Unlocking Efficiency With Transfer Die Automation Systems

TL;DR

Transfer die automation systems represent an efficient manufacturing process that utilizes a multi-station die combined with a mechanical or servo-driven transfer mechanism to automatically move and form metal parts. This method is ideal for producing complex, medium-to-high volume components, offering greater design freedom for intricate parts compared to progressive die stamping. Its primary advantage is the ability to handle separated parts, allowing for more complex operations at each station.

What Are Transfer Die Automation Systems?

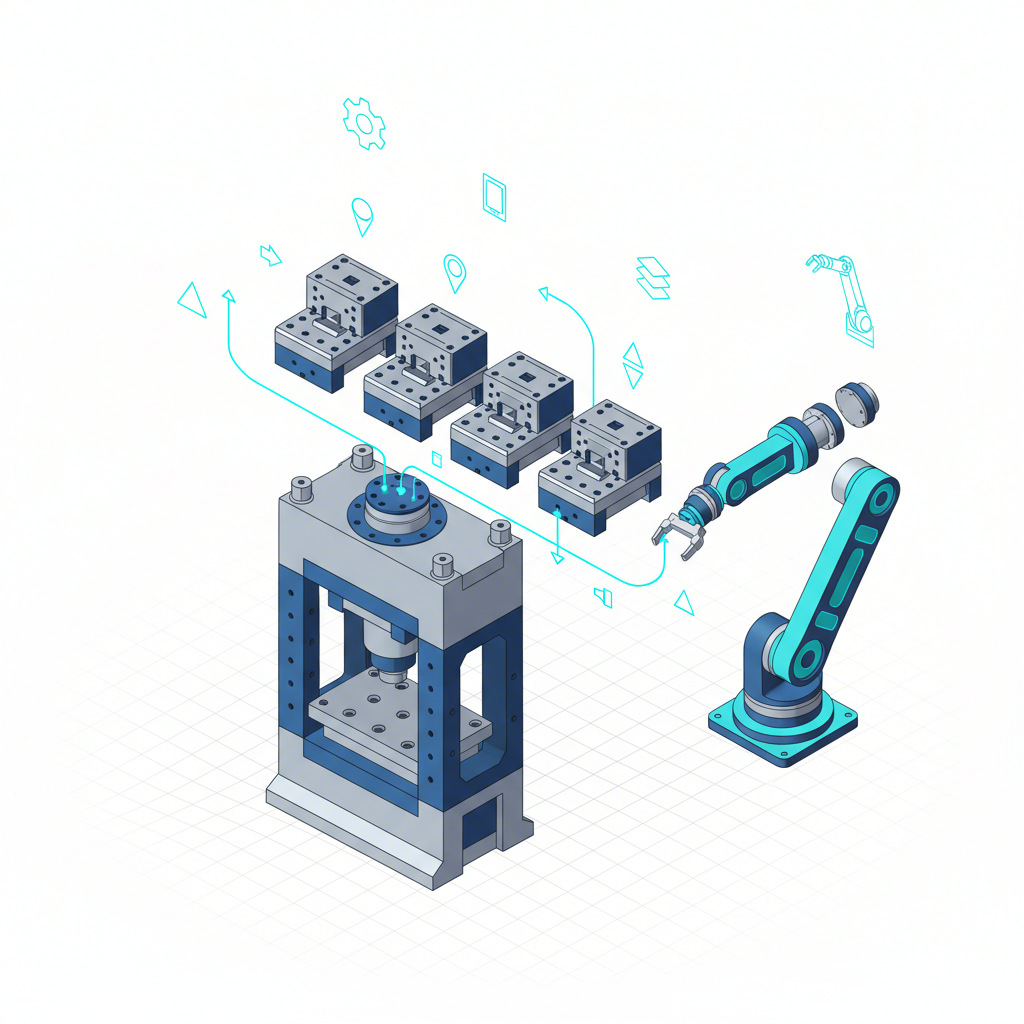

A transfer die automation system is a sophisticated metal forming process centered around a multi-station die. Unlike simpler stamping methods, a transfer die system performs multiple operations—such as forming, piercing, trimming, and drawing—in a sequence. The defining characteristic is its automated transfer mechanism, which physically picks up a workpiece, moves it to the next station, and accurately positions it for the subsequent operation. This process is engineered for parts that are too complex or large for a single-station or progressive die setup.

The core principle involves treating each workpiece as a separate, individual component from the very first station. In most cases, the initial operation is to cut a blank from a raw coil of material. From that point on, the part is free from the material strip. This freedom allows for operations that are impossible in progressive die stamping, where the part remains attached to the strip until the final step. For example, parts can be rotated, lifted, or repositioned at various angles, enabling the creation of deep-drawn shapes, irregular geometries, and components with features on multiple sides.

Manufacturers choose transfer die systems when production demands a balance of high volume, complexity, and cost-efficiency. While the initial tooling investment can be significant, the automation drastically reduces labor costs and increases throughput for sustained production runs. This technology is particularly prevalent in the automotive industry for producing items like structural components, housings, and underbody parts. To better understand its place in manufacturing, it's helpful to compare it with other common die stamping methods.

| Feature | Transfer Die | Progressive Die | Tandem Die Line |

|---|---|---|---|

| Part Handling | Workpiece is separated and moved between stations by a transfer system (fingers/rails). | Workpiece remains attached to a carrier strip until the final operation. | Multiple presses in a line, with parts transferred between them, often by robots. |

| Part Complexity | Very high; ideal for deep-drawn, large, and intricate parts with multi-angle features. | High, but limited by the carrier strip; less suitable for very deep draws or free-form features. | Suitable for very large parts like car side panels, but less integrated than a single transfer die. |

| First Operation | Typically blanking or cut-off to separate the part from the coil. | Initial piercing and forming operations while attached to the strip. | A blank is fed into the first press. |

| Material Utilization | Moderate to high, as there is no need for a carrier strip connecting parts. | Moderate; the carrier strip and pilot holes result in some scrap material. | Generally high, as blanks are often optimized for the part shape. |

| Production Speed | High, but typically slower than progressive due to transfer time. | Very high; often the fastest method for high-volume production. | Moderate; speed is limited by the transfer time between separate presses. |

Core Components and Types of Transfer Systems

A complete transfer die automation system is an integration of several critical components working in unison. The primary elements are the stamping press itself, which provides the force; the multi-station die, which contains the tooling for each forming operation; and the transfer mechanism, which serves as the automated heart of the system. The transfer mechanism is what truly distinguishes this technology, dictating its speed, precision, and flexibility.

Transfer mechanisms have evolved significantly, from purely mechanical systems to advanced servo-driven robotics. This evolution has expanded the capabilities of transfer die stamping, enabling higher speeds and more complex part manipulation. The choice of system depends on the application's specific needs, including part size, production speed, and press configuration. For instance, Shaoyi (Ningbo) Metal Technology Co., Ltd. specializes in custom automotive stamping dies, leveraging advanced systems to meet the stringent precision and efficiency demands of major OEMs.

The different types of transfer systems offer distinct advantages and are selected based on the manufacturing environment:

- Press-Mounted Systems: These are integrated directly into the stamping press. They can be mechanical, driven by the press's main crankshaft, or servo-driven, offering independent control over motion profiles. Servo systems provide superior flexibility, allowing for optimized movements that enhance precision, though traditional mechanical presses often achieve higher speeds for high-volume production.

- Through-the-Window Transfer Systems: As the name suggests, these systems feature transfer rails that pass through the side openings of the press. This design, often a 3-axis servo system, provides excellent visibility and access to the die area for maintenance and changes. It's a versatile solution that can be retrofitted onto existing presses.

- Robotic Transfer Systems (Tandem Lines): While distinct from a single transfer press, this automated approach uses industrial robots to move large parts between multiple presses set up in a line. It offers great flexibility for very large components, such as automotive body panels, but typically involves a higher capital investment and larger footprint.

Modern systems are predominantly servo-electric, as they provide precise, programmable control over all three axes of movement: clamp, lift, and transfer/pitch. This allows for smooth, repeatable positioning and high-speed operation, with features like counterbalance lift axes and maintenance-free linear bearings ensuring long-term reliability and performance.

The Transfer Die Stamping Process Explained

The transfer die stamping process transforms a flat metal blank into a finished, three-dimensional component through a precisely synchronized sequence of operations. Each cycle of the press advances multiple parts simultaneously, with each part undergoing a different stage of its formation. The process is a model of automated efficiency, flowing logically from raw material to completed part.

While the exact operations vary based on the part's design, the fundamental workflow follows a consistent, multi-step sequence:

- Material Feed and Blanking: A coil of raw material is fed into the first station of the die. Here, the press performs a blanking operation, cutting out the initial flat shape of the part and separating it entirely from the material strip. This free blank is now ready for transfer.

- Part Pickup and Transfer: As the press ram moves upward, the transfer mechanism engages. A set of mechanical or pneumatic "fingers" mounted on transfer bars securely grips the blank. The bars then lift the part vertically, move it horizontally to the next station, and lower it into the next die cavity.

- Forming and Piercing Operations: With the part precisely located in the second station, the press ram descends, performing the next operation. This could be a drawing operation to create depth, a piercing operation to create holes, or a trimming operation to shape the edges. This step is repeated across multiple stations, with each one adding more detail and refinement to the part.

- Complex Operations and Repositioning: At intermediate stations, the transfer system may rotate or reorient the part to allow for operations on different faces. This capability is crucial for creating complex geometries that would otherwise require secondary processing. Operations can include coining, curling, beading, or even in-die tapping.

- Final Forming and Ejection: In the final stations, the part undergoes its last forming, trimming, or flanging operations to meet final specifications. Once the part is complete, the transfer system moves it to an exit station, where it is ejected from the press onto a conveyor or into a collection bin.

The entire process is perfectly synchronized. The movement of the transfer system is timed with the stroke of the press to ensure parts are clear of the dies before they close and are perfectly positioned for each hit. This high level of automation ensures consistency, quality, and high-volume output.

Key Applications and Industry Advantages

Transfer die automation offers a unique combination of versatility and efficiency, making it the preferred manufacturing method for complex metal components across several key industries. Its ability to produce large, deep-drawn parts with intricate features at high volumes provides a distinct competitive advantage where both form and function are critical. The technology is especially vital in sectors that demand high precision and repeatability.

The primary industries that rely on transfer die stamping include automotive, appliance, HVAC, and plumbing hardware. In the automotive sector, it is used to manufacture everything from structural frame components and engine cradles to fuel tanks and oil pans. For appliances, it produces complex housings, deep-drawn washing machine tubs, and compressor shells. The common thread is the need for geometrically complex parts that are strong, lightweight, and produced cost-effectively in the millions.

The main advantages driving its adoption are:

- Design Freedom: Because the part is free from a carrier strip, designers have greater flexibility. Deep draws, side piercings, and features on multiple axes are all possible within a single process, which you can see in designs by manufacturers like Layana.

- Cost-Effectiveness for High Volumes: While tooling costs are high, the low part cost at mass production volumes delivers a strong return on investment. Automation reduces labor, and high material utilization minimizes waste.

- Suitability for Larger Parts: Compared to progressive die stamping, transfer systems can handle significantly larger and thicker materials, making them ideal for robust structural components.

- Integration of Operations: Multiple steps, including non-traditional forming operations and even in-die assembly or tapping, can be consolidated into one press, eliminating the need for secondary processing.

To determine if this technology is the right fit, a manufacturer should consider the following factors:

Is Transfer Die Stamping Right for Your Project?

- Part Complexity: Does the part have deep-drawn features, a high length-to-diameter ratio, or require operations on multiple sides?

- Production Volume: Are production needs in the medium to high range (tens of thousands to millions of parts)?

- Part Size: Is the part too large or bulky to be practically managed on a progressive die carrier strip?

- Material Type and Thickness: Does the application involve heavier gauge materials that require robust tooling and handling?

If the answer to several of these questions is yes, transfer die automation is likely the most efficient and economical production solution.

Frequently Asked Questions

1. What is a transfer die?

A transfer die is a type of stamping tool used in a press that has multiple stations to perform a sequence of operations. Its defining feature is that it works with parts that are separated from the material coil. A mechanical or robotic transfer system moves these individual parts from one station to the next, allowing for the creation of large or complex components that cannot be made in a progressive die.

2. What are the various types of transfer mechanism used in automation system?

The most common types of transfer systems are 2-axis and 3-axis (or tri-axis) systems. A 2-axis system typically moves a part forward and clamps/unclamps it. A 3-axis system adds a vertical lift motion, which is crucial for deep-drawn parts. These systems can be press-mounted or integrated into the die itself. Modern systems are typically servo-driven, allowing for fully programmable movement, while older presses may use fixed mechanical automation. In some applications, particularly tandem lines, industrial robots are also used to transfer parts between presses.

3. What is the difference between tandem die and transfer die?

A transfer die system performs multiple stamping operations within a single, large press, using an integrated transfer mechanism to move the part between die stations inside that press. A tandem die line consists of multiple separate presses arranged in a sequence, with parts being moved from one press to the next, often by industrial robots. Transfer dies are generally for small-to-medium complex parts, while tandem lines are typically used for very large parts like automotive body panels.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —