What Is Baking Paint? Durable And Glossy Coating For Automotive Metal Surfaces

Baking Paint Explained For Automotive Metals

Ever wondered why some metal parts on cars look deep and glossy and hold up better over time? That is the promise behind baking on paint. In simple terms, bake painting means you apply the coating, then add controlled heat so the film develops full strength and gloss. Historically, this approach shows up as the baked enamel paint finish, a hard, glossy coating baked to achieve its properties, often built on alkyd, melamine, epoxy, cellulose nitrate, or urea resin binders CAMEO baked enamel overview. Today, both OEM and refinish operations use paint and bake stages to bring out durable appearance on automotive metal surfaces.

What Baking Paint Means in Automotive

In the shop, you will hear techs say they need to run a bake paint cycle after spraying. The idea is simple. Heat helps the applied film finish forming and reach its designed performance. Unlike products intended to air dry, baking requires following the exact conditions the paint maker specifies. Those instructions live in the product's Technical Data Sheet (TDS), and may specify temperature as booth air or as part substrate. Measurement method, time windows, and even whether force drying is allowed can differ by product, so always check the TDS and any OEM service information before you bake I-CAR guidance on clearcoat baking and TDS.

- High gloss, uniform appearance

- Hard, dense, tough film

- Wear resistance on metal parts

- Process consistency when you follow the TDS

Why Heat Curing Improves Durability and Gloss

Heat drives off solvents and other volatiles and helps the binder form a more uniform, dense coating. That is why a baked enamel can look glossier and feel tougher than a comparable air dry. You will notice fewer print marks and better edge hold when the film reaches full cure. The key is not to guess at times or temperatures. Follow the paint maker schedule to avoid under or over cure, and do not substitute another product’s bake schedule.

Where Baked Coatings Are Used on Vehicles

In refinish, clearcoats are often baked per the product’s TDS to stabilize gloss and hardness after spray. Beyond liquid systems, many metal parts such as door handles, trim pieces, under the hood components, suspension items, and even wheels commonly use powder coatings that are applied and then baked for durability ChemPoint overview of powder coated automotive parts. Together, these paint and bake approaches complement different types of automotive paint and finishing needs across the vehicle.

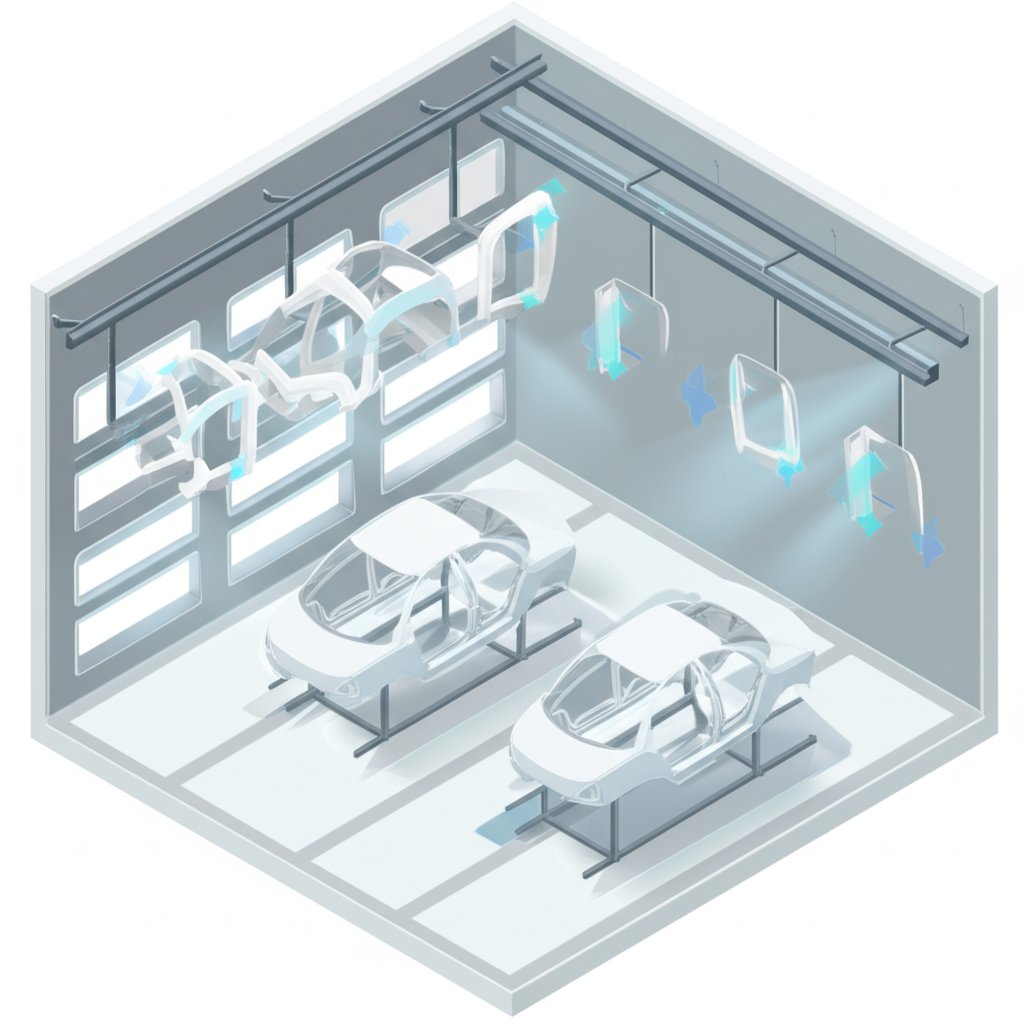

Image idea: simple process schematic showing clean > spray > flash > bake > cool > inspect.

Heat cure is about a controlled bake that develops gloss and toughness. Always set your schedule from the product TDS or SDS.

Up next, we will map the chemistry basics, show compatibility tables, and share oven guidance you can bookmark for quick reference.

Curing Chemistry Made Understandable

Sounds complex? When you paint and bake, you are speeding up chemistry that gives automotive finishes their hardness and gloss. The binder is the star, and heat helps it form a tighter, tougher network. Wondering what is paint made out of in this context? Think resin binder plus pigments, solvents, and additives, with the binder chemistry driving how a bake works.

Resins And Crosslinkers That Benefit From Baking

Different resin families cure in different ways. In short, alkyd baked enamels can be combined with amino resins, acrylic systems often crosslink with melamine, and 2K urethanes cure when an isocyanate reacts with a polyol. Each pathway responds uniquely to oven ramp, dwell, and cool down, so always follow the exact schedule in the product's Technical Data Sheet (TDS).

| Resin family | How bake cure works, catalysts, sensitivities |

|---|---|

| Alkyd baked enamels | Short-oil alkyds are commonly crosslinked with melamine formaldehyde during stoving to build a durable film. Drying-alkyd variants may also use metal driers to promote oxidation in air. Selection and modification of the alkyd and the amino crosslinker are key to film properties ScienceDirect overview of alkyds. |

| Acrylic–melamine 1K systems | Heat activates condensation between acrylic functional groups and melamine, producing a dense, glossy network widely used in automotive topcoats. These systems are designed for controlled bake in plant or booth ovens Automotive coating and curing review. |

| 2K polyurethane urethanes | Polyol + isocyanate react to form urethane linkages. Baking accelerates cure, but moisture also reacts with isocyanate to form polyurea and CO2, so components and air must be managed for humidity. Keep equipment dry and rely on the specified bake window Moisture in 2K polyurethane coatings. |

How Heat Changes Film Properties

Heat does two things at once. It drives off volatiles and it increases crosslink density. That is why a bake can turn a just-sprayed film into a hard, glossy, chemically resistant coating. In high-throughput paint shops, ovens convert wet layers into durable films as part of a controlled sequence that supports appearance and corrosion performance Automotive coating and curing review.

- Higher scratch and mar resistance

- Better gloss retention over time

- Improved resistance to fuels, solvents, and road salt

- More stable edges and complex shapes once fully cured

When Air Dry Systems Are Not Enough

Comparing enamel vs lacquer helps. Lacquer-style builds mainly rely on solvent loss, while baked enamel films are designed to crosslink with heat. Air dry auto products can work well for small parts and minor repairs, but when you need repeatable hardness, chemical resistance, and throughput on steel or aluminum, bake curing is often preferred in OEM-style processes Automotive coating and curing review. If you are asking what is automotive paint made of for these results, the binder choice is central. In plain terms, what is paint made out of that makes baking effective is the resin chemistry designed to react under heat.

Next up, we move from molecules to practice, mapping the full layer stack and pretreatment so your bake-ready system bonds and protects as intended.

Layer Stack And Pretreatment For Bake‑Ready Automotive Paint System

When you look at a mirror‑gloss hood, what sits under that shine? A tuned stack of layers designed to bond, protect, and then bake to full performance. In automotive, a typical stack on steel or aluminum includes a conversion coating, an electrocoat primer, a primer surfacer, the color base coat, and a protective clear coat. The conversion coating is formed by chemical reaction at the metal surface and boosts both corrosion resistance and paint adhesion, while electrocoat adds uniform coverage before spray steps industry review of conversion coatings and the automotive coating stack.

From Bare Metal To Clearcoat

Layer by layer, here is the flow you will see in a modern automotive paint system. Conversion coating prepares the metal and creates an anchor profile. Electrocoat, applied by electrodeposition, builds a continuous, corrosion‑resistant film. Primers level and provide stone‑chip resistance. The base coat for cars supplies color and effects. The clear coat locks in gloss and weatherability. In common 2 stage paint, the base and clear are staged with defined flashes and then baked per the product TDS.

Looking at primer options, common types of automotive primer paint found in OEM segments include saturated polyester primers, epoxy‑modified alkyds for adhesion and corrosion resistance, and urethane‑modified polyesters, alongside polyurethane dispersions that can improve chip resistance representative OEM layer families and features. These categories also map to how shops discuss types of auto primer or types of car primer.

Pretreatment And Adhesion Fundamentals

Pretreatment quality determines how well everything above it lasts. Phosphate and newer zirconium‑based conversion coatings both improve corrosion resistance and adhesion by creating a reactive surface. Zr technologies have gained traction as greener options and to support multi‑material bodies with more aluminum, while the overall stack still matters for durability, not just the pretreatment step conversion coating advances and system perspective. Do not confuse a clear coating primer with the transparent clearcoat layer. Primers are usually pigmented build layers, while the clear is the top protective film.

- Degrease or alkaline clean per system instructions

- Abrade only if the paint system permits it

- Remove dust thoroughly

- Approved solvent wipe

- Tack to capture remaining lint

- Mask cleanly and securely

- Allow substrate temperature to equalize before spraying

Always set flash and bake stages from the product TDS.

Bake Compatibility Across Paint Families

| Paint family | Bake‑compatibility | Recommended pretreatment | Typical uses | Pros / cons |

|---|---|---|---|---|

| Waterborne basecoat | Physical dry then clear is baked | Phosphate or Zr conversion + electrocoat | Color layer in 2 stage paint on metal panels | Good appearance and metallic orientation when formulated; relies on clear for durability |

| 1K acrylic–melamine stoving topcoats/clears | High‑temperature stoving per TDS | Phosphate or Zr conversion + electrocoat | Glossy topcoats and clears in OEM lines | High gloss and durability; needs controlled bake window |

| 2K polyurethane clears | Assisted bake accelerates cure | Phosphate or Zr conversion + electrocoat | Clear over base coat for cars | Strong chemical and scratch resistance; moisture management is critical |

| Alkyd baked enamels | Moderate to high temperature stoving | Phosphate or Zr conversion + electrocoat | Selected metal parts and heritage finishes | Hard films and classic look; slower cure than modern systems |

Instruction: insert explicit cure temperatures and dwell only when cited from the specific product TDS or OEM refinish documentation. Otherwise keep qualitative descriptors.

Next we will turn these stack choices into practice by selecting an oven, reading bake schedules, and integrating booth, flash, and bake stages without defects.

Ovens And Bake Schedules That Deliver Results

Ready to turn the layer stack into real, repeatable gloss? The right paint oven and a disciplined schedule make baked on paint predictable, even when parts vary in size and thickness.

Choosing The Right Oven For Automotive Metals

Most refinish and parts lines rely on convection for even heat and airflow around complex profiles. Look for an automotive paint oven that delivers uniform temperature at the part, adjustable airflow, PLC or HMI controls with PID ramps, optional data logging, and NFPA compliant purge and safety interlocks. IR assist can help preheat high mass parts before the main cure Spray Tech convection oven features and controls.

- Capacity and part clearance

- Temperature uniformity at the part

- Airflow architecture and adjustable nozzles

- Controls, PID ramps, and recipe/data logging

- IR assist for heavy sections

- Batch vs conveyor integration

- NFPA or OSHA compliant safety systems

How To Read And Apply Bake Schedules

Do not guess. Use the product TDS for ramp, dwell, and cool down. Aggressive heat too soon can trap solvent and create solvent pop; controlled bake cycles, good ventilation, and IR assist mitigate that risk solvent pop causes and prevention. The aim when you cure paint in oven cycles is a dense, glossy film without trapped volatiles.

| Paint family | Flash requirements | Recommended bake range | Dwell time | Notes |

|---|---|---|---|---|

| Liquid clears and topcoats | Use booth flash to vent solvents per TDS/SDS | Per TDS | Per TDS | Uniform ramps help stabilize appearance |

| Alkyd baked enamel | Allow adequate flash per TDS | Per TDS | Per TDS | High mass parts may benefit from IR preheat |

| Powder coating | Gel then full cure per TDS | Per TDS | Per TDS | Airflow and uniformity are critical on edges |

Instruction: insert exact temperatures and times only from the product TDS or OEM documentation.

Integrating Booth, Flash, And Oven Stages

In practice you will spray, flash, cure, then cool down. Heated booths provide defined modes that support this flow. Flash helps release solvents before the next coat or final cure. During cure, the booth holds a preset temperature and should not be entered. After cure, allow the automatic cool down to run and never shut off power early, which can prevent proper chamber cooling heated booth modes and cool-down guidance. When baking a car or a rack of brackets, space parts for airflow and avoid overloading. For car baking in a compact booth, you will notice better results when part mass, airflow paths, and schedule discipline work together.

Process flow diagram: spray > flash > load oven > bake > cool > inspect.

Set ramp, dwell, and cool-down from the TDS and log your oven profile.

Next, we translate these choices into a step-by-step SOP you can post in the booth for consistent results when baking car panels and small parts.

How To Paint Automotive Panels With A Bake Process SOP

Ready to turn your oven and booth settings into repeatable results? If you are searching for car paint how to that actually minimizes rework, post this SOP at the booth. It walks through the auto paint process from prep to bake so you know how to paint automotive panels and small parts with confidence.

Step By Step SOP For Bake Cured Automotive Coatings

- [ ] Clean substrate in a ventilated area and keep containers closed when not in use. Maintain your booth and mixing room ventilation to reduce contamination and emissions EPA DfE best practices for auto refinishing.

- [ ] Check surface profile and pretreatment per your paint system. Remove dust, solvent wipe, and tack thoroughly before application as specified for many clearcoats example TDS guidance.

- [ ] Mask cleanly. Keep floors, walls, and racks free of overspray to avoid oven contamination. Inspect and replace booth filters on schedule and keep the oven clean for consistent results booth and oven maintenance practices.

- [ ] Mix materials strictly by the product TDS. For example, one 2K baking clear lists a 2:1 mix with an activator and a 2–4 hour pot life at 70 F and 50% RH. It also specifies a target dry film build window for durability example TDS guidance.

- [ ] Set up your auto paint gun kit per gun maker and TDS. HVLP or equivalent is recommended for transfer efficiency and emission reduction, and some 2K clears specify 1.2–1.4 mm tips with defined pressures example TDS guidance. Perform all spraying in a filtered booth and keep painters trained and protected EPA DfE best practices.

- [ ] Apply primer, then flash per TDS. Apply base color, flash, then apply clear in flowing coats at the prescribed gun distance to avoid air entrapment per the product instructions example TDS guidance.

- [ ] Move parts to bake. Respect ramp rates and dwell. Monitor oven temperature with calibrated controls and sensors to avoid defects and undercure, and allow a controlled cool down before handling maintenance and temperature control.

- [ ] De-mask after cool down and perform final inspection. If you use automotive can spray paint for small brackets or let-down panels, still spray in a booth or prep station to control emissions and overspray EPA DfE best practices.

Never substitute another brand’s bake schedule—always follow the exact TDS for the system on the surface.

Flash And Recoat Windows That Protect Finish Quality

Sounds obvious, but this is where many jobs go wrong. Follow the specific flash, recoat, and cure windows for your product. For example, one baking clear specifies 5–15 minutes flash between coats, a critical recoat limit of 60 minutes at 70 F, a force dry of 30 minutes at 140 F, dust free in 30–45 minutes, and a post‑cool sand or delivery window, along with a target dry film build range and typical tip sizes example TDS guidance. Use these as examples only—your product’s TDS rules.

- If you miss a recoat window, follow the product’s scuff and reapply instructions.

- When learning how to auto paint with bake assist, set visible timers to hit flashes consistently.

- Keep a one‑page cheat sheet of your system’s windows as part of your how to paint a vehicle routine.

Inspection And Documentation

- Document mix ratios, lot numbers, environmental conditions, flash times, and oven program used. Ongoing logs and calibration records help maintain compliance and reduce defects maintenance and documentation.

- Check appearance under consistent lighting. Verify film build where specified by the TDS before delivery.

- PPE and booth practices matter. Perform all spray operations in a filtered booth, use HVLP or equivalent, and maintain training and records to align with regulations EPA DfE best practices.

Common pitfalls to avoid

- Poor degreasing or inadequate tack that seeds dust into the clear.

- Insufficient flash that traps solvent before bake.

- Overloaded racks and non‑uniform airflow that produce uneven cure.

- Ignoring the product’s film build limits or tip settings in the TDS.

Imagine posting this checklist where you mix and spray—you will notice fewer surprises and cleaner outcomes. Next, we will troubleshoot bake‑stage defects and tighten quality control so every job leaves with consistent gloss and adhesion.

Quality Control And Defect Prevention In Bake Finishes

Seeing waves, blisters, or dull spots after the bake? The good news is that most defects in car paint finishes are preventable with a few disciplined checks before and after the oven.

Defects Linked To Bake Stages And How To Prevent Them

Orange peel often traces back to viscosity and solvent management. When material is too thick, droplets do not flow together and the film stays textured; excess solvent or poor release can also disturb the film and shift gloss or even form blisters. Control viscosity, solvent addition, and application technique to avoid these outcomes mechanisms and prevention guidance.

- Match reducer and viscosity to the product TDS and booth conditions.

- Respect flash times so volatiles can escape before heat.

- Spray even film builds and avoid piling on heavy coats.

- Load parts with airflow spacing; do not crowd racks.

Pros of bake systems in refinish

- Repeatable gloss and hardness when schedules and flashes are followed.

- Faster return to service compared with many air dry approaches.

- Helps deliver consistent results across different types of auto paint finishes.

Cons compared with air dry

- Requires oven capacity, uniformity, and process discipline.

- More sensitive to missed flash windows and load density.

- Added steps for documentation and oven profile checks.

Inspection Checkpoints Before And After The Oven

- DFT measurement: Verify dry film thickness with the right gauge. Magnetic pull-off is commonly used on steel; eddy current gauges measure non-conductive coatings on non-magnetic substrates like aluminum. Choose and calibrate instruments per procedure DFT testing overview.

- Gloss and texture: Inspect gloss paint metal panels under consistent lighting; look for uniform lay and minimal texture.

- Adhesion check: Where approved, perform an adhesion check per your shop method and product instructions.

- Edge coverage: Confirm coverage on edges, seams, and high-mass areas.

- Recordkeeping: Log mix ratios, flashes, oven program, and part placement.

Short or skipped flash increases solvent entrapment risk during bake—build in flash time.

When To Sand And Recoat Versus Strip

- Sand and recoat when defects are shallow and the film has reached full cure per TDS. Nib-sand dust, refine orange peel, and reapply within the stated recoat guidance.

- Strip and restart when you see widespread blisters, lifting between layers, or systemic adhesion concerns across panels. Use masking protection, then select an appropriate removal method such as chemical stripping, controlled sanding, or media blasting; manage risks like plastic or fiberglass sensitivity and potential metal warping with blasting automotive paint removal tips.

Whether you build show-level paint finishes cars or daily driver touch-ups, these checkpoints help stabilize appearance across different types of car paint finishes. Up next, we compare bake cure with air dry and powder so you can pick the right path for your types of auto paint finishes.

Bake Cure vs Air Dry vs Powder For Automotive Spray Paint

Not sure which finishing route fits your part? Imagine you have steel brackets, an aluminum cover, and a tight deadline. Do you bake, air dry, or powder coat? Use this side-by-side guide to match process to performance without guesswork.

When To Choose Bake Cure Over Air Dry

Bake-cured liquid coatings are about speed and consistency. Heat shortens dry times and helps the film build hardness and adhesion in a more controlled environment. That translates to better durability and faster turnarounds. The tradeoffs are equipment, energy use, and the need for trained operators. By contrast, air drying is simple and flexible, with lower upfront equipment needs, but it takes longer, is more sensitive to temperature, humidity, and dust, and increases contamination risk. Air dry fits small jobs, DIY touch-ups, and spaces without ovens, while bake cure supports professional throughput and robust finishes air drying vs baking overview.

Choosing among the different types of automotive paint also matters. Urethane systems are known for durability, and many OEM lines use water-based basecoats with clear on top, which pair well with controlled bake stages. If you are comparing the types of car paint like urethane, acrylic enamel, or water-based, align the cure method with the product’s TDS.

Powder Coating Versus Liquid Baking On Complex Geometries

Powder coating lays down a thick, consistent, and very durable film with little to no VOCs, and overspray can often be reclaimed. It shines on metal parts that tolerate heat and benefit from a resilient finish. Limitations include higher initial equipment needs, difficulty achieving very thin coats, and ineligibility for heat-sensitive substrates. Liquid painting remains versatile across more materials, offers fine control over thin films and color effects, and typically carries lower initial setup, but it involves solvents and generally less durability than powder in harsh environments powder vs liquid comparison.

| Process | Durability | Gloss retention | Edge coverage | Reworkability | Masking | Environmental controls | Typical automotive use cases |

|---|---|---|---|---|---|---|---|

| Bake-cured liquid paint | Enhanced hardness and adhesion with heat | High with modern urethane clears | Thin, controllable films suit sharp edges | Follow liquid paint TDS for sand and recoat | Standard tapes and films | Ventilation and oven; VOCs depend on product | Body panels, trim, brackets needing quick turnaround |

| Air-dry liquid paint | Good, but more sensitive to ambient conditions | Dependent on paint type and room conditions | Similar to baked liquid with proper application | Standard liquid rework per TDS | Standard tapes and films | Highly sensitive to temperature, humidity, and dust | Small parts, touch-ups, DIY, areas without ovens |

| Powder coating | Very durable, thick, consistent finish | Excellent; broad range of textures and sheens | Thicker films; very thin edges may be challenging | Varies by system; plan process routing | Use process-appropriate masking and fixturing | Low VOC process; curing oven required | Metal brackets, underhood parts, wheels, trim |

Throughput, Energy, And Floor Space Considerations

Think practical. Baking needs an oven or heated booth and trained staff, yet it boosts cycle time and consistency compared with air dry. Air dry minimizes equipment but stretches schedules. Powder lines require specialized equipment and cure ovens, but deliver a durable, efficient finish with minimal VOCs. If you are working with automotive spray paint or even an auto spray paint can for minor work, air dry may be sufficient. For production panels and high-wear parts, a bake path or powder often pays off. Across these types of paints, always confirm cure and compatibility in the product’s TDS.

- Substrate type and heat tolerance

- Part geometry and target film thickness

- Target gloss and appearance standard

- VOC compliance and ventilation capability

- Line speed, takt time, and rework plan

- Oven availability and floor space

If you are weighing the types of car paint and process together, the next section walks through how to evaluate integrated partners who can pretreat, paint, and validate bake schedules under one roof.

Partnering For Integrated Bake Coating Success

Choosing a partner for bake-cured coatings and metal parts can feel complex. When you need durability, gloss, and launch-ready documentation, the right team makes the difference.

What To Look For In A Bake Coating Partner

Start with fundamentals you can verify. You will notice faster ramps and fewer surprises when these boxes are checked.

- IATF 16949 quality system with PPAP capability and clear document control.

- Bake schedules derived from product TDS or SDS, not generic recipes, and kept under revision control.

- Automotive paint oven capacity suited to your parts plus uniformity mapping and real-time temperature logging. Advanced oven profiling that tracks peak metal temperature and time-in-window helps validate cure and can streamline testing via single-pass methods oven profiling and validation overview.

- In-house pretreatment and finishing options so adhesion and corrosion targets are built in, not bolted on.

- Fixture, masking, and rack design support for repeatable edge coverage and throughput.

- Traceability from raw material to finished part, with logged lot numbers and cure data.

- Rapid sample turnaround and clear communication on feasibility, especially for complex geometries.

- If you are a consumer asking where to paint my car or where can i paint my car, choose a vehicle painting service or car paint shop with a bake-capable booth and documented cure procedures. If you wonder where should i get my car painted, ask to see their oven logs and finish standards.

From an automotive paints production perspective, automatic car painting lines and disciplined oven controls raise consistency and reduce rework.

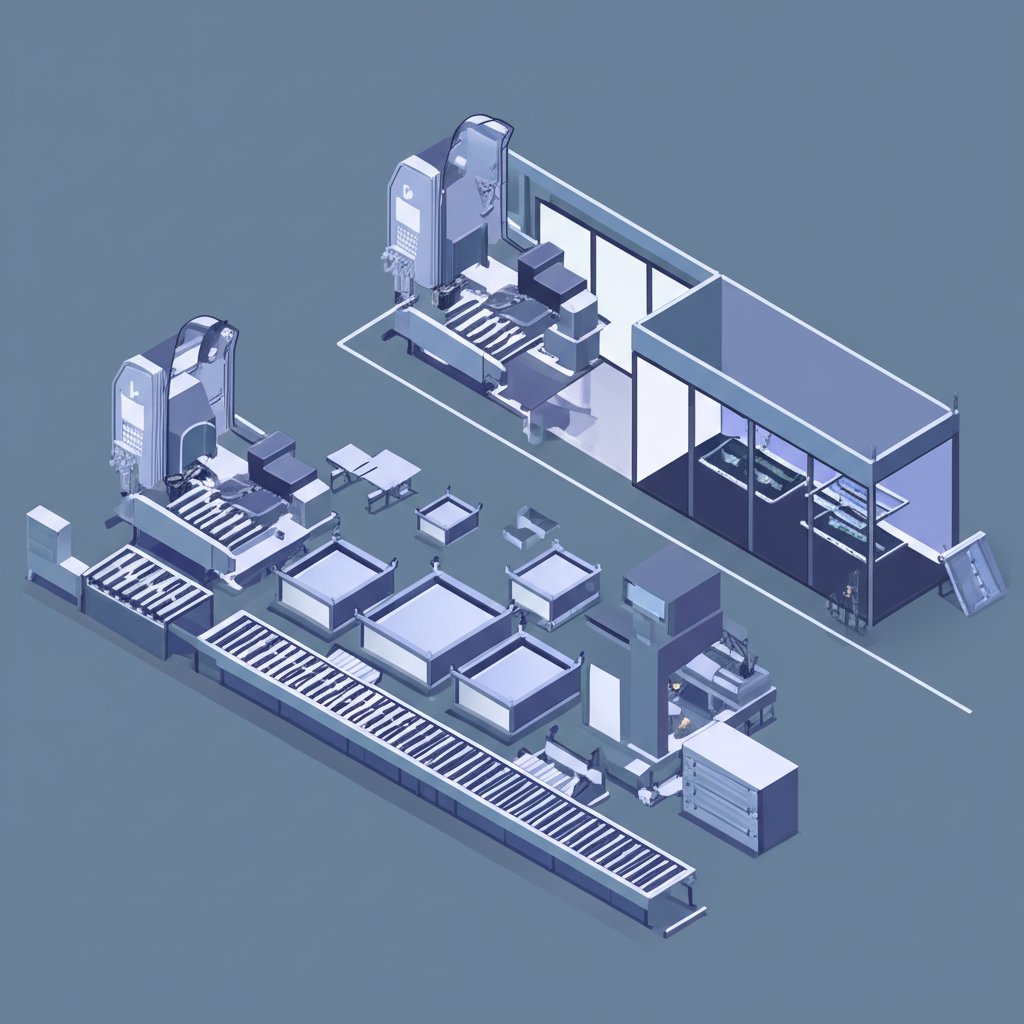

Integrating Fabrication Pretreatment And Paint

Why juggle multiple suppliers when one can stamp, machine, pretreat, paint, and assemble to the same spec? Integrated flow reduces handoffs, contamination risk, and schedule loss. It also tightens feedback loops between part design, fixturing, and bake parameters.

One example of this integrated approach is Shaoyi, which provides end-to-end automotive metal solutions including stamping, CNC machining, surface treatments such as phosphating, electrophoretic coating, powder coating, and spray painting, plus assembly and quality inspection, under an IATF 16949 certified quality system Shaoyi integrated metal processing and surface finishing. That combination helps align pretreatment, coating choice, and oven scheduling from prototype to mass production.

Faster PPAP And Launch With One Supplier

Launch speed depends on clean paperwork and proven process capability. A supplier comfortable with PPAP can organize Part Submission Warrants, capability studies, and layered process audits while maintaining consistent quality across runs and sites. A structured PPAP approach reduces risk, clarifies requirements, and supports smoother production validation PPAP audit checklist benefits.

- Shaoyi IATF-certified, integrated metal processing and surface treatments for bake-cured finishes

- OEM refinish or internal standards alignment and documented bake schedules

- Oven validation reports and real-time temperature logging capability

- Rapid prototyping to production scale with consistent quality

- Validated pretreatment options matched to your substrate and corrosion targets

- Traceability, lot control, and cure data attached to each shipment

- Fixture and masking plans that support appearance and cycle time

Pick partners who can prove their cure, document it, and repeat it when volumes rise.

If you need an integrated, audited partner to take bake-cured automotive metal components from prototype to production, review Shaoyi’s services and start a conversation about requirements, oven profiling, and documentation.

Baking Paint FAQs for Automotive Metal

1. What is the toughest coating for metal?

Toughness depends on the part and process. For many automotive metal parts, powder coating delivers a thick, resilient film. On body panels, a bake-cured 2K urethane clear over a compatible base can provide excellent chemical resistance and gloss retention. Ceramic-style coatings are very hard but are typically used as top layers rather than primary color coats. Choose based on substrate, geometry, cure capability, and the product TDS.

2. What is the most durable paint finish for metal?

On automotive metals, a well-prepared stack with conversion coating or e-coat, color base, and a bake-cured urethane clear is a proven path to a long-lasting, glossy finish. For brackets and underhood parts, powder coating is often selected for durability. Whichever you choose, durability comes from correct pretreatment and strictly following the product TDS for flash and bake. A classic baked enamel paint finish remains viable for certain parts, but modern urethanes typically lead for overall performance.

3. Is baking auto paint necessary or can I air dry?

You can air dry some systems, but paint and bake methods elevate hardness, chemical resistance, and throughput. Air dry can be suitable for small parts and touch-ups when time and equipment are limited. When you need consistent gloss, faster turnaround, and repeatable results, a controlled bake paint schedule per the TDS is preferred.

4. What should I look for in a bake-coating partner?

Verify a quality system such as IATF 16949, in-house pretreatment, documented bake schedules derived from the TDS, oven uniformity mapping, and real-time temperature logging. Look for PPAP capability, traceability, and fast sample turnarounds. Integrated suppliers like Shaoyi combine fabrication, pretreatment, spray, powder, and oven validation under one roof, which reduces handoffs and helps keep launch timing on track.

5. Can small shops use a compact oven for bake painting?

Yes, where codes and ventilation allow. A convection booth with a bake mode or a small batch automotive paint oven can reliably cure baked on paint if you manage airflow, load spacing, and ramp rates. Always set ramp, dwell, and cool-down from the product TDS and log the cure profile for consistency.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —