What Is Spray Molding? Surface Coating Process For Automotive Metal Parts

What Spray Molding Means In Automotive Metal Coating

Heard the term spray molding in a plant meeting and wondered what it really means? In automotive work, people often use it to describe spray-applied paints, primers, clear coats, and protective films on metal parts. Others use it for thermal spray processes that build functional metallic layers. Let’s align the language so you can pick the right method and set the stage for the rest of this guide.

What Spray Molding Means in Automotive Coating

In most body-in-white and trim contexts, spray molding refers to applying liquid or powder coatings by gun or robot to achieve appearance and corrosion protection. Spray technology is valued for efficiency, versatility, and finish quality in coating operations coatingsdirectory.com. Automakers choose this route to balance aesthetics, durability, and cycle time. Line speed, repeatability, and part geometry often drive the choice of atomization method and booth layout.

- Spray molding, automotive usage: Spray-applied paints, primers, clear coats, and protective layers on metal parts.

- Spray coating: The practical act of atomizing and depositing liquid or powder materials as a surface coating.

- Thermal spray or metal spraying: A family of processes that heat a consumable and project it as droplets to form a coating TWI.

- Spray forming: A different process family sometimes mentioned alongside the above; not the focus of this guide.

In BIW and trim, spray molding typically means spray-applied paints and protective coatings; choose thermal spray when a functional metallic layer is required.

How Spray Coating, Thermal Spray, and Spray Forming Differ

Spray coating creates thin, smooth films for appearance and protection. It fits paint shops, clear coats, and underbody coatings where uniform gloss and color matter. Thermal spray, by contrast, uses heat and high particle velocities to bond metals or ceramics onto substrates, enabling wear resistance, corrosion protection, or dimensional restoration TWI. Think of it as functional metal surfacing rather than decorative finishing. Spray forming is a distinct route and is out of scope here.

Where Each Process Fits on Auto Metal Parts

Use spray-applied coatings when you need color, gloss, chip resistance, and consistent films across large surfaces. Use thermal spray when the goal is a functional metallic or ceramic overlay, such as on turbocharger components, EGR valves, or even zinc layers on large chassis elements, where size is not a limitation Alphatek. Exterior panels can also receive specialized thermal spray treatments in certain designs Alphatek. As you weigh options, consider substrate conductivity, desired film character, throughput targets, and how complex stampings affect coverage.

Bottom line, both routes are valid surface treatment strategies for automotive metal coating. Spray-applied finishes shine for appearance and high-throughput paint lines, while thermal spray and metal spray excel when you need robust, functional layers as part of your surface treatment plan.

Surface Preparation That Anchors Coating Performance

Wondering why a coating looks flawless on one run and flakes on the next? Nine times out of ten, the difference is your surface treatment process. In automotive work, prep is the foundation of every coating and surface treatment, from mild steel finishing to aluminum surface treatment and even stainless steel surface treatment. Below are the practical options and how to choose them for predictable adhesion and corrosion performance.

Mechanical Versus Chemical Prep for Automotive Metals

Mechanical and chemical methods tackle different contaminants and create different paint-ready surfaces. Abrasive blasting removes heavy rust and old films while building an anchor profile. Chemical cleaning excels at oils, grease, and light oxidation, but needs thorough rinsing and safe handling. Industry bodies also define cleanliness levels to guide results HC Steel Structure.

-

Abrasive or shot blasting

- Best for: Heavy rust, mill scale, and stripping old coatings on surface treatment of steel.

- Benefits: Creates a uniform profile that helps paints and primers grip.

- Considerations: Generates dust and waste, needs containment, and can be aggressive on thin stampings.

-

Chemical cleaning and degreasing

- Best for: Oils, cutting fluids, and light oxidation before paint.

- Benefits: Non-abrasive access to complex geometries and seams.

- Considerations: Requires complete rinsing and responsible disposal to avoid residues that hinder adhesion.

When to Use Phosphating on Body and Chassis Parts

Conversion coatings are chemically formed layers between the base metal and paint that increase corrosion protection and paint adhesion, while also creating a micro-roughened anchor profile. In automotive bodies, tricationic zinc phosphate remains common, while zirconium-based chemistries offer greener alternatives and compatibility with multi-material designs Finishing & Coating.

- Choose zinc phosphate when you need robust bonding and edge protection on stamped steel, galvanneal, or EG-coated panels.

- Consider zirconium conversion layers where aluminum content is high or sludge reduction is a priority.

- Fit to substrate and finish goals: for mild steel finishing, phosphate builds profile and adhesion continuity; for aluminum surface treatment, Zr layers support adhesion without heavy build that can telegraph less; both integrate with e-coat and paint stacks.

Where Laser Cleaning Fits in Sensitive Assemblies

Laser pretreatment removes rust, prior coatings, and residues using a controllable beam with minimal prep and cleanup. It can be deployed handheld or in automated cells, reduces operator exposure to blasting media or harsh chemistries, and equipment can last for decades Tech Briefs.

- Use when parts are assembled, delicate, or hard to mask against grit ingress.

- Advantages: Precise, low-waste, consistent cleanliness that supports uniform coating wetting.

- Considerations: Capital investment and programming for consistent path planning in automated cells.

Simple selection flow

- If oil or shop soils are present, start with chemical degreasing.

- If heavy rust or thick coatings persist, move to abrasive blasting to establish profile.

- For sensitive or assembled parts, or where cleanliness documentation is critical, consider laser cleaning.

- Apply the appropriate conversion coating, matching chemistry to substrate mix and downstream paints as part of your metal surface treatment plan.

Practical fundamentals still matter. Mask threads, bearing seats, and electrical contact points before blasting or conversion. Lightly break sharp edges so films do not thin on corners. Keep the surface profile and cleanliness consistent across the lot, because uniform roughness and chemistry improve both corrosion resistance and final paint smoothness in electrostatic and HVLP applications. Dialed-in prep is the springboard to the next step, where you will match application equipment and automation to the part and coating.

Application Technologies And Smart Automation

Unsure whether electrostatic, HVLP, or airless is the right fit for your part and paint shop? Imagine needing a flawless finish on visible panels one hour, then a high-build anti-chip layer on brackets the next. Choosing the right coating spraying method and automation level makes that shift seamless.

Electrostatic, HVLP, and Airless Systems in Auto Plants

First, do not confuse metal spray coating used for functional thermal overlays with the paint-like systems below. In automotive appearance work, these surface finishing technologies atomize and deposit liquid or powder to build protective, uniform films. Key performance traits like transfer efficiency, finish quality, and viscosity handling are summarized in industry guidance on spray gun types and capabilities FUSO SEIKI.

| Technology | How it atomizes | Transfer efficiency | Typical automotive use-cases | Pros | Cons | Substrate suitability | Finish character and film build |

|---|---|---|---|---|---|---|---|

| Electrostatic liquid spray or rotary bell | High voltage charges droplets; bell adds centrifugal atomization | Often high, can reach very high levels depending on setup | Primer surfacers, basecoat, topcoat on BIW and exterior panels | Excellent transfer efficiency and wrap-around to back sides | Higher capital cost; Faraday recesses are challenging; needs conductivity | Best on conductive metals; plastics require conductive prep | Smooth, appearance-grade films at controlled build |

| HVLP | Low-pressure air softly atomizes | Moderate to higher than conventional air | Repairs, detail work, trim where fine control matters | Reduced overspray vs conventional; good for varnish and metallics | Slower; not ideal for high-viscosity materials | Broadly compatible with coated metals and assemblies | Fine finish, controlled but thinner passes |

| Airless | Hydraulic pressure through a small orifice | Around mid-range | High-build primers and viscous coatings on large parts | Fast application; supports thick coats | Rougher finish; not for small intricate items | Large, robust metal parts | More textured; efficient for high film build |

| Air-assisted airless | Lower hydraulic pressure plus air shaping | Improved vs straight airless | Mid to high build where better pattern uniformity is needed | Balances speed with smoother pattern | More complex setup than pure airless | Large and mid-size metal parts | Moderate texture at practical build rates |

Conventional air spray remains versatile and capable of beautiful finishes, but with notably lower transfer efficiency and more overspray than the options above, so it is often reserved for specialty or rework situations per plant constraints.

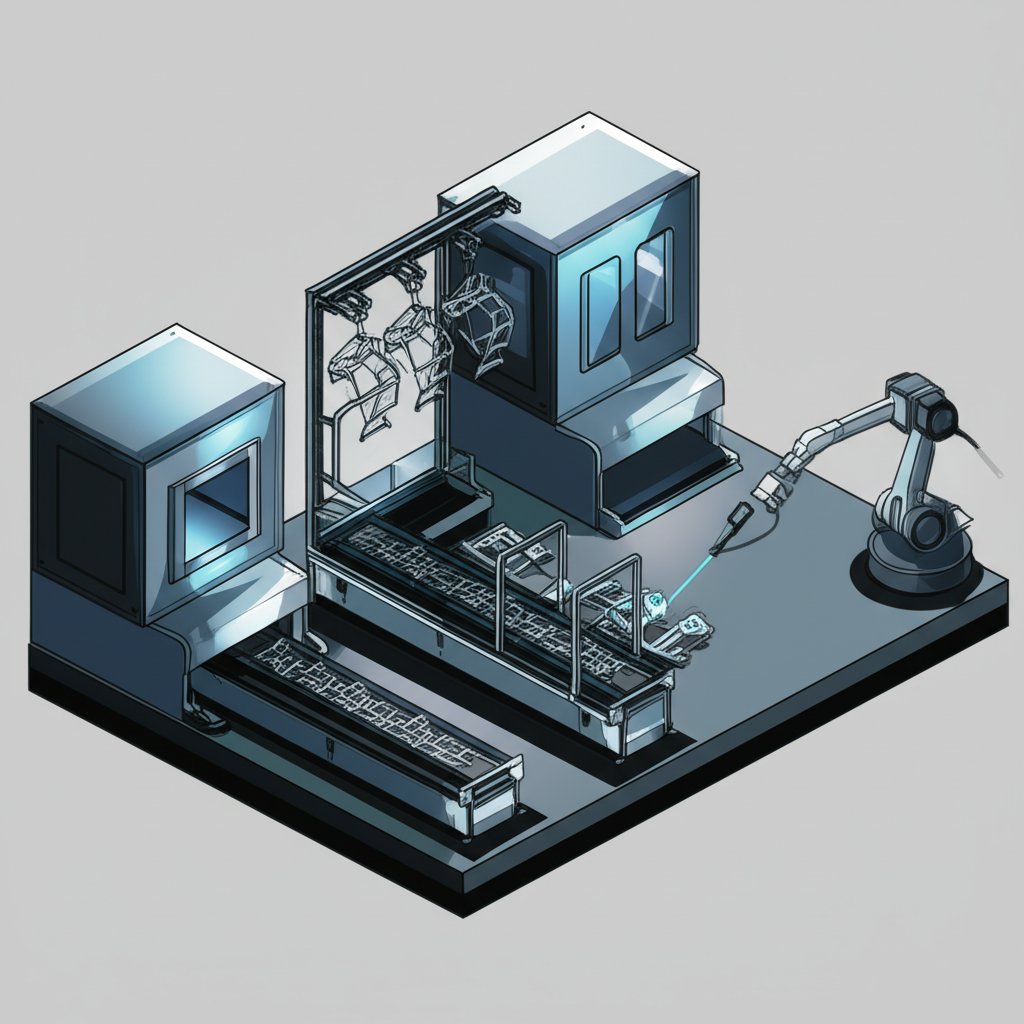

Robotic Paths, Fixturing, and Consistency

Want repeatable coverage on complex stampings and deep draws when you spray steel subassemblies? Robots help. In powder and liquid cells, autonomous robots with 3D vision can auto-generate paths, improve consistency, and reduce rework, while still facing limits in cavities and Faraday caging. Typical industrial robot hardware costs are often cited in the tens of thousands per unit, and reports describe ranges like 80,000 to 120,000 USD depending on configuration and scope Powder Coated Tough. Practical tips:

- Program approach angles that reduce Faraday effects in corners and pockets.

- Use consistent racking and grounding to maintain electrostatic wrap and film uniformity.

- For high-mix parts, consider vision-guided auto-path generation to avoid manual teach time.

- Keep manual touch-up stations for edge cases where skilled metal sprayers can quickly correct misses.

Low-Volume Versus High-Volume Fit

For short runs, manual HVLP or conventional air stations keep changeover fast. For volume, integrate booths with conveyors, flash-off zones, and curing ovens so the surface finishing line flows without bottlenecks. Conveyorized finishing systems are designed to connect wash, dry-off, paint, flash-off, and cure sections with controlled airflow and temperature zoning for repeatable results Epcon Industrial Systems.

- Electrostatic cells excel on conductive substrates and appearance-critical areas.

- Airless or air-assisted airless speed high-build underbody and structural coats.

- HVLP remains a precise tool for detail, repair, and small-lot work.

Once you choose the right automated finishing technology and layout, the next win comes from dialing in nozzles, stand-off, overlap, viscosity, and pressure for stable, repeatable films.

Dialing In Parameters For Repeatable Metal Coating Spray Results

Want fewer defects without changing your booth or guns? The secret is parameter discipline. When you align nozzle size, stand-off, overlap, viscosity, and pressure, your chosen coating methods become stable and predictable across shifts and lots.

Nozzle Selection and Atomization Basics

Nozzle size should follow coating viscosity and finish target. In automotive work, available tips commonly span about 0.5 mm to 2.5 mm. Smaller orifices suit basecoats and clearcoats, medium sizes fit single-stage paints, and larger tips help atomize high-build primers. Nozzle size also affects fan width and coverage, and many finishers aim for roughly 75% overlap between passes for consistent films Maxi-Miser. Use a quick test panel before you spray on metal parts to confirm atomization quality and pattern uniformity.

Stand-Off Distance, Overlap, and Edge Coverage

Keep a steady gun-to-part distance so the pattern stays fully wet and even. Too close can cause heavy centers and runs; too far can dry-spray edges. Pair consistent travel speed with disciplined triggering to limit overspray when you spray metal brackets or deep-draw stampings. Remember, transfer efficiency, defined as the ratio of solids deposited to solids sprayed, shifts with grounding quality, part geometry, and electrostatic settings. Small parts often show lower efficiency than broad panels, and training has outsized impact on results Powder Coating Online.

Dialing In Viscosity and Pressure for Stability

Fluid temperature control is a powerful lever because viscosity moves with temperature. Research shows atomized droplets are airborne for about 0.5–1.5 seconds, so they do not significantly change temperature in flight; even with a 13°F difference between paint and air, droplet temperature shift was calculated at roughly 0.25–2.5°F. Substrate temperature, however, strongly influences flow, runs, and orange peel, so keep both paint and part in a stable window PF Online. Set atomizing pressure just high enough to achieve full pattern formation without excessive bounce-back. Document the combination that yields a smooth, uniform film for your specific material and part mix.

-

Setup checklist

- Select tip size to match viscosity and target film build.

- Strain material and verify fan shape on a test panel.

- Confirm consistent stand-off and a repeatable gun path.

- Establish pass overlap near your validated target.

- Verify part grounding and booth balance for electrostatics.

- Stabilize paint and substrate temperatures before starting.

-

Optimization levers

- Fine-tune fluid temperature to nudge viscosity into the sweet spot.

- Adjust atomizing pressure to reduce dry spray at edges.

- Refine gun angle in corners to improve edge coverage.

- Coach trigger discipline to cut overspray and raise transfer efficiency.

- Improve grounding and spacing when using electrostatics on small, intricate parts.

Small shifts in viscosity or stand-off can swing appearance and film uniformity; lock in and document your spraycoating parameter windows.

Apply these fundamentals whether you spray on metal panels or complex assemblies, and your metal coating spray process becomes predictable. Next, let’s turn these settings into a simple, step-by-step workflow you can run every shift for consistent results.

Step By Step Spray Molding Workflow For Auto Parts

Want a workflow you can run every shift without firefighting? Use the steps below to turn spray molding into a reliable surface finishing process for automotive metal parts. The flow works for sheet metal finishing, brackets, and complex stampings. When processing metal across mixed models, consistency wins.

Pre-Treatment and Cleanliness Verification

Start clean. Independent studies attribute most coating failures to upstream prep issues, not the paint itself SurfacePrep. Verify degreasing, rinse quality, and conversion coating coverage per your route. Before any spray step, check substrate temperature versus dew point to avoid hidden condensation that undermines adhesion. This stabilizes your surface processing and supports uniform sheet metal finishes.

Masking, Fixturing, and Grounding Checks

Small setup errors cause big defects. Confirm masking per drawing and use repeatable fixtures so gun paths align run to run. If electrostatics or powder are involved, prove the ground path. Ensure separate earth ground for the part, bare-metal contact, clean hooks, and confirm continuity with a multimeter, as outlined in this grounding checklist ACR Hooks.

Application, Flash-Off, Curing, and Post-Process Inspection

-

Verify substrate and pretreatment

- Oils and shop soil removed, conversion layer uniform, parts fully dry.

- Substrate temperature kept above dew point by your site margin.

-

Confirm masking, fixturing, and grounding

- Mask critical features and edges as specified.

- Rack for repeatable orientation and spacing, then confirm ground continuity.

-

Set equipment parameters

- Match nozzle or tip to viscosity and target finish, verify pattern on a test panel.

- Stabilize booth airflow and environmental conditions before coating.

-

Run a short validation panel or first-off part

- Record wet film thickness at start, mid, and end, then confirm DFT after cure.

- Capture photos of edges and recessed areas to verify coverage.

-

Apply coating on metal with consistent passes

- Maintain steady stand-off, overlap, and travel speed.

- Use disciplined triggering to limit overspray and misses.

-

Manage flash-off windows

- Control time and airflow to prevent solvent entrapment before cure.

- Track booth temperature, humidity, and dew point delta during runs.

-

Cure per coating specification

- Follow the product datasheet for time and temperature, and log part temperature, not just air.

- For context, automotive paint shop bake temperatures vary by coating layer; for example, some topcoats may be cured at around 140-150°C for 20-30 minutes, while e-coats on the bare body shell are typically baked at higher temperatures (e.g., 180°C).

-

Post-process inspection and documentation

- Visual uniformity: no runs, sags, orange peel, or fisheyes.

- DFT within spec, adhesion readiness per your OEM method, and clean edges.

- Record lot numbers, parameters, and fixture maintenance actions for traceability.

Run this checklist every time and you will see steadier results across coating on metal parts and diverse sheet metal finishes. With a stable routine in place, the next step is choosing the right finish type for your targets, from spray-applied paints to thermal options.

Selecting Spray Coating vs Thermal Metal Spray For Auto Parts

Stuck choosing between a glossy paint stack, a rugged metallic overlay, or something in between? Imagine your part on the road for ten winters, or cycling at high temperature. The right choice depends on which performance knob you need to turn first.

When to Choose Spray Coating for OEM and Tier 1 Needs

Use liquid paint, powder, or e-coat when appearance and barrier protection are top priorities. Non-metallic coatings form insulating barriers that separate the metal from corrosive environments, and their chemistry can be tuned for different exposures and roles like primers and topcoats Corrosionpedia. In practice, e-coat lays down an ultra-thin, uniform primer on complex geometries, and powder coating supplies a tough, chip-resistant top layer that is also more sustainable than solvent paint, fitting common types of coatings for metal in auto plants PBZ Manufacturing.

Where Thermal Metal Spray Adds Functional Layers

Choose thermal metal spray when you need functional overlays for corrosion resistance, wear protection, or even restoration. In thermal metal spraying, the feedstock is heated and projected as droplets that solidify on the surface, creating robust, versatile coatings for demanding service Alphatek. Expect a more textured, functional finish that may require post finishing for dynamic or sealing surfaces, and remember coverage tends to favor simpler outer geometries.

Comparing Finish Types for Durability and Cost-in-Use

Use the table to align the types of finishes on metal with your target properties. These are qualitative comparisons based on widely used automotive practices and documented characteristics of each method.

| Method | Typical automotive use-cases | Pros | Cons | Substrate compatibility | Expected finish character |

|---|---|---|---|---|---|

| Spray-applied liquid paint or powder | Exterior panels, brackets, underbody, trim over e-coat | Appearance-grade films, barrier protection, powder resists fading and chipping | Polymer coatings are less suited for sustained high temperatures | Steel, aluminum, coated steels | Smooth, paint-like; color and gloss control |

| E-coat primer | Body-in-white shells, complex stampings with cavities | Ultra-thin, uniform coverage into recesses; ideal primer layer | Not a final UV-resistant finish by itself | Conductive metals | Very uniform, thin, black or gray primer |

| Thermal spray | High-wear areas, corrosion-prone zones, dimensional restoration | Durable functional layer for wear and corrosion; versatile materials | May need post machining; best on simpler outer surfaces | Broad, including ferrous metals | More textured functional layer; engineered build |

| Electroplating | Fasteners, decorative trim, hardware | Thin metallic coating with decorative or protective effect | Certain deposits can introduce residual stresses affecting fatigue | Steel and other conductive metals | Bright metallic coating or satin, depending on process |

| Hot-dip galvanizing | Chassis parts, structural items, brackets | Thick, durable zinc layer that coats edges and recesses well | Limited aesthetic options compared to paints | Primarily steel | Matte to spangled zinc appearance |

| Anodizing | Aluminum trim and housings | Hard, corrosion-resistant oxide layer | Limited mainly to certain nonferrous alloys | Aluminum, magnesium, titanium | Uniform, dyed or clear oxide finish |

Quick selection matrix

- Priority property: appearance and color control favors spray-applied stacks; wear or restoration leans to thermal metal spray.

- Production volume: continuous lines often pair e-coat with powder or liquid; thermal spray suits targeted functional zones.

- Geometry and access: deep cavities favor e-coat coverage; open surfaces fit thermal overlays and powder.

- Operating temperature: polymer systems are generally avoided for very high heat exposure; consider metallic coating routes when heat is severe.

- Change management and rework: plan fixtures, masking, and repair paths early, especially across different types of metal finishes.

In short, spray-applied coatings dominate appearance-critical areas, while thermal spray provides functional overlays where durability or repair drives the spec. With a method selected, the next step is to lock down quality checks for coverage, adhesion, thickness, and corrosion to meet OEM expectations.

Quality Assurance And Testing That Stands Up To OEMs

What does good look like on the line? Sounds complex? Anchor your checks to proven standards and your customer spec. In industrial metal finishing and automotive metal finishing, the fastest way to consistency is a simple, repeatable checkpoint plan that your team can run every shift.

In-Process Checks for Consistency and Coverage

- Visual inspection at about 3 ft with lighting near 100 foot-candles to judge runs, sags, orange peel, and overspray in the correct appearance zones. An OEM example documents these conditions and zone-based acceptance, including no visible or felt overspray in appearance-critical zones Freightliner Service Bulletin.

- Gloss and color harmony. Use ASTM D523 for specular gloss and ASTM D2244 for instrumented color difference to keep adjacent panels uniform on metal surface finishes.

- Dry film thickness. Verify with ASTM D1186 on ferrous substrates or ASTM D1005 micrometer methods, and record readings at representative locations after cure.

- Orange peel benchmarking. Compare to boundary panels or instrument readings per plant practice, as referenced by OEM zone methods in the bulletin above.

Adhesion, Thickness, and Corrosion Validation

- Adhesion. Use ASTM D3359 tape test for quick screening and ASTM D4541 pull-off when you need quantitative values. For metallic layers, see ASTM B571.

- Thickness confirmation. Pair D1186 or D1005 with process logs to confirm stack build after bake.

- Corrosion exposure and rating. Run ASTM B117 salt spray and evaluate creepage and failure per ASTM D1654. Assess blistering via ASTM D714.

- Durability spot checks. Consider ASTM D4060 abrasion, D2794 impact, D522 flexibility, and G154 or G26 accelerated weathering as required. Method summaries are compiled here High Performance Coatings ASTM overview.

- Sensor areas. Near ADAS and radar zones, control mil thickness precisely to meet OEM statements and avoid interference 3M guidance.

Visual Standards and Defect Acceptance

- Apply zone-based limits for dirt, chips, pinholes, and sags, and use boundary samples to judge severity. Uniformity should not visibly shift between adjacent panels in the same zone per OEM practices noted above.

- Field adhesion check. A simple tape pull can flag loss of adhesion on chassis and hidden areas, with photos taken before and after for records, as outlined in the bulletin source.

- Rework documentation. Note location, root cause, and blend limits. Feather edges, extend blends to natural breaks, and verify gloss and texture with D523 and visual comparators to avoid halos on visible metal surface finishes.

- System thinking. Build these gates into your metal finishing systems so defects are found early and corrected before cure.

Align test frequency and sample plans with customer requirements and process capability.

With QA locked in, the next step is managing VOCs, PPE, ventilation, and waste so your line stays compliant and safe.

Environment Health And Safety Essentials

What keeps a spray line compliant and safe without slowing throughput? Start with controls that target emissions, airflow, and worker protection, then document them as part of your coating program for automotive metal parts.

Managing VOCs and Emissions in Spray Operations

- Use enclosed paint booths to control overspray and fumes. Airflow patterns pull particles into multi stage filtration, with options like activated carbon for VOC capture, supported by make up air and proper exhaust routing how paint booths control overspray and emissions.

- Expect regulators to tighten VOC and energy efficiency expectations. Booth upgrades such as optimized airflow, efficient lighting, and fan controls, plus advanced low emission coatings, help meet evolving standards EPA and local agency focus on VOCs and efficiency.

- Favor high transfer efficiency techniques and disciplined gun setup to reduce material usage and emissions. When feasible, evaluate lower VOC chemistries as part of your surface treatment solutions strategy.

- Balance booth pressure to keep contaminants in check and surfaces clean for appearance critical surface coatings.

Worker Safety, PPE, and Ventilation

- Follow OSHA and NFPA guidance for spray booths, including proper ventilation, explosion proof equipment, hazardous chemical labeling, PPE, and employee safety training OSHA and NFPA 33 compliance basics.

- Provide respirators, eye and hand protection, and ensure fit and use training before entering spray areas.

- Maintain clear airflow paths and replace filters on schedule so ventilation stays effective across surface treatments.

- Ground equipment and racks to minimize static discharge risk in electrostatic operations.

- Before servicing robots or atomizers, de energize and follow your site lockout tagout program, then restore and test ventilation before restart.

Waste, Overspray, and Cleanup Best Practices

- Keep filtration in top condition. Multi stage filters, pressure control, and well routed exhaust stacks help capture overspray and VOCs in industrial surface treatment environments.

- Store and handle paints and solvents correctly to reduce spill, fire, and health hazards, and use defined cleanup protocols for drips and leaks.

- Manage booth sludge, spent filters, and solvent waste per local environmental rules and OEM mandates. Document segregation, labeling, and disposal steps in your surface treatment systems procedures.

- Use high quality atomizers and training to cut overspray at the source. Pair with calibrated air make up to stabilize temperature and humidity during runs.

- Record maintenance intervals for atomizers, booths, and sensors so performance stays consistent across your surface treatments program.

Locking in these EHS controls protects people and uptime while improving finish quality. With compliance and safety defined, you are ready to select partners that can integrate these safeguards into production ready surface treatment solutions and line setups.

Selecting Partners And Integrating Into Your Line

Sounds complex? When you turn spray plans into production, the right partner shortens trials, stabilizes quality, and keeps takt time intact. Use the checkpoints below to source metal processing services that support coating performance, not just the processing of metal.

What to Look For in a Coating and Metal Processing Partner

- Vertical integration that reduces handoffs. Look for machining, assembly, surface treatments, metrology, and in-house QA under one roof, plus strong certification discipline such as IATF 16949 and ISO 14001, and early engineering support from prototype through pre-production BCW Engineering guidance.

- Scalability and lead-time control. Tooling flexibility, batch planning, and pre-series support help new platforms ramp smoothly.

- Supply chain fluency and ESG alignment. Partners who manage risk, traceability, and reporting avoid late surprises, especially as sustainability targets tighten BCW Engineering guidance.

- Coating-readiness QA. Require documented raw material compliance, surface roughness control, salt spray and film thickness checks, and dimensional verification to support stable finishes Shaoyi QA practices.

Line Integration, Lead Times, and Validation Support

- Integration expertise. A capable integrator can combine conveyors, robots, and process controls to increase throughput and reduce downtime, instead of overbuilding new equipment Precision Automation line-integration approach.

- Validation discipline. Expect defined trials, fixture reviews, and first-article gates so application, flash-off, and cure stay in sync with your coating windows.

From Prototype to Production With Consistent Quality

| Provider option | Where they help most | QA and compliance support | Integration and scale | Buyer notes |

|---|---|---|---|---|

| Shaoyi — custom metal processing with coating-readiness focus | Prototype through production of coated metal parts where documented inputs protect finish quality | Elemental and ELV checks, mechanical testing, layout inspection, salt spray and film thickness, buckling, roughness reporting QA reference | Supports coating stability by controlling upstream variables that affect adhesion and appearance | Audit against your OEM specs and capacity targets before committing to high volume |

| Metal finishing plants or coating job shops | Flexible batches and diverse paint or powder options | QA depth varies by site; confirm thickness and adhesion controls | Good for overflow or specialty colors | Verify masking, racking, and rework paths for appearance panels |

| Line integrator for coating cells | Conveyors, robots, booths, and controls into one flow | Process documentation and start-up support | Shortens ramp by optimizing layout and uptime | Define ownership of ongoing maintenance and programming |

| Surface finishing plant manufacturer | Turnkey equipment for a new surface treatment plant | Equipment manuals and safety compliance frameworks | High capital but tailored capability | Plan operators, spares, and training for sustained results |

Choose a partner who can prove coating-readiness, integrate cleanly with your line, and sustain quality as volumes rise. That is how metal processing and the processing of metal turn into durable, repeatable finishes without slowing production.

Frequently Asked Questions

1. What is the process of spray coating?

In automotive plants it follows a repeatable flow: clean and pretreat the metal, mask and fixture, apply the coating by electrostatic, HVLP, airless, or air‑assisted airless, allow flash‑off, then cure and inspect for thickness, adhesion, and appearance. This mirrors common OEM lines where parts move through cleaning, application, and ovens before final checks, as outlined for automotive surface coating operations by the U.S. EPA https://www.epa.gov/sites/default/files/2020-10/documents/c4s02_2h.pdf. Working with an IATF 16949 supplier helps standardize each gate from prototype through production.

2. What are the disadvantages of metal spraying?

Thermal metal spraying can produce more porous or oxidized deposits with some flame processes, may need post‑machining for fit or sealing surfaces, and can be challenged in tight recesses. It is excellent for functional layers, but not the first choice when you need a smooth, color‑critical finish. TWI summarizes typical tradeoffs for flame spraying versus other thermal spray routes https://www.twi-global.com/technical-knowledge/faqs/faq-what-are-the-disadvantages-of-flame-spraying. If appearance is key, spray‑applied paints or powder coatings usually win.

3. What is the toughest coating for metal?

Toughness depends on the job. For appearance plus durability, polymer coatings like epoxy primers with polyurethane or powder topcoats provide strong barrier protection. For wear or high‑stress service, thermal spray overlays such as carbides or metals deliver functional hardness and repairability. For corrosion on steel structures, zinc‑rich systems or galvanizing are proven. A&A Coatings highlights several anti‑rust options commonly used in industry https://www.thermalspray.com/top-5-anti-rust-coatings-for-long-lasting-metal-protection/. Match the coating family to the environment, temperature, and service life you need.

4. What is the cost of thermal spray coating?

Costs vary with process type, coating material, surface area, masking, and any post‑finishing. Market listings often quote per‑area pricing to give ballpark expectations, but total cost is driven by part geometry and quality requirements. An example listing shows per‑square‑meter pricing for thermal spray services https://dir.indiamart.com/impcat/thermal-spray-coating.html. For accurate budgeting, request a routed quote that includes prep, spray, finishing, and inspection.

5. How do I choose between spray‑applied coatings and thermal metal spraying for auto parts?

Start with the priority property. Choose spray‑applied paint or powder when you need color, gloss, and uniform barrier protection at high throughput. Choose thermal metal spraying when you need a functional metallic or ceramic layer for wear, corrosion, or dimensional restoration. Then weigh geometry access, production volume, rework strategy, and curing constraints. Running small trials with an IATF 16949 partner can de‑risk the path from prototype to production; for example, Shaoyi provides end‑to‑end metal processing and advanced surface treatments suitable for coating validation https://www.shao-yi.com/service.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —