What Is Galvanizing? Zinc Coating Process For Corrosion Protection In Automotive Metals

Understanding galvanizing for automotive metals

What does galvanized mean on your print, and why do so many auto parts call for a zinc coating? If you are searching what is galvanizing or asking what is galvanization, here is the short answer engineers and sourcing managers can use.

What Is Galvanizing and Why Zinc Protects Steel

Galvanizing is the application of a zinc coating to steel or iron to resist corrosion. Zinc protects in two ways. First, it forms a physical barrier that separates steel from moisture and oxygen. Second, zinc sacrifices itself and corrodes preferentially, so even if steel is exposed, the zinc reacts first and shields the base metal. In hot-dip galvanizing, clean steel is immersed in molten zinc around 860°F 460°C, creating a metallurgical bond and often a visible crystalline spangle; once removed, the surface reacts to air to form zinc oxide and then zinc carbonate, the protective patina that improves durability over time National Material. In typical environments, galvanized steel can deliver long service life with minimal maintenance.

Galvanizing = a bonded zinc layer that protects steel by barrier action plus sacrificial action.

What Galvanized Steel Means in Automotive Programs

On automotive drawings, the word galvanized may refer to several related zinc coatings. To avoid confusion, specify the process. Wondering what is galvanized steel? It is steel with a bonded zinc layer produced by one of the methods below.

- Hot-dip galvanizing HDG Immersion in molten zinc forms a tough, bonded layer; you will notice spangle on many parts. Typical coating thickness is about 0.045 to 0.10 mm and HDG is well suited for outdoor or wet service Lined Pipe Systems.

- Pre-galvanizing Zinc applied early to coils and then recoiled, giving rapid, uniform coverage for sheet products.

- Electrogalvanizing Zinc deposited by electric current on steel at the first stage of production sometimes called zinc plating in some contexts.

- Galvannealed Hot-dip followed by in-line annealing to create a zinc-iron alloy. The surface is matte gray, weld friendly, and excellent for paint adhesion galvanising is often used informally for this whole family.

Common Misconceptions That Hurt Corrosion Performance

- Plated is not the same as galvanized. Zinc plating electrogalvanizing usually applies a much thinner layer and is intended for indoor or moderately corrosive environments. Using plated parts in road-salt or marine splash zones can lead to early red rust. Choose HDG or appropriate galvanized sheet for those exposures zinc and rust do not behave the same as steel and rust.

- Shiny does not equal better. Galvannealed looks dull but paints and welds well, which is why many BIW parts use it.

- Vague callouts cause misses. Do not just write zinc coat. State the method hot-dip, pre-galvanized sheet, electrogalvanized, or galvannealed and, where required, the target thickness or range. That clarity prevents premature failure and rework.

With the basics set, the next section explains how a zinc coating actually stops rust in service.

How zinc coating protects steel from corrosion

Ever wonder why a thin zinc layer keeps automotive steel alive in road salt and spray? Sounds complex? Here is the simple science engineers can use on day one.

How Zinc Coating Stops Rust on Steel

A galvanized coating is not just paint sitting on top. When clean steel meets molten zinc, iron and zinc react to form tough intermetallic layers in the coating stack gamma, delta, and zeta with a ductile outer eta layer of nearly pure zinc. Those inner layers are harder than the base steel, while the eta layer absorbs minor impact, so the system resists handling and abrasion. Just as important, the zinc coating on steel grows uniformly around edges and corners, avoiding thin spots where corrosion usually starts.

- Barrier protection blocks electrolytes from the steel.

- Galvanic or sacrificial action means zinc and rust compete and zinc always corrodes first, shielding exposed steel.

- Patina formation builds zinc oxide on metal that transforms to zinc hydroxide and then stable zinc carbonate, slowing further attack.

Durability scales with coating mass and environment; thicker zinc usually lasts longer, especially in harsher atmospheres American Galvanizers Association.

In service, that patina can reduce the corrosion rate to roughly a fraction of bare steel, and time to first maintenance rises with coating thickness. The intermetallic-plus-eta structure explains why zinc coated metal often outlasts coatings that rely only on film integrity.

Why Cut-Edge Protection Matters in Body-in-White

Scribe lines, pierced holes, and trimmed flanges expose steel. Here, sacrificial behavior is your safety net. Even if a scratch or cut exposes steel, surrounding zinc corrodes preferentially and protects the area until the nearby zinc is consumed. Guidance from hot-dip data shows that small exposed areas for example a spot up to about a quarter inch in diameter can be cathodically protected before red rust initiates, which is critical for BIW seams and hem flanges where edge exposure is inevitable American Galvanizers Association.

When Galvanized Surfaces Still Corrode

Seeing white or red staining does not always mean failure, but it does point to conditions to fix.

- Trapped moisture on fresh zinc can cause wet storage stain a bulky white product from the rusting of zinc before the carbonate patina forms. Dry and ventilate parts so the normal patina can develop.

- Aggressive waters and pH extremes can accelerate galvanized rusting. Zinc is most stable in water roughly between pH 5.5 and 12.5, while hot, fast flowing water can increase attack.

- Marine and deicing chlorides raise risk, but natural magnesium and calcium salts in sea air can help passivate zinc. Design to shed salt, and rinse when practical.

- If alloy layers outcrop at the surface, slight brown staining may appear from exposed iron. This is usually aesthetic, not structural.

All of these effects and the storage best practices above are well documented for zinc coating systems Nordic Galvanizers. The takeaway for automotive teams is simple. Control moisture, specify adequate thickness, and let the patina form. With the protection science clear, the next section compares galvanizing processes so you can pick the right one by part, risk, and finishing plan.

Hot dip galvanizing vs galvannealed vs electrogalvanized for auto parts

Choosing among the types of galvanizing can feel tricky. Which zinc coating fits your part, finish plan, and budget? Start by matching process capability to how the part will be formed, joined, and finished in your program. For an overview of the main types of galvanized steel and how they are produced, see this process summary Four Steels.

Choosing the Right Galvanizing Method by Use Case

| Process | What it is | Typical automotive part cues | Advantages | Watchouts | Paintability | Weldability |

|---|---|---|---|---|---|---|

| Batch hot-dip galvanizing HDG | Full immersion in molten zinc forms metallurgically bonded zinc-iron layers and an outer zinc layer | Brackets, frames, housings, complex shapes | Durable, abrasion-resistant coating; suits complex geometries | Bulk process may influence surface look and downstream finishing choices | Coating can be finished; surface prep steps should be planned | Welding after coating requires controls due to zinc fumes |

| Continuous galvanizing sheet pre-galvanized | Strip runs through a continuous galvanization line with controlled zinc coat; recoiled for stamping | Body panels, enclosures, stampings | Uniform coverage at high speed; wide control of coat levels | Sheet is coated early, so later fabrication must respect the zinc layer | Common in painted sheet systems with proper pretreatment | Spot welding is common; parameters depend on coating |

| Electrogalvanizing | Electrolytic deposition of zinc ions onto steel at the first production stage | Precision sheet parts made from coil | Controlled, uniform deposit; early-stage application | Process route and intended environment should be aligned | Compatible with paint after standard pretreat | Weldable with standard practices |

| Galvannealed GA | Hot-dip then in-line anneal to form a zinc-iron alloy coating | Stamped parts where surface robustness matters | Harder surface, resistant to chipping and scratches | Different surface appearance versus galvanized | Matte surface often favored for coatings | Improved weldability versus galvanized |

| Sherardizing | Heated in a sealed container with zinc below melting; forms zinc-iron alloy with an outer zinc layer | Small or intricate components | Uniform, corrosion-resistant coating; excellent base for paint | Batch furnace route; assess part size limits | Coating provides a good paint base | Weld after coating only with suitable controls |

All of the processes above fall within the broader types of galvanized steel, including hot dip galvanizing, hot dipped galvanizing, electrogalvanizing, galvannealing, and sherardizing Four Steels.

Paintability and Weldability Considerations

- Galvannealed GA forms a zinc-iron alloy. The coating is harder and more resistant to surface damage than galvanized, and it offers better weldability. It also gives off less fumes during welding, though proper ventilation and PPE are still required Xometry.

- Galvanized coatings can be welded, but expect zinc oxide fumes and potential issues like spatter and lack of fusion if procedures are not controlled. Many teams weld parts before they are coated when possible Xometry.

- Sherardizing yields a uniform surface that creates an excellent base for paint, which can simplify finishing steps Four Steels.

When to Avoid Over-Coating Thickness

- Pre-galvanized sheet produced on a continuous line typically carries a relatively thin layer, which helps with forming and dimensional control downstream Four Steels.

- Batch hot dip galvanized parts develop robust intermetallic layers that boost abrasion resistance. Plan tolerances and finishing steps so this bonded layer works with your assembly fit and appearance goals Four Steels.

- If your priority is weldability, galvannealed offers a wider process window at the spot gun than galvanized sheet, thanks to its zinc-iron alloy coating Xometry.

With your process matched to the part, the next step is understanding how hot-dip galvanized coatings are made and controlled on the line. In the next section, we walk through hot-dip galvanizing step by step to show the controls that drive quality.

Inside the hot dip galvanizing process steps and controls

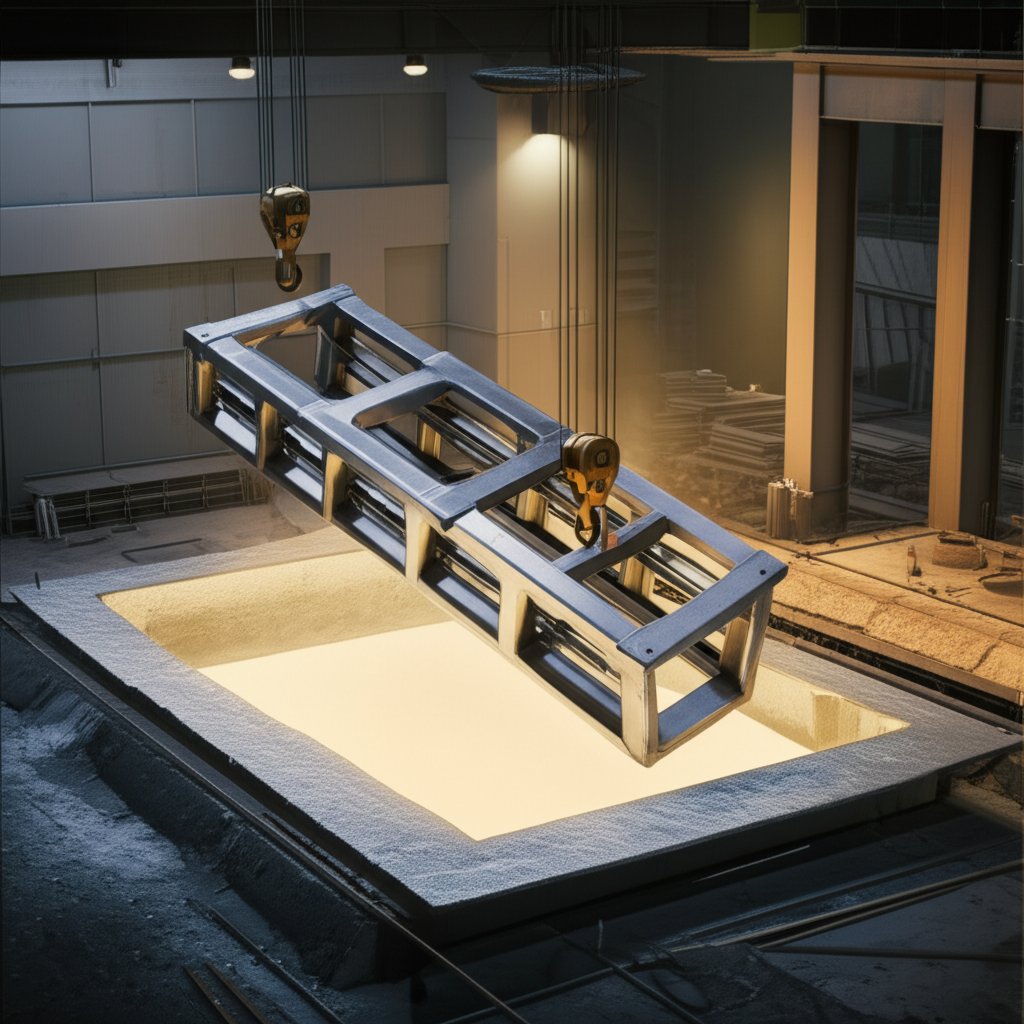

When you watch a rack of brackets sink into a zinc kettle, what actually controls the final thickness and quality? Here is the hot dip zinc coating process you will see at a modern galvanizing plant and the levers that keep coatings consistent for automotive parts.

Hot‑Dip Galvanizing Step by Step

- Degreasing and cleaning Remove oils, paint marks, and dirt with alkaline or mild acidic cleaners. Heavy contaminants or welding slag are mechanically cleaned by blasting. Checkpoint surfaces are visibly clean so zinc can react uniformly Stavian Metal.

- Pickling Remove mill scale and rust using sulfuric or hydrochloric acid, or abrasive blasting. Checkpoint a uniform metallic appearance indicates oxides are gone Stavian Metal.

- Fluxing Dip into a flux solution or pass through a flux chamber to strip any remaining oxides and protect the surface until immersion. Checkpoint a continuous, even flux film is present Stavian Metal.

- Immersion in molten zinc Lower parts into a bath that is at least 98% zinc and typically held around 450–460 °C. Iron and zinc form intermetallic layers with an outer eta zinc layer, creating a hot dip galvanized zinc coating. Checkpoint full coverage without trapped air, especially in tubular or pocketed areas; lower parts at an angle to vent properly Stavian Metal.

- Withdrawal, drain, and finishing Control withdrawal speed, drain, vibrate, or centrifuge to shed excess metal and improve uniformity. Checkpoint smooth flow-off with no heavy runs or bare spots Stavian Metal.

- Cooling or passivation Air cool or quench in a passivation solution to stabilize the surface. Checkpoint consistent appearance ready for downstream finishing Stavian Metal.

- Inspection Verify appearance and coating thickness to the specified standard. Checkpoint document coating measurements and note any rework needed Stavian Metal.

How Bath Temperature Affects Coating Thickness

The effect of bath temperature on hot dip galvanizing coating thickness is direct. Higher temperature accelerates the zinc–iron reaction and grows thicker intermetallics, while lowering the kettle temperature can help control build on reactive steels. Guidance notes that dropping below about 820 °F slows growth, providing time to pull the load before excessive thickness or brittleness develops. Immersion time also matters, with reactive steels showing near‑linear growth with time, so shorter dwell helps limit thickness American Galvanizers Association.

Temperature and dwell drive coating growth; set both to match steel reactivity and target thickness.

For dimensional control, remember that all surfaces gain thickness. Plan critical fits and hole sizes so the final hot dip galvanized steel assembles without grinding or rework, especially on hot dipped steel brackets and welded frames.

Steel Chemistry and Surface Prep Effects

Not all steels react the same. High‑silicon steels especially in the Sandelin range are more reactive. Two practical controls are often used. First, adjust bath chemistry nickel additions can reduce coating growth on reactive heats. Second, increase surface profile by blasting to encourage intermetallic crystals to grow into each other, which limits height and overall thickness. Both approaches are documented controls for managing coating growth, along with tighter control of immersion time American Galvanizers Association.

Design still matters. Provide clear vent and drain paths so cleaning solutions and zinc do not trap in crevices. Lower loads into the bath at an angle to let air escape, and avoid sharp pockets that slow drainage. These practices support uniform coatings and reduce cosmetic defects during hot dip galvanization and beyond Stavian Metal.

With process steps and controls defined, the next section shows how to translate them into clear standards and RFQ language that gets you the coating mass and documentation you need.

Specify G90 zinc coating and galvanizing standards in RFQs

Sounds complex? When you draft an RFQ, a few precise callouts can prevent confusion, delays, and rework. Start by tying the process to the correct standard and by stating how thickness is designated and verified.

How to Read and Specify G-Series Zinc Coatings

G90 is a coating mass designation within ASTM A653 for continuously galvanized sheet, not a standalone galvanizing spec. G90 equals 0.9 oz/ft^2 total both sides, which is about 0.76 mil per side roughly 18 µm. Other common designations include G60 and G185. Continuous sheet coatings are almost pure zinc, uniform, and ductile, with typical per‑side ranges from about 0.25 mil to just under 2 mils American Galvanizers Association. If you need batch hot‑dip on fabricated parts, reference ASTM A123 instead of a G‑series callout.

Standards That Matter in Automotive Procurement

- ASTM A653 for coil and sheet using G‑series designations like G90.

- ASTM A123 for after‑fabrication hot‑dip galvanized articles racks, frames, brackets.

- ISO 1461 is a common international alternative to A123; minimum thickness values and local thickness rules differ slightly, and ASTM requirements are typically higher on many categories. Both standards describe sampling and measurement, including making five or more readings per reference area at widely dispersed points ISO 1461 vs. ASTM A123, AGA.

- ASTM A153 often applies to centrifuged fasteners and small parts referenced within the ISO 1461 discussion.

To avoid ambiguity, include a plain, on‑drawing galvanized steel definition. For example, define galvanized steel as steel with a zinc coating per ASTM A653 continuous sheet or ASTM A123 batch hot‑dip. If your team asks to define galvanized steel or requests a galvanised steel definition, point directly to the governing standard.

Acceptance Criteria and Documentation Checklist

- Use this language in RFQs and drawings

- Steel sheet per ASTM A653, minimum G90 zinc coating, suitable for e‑coat; verify average coating mass per ASTM A653.

- Fabricated parts per ASTM A123; measure coating thickness and acceptance per the specified standard; record reference areas and readings.

- Fasteners per ASTM A153 as applicable.

- Appearance note state expected galvanized finish by process continuous sheet near‑pure zinc vs batch intermetallic layers coating types must be explicit.

- Inspection and records require thickness readings per the standard, sampling details, and a certificate or declaration of compliance.

Use the latest standard revisions; if your OEM has superseding specs, those govern.

With your specs locked, the next step is designing parts venting, draining, and joints so the coating meets the callout in production.

Design rules to get steel galvanized without defects

When you release a hollow bracket or weldment, will it vent, drain, and still fit after the zinc coat? Use these field‑proven rules to galvanise steel parts right the first time and avoid rework.

Vent and Drain Rules That Prevent Defects

Galvanising steel is a total‑immersion process, so cleaning solutions and molten zinc must flow freely. Place vent holes at the highest points and drain holes at the lowest points in the orientation used at the plant. Without proper venting, trapped liquids can flash to steam with pressures up to 3600 psi, risking rupture and bare spots. Crop gusset corners or add holes near corners, and provide through‑holes in end plates to prevent pools and runs American Galvanizers Association, Venting & Drainage. Typical practices include cropping stiffeners about 3/4 in, and using 1/2 in holes placed close to interior corners for drainage. For tubular work, keep ends open when possible and locate small external vents close to welds; always lower parts into the bath at an angle to help air escape.

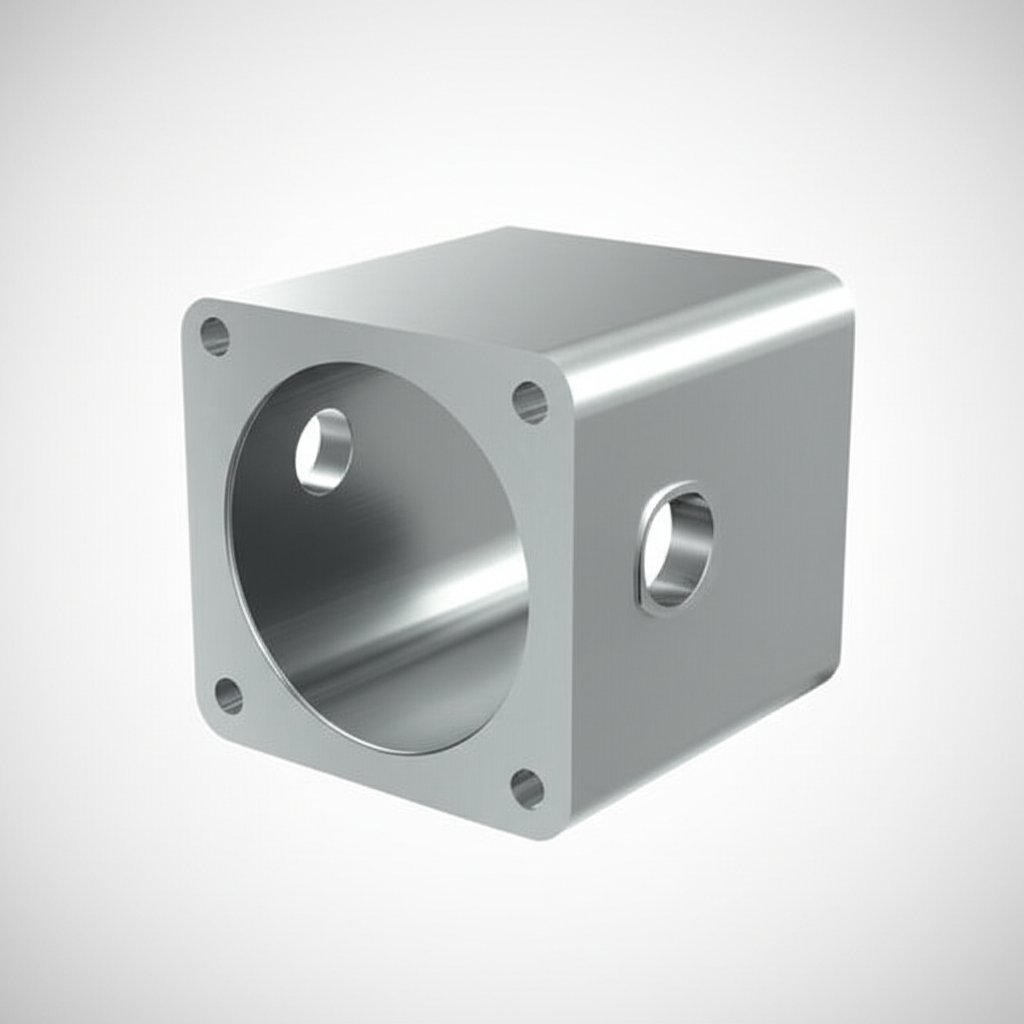

Managing Faying Surfaces and Fastener Interfaces

First, define faying surfaces clearly on your drawings. Faying surfaces are the mating faces of a joint that remain in contact after assembly. For slip‑critical joints on steel galvanized parts, unprepared hot‑dip galvanized faying surfaces are typically treated as Class A friction. Higher friction classes can be achieved by using approved zinc‑rich systems over properly prepared galvanized surfaces. Always use washers under turning pieces to protect the coating and to stabilize torque‑tension. Tap nuts after galvanizing, and allow added clearance or plan for reaming when bolts pass through coated holes; many teams specify holes with about 1/8 in total clearance over the bolt diameter in slip-critical conditions. These practices are consolidated in the AGA Design Guide, which also details joint prep for coated faying surfaces and fastener handling American Galvanizers Association, Design Guide.

Welds, Masking, and Dimensional Control

Clean welds thoroughly. Remove all slag and flux before coating, and avoid high‑silicon rods that can produce overly thick, rough coating over the weld area. Seal or vent overlapped joints. If gaps are tight, seal‑weld completely or provide vent holes; where bars meet at angles, a post‑weld gap of about 3/32 in helps zinc wet the joint. For moving parts, allow at least 1/16 in radial clearance so hinges and shafts move freely after coating. Use generous radii, avoid sharp notches, and plan weld sequencing to minimize residual stress and distortion at galvanizing temperatures. Flag heat‑sensitive items early because the process heats steel to roughly 830 °F. Finally, coordinate galvanised steel finishes up front if parts will be duplexed later.

- Confirm orientation, lift points, and kettle fit with your galvanizer; design vent at high points and drain at low points.

- Provide cropped corners or add 1/2 in drain holes near gusset and end‑plate corners; crop stiffeners about 3/4 in.

- For tubes, leave ends open when possible and place vents near welds; avoid blind cavities.

- Define faying surfaces, joint type, and friction class in notes; specify washers under turning parts.

- Tap nuts after coating; add hole clearance or specify reaming for bolt‑through locations.

- Seal or vent overlapped areas; avoid crevices that trap solutions.

- Remove all weld flux and soot; choose welding consumables compatible with galvanizing.

- Call out no‑galvanize zones and mask where necessary to maintain torque‑tension or electrical contact.

- Allow clearance for moving parts; verify tolerances where intermetallic growth could affect fit.

- Identify heat‑sensitive components and confirm any post‑galvanizing operations.

- Masking and labeling conventions

- Use acid‑resistant tapes, water‑based pastes, resin‑based high‑temperature paints, or high‑temperature greases to mask no‑coat areas.

- Do not use oil‑based markers for identification; they may create unintended bare spots. Use water‑soluble markers or detachable metal tags.

- Clearly mark plug locations if vent and drain holes must be closed after coating.

- Note finishing plan on the traveler to align pretreatment for duplex coatings and desired zinc for galvanizing appearance.

Pro tip Coordinate galvanizer and paint shop early when galvanizing precedes e‑coat to lock pretreatment and avoid adhesion issues.

Plan these details before release and your galvanising steel parts will coat cleanly, assemble smoothly, and be ready for the next step. Next, we will prep those surfaces for paint, e‑coat, and powder without compromising adhesion.

Painting and powder coating galvanized steel for automotive finishes

Ever had paint peel from a shiny new bracket? When you finish over zinc, adhesion lives or dies on prep. Let’s turn design-ready parts into durable paint or powder systems that survive the road.

Preparing Galvanized Surfaces for Paint or E‑Coat

Successful painting galvanized steel starts with identifying the surface condition and then cleaning and profiling it per ASTM D6386 guidance American Galvanizers Association.

- Communicate duplex intent early. Ask your galvanizer to avoid quench passivation when parts will be painted. If uncertain, test for passivation per ASTM B201.

- Identify the condition. Newly galvanized is smooth and needs profiling. Partially weathered has zinc oxide and zinc hydroxide that must be removed. Fully weathered is zinc carbonate and usually needs only mild cleaning.

- Flatten bumps, runs, or drips by light grinding or filing before cleaning. Do not cut into the underlying coating.

- Remove organics. Use a mild alkaline cleaner at 10 parts water to 1 part cleaner, keeping pressure below 1450 PSI. Or use a mild acidic solution at 25 parts water to 1 part acid, rinse within 2–3 minutes, or solvent wipe with clean cloths.

- Fresh water rinse and dry. Minimize time-to-paint. Aim to apply coating within 12 hours after drying.

- Profile the surface. Options include sweep blasting at 30–60 degrees with abrasives 200–500 micrometers and Mohs hardness ≤5, wash primer forming a film up to 13 microns, acrylic pretreatment, or careful power-tool grinding up to about 1 mil removal.

- Compatible surface treatments and primers by category

- Wash primers for chemical etch and adhesion build.

- Acrylic pretreatments applied by dip, flow, or spray.

- Sweep blasting per profile limits to avoid zinc damage.

- Zinc phosphate conversion for powder workflows.

- Consult your supplier for zinc coating paint systems to achieve the required zinc paint finish.

On zinc, pretreatment quality is as critical as coating thickness.

Powder Coating Over Zinc Without Adhesion Failures

Can you powder coat zinc coated parts? Yes, if you follow ASTM D7803 preparation steps to avoid outgassing and poor adhesion American Galvanizers Association.

- Classify the surface as newly galvanized or partially weathered. Then remove bumps, runs, and skimmings.

- Clean as above. Rinse and thoroughly dry. Heated drying is preferred.

- Profile by sweep blasting per SSPC SP16, zinc phosphate conversion, or power-tool grinding.

- Pre-bake before coating to drive off trapped water and air and prevent pinholes and blisters. Set the oven about 30 C above the powder cure temperature and bake until the part reaches oven temperature or at least one hour.

- Apply powder promptly after baking and cure per the powder manufacturer. This duplex approach yields assemblies that are galvanized and powder coated for long life.

Heat Treatment and Its Effect on Coating Performance

Thermal cycles matter. Avoid quench passivation when parts will be painted or powder coated because passivation can inhibit adhesion. Pre-baking controls outgassing and improves bond. Document bake and cure schedules in your process notes, including any reheat after assembly, so adhesion and appearance remain consistent across builds.

Looking for a zinc metal paint that sticks on coil or batch HDG? Coordinate with the paint manufacturer on compatibility and application conditions, especially for e‑coat pretreatment sequences noted above.

With finishing locked in, the next section lays out inspection steps and quick fixes for common coating defects before parts reach the line.

Inspection, quality control, and troubleshooting for galvanized zinc coating

Pressed for time on launch builds? Use this focused plan to verify a galvanized zinc coating before parts hit the line.

Inspection Steps and Measurement Techniques

- Visual on receipt Check for runs or drips, bare spots, black spots, weld-area staining, ash staining, mottled gray areas, dross pimples, blisters or pinholes, and white rust. Handle coated zinc carefully to avoid scratches.

- Confirm specification Verify process and coating type on the traveler or certs, and match to the drawing standard. Note whether parts are zinc coated by batch HDG or continuous sheet route.

- Thickness measurement Use magnetic or electronic gauges per ASTM E376. Follow best-practice tips: take at least five readings, space readings widely, stay 4 inches from edges, avoid corners and curved areas where possible, and reverify accuracy with shims above and below the expected range. See guidance on gauge types and procedures American Galvanizers Association.

- Dispute resolution For arbitration or R&D, section a sample and measure by optical microscopy. This is destructive and operator dependent, so reserve it for special cases per the same guidance above.

- Workmanship check Verify uniform drainage at holes and edges created by the galvanized steel process. Flag areas where touch-up or rework may be needed before paint or e-coat.

Common Coating Defects and How to Prevent Them

Here are frequent issues on zinc galvanized steel and practical fixes, based on recognized causes and treatments Steel Pro Group.

| Defect | Likely cause | Corrective action |

|---|---|---|

| Bare spots | Poor cleaning or fluxing | Improve degrease, pickling, and flux; re-galvanize |

| Black spots | Flux residues | Rinse thoroughly, control flux heat, maintain flux quality |

| Weld-area dark stain | Residues or reactive weld chemistry | Clean welds fully, select compatible consumables |

| Drips or spikes | Insufficient drainage or low bath temp | Orient for flow-off, adjust bath and withdrawal |

| Ash staining | Zinc oxide ash on bath surface | Skim bath, control oxygen and maintenance |

| Dull or mottled gray | Reactive steel or uneven cooling | Manage steel chemistry effects, steady cooling |

| Dross pimples | Zinc-iron particles in bath | Reduce agitation, manage dross, maintain bath |

| Blisters or pinholes | Trapped moisture or gases | Dry parts, improve preheat and cleaning |

| Peeling or flaking | Overly thick coating or poor adhesion | Limit thickness growth, review surface finish |

| White rust | Wet storage before patina forms | Dry, ventilate, separate parts, improve storage |

Acceptance Reporting That Keeps Launch on Track

- Lot identification heat, part number, date, supplier.

- Process and coating type HDG batch or sheet, standard referenced.

- Gauge model, calibration shim IDs, and method per ASTM E376.

- Measurement map locations, at least five readings per area, individual values, and averages.

- Visual findings with photos and disposition rework, accept, or reject.

- Rework instructions, retest data, and final signoff.

Align pass or fail with the specified standard and OEM targets, and only apply numeric thresholds sourced from the governing specification.

With inspection dialed in, the next section connects these controls to lifecycle decisions, repair options, and supplier selection for durable, zinc coated assemblies.

Lifecycle limitations and proven procurement choices

Is zinc plated the same as galvanized for the parts you are sourcing? When you weigh galvanized vs zinc plated for an outdoor bracket or a cabin fastener, start with service life, repairability, and lead time. The right choice protects performance and your launch schedule.

Sustainability and End-of-Life Considerations

Think lifecycle, not just unit price. For long-term outdoor protection, hot-dip galvanized steel generally outperforms zinc plating because HDG builds a thicker, metallurgically bonded coating that can deliver decades before first maintenance in many atmospheres, while zinc plating is best for short-to-medium indoor service and tight tolerances. Both rely on sacrificial zinc, but coating mass drives outdoor life M&W Alloys. Is zinc or galvanized better for outdoor use? For bolts and brackets exposed to weather or deicing salts, HDG is usually the safer pick. Small field repairs are practical with zinc-rich cold galvanizing paints often called zinc spray coating. Rework paths exist too, from re-plating in-shop to re-galvanizing when specs allow, which helps extend service life without full replacement.

Limitations and How to Mitigate Failure Modes

- Environment matters. High humidity, coastal salt, and industrial pollution accelerate zinc loss. Outdoors, HDG or stainless is preferred; indoors, plating can be sufficient (source as above).

- Tolerance control. Zinc plating deposits are thin 5 to 12 microns typical for indoor parts, so threads and tight fits remain in-spec. HDG thickness can alter fits; plan oversize nuts or post-process threads (source as above).

- Forming and joining. Plated coatings follow severe deformation better; HDG may crack on tight bends. Welding galvanized requires fume controls; cut edges often need touch-up with zinc-rich paints (source as above).

- Hydrogen embrittlement concerns on high strength steels. Zinc-rich primers historically raised questions, so critical parts should be validated. Current work uses ASTM F519 methods to evaluate susceptibility, and recent research suggests zinc primers may not induce embrittlement on certain high strength steels, with testing ongoing NSRP.

- Appearance vs durability. Plating wins on bright, uniform look. HDG wins on rugged outdoor durability. Post-treatments like chromate passivation and powder coatings can boost short-term performance, but they do not replace the thicker sacrificial reserve of HDG outdoors (source as above).

Decision Framework and RFQ Checklist

| Option | Durability | Edge protection | Paintability | Weldability | Typical automotive use |

|---|---|---|---|---|---|

| Hot-dip galvanizing | Thick, bonded layers; often decades outdoors | Strong sacrificial reserve at scratches and cut edges | Yes, with proper prep; duplex systems common | Manage zinc fumes; repair cut edges | Underbody brackets, housings, outdoor hardware |

| Zinc plating | Thin deposits; best indoors or protected areas | Limited reserve; faster red rust outdoors | Yes; passivations and lacquers available | Minimal impact on fit; good for threads | Interior fasteners, clips, precision hardware |

| Zinc-rich primers and repairs | Useful barrier plus sacrificial layer; for small repairs or systems | Good cut-edge touch-up capability | Topcoat with paint or powder | N A for welding; apply after fabrication | Field repairs, supplemental protection |

| Powder or paint over zinc | Combined protection; improves aesthetics | Relies on zinc beneath for sacrificial action | Yes; common post-treatment | Paint after welding; plan sequence | Visible brackets, covers, cosmetic parts |

- Define the environment and target life. Use HDG for outdoor or chloride exposure; use plating for indoor. Reference zinc plated vs galvanized expectations in your RFQ.

- Name the standard and class. For HDG, call out ASTM A123. For plating, call out ASTM B633 with Fe Zn thickness class and passivation type. Include acceptance testing.

- Specify finish and post-treatments. State chromate or lacquer needs, and whether a powder topcoat is required.

- Control fit and joints. For HDG, plan thread strategy oversize nuts, tapping after. For plating, confirm class thickness to protect fits.

- Plan fabrication sequence. Weld before coating when possible, or document fume controls and cut-edge repair with zinc-rich paint.

- Inspection and records. Require coating thickness measurements and certs. Align sampling and methods to the cited standard.

- Lead time and capacity. Plating shops can turn small runs quickly; HDG kettles often need scheduling. Ask for typical turnaround and peak capacity.

- Rework path. Confirm stripping and re-plating, or re-galvanizing options if parts miss spec.

Quick FAQ you can paste into sourcing notes. Zinc plated versus galvanized for outdoor fasteners. Choose HDG. Is zinc plated the same as galvanized. No, coating structure and thickness differ. For precision fits, zinc vs galvanized steel usually points to plating, not HDG (source as above).

If you need an end-to-end partner that can integrate forming, welding, zinc coating, and finishing under tight PPAP timelines, consider benchmarking IATF 16949 certified suppliers. One example is Shaoyi, which offers integrated metal processing and surface treatments with automotive quality systems in place. See their capabilities at shao-yi.com. Always compare multiple qualified sources for cost and capacity.

For outdoor durability, select HDG and specify the right standard; for tight fits or indoor use, use plating; document inspection and repair methods, and consult experts for complex assemblies.

Galvanizing and zinc coating FAQs

1. What is the process of galvanized zinc coating?

It is galvanizing. For hot dip galvanizing, steel is cleaned, pickled, fluxed, immersed in molten zinc, then cooled and inspected. This forms zinc‑iron layers with an outer zinc layer that protects by barrier action and sacrificial action. Process controls like bath temperature, dwell time, and steel chemistry determine coating quality and thickness in production.

2. What are the disadvantages of zinc coating?

Potential drawbacks come from poor fit between process and use. Thick coatings can affect tight tolerances, fresh zinc can develop white storage stain if kept wet, welds need fume controls, and appearance varies by method. In harsh, chloride‑rich environments, a thin zinc layer from plating may be inadequate. Good design for venting and draining, correct standards on drawings, and proper pretreatment before paint reduce these risks.

3. Which is better, stainless steel or galvanized steel?

It depends on the environment, load case, and budget. Stainless steel resists corrosion without a sacrificial layer and is often favored for severe marine or high‑temperature service. Galvanized steel provides cost‑effective sacrificial protection and strong cut‑edge defense, making it a go‑to for brackets, frames, and body‑in‑white applications when specified and finished correctly. Validate with the applicable standards and your corrosion targets.

4. What is the process of coating a metal with zinc to prevent corrosion called?

It is called galvanization or galvanizing. Common routes include hot dip galvanizing for fabricated parts, continuous galvanizing for sheet, electrogalvanizing, and galvannealing. All create a zinc layer on steel to slow rust and protect exposed cut edges.

5. Is zinc plated the same as galvanized?

No. Zinc plating is an electrolytic process that typically leaves a thin deposit suited to indoor or tight‑tolerance parts. Galvanized usually refers to hot dip or continuous coatings that are thicker and metallurgically bonded, better for outdoor or chloride exposure. Choose by environment and edge protection needs, specify the correct standard, and if in doubt, consult an IATF 16949 certified partner such as Shaoyi for process selection aligned with forming, welding, and finishing.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —