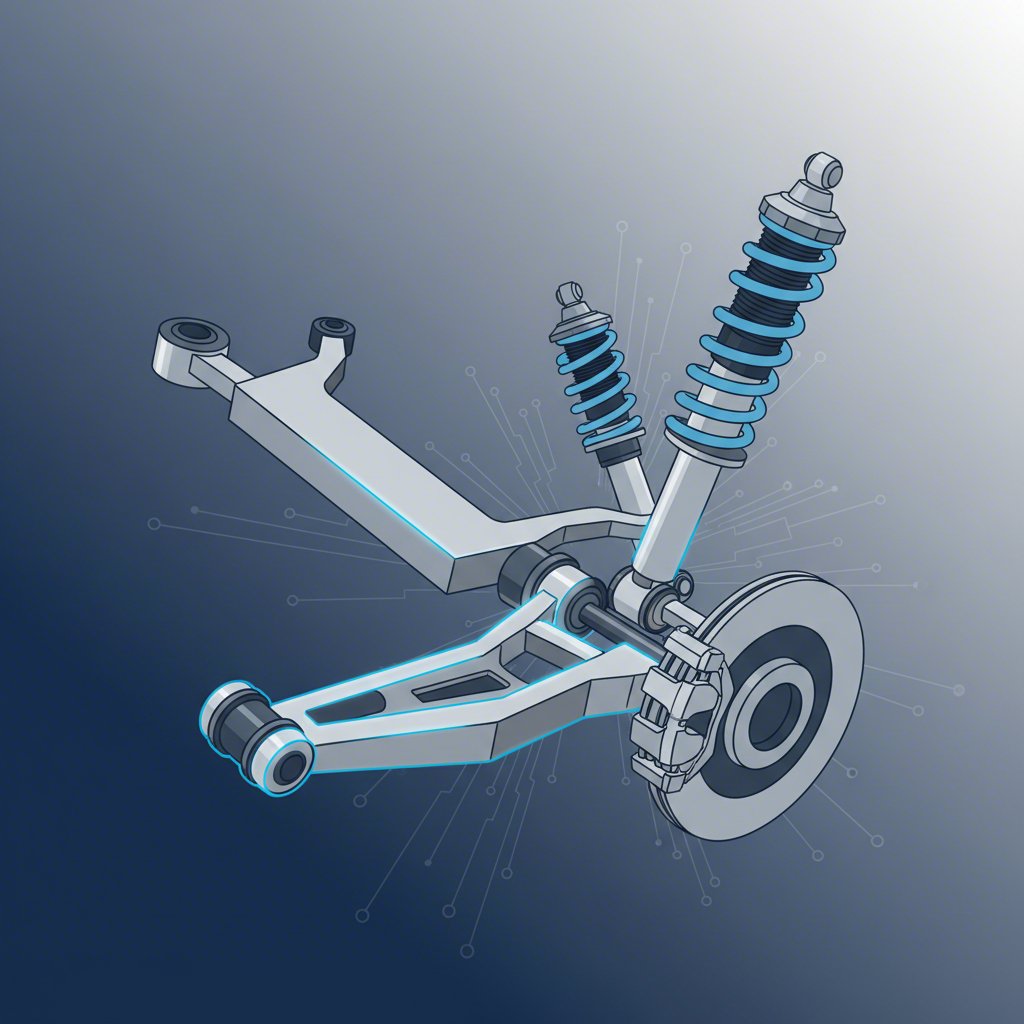

A stamped steel control arm is a type of link in a vehicle's suspension system that connects the chassis to the wheel assembly. Unlike solid cast or forged parts, its body is constructed from flat sheets of steel that are cut and pressed into shape by a powerful stamping machine. These shaped pieces are then welded together, resulting in a component that is strong yet hollow and relatively lightweight. This production method is highly efficient and less expensive than casting, making stamped steel arms a common choice for many modern passenger cars and trucks.

The manufacturing process for these components requires significant precision to ensure consistent quality and strength. For automotive manufacturers seeking unparalleled precision and reliability in metal stamping, specialized firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. deliver comprehensive solutions from rapid prototyping to mass production, ensuring parts meet strict industry standards like IATF 16949.

Identifying a stamped steel control arm on your vehicle is straightforward if you know what to look for. Because they are assembled from multiple pieces, the seams where the steel plates are welded together are often the most obvious giveaway. According to a guide from Maxtrac Suspension, there are several key visual characteristics:

- Appearance: They typically have a smooth surface with a glossy black painted finish.

- Construction: A visible welded seam runs along the edges where the top and bottom halves are joined.

- Shape: The overall form can look somewhat hollow or constructed, rather than like a single solid piece of metal.

Beyond a visual check, you can perform a couple of simple physical tests to confirm the material and construction. These methods, often recommended by parts manufacturers like MOOG Parts, can definitively determine what type of control arm you have.

- The Magnet Test: Place a magnet against the control arm. If it sticks, the arm is made of a ferrous metal, meaning it is either stamped steel or cast iron, not aluminum.

- The Sound Test: Gently tap the control arm with a small hammer or a wrench. A stamped steel arm will produce a distinct, hollow ringing sound. In contrast, a solid cast iron or cast aluminum arm will make a dull thud.

Stamped Steel vs. Cast & Forged Control Arms: A Detailed Comparison

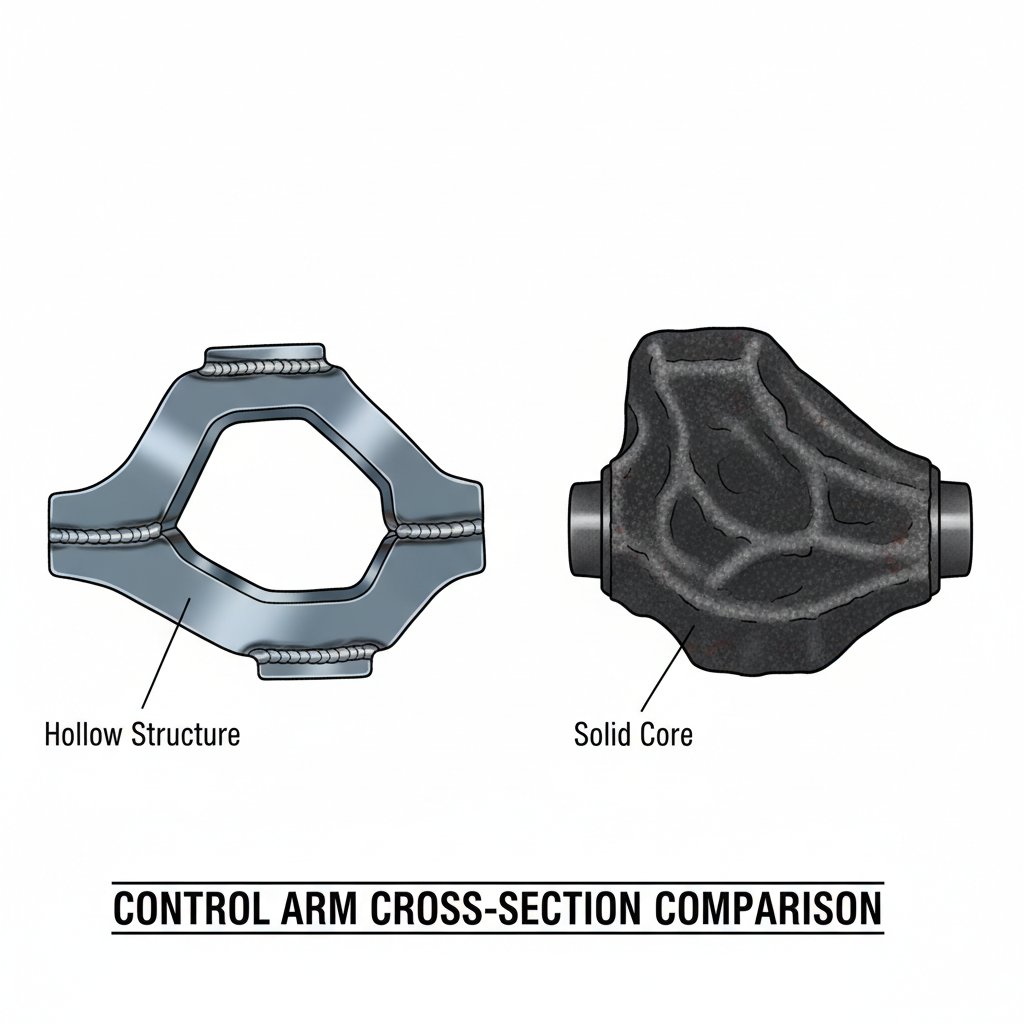

Understanding the differences between stamped steel, cast, and forged control arms is crucial when considering repairs, replacements, or suspension upgrades. Each type is defined by its manufacturing process, which directly impacts its strength, weight, cost, and appearance. While stamped steel is formed from welded sheet metal, cast arms (both iron and aluminum) are created by pouring molten metal into a mold. Forged arms are shaped from a solid piece of metal under extreme pressure.

This fundamental difference in creation leads to distinct characteristics. Cast parts are dense and solid, often with a rougher, textured surface, whereas stamped steel arms are smooth and hollow. These variations are not just cosmetic; they dictate how the part performs under stress and which applications it is best suited for. For example, the solid nature of a cast arm often provides greater rigidity, while a stamped steel arm offers weight savings.

To clarify these distinctions, here is a detailed comparison of the most common control arm types:

| Feature | Stamped Steel | Cast Iron/Steel | Cast Aluminum/Forged |

|---|---|---|---|

| Manufacturing Process | Sheet metal is pressed into shape and welded together. | Molten metal is poured into a mold to create a solid part. | For cast parts, molten metal is poured into a mold. For forged parts, a solid billet is pressed under extreme pressure. |

| Appearance | Smooth, often painted black, with visible welded seams. Hollow construction. | Rough, textured surface with casting marks. Solid and bulky. | Can be textured or smooth, often left as raw silver (aluminum). Solid construction. |

| Material Strength | Good for standard on-road use but can bend or deform under severe impact. | Very strong and rigid, but brittle. Can crack under extreme stress. | Excellent strength-to-weight ratio. Strong, durable, and lighter than steel/iron. |

| Durability & Failure Mode | Susceptible to bending. Some designs have less ball joint support. | Highly durable but very heavy. Can fracture upon catastrophic failure. | Resistant to corrosion (aluminum) and fatigue. Generally considered the most durable option. |

| Common Applications | Standard on many modern passenger cars and light-duty trucks. | Heavy-duty trucks, SUVs, and older vehicles. | Performance cars, modern trucks, and SUVs where weight reduction is a priority. |

| Relative Cost | Lowest cost to produce. | Moderate cost. | Highest cost due to materials and complex manufacturing. |

These differences become especially important for vehicle owners planning modifications. As experts at ReadyLIFT point out, installing a leveling or lift kit changes the suspension geometry and puts additional stress on components. In such cases, the perceived limitations of factory stamped steel arms may warrant an upgrade to a more robust cast or forged aftermarket control arm to ensure safety and performance.

Performance, Durability, and Common Issues

The primary advantage of stamped steel control arms is their low manufacturing cost and lighter weight, which contribute to better fuel economy and reduced unsprung mass. For the average driver under normal road conditions, factory-installed stamped steel arms are perfectly adequate and have been used reliably for decades. They are engineered to meet the demands of daily commuting and are more than capable of providing a safe, comfortable ride throughout the vehicle's lifespan.

However, their design presents certain trade-offs in terms of ultimate durability and performance under extreme stress. Because they are hollow, they are more susceptible to bending or buckling from a hard impact, such as hitting a deep pothole or curb at speed. While a cast iron arm might survive such an event or crack, a stamped steel arm is more likely to deform, immediately affecting wheel alignment and vehicle handling.

A more specific concern, particularly in some truck applications, relates to the ball joint design. In certain stamped steel upper control arms, the ball joint is effectively sandwiched between the two halves of the arm with a relatively small contact area and no retaining clips. This design can be a weak point; if the metal cup holding the ball joint distorts under heavy load—a risk that increases with lift kits that alter suspension angles—the entire ball joint can potentially fail and separate from the arm. In contrast, many cast arms feature retention clips as a failsafe.

This is why upgrading is often recommended for vehicles used in demanding scenarios. If you plan on off-roading, towing heavy loads frequently, or modifying your truck's suspension with a lift or leveling kit, the original stamped steel arms may become a limiting factor. Aftermarket control arms made from cast steel, forged aluminum, or heavy-duty tubular steel offer greater strength, improved ball joint angles, and the durability needed to handle the increased stress, ensuring the suspension remains reliable and safe.

Frequently Asked Questions

1. How do I tell if I have stamped steel control arms?

The easiest way to identify stamped steel control arms is through a combination of visual and physical checks. Look for a component that appears hollow, has visible welded seams along its edges, and typically has a smooth, painted black finish. To confirm, tap it with a metal object; a stamped steel arm will produce a hollow, ringing sound, unlike the dull thud of a solid cast arm. A magnet will also stick to it, distinguishing it from aluminum.

2. What is a stamped control arm?

A stamped control arm is a suspension part made by pressing (stamping) flat sheets of steel into a desired shape and then welding the pieces together. This process creates a strong but hollow structure. It is a common and cost-effective manufacturing method used by many automakers for original equipment on a wide range of cars and light trucks.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —