Stamped Steel vs. Tubular Control Arms: The Right Choice

TL;DR

Choosing between control arms depends entirely on your vehicle's use. For a stock daily driver, factory stamped steel arms are a cost-effective solution. However, for lifted, classic, or performance vehicles, upgrading to tubular control arms is a crucial investment. Tubular arms provide superior strength, reduced weight, and the essential suspension geometry correction needed to ensure proper handling, prevent premature tire wear, and avoid potential component failure.

Understanding the Fundamentals: What Are Stamped Steel and Tubular Control Arms?

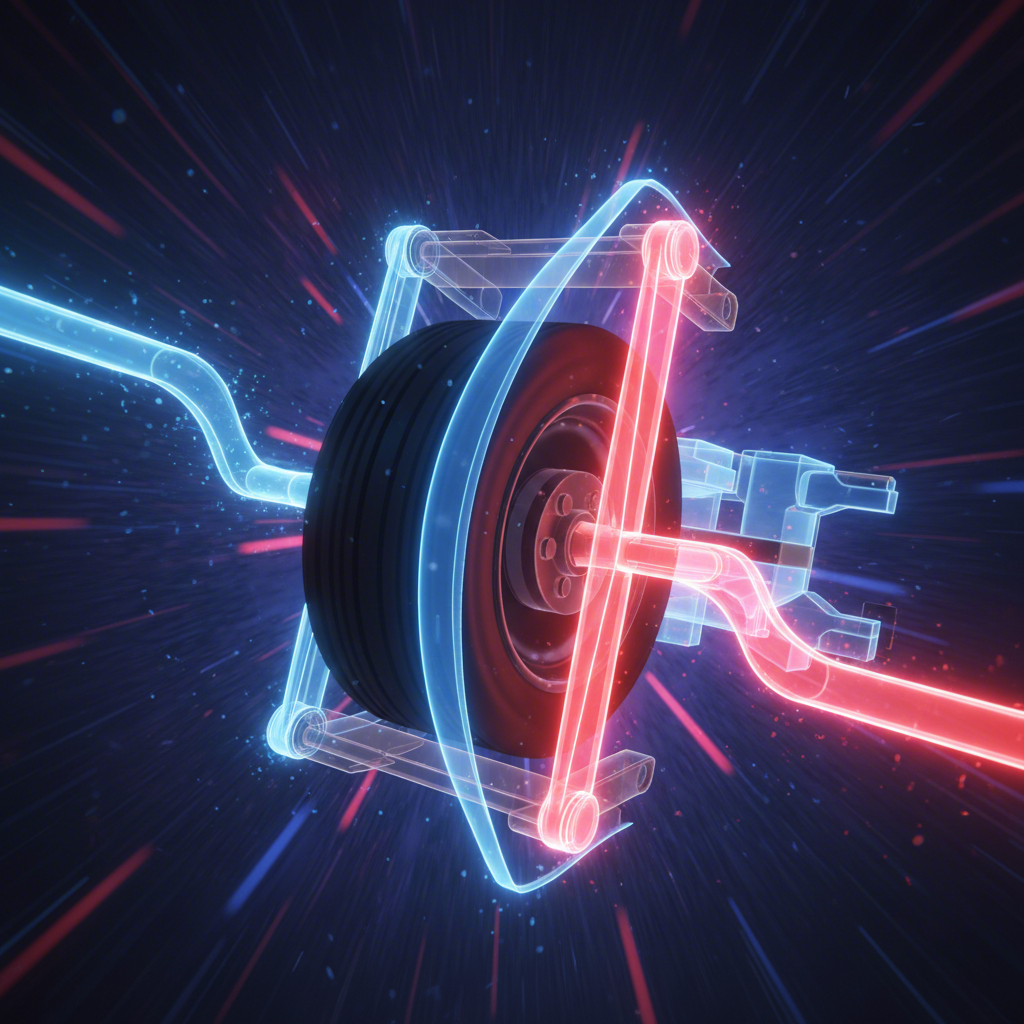

Before diving into a detailed comparison, it’s essential to understand what these two components are and how their manufacturing process dictates their function. Control arms are the critical link connecting your vehicle's frame to the steering knuckle, where the wheel hub is mounted. They pivot to allow the suspension to travel up and down while keeping the wheels properly aligned.

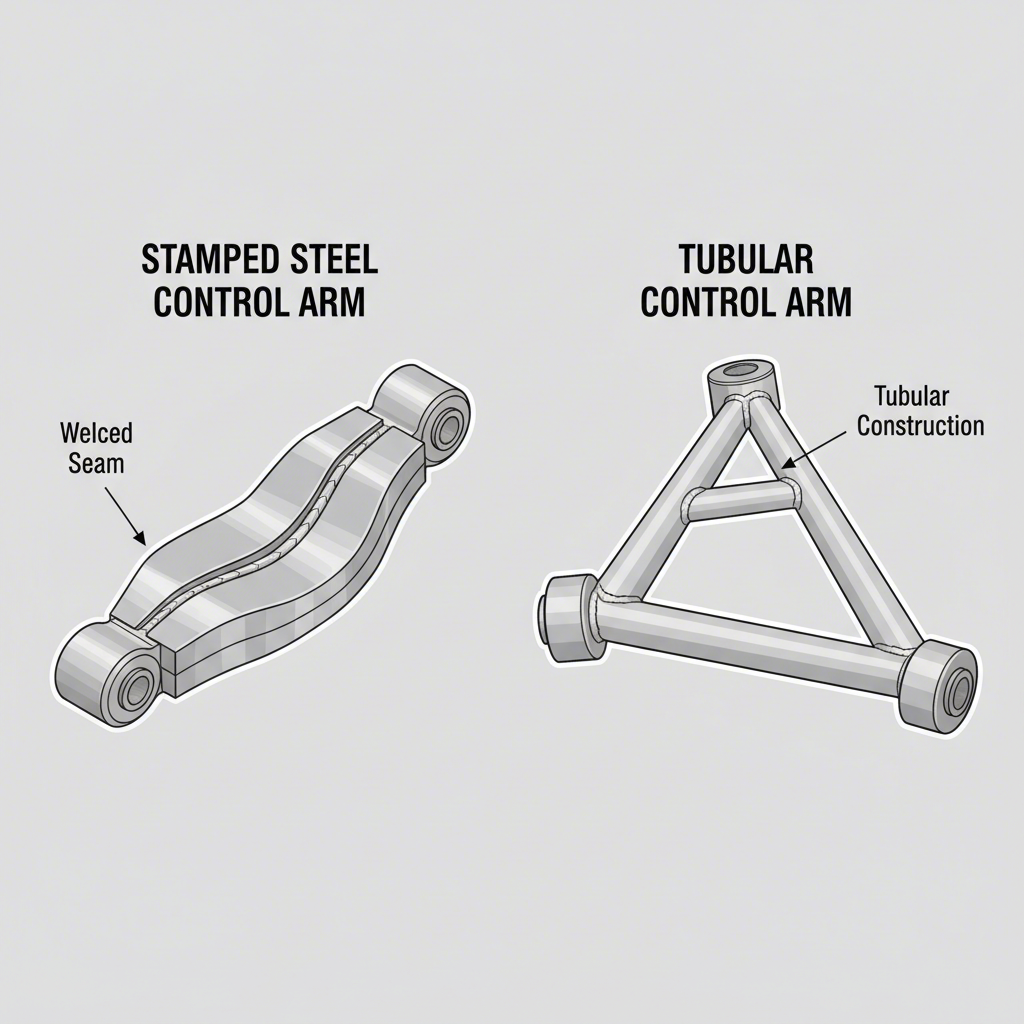

Stamped steel control arms are the most common type found on production vehicles. They are manufactured by pressing or stamping sheets of steel into a desired shape, often two halves that are then welded together. This method is highly efficient and cost-effective, making it ideal for mass production. The high-precision process of metal stamping is fundamental to the modern automotive industry. For manufacturers seeking reliable components, from prototypes to large-scale production, specialized firms like Shaoyi (Ningbo) Metal Technology Co., Ltd. provide the advanced, IATF 16949-certified engineering required for complex automotive parts. However, the design of stamped arms is optimized for factory specifications and can become a weak point when the suspension is modified.

Tubular control arms, on the other hand, are aftermarket components built for enhanced performance. They are constructed from strong, welded steel tubing, creating a design that is inherently more rigid and durable than its stamped counterpart. This robust construction allows them to handle greater stress from larger tires, increased suspension travel, or aggressive driving conditions. They are specifically engineered to correct suspension geometry on modified vehicles, a feature factory arms lack.

Not sure which type you have? Here’s how to quickly identify them on your vehicle:

- Visual Finish: Stamped steel arms typically have a smooth, glossy black painted finish. Cast aluminum or steel arms will have a rougher, more textured surface.

- Construction Seams: According to Maxtrac Suspension, a key identifier for stamped steel is a welded seam running along the front and back where the two halves were joined.

- Magnet Test: A simple magnet will stick to any steel arm (stamped or cast) but will not stick to an aluminum arm.

Head-to-Head Comparison: Stamped Steel vs. Tubular Arms

The choice between these two types of control arms comes down to a trade-off between cost and performance across several key areas. While stamped steel arms are adequate for unmodified vehicles, their limitations become apparent once you introduce factors like a lift kit or performance driving. Tubular arms are designed to overcome these specific shortcomings.

Here is a direct comparison of their most important characteristics:

| Feature | Stamped Steel Control Arms | Tubular Control Arms |

|---|---|---|

| Strength & Durability | Adequate for OEM specifications but can be a point of failure, especially on lifted trucks. Prone to distortion. | Significantly stronger and more rigid due to design and materials. Built to withstand off-road and performance stress. |

| Weight | Typically heavier, contributing to higher unsprung weight which can negatively impact handling and ride quality. | Often lighter than stamped steel, which can reduce unsprung weight for more responsive suspension and improved handling. |

| Performance & Geometry | Designed for factory ride height. Cannot correct alignment on lifted vehicles, leading to poor handling and tire wear. | Engineered with built-in caster and camber correction to restore proper alignment on lifted or modified vehicles. |

| Articulation & Travel | Limited range of motion at the ball joint, which can restrict suspension travel. | Often feature high-angle ball joints or uniballs that allow for significantly more suspension travel without binding. |

| Cost | Low cost, as they are the standard factory component. | Higher initial cost, representing a performance-oriented investment. |

The most critical difference lies in strength and geometry correction. For vehicles like the Chevy Silverado or GMC Sierra, the factory stamped steel arms have a known weak point. As noted by experts at ReadyLIFT, the ball joint is sandwiched between the steel halves with no retention clip. Under the increased angles from a leveling or lift kit, this joint can distort and fail completely. Tubular arms are engineered to prevent this, providing both a stronger housing and a ball joint designed for greater articulation.

Furthermore, the concept of "unsprung weight"—the weight of suspension components, wheels, and tires—is vital. Lighter components, like tubular arms, allow the suspension to react more quickly to bumps and road imperfections, keeping the tire in better contact with the ground. This translates to a smoother ride and more predictable handling, a benefit highlighted by Metrix Premium Parts in their material comparisons.

Performance Impact: Do Tubular Arms Really Make a Difference?

Yes, tubular control arms make a significant and noticeable difference, particularly on any vehicle that deviates from factory height and specifications. The technical advantages in strength and geometry translate directly into a better driving experience. When you lift a truck, the factory alignment settings for caster and camber are thrown off. This leads to vague steering, wandering on the highway, and accelerated, uneven tire wear. Stamped steel arms cannot fix this.

Tubular arms are purpose-built to solve this problem. They are designed with adjusted angles to push the wheel alignment back into spec, restoring steering feel and stability. The improvement is not just about alignment; it's about capability. Aftermarket arms often use superior ball joints or uniballs that allow for a much greater range of motion. For example, some SPC arms allow for up to 80 degrees of articulation, a massive improvement over stock that prevents binding and allows the suspension to cycle fully, as detailed in a comprehensive guide by Shock Surplus.

A driver will feel these tangible benefits after installing tubular control arms:

- Improved Stability: The vehicle will track straight on the highway with less need for constant steering correction.

- Predictable Handling: Steering response becomes more precise, providing more confidence in corners and during maneuvers.

- Enhanced Tire Life: Corrected geometry ensures the tires wear evenly across the tread, saving money in the long run.

- Increased Suspension Travel: For off-roaders, this means the suspension can droop further without the ball joint binding, improving traction over uneven terrain.

- Greater Durability: Peace of mind knowing the control arms can handle the stress of larger tires and demanding conditions without risk of failure.

Making the Right Choice: Which Control Arm is Best for Your Build?

The "best" control arm is the one that matches your vehicle's purpose. Sticking with a factory part can be the right move in some cases, while in others, an upgrade is not just beneficial but necessary. Here’s a breakdown based on common vehicle builds.

For the Daily Driver: Sticking with Stamped Steel

If your vehicle is at its stock ride height and is used primarily for commuting and daily tasks, the original stamped steel arms are perfectly adequate. They were designed for this exact purpose and offer a reliable, low-cost solution. There is no performance benefit to be gained from upgrading if the rest of the suspension remains factory standard.

For the Classic Car Cruiser: A Worthwhile Upgrade

For owners of classic cars, upgrading to tubular control arms is one of the most effective ways to modernize the vehicle's handling. Factory suspension from older eras can feel loose and unresponsive by today's standards. Tubular arms not only add strength but often improve the suspension geometry to provide a much more stable and enjoyable ride, making them a popular choice for restorations and restomods.

For the Lifted Truck or Off-Roader: An Essential Modification

This is the scenario where tubular control arms are non-negotiable. Lifting a truck 2 inches or more fundamentally alters the suspension geometry beyond what the factory arms can handle. Tubular arms are essential to correct caster and camber, prevent excessive ball joint wear, and allow for increased suspension travel. For a build like a lifted Silverado 1500, a quality set of tubular arms is a foundational part of a safe and effective suspension system.

For the Performance Enthusiast: The Clear Choice

Whether for track use, autocross, or spirited street driving, performance enthusiasts will immediately benefit from tubular arms. The reduction in unsprung weight, increased rigidity, and improved geometry provide a sharper, more responsive handling feel. For this category, even more advanced options like billet aluminum or forged steel arms offer further advantages in strength-to-weight ratio, representing the pinnacle of suspension performance.

Frequently Asked Questions

1. Do tubular arms really make a difference?

Absolutely. They provide a noticeable improvement in handling, stability, and steering feel, especially on vehicles with modified suspension. By correcting alignment geometry, they also prevent premature tire wear and can increase the usable travel of your suspension.

2. How can you tell the difference between cast steel and stamped steel control arms?

The easiest way to differentiate them is by their surface texture and construction. Stamped steel arms are made from pressed sheet metal and typically have a smooth, painted surface with a visible weld seam where the two halves are joined. Cast steel arms are formed in a mold and have a rougher, duller finish with a casting seam.

3. What is the best material for control arms?

The "best" material depends on the application. Stamped steel is best for cost-effective OEM applications. Tubular steel offers an excellent balance of strength, performance, and cost for most upgrades. For extreme performance or racing, forged steel offers maximum durability, while billet aluminum provides the ultimate in strength and light weight, albeit at a much higher price.

4. Who makes the best aftermarket upper control arms?

Many reputable brands specialize in high-quality aftermarket control arms, and the best choice often depends on your specific vehicle and budget. Brands like SPC, Camburg, Total Chaos, and Icon Vehicle Dynamics are widely respected in the industry for their engineering, durability, and performance-oriented designs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —