What Is Galvanized Coating? Automotive Metal Protection Against Rust And Corrosion

Galvanized coating fundamentals for automotive

Ever wonder why modern vehicles survive winters, road salt, and rain without turning into rust buckets? The short answer is zinc. In this primer on What Is Galvanized Coating? Automotive Metal Protection Against Rust and Corrosion, you will see how a thin zinc layer on steel delivers durable, paintable protection and sets up the deeper topics that follow.

Definition and purpose of galvanized coating

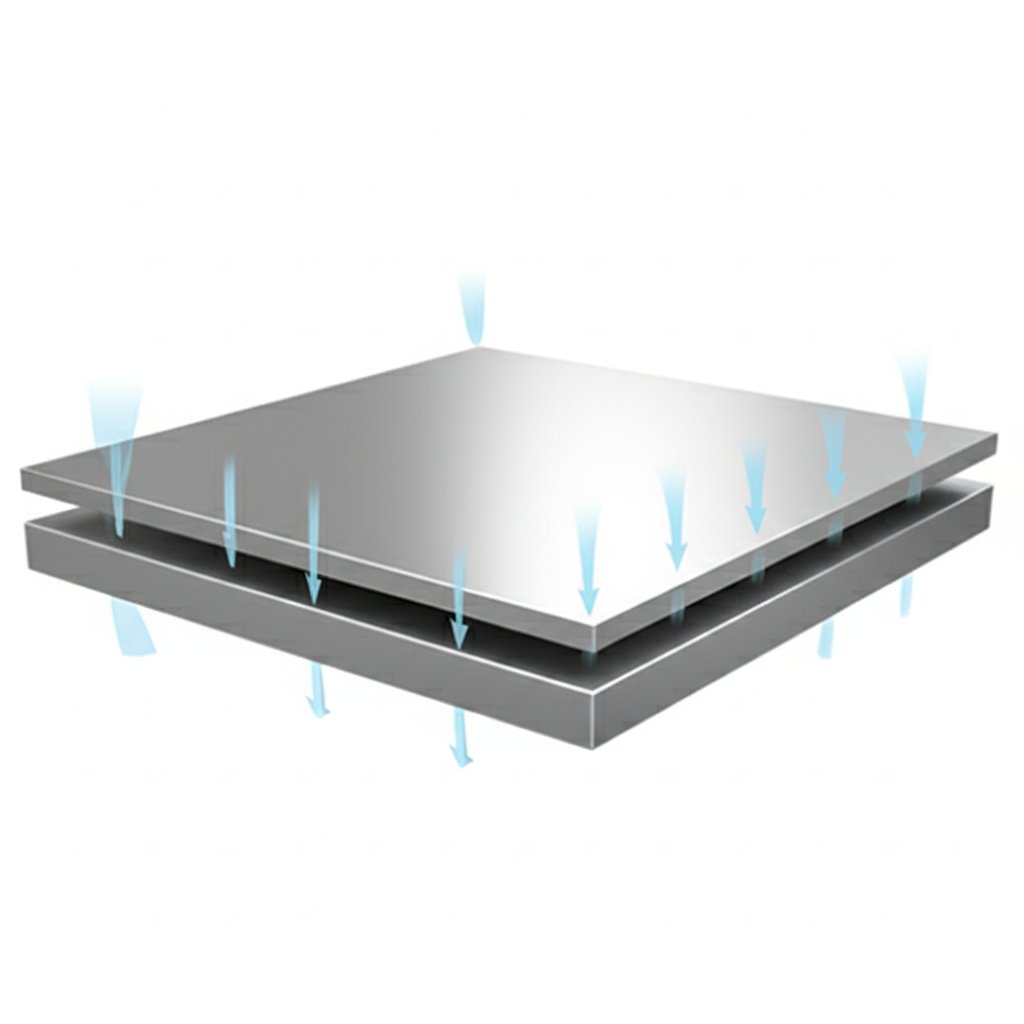

Galvanizing means coating steel with zinc so it shields the base metal in two ways, as a barrier and as a sacrificial anode. That dual action is the core of corrosion control galvanizing provides barrier and cathodic protection. In automotive, you will commonly see hot dip galvanizing and electrogalvanizing. If you are asking what is hot dip galvanizing, think immersion of clean steel in molten zinc that creates a metallurgical zinc iron bond on the surface, used for many structural and underbody components, while electrogalvanizing is preferred for exposed body panels hot dip galvanizing forms a metallurgical zinc iron bond. Electrogalvanizing uses electrical current to deposit a thinner, very uniform zinc layer.

Zinc protects steel twice, with a barrier film and sacrificial anode action.

| Protection mode | How it works | Where it helps most | Notes |

|---|---|---|---|

| Barrier film | Zinc layer separates steel from water, oxygen, and salts | Clean, intact coatings under paint and sealers | Acts like a physical shield against the environment |

| Sacrificial action | Zinc gives up electrons and corrodes first to protect steel | At scratches, cut edges, and chips | Why hot dip galvanized parts can still resist rust after minor damage |

Where galvanized metal fits in automotive

You will notice galvanized metal across the vehicle, often as galvanised steel sheet for stampings and closures. Typical uses include:

- Body-in-white panels and skins

- Rails, rockers, and crossmembers

- Brackets, hangers, and mounts

- Chassis shields and reinforcement parts

- Fasteners and clips that match the coating system

Automakers select electrogalvanized and hot dip galvanized sheet for corrosion resistance, formability, and paintability. You will also encounter hot dipped galvanized options where thicker coatings and rugged service are desired.

Galvanized coating versus paint-only protection

Paint alone is a barrier. If it is breached, steel can rust at the scratch. Zinc adds a second line of defense. Its sacrificial behavior continues to protect exposed steel, which is why systems based on hot dip galvanizing are valued for durability even after minor damage. That said, galvanized is corrosion resistant, not immortal. Coating choice, thickness, and environment still matter. We will dig into metallurgy, process controls, inspection, and repair in the next sections.

How zinc prevents rust and when galvanized can fail

Sounds simple, right? If zinc coats the steel, does galvanized steel rust? The real answer is about how zinc blocks the environment and also sacrifices itself at scratches so the steel stays protected.

How zinc stops corrosion on steel

Think of zinc as a shield and a bodyguard. First, it is a barrier that keeps water, oxygen, and salts away from the steel. Second, zinc is more willing to corrode than iron, so at a cut edge or scratch it gives up electrons and protects the base metal. Over time, a thin, dull film forms on the surface called a patina. This film slows future attack and keeps protection going.

Patina formation and why white rust appears

In normal air, fresh zinc reacts with moisture and carbon dioxide. It first forms zinc hydroxide, which converts to zinc carbonate, the stable patina that reduces corrosion rate. When galvanized parts stay wet with little airflow, the surface can keep forming zinc hydroxide instead of maturing into that stable film. You will notice a white, powdery stain or even dark spots called wet storage stain or white rust. Provide airflow, let parts dry, and remove heavy deposits with gentle cleaning as needed. In salty locations, rinsing off chloride deposits helps because salt makes moisture more conductive and speeds attack GAA guidance on patina, white rust, storage, and cleaning.

Does galvanized steel rust and under what conditions

So, does galvanized steel corrode? Under sustained aggressive exposure, yes. Will galvanized steel rust? It can, especially when zinc is thin, damaged, or starved of air.

- Coastal exposure with frequent, chloride-rich winds can drive rust on galvanized metal sooner. On some projects within about a mile of the ocean, surfaces facing regular salty winds showed rust in 5–7 years, while sheltered faces retained protection 15–25 years longer. A duplex paint-over-galvanizing system can extend life even more via synergy AGA coastal performance and duplex system guidance.

- Persistent wet storage or water traps keep the surface from forming its protective patina, leading to white rust and faster zinc loss (see GAA reference above).

- Abrasion, chips, and cut edges consume local zinc. Thicker coatings offer enhanced protection, while scratches that reach bare steel need attention Woodsmith overview of rust factors and care.

- Crevices and tight overlaps can trap salts and moisture. Fastener interfaces and panel seams are common risk points.

Let the patina form, keep surfaces clean and dry, and zinc will do its job.

- Rinse with potable water to remove salt and grime, especially after marine exposure (see AGA reference above).

- Gently clean with mild detergent and a soft brush. Avoid abrasive pads that can damage zinc (see Woodsmith reference above).

- Dry thoroughly and restore airflow to damp, stacked, or wrapped parts.

- Inspect. If rust is visible, treat it promptly with a rust converter, then apply a zinc-rich primer and compatible topcoat (see Woodsmith reference above).

Bottom line, does galvanized rust or can galvanized rust? Yes, in the wrong conditions. Manage moisture, salts, and damage, and you will maximize service life. Next, we will unpack how process choice and metallurgy—hot-dip, electrogalvanized, and galvannealed—shape formability, welding, and paint performance.

HDG galvanized, electrogalvanized, and GA

Why do two zinc-coated panels behave so differently in a press, at the spot welder, or under paint? The answer lives in how the coating is made and the layers it creates on steel.

Hot-dip galvanizing process and coatings

Automotive sheet is most often coated on continuous lines that clean, anneal, immerse in molten zinc, then condition the surface. This hot dip galvanizing process produces either GI or, with a short post-heat, GA. For paint-critical auto panels, lines tightly control bath chemistry, temperature, wiping, and cooling to deliver consistent coating weight and appearance GalvInfo Center, Galvanizing 2022.

Sounds complex? Here is the hot dip galvanizing procedure in a few steps you can visualize.

- Clean and activate the strip to remove oils and oxides.

- Anneal in a controlled, reducing atmosphere to set properties and a reactive surface.

- Immerse in the molten zinc bath.

- Exit the bath and use gas knives to wipe excess and set thickness.

- Optional galvannealing: briefly reheat so zinc and iron interdiffuse for a zinc–iron alloy surface.

- Cool, temper pass, level, and oil for a stable, uniform finish.

In short, the hot dip zinc coating process is about surface cleanliness, controlled reactions in the bath, and precise thickness control.

Electrogalvanizing and galvannealed differences

Electrogalvanizing deposits a thin, very uniform layer of pure zinc by electricity. It excels when ultra-smooth surface and deep drawability are priorities. Galvanized sheet from HDG can offer thicker zinc for cut-edge protection, while galvannealed (GA) adds a zinc–iron alloy surface that is matte, harder, and highly paint friendly per automotive practice (see GalvInfo reference above). For joining, galvannealed generally welds more consistently than galvanized because the iron-rich surface reduces spatter and fumes compared to pure zinc coatings Xometry, Galvanneal vs Galvanized.

Galvannealed often wins for paint adhesion and spot weld consistency on exposed panels.

Zinc–iron intermetallic layers and spangle morphology

Whether GI or GA, performance flows from the coating microstructure. A hot dip galvanized zinc coating typically has an outer eta layer of ductile zinc over harder zinc–iron intermetallics. Galvannealed drives more iron into the coating, leaving only intermetallic layers at the surface. These inner layers are harder than steel and resist abrasion, while the eta layer in GI adds ductility for impact resistance American Galvanizers Association, HDG Coating.

| Layer | Found in | Typical properties and role |

|---|---|---|

| Eta (pure Zn) | GI | Soft, ductile; impact tolerance and barrier film |

| Zeta (Fe–Zn) | GI and GA | Hard; abrasion resistance |

| Delta (Fe–Zn) | GI and GA | Hard; strong bond layer |

| Gamma (Fe–Zn) | GI and GA | Very hard; anchors coating to steel |

Process control shapes thickness and look. Factors include steel chemistry, immersion time, withdrawal rate, and the effect of bath temperature on hot dip galvanizing coating thickness. Higher bath temperatures and longer times generally grow heavier alloy layers, while withdrawal rate influences the outer zinc thickness and appearance. Spangle, the visible crystal pattern, is a function of bath chemistry and cooling; modern automotive lines often suppress spangle for smooth paint, and its presence or absence does not change corrosion performance AGA, coating factors and appearance.

Putting it together, HDG galvanized (hdg galvanized) sheet maximizes sacrificial zinc, GA boosts paintability and weld consistency, and EG optimizes surface uniformity. Next we will connect these coatings to the right fasteners and isolation practices to prevent galvanic attack at joints.

Compatibility and fastener choices to prevent galvanic attack

When you bolt a zinc coated bracket to stainless or aluminum and the first storm hits, where does the rust show up first? In mixed-metal joints, the zinc layer can become the anode and dissolve faster whenever an anode, a cathode, an electrical path, and an electrolyte are all present. Break any one of those and you stop the cell American Galvanizers Association, dissimilar metals and prevention.

Joining galvanized to stainless and aluminum

Here is the practical takeaway. The farther the electrical potential difference and the wetter the joint, the higher the chance of accelerated corrosion on galvanized steel. Keep the exposed zinc area large relative to the more noble metal, and avoid wet, tight gaps that trap salts. AGA guidance also warns that a small anode coupled to a large cathode corrodes quickly, recommending an anode-to-cathode area ratio of at least 10:1 to minimize attack (see AGA reference above). At zinc and steel interfaces you will usually be fine, but add stainless in the stack and you will notice zinc and corrosion accelerating where water lingers. For aluminum housings, stainless or brass bushings can drive localized attack at edges; coating the aluminum, adding isolation films, and using RTV sealers have been shown to prevent crevice corrosion at sealing interfaces Southwest Research Institute, aluminum enclosure crevice corrosion.

Fastener selection that minimizes galvanic risk

Choose fasteners with surfaces close in potential to the galvanized part. Use zinc coated carbon steel fasteners or similar, not bare stainless or copper in direct contact, to reduce galvanized steel corrosion. Avoid using a small galvanized fastener to join a large stainless, copper, or painted steel assembly, because the fastener becomes the tiny anode and can disappear fast (see AGA reference above). For high strength bolts where electroplating risks hydrogen embrittlement, zinc flake coatings provide cathodic protection without introducing hydrogen during processing, making them a common automotive choice for classes such as 10.9 and above Wikipedia, zinc flake coatings overview. Where steel and zinc must touch directly, add dielectric washers or sleeves to break the current path and seal the joint so water cannot bridge it.

Sealants, coatings, and electrical isolation practices

Think layers of defense for mixed-metal joints. Paint both metals at the interface and maintain the coating. Add isolators so the metals do not touch, and block the electrolyte so the cell cannot run (see AGA reference above).

- Do use isolators such as neoprene, nylon, Mylar, Teflon, or GRE gaskets.

- Do seal overlaps with RTV or compatible liquid sealers to prevent crevice traps, especially on aluminum interfaces (see SwRI reference above).

- Do provide drainage and avoid water traps at flanges and hems.

- Do paint both sides of the joint, and keep coatings repaired.

- Do size joints so the zinc area is large relative to the other metal.

- Do not assume there is such a thing as rust proof galvanized steel in a wet salt environment.

- Do not rely on a small galvanized fastener to carry a large stainless or copper assembly.

- Do not default to conductive elastomers at seals on aluminum if corrosion is a concern (see SwRI reference above).

Trend-only guide under wet conditions. Actual severity depends on electrolyte, area ratio, and coating condition (see AGA reference above).

| Metal pair | Risk trend in wet exposure | Key drivers | Preferred mitigations |

|---|---|---|---|

| Galvanized to stainless | Moderate to high when stainless area is large | Potential difference, small zinc area, trapped moisture | Increase zinc area, isolate with washers/films, paint both metals |

| Galvanized to aluminum | Low in most atmospheric conditions | Crevices at seals, electrolyte retention | Anodize aluminum, add isolation film and RTV, ensure drainage |

| Galvanized to copper | High if wet and copper area is large | Large potential difference, conductive salts | Fully isolate, paint both, avoid small galvanized fasteners |

Isolate the metals, seal out the water, or match potentials to stop galvanic attack.

Wondering if you should galvanize stainless steel to solve this? In practice, it is usually better to isolate, seal, and select compatible fasteners than to change base materials. Apply these rules now, and in the next section we will tune forming, welding, and paint pretreatment so the coating survives production.

Manufacturing and finishing best practices for coated steel

When you stamp, weld, and paint hot dipped galvanized steel, how do you keep the coating working for you instead of against you? Use the steps below to carry a clean, consistent galvanized metal finish from the press room to the paint booth.

Forming and stamping practices on coated sheet

Coated AHSS develops high contact pressures at the tool interface. Simulations and lab tests on galvanized AHSS have shown about 200 MPa on side walls and up to 400 MPa at sharp corners, where galling and lubricant failure spike. Selecting the right lubricant, die material, and tool coating is critical in these zones The Fabricator study on galling and lubrication in galvanized AHSS.

- Choose lubricants validated for GI or GA under severe pressures, and keep die surfaces polished. Evaluate PVD-coated dies where galling risk is high.

- Increase die radii at tight bends, tune clearances, and manage blankholder force to reduce local pressure at corners.

- Minimize dry sliding. Re-oil consistently and wipe residues before welding or pretreatment.

- Protect surfaces in handling. Use nonmetallic contact points and interleaf to avoid transit abrasion on the galvanized steel finish.

Spot welding and repair welding considerations

Zinc changes the heat balance at the electrode. Most shops successfully weld galvanized with RWMA Class 1 or 2 electrodes, while Class 20 helps when schedules run hotter. There is no single best choice; standardize if you can and select based on the actual heat generated by your schedule HowToResistanceWeld on electrode materials for galvanized.

- Expect more frequent tip dressing. Use appropriate current, squeeze, and hold to manage expulsion and nugget growth.

- Ventilate well. The coating softens and volatilizes before the steel, so control heat input with awareness of the galvanized steel melting temperature of the zinc layer and the melting point of galvanised steel discussion for the substrate.

- After weld cleanup, re-protect bare spots. Teams often ask does zinc plated rust. If a protective zinc layer is burned off, it can, so touch up promptly with compatible zinc-rich products.

Pretreatment and paint system compatibility

Paint adhesion lives or dies on surface prep. A proven sequence is clean, activate, conversion coat, prime, then topcoat. Iron phosphate is a common prepaint treatment, zinc phosphate is often chosen for higher corrosion resistance, and zirconium-based pretreatments offer a phosphate-free alternative that many lines use today. Phosphate-coated panels that are painted or powder coated may improve salt spray resistance roughly tenfold versus no phosphate under ASTM testing Finishing And Coating overview of phosphate pretreatments.

- Store and handle dry. Unwrap coils and blanks to avoid wet stack staining on hot dipped parts.

- Form and trim with the right lube and smooth dies. Remove excess oil before welding.

- Hem and flange with generous radii to limit coating cracking.

- Spot weld with selected electrodes. Dress tips routinely and clean spatter.

- Clean thoroughly, rinse well, and activate.

- Apply conversion coating appropriate to your line and substrate.

- Prime, topcoat, and cure to achieve the specified galvanized metal finish.

- Powdering of zinc at tight bends. Mitigation: increase bend radii, improve lubrication, and reduce re-strikes.

- Microcracks along hinge lines. Mitigation: add reliefs, deburr edges, and soften forming paths.

- Transit abrasion and rub marks. Mitigation: use interleaf, soft tooling covers, and clean conveyors.

- Prepaint white film. Mitigation: dry parts, ensure airflow, and clean before conversion coating.

Clean metal, controlled pretreatment, and a proper cure build durable paint over galvanized.

With processes dialed in, the next step is to lock down inspection and acceptance so every coated part meets spec and is ready for final paint.

Inspection and acceptance for hot dipped zinc coating

Not sure what to check first when galvanized coils or stampings arrive? Use this practical plan to verify the coating you ordered, measure it correctly, and document a pass or hold so paint can proceed with confidence.

Visual inspection and typical surface conditions

Start simple. Confirm the product tag shows the ASTM spec, coating designation, grade, size, and unit identification. These are required identifiers on metallic-coated sheet shipped from the mill ASTM A924 general requirements. Then look at the surface.

- Appearance class. If a paint-critical surface is required, it should be ordered as extra smooth. Regular or minimized spangle is allowed and not restricted by texture in the standard.

- Workmanship. Coils and blanks should present a workmanlike appearance for the grade and designation. Some coil-related imperfections can occur on portions of a coil.

- Oiling and passivation. Mills may supply light oil or a passivation film to reduce storage stain. If you see white, powdery storage stain, parts likely stayed wet in low airflow. Adjust storage and drying practices per your line.

Remember, galvanized metal is coated with zinc or a zinc–iron alloy under the hot-dip family, and finish expectations must be set in the order to align with galvanised steel finishes (see A924 reference above).

Coating thickness measurement and acceptance

Acceptance of hot dipped zinc coating is based on coating weight or mass per the product standard, not just measured thickness. A924 points to two referee methods and the sampling pattern:

- Weigh–strip–weigh per ASTM A90 for destructive mass measurement, using triple-spot sampling edge–center–edge on a sample piece, with edge samples set back from the slit edge.

- X-ray fluorescence per ASTM A754 for non-destructive mass measurement off-line or on-line, with defined traverses and reporting of the lightest single-spot and the triple-spot average.

Magnetic or eddy-current gauges per ASTM E376 can estimate coating thickness, but rejection decisions are governed by the mass tests above (see A924 reference above). For context, common designations convert as follows: G90 equals Z275 and adds about 0.0016 in total thickness to the sheet, roughly 0.0008 in per side when split evenly Coating weight and conversion guidance. Use these conversions to sanity-check gauge readings during the galvanizing steel process, then record acceptance by the specified coating mass.

Adhesion, continuity, and documentation

Need a quick functional check? Use the coating bend test referenced in the product spec to screen for brittle or poorly adhered layers (see A924 reference above). For painted parts, verify Dry Film Thickness of the paint with calibrated gauges and apply a statistical acceptance rule such as 90:10 to keep most readings at or above the nominal DFT while allowing normal variation Elcometer DFT and best practices. Close the loop with documentation: certificate of compliance or test report showing spec, coating designation, and unit identification are common deliverables per A924.

Measure at the same edge–center–edge locations every time and log gauge calibration before use.

- Receiving. Verify tags, spec, coating designation, and packaging. Note oiling or passivation.

- Visual. Check for storage stain, handling damage, and surface class suitable for a galvanized finish.

- Sampling. Prepare coupons and perform triple-spot weigh–strip–weigh or XRF per the galvanising procedure.

- Correlation. Use magnetic or eddy-current gauges for quick checks, correlated to the referee method.

- Adhesion. Run the coating bend test as required by your product spec.

- Pre-paint. Clean, then verify paint DFT with calibrated gauges.

- Records. File results with coil numbers, locations measured, methods, and calibration logs.

| Defect or condition | Likely cause | Corrective action |

|---|---|---|

| White storage stain | Wet stacking, low airflow during storage or transit | Dry and separate parts, improve ventilation, consider passivation or oiling practices noted in standards |

| Coil breaks or strain lines | Coiling to small ID or handling stresses | Review coil ID compatibility and handling; temper pass per mill practice |

| Unexpected spangle pattern | Bath chemistry and cooling practice | Confirm ordered surface class; spangle is not a defect unless restricted by order |

| Low coating mass at edges | Process variability across strip width | Increase sampling frequency edge–center–edge and work with supplier on line settings |

With this checklist you can accept or hold parts without guesswork and keep galvanised steel finishes consistent. Next we will turn these checks into fill-in-the-blank specifications and a selection guide you can drop into RFQs.

Specifications templates and selection for real-world environments

Writing an RFQ and unsure what to call out for zinc coatings? Use this fill-in template and selection guide to move from guesswork to clear, testable requirements.

Specification template for galvanized automotive parts

- Product standard and grade. Specify the governing standard and grade. Examples include ASTM A653 for hot-dip galvanized sheet, EN 10346 DX-series for cold-forming, JIS SECC for electrogalvanized, and GA grades such as GA340 or GA590 for galvannealed. See typical types, grades, and use cases including G90, G235, ZM310, and ZM430 in the industry guide SteelPRO Group galvanized types and grades.

- Coating type and designation. Choose HDG GI, EG, GA, or ZAM. Coating mass by designation such as G90 or G235 for hot-dip galvanized, and ZM310 or ZM430 for Zn–Al–Mg.

- Formability and strength. Call the base steel target, for example DX52D+Z for shaping, or GA590 for higher strength panels per EN or GA naming conventions in the cited guide.

- Surface quality and paint intent. State paint-critical finish requirements. Note if galvannealed is preferred for paint adhesion and welding.

- Acceptance methods. Acceptance by coating mass per the invoked product standard. Align in-plant measurements with the same standard.

- Welding and joining notes. Indicate spot-weld or adhesive-bonding compatibility expectations for GI vs GA.

- Packaging and handling. Minimize time of wetness, allow airflow, and avoid wet stacking because atmospheric corrosivity depends on moisture, salinity, and pollutants per ISO 9223 ISO 9223 corrosivity categories and drivers.

- Traceability. Require coil or unit ID, grade, coating designation, and batch references on documents.

- Post-process finish. State pretreatment and paint system family intended for the coated substrate.

Match environment class, coating mass, and paint system before you pick a grade.

Environment-based selection guide

Start by classifying the atmosphere. ISO 9223 explains that corrosivity rises with time of wetness, airborne salinity, and sulfur dioxide. Then pick the coating family and mass that fits the exposure, using proven use-cases for HDG, EG, GA, and ZAM from the industry guide above.

| Exposure scenario | Corrosivity drivers | Recommended zinc solution | Notes |

|---|---|---|---|

| Interior panels, appliance-like finishes | Low wetness, aesthetics first | EG such as SECC | Very smooth surface for paint or visible areas |

| General exterior, suburban road use | Intermittent wetting, deicing salts | Hot-dip galvanized GI such as G90, or GA340 | Balance formability with sacrificial protection |

| Coastal or industrial spray zones | Airborne chlorides, pollutants | G235 HDG or ZAM like ZM310; use ZM430 for more extreme | Heavier coating mass and Zn–Al–Mg boost durability per guide |

| Frames, crossmembers, brackets | Road splash, grit | Galvanised structural steel grades such as S-series with +Z, or GA590 | Combine with robust paint where needed |

As you weigh hot dip vs electro galvanizing, remember that electro galvanized vs hot dip is often a choice between ultra-smooth uniformity and higher cut-edge protection. Hot-dip galvanised steel is also widely available for automotive sheets and stampings.

Lifecycle and procurement decision factors

- Corrosion strategy. Is galvanized steel rust proof? No. It is resistant, and the right coating mass and paint stack should reflect the environment named above.

- Manufacturability. GA often aids welding and paint adhesion, EG favors top-tier appearance, and HDG offers thicker sacrificial zinc for edges and chips.

- Cost and supply. Specify only what you need. In hot dip galvanizing for automotive market analyses, HDG remains a dominant choice for many body and chassis applications Automotive zinc galvanized steel market overview.

- Risk control. Call out packaging to limit time of wetness, and define acceptance by the invoked standard to avoid disputes.

| Option | Corrosion resistance | Edge protection | Paintability | Weldability | Typical use |

|---|---|---|---|---|---|

| Paint-only steel | Good if intact | Low | Good | Good | Interior parts |

| EG | Good | Moderate | Best | Good | Exposed panels |

| HDG GI | Better | Better | Good | Good | Underbody, general exterior |

| GA | Better | Better | Best | Best | Painted, spot-welded panels |

| ZAM | Best | Best | Good | Good | Harsh coastal or industrial zones |

Lock these choices into your RFQ, then be ready to validate them in production. Next, we will tackle real-world failure modes and give step-by-step repair procedures you can use in the shop and in the field.

Failure modes and repair procedures for automotive panels

See a powdery white film or brown streaks at a seam and wonder what happened? Do galvanized steel rust The short answer is that damage, moisture traps, and storage conditions decide whether you will see galvanized rust. Will galvanized metal rust in service It can, but you can stop it and fix it before galvanized steel rust spreads.

Common failure modes in service

- White storage stain. Newly galvanized parts that stay wet without airflow develop white or gray zinc hydroxide deposits instead of a stable patina. Drying and ventilation are the first fixes, because the protective patina needs air cycles to form American Galvanizers Association, wet storage stain and patina.

- Cut-edge and seam undercutting. At cut edges and overlaps, water held by capillary action creates a crevice where corrosion progresses inward. Early cleaning, sealing, and coating prevent escalation Bradley-Mason, cut edge corrosion overview.

- Handling abrasion. Small voids or scratches from handling become initiation sites. Address them promptly to prevent galvanized rusting from creeping under paint.

Shop and field repair sequences

- Stop active attack. Separate parts, promote airflow, and dry thoroughly. This is step one for white storage stain per AGA guidance.

- Assess severity. Light or medium white stain can often weather out once exposed to free air. Heavy or extreme deposits require removal and repair per standards in the AGA document above.

- Clean. Use a stiff nylon brush and a suitable cleaning solution, then rinse with tap water and dry. Measure remaining zinc thickness to verify protection per AGA practice in the same source.

- Repair damaged areas per ASTM A780 methods. Options include zinc-rich paint, zinc spray metallizing, or zinc-based solder. For zinc-rich paint, the dry film contains 65%–69% or >92% metallic zinc by weight, and the repair coating should be 50% thicker than the surrounding zinc but not over 4.0 mil. Zinc-based solders require about 600 F 315 C preheat, with final repair thicknesses controlled by the spec. Touch-up materials must achieve at least 2.0 mil in one application AGA touch-up and repair, ASTM A780 methods.

- Seal edges and seams. After cleaning and repair, seal laps to block water traps that drive rusting of galvanized steel in crevices (see Bradley-Mason reference).

- Prime and topcoat. Use coatings compatible with the existing paint stack. Avoid passivation films before painting because they can interfere with adhesion (see AGA wet storage stain reference).

Welding and touch-up considerations

After welding, remove residues at the heat-affected zone and restore protection using ASTM A780 repair methods. Will galvanized rust if the HAZ is left bare Yes, so recoat promptly where zinc was burned away.

Zinc-rich paint

- Pros: Cold-applied, reaches complex shapes; defined zinc content and thickness targets per A780.

- Cons: Requires clean, dry steel; appearance may not perfectly match surrounding zinc.

Zinc spray metallizing

- Pros: Builds robust zinc layers to at least the product requirement; good for larger areas.

- Cons: Requires specialized equipment and skilled application.

Zinc-based solder

- Pros: Blends well with surrounding zinc; durable metallurgical repair.

- Cons: Needs ~600 F 315 C preheat; heat can affect adjacent finishes.

Dry fast, seal seams, and protect edges to stop undercutting.

Bottom line, will galvanized rust without airflow or at damaged edges It can, but with the steps above you can control where galvanized steel rust tends to start and extend service life. Next, we will show how to choose an integrated partner who aligns storage, fabrication, and coating controls from prototype to SOP.

Choosing an integrated partner for galvanized automotive parts

When timelines tighten and tolerances shrink, who keeps your zinc coating consistent from coil to finished assembly? The right partner. Here is how to evaluate one, step by step, so your galvanized process supports quality, cost, and launch dates.

What to look for in a galvanizing-capable metal partner

- Quality systems that fit automotive. Verify ISO 9001 and IATF 16949, supported by robust inspection like CMM and vision systems, plus SPC and APQP style planning. These are core selection criteria for stamping and assemblies in demanding sectors PrimeCustomParts selection framework.

- Technical breadth. Progressive and transfer stamping, in-house tooling, welding, and assembly. Ability to scale from prototypes to millions of parts.

- Engineering collaboration. DFM support, forming simulation, and rapid prototyping help de-risk early builds.

- Technology adoption. Modern presses, automation, in-die sensing, and data-driven controls improve repeatability.

- Surface treatment know-how. Experience coordinating HDG, EG, and GA, including pretreatment and paint readiness.

- Sustainability and reliability. Environmental practices and a track record of on-time delivery signal long-term stability.

Process integration and quality assurance

Imagine one accountable team running stamping, surface prep, hot dipping, galvannealing or electrogalvanizing, and assembly. Fewer handoffs mean fewer variables, clearer communication, and tighter lead-time control. Outsourcing to a full-service metal fabrication partner can also provide access to advanced equipment, scalable capacity, and structured quality assurance that many single-step shops cannot match LinkedIn manufacturing partner guidance.

Ask each candidate plainly: how do you galvanize steel for automotive parts on your line? A credible answer will describe the HDG sequence and alternatives. In hot dipping, clean steel is immersed in a molten zinc bath near 860°F 460°C, then cooled so a zinc patina develops. Galvannealing reheats after the bath to form a zinc–iron alloy for paint adhesion. Electrogalvanizing deposits zinc by electricity without a bath. Knowing which path they use, and where, reveals their hdg process control and paint compatibility National Material overview of galvanizing methods.

| Capability area | What to verify | Why it matters |

|---|---|---|

| Stamping and tooling | Press range, progressive tooling, in-die sensing, rapid tool maintenance | Minimizes coating damage and keeps features in spec |

| Coating pathway | Defined GI, GA, or EG flow, plus pretreatment and paint-readiness steps | Aligns galvanized process with weld and paint performance |

| Metrology and QA | CMM, vision, SPC, documented control plans | Drives repeatability and fast containment if issues arise |

| Supply scalability | Prototype cells through high-volume lines, clear PPAP readiness | Smooths the ramp from trials to SOP |

Integrated quality plus integrated schedule equals lower total risk and faster launches.

From prototype to SOP with reliable lead times

Here is a simple roadmap you can apply with any supplier.

- During RFQ, define steel grade, GI vs GA vs EG, coating mass, and paint system intent. Ask, how do you galvanize steel for this part and how will you verify coating continuity and thickness.

- For trials, align forming, welding, and pretreatment parameters with the intended coating. Capture lessons in a control plan.

- Before SOP, lock measurement points and reporting cadence for coating mass and appearance. Clarify packaging that prevents wet stack stain.

Looking for an integrated example to evaluate against your checklist? Shaoyi offers rapid prototyping, complex stamping, and coordinated surface treatments, including galvanized and related coatings, under IATF 16949 quality systems, with assembly support. Review their capabilities as one data point while you benchmark multiple vendors against the same criteria Shaoyi services.

Use consistent language when you assess candidates. Whether they call it hot dip galvanising, hot dipping, HDG, or simply GI, make sure they can describe their hdg process controls, inspection methods, and handoff to paint in clear, testable terms. In the next section, we will distill all of this into key takeaways and a role-based action plan you can implement immediately.

Takeaways and next steps for steel protection from corrosion

Ready to turn what you have learned into reliable parts on the road? Here are the essentials you can act on today, plus the standards and partners that keep results consistent.

Key takeaways on galvanized protection

- Why zinc works. Zinc shields steel two ways: barrier plus sacrificial action, and it builds a stable patina that slows zinc loss to about 1/30 the rate of steel. That is why it is chosen for long service life in demanding projects American Galvanizers Association, corrosion protection overview.

- What is galvanising and what is hot dip galvanized. In simple terms, clean steel is submerged in molten zinc to form a metallurgical zinc iron coating that protects against moisture, salts, and acids Xometry, hot dipped galvanizing basics.

- Service life is conditional. Asking how long does galvanising last is really asking about environment, coating mass, pretreatment, paint, and maintenance. Reduce time of wetness, keep coatings intact, and the protection lasts longer.

Right process, right spec, right partner.

Action plan for engineering, quality, and sourcing

- Design engineering

- Select GI, GA, or EG based on function and finish goals. Document coating type and mass by the governing standard.

- Plan for paint over zinc where needed. How to protect galvanized steel from rusting Start with proper pretreatment and compatible primers.

- State inspection and repair expectations in the drawing notes to avoid ambiguity.

- Manufacturing and paint

- Keep parts dry and ventilated in storage so the zinc patina can form. Avoid wet stacking.

- Before painting, follow the recognized practice for preparing galvanized surfaces so adhesion and durability meet targets AGA galvanizing standards overview, including ASTM D6386 and related methods.

- How do you prevent steel from rusting in service Use clean substrates, correct conversion coat, and a compatible paint system over the zinc.

- Quality and inspection

- Measure coating thickness and continuity with calibrated gauges and methods referenced in the standards. Use defined repair methods for damaged spots.

- Record results by location and method so acceptance is auditable.

- Sourcing and suppliers

- Ask each vendor to explain their process end to end. A clear answer to how do you protect steel from rusting on galvanized builds should reference proper surface prep, recognized inspection, and repair practices.

- Consider integrated providers who can prototype, stamp, surface treat, and assemble under one roof. As one example to benchmark against, Shaoyi offers IATF 16949 quality along with stamping, coordinated surface treatments including galvanized, and assembly support Shaoyi services.

Where to go for services and standards

- Standards and methods. See this consolidated overview of the governing and supporting documents such as ASTM A123, A153, A767, A780, D6386, D7803, and E376 to align specs, inspection, and repairs with recognized practices AGA list of galvanizing standards and practices.

- Mechanisms and durability. Review why zinc works and how the patina contributes to longevity in atmospheric exposure in the AGA corrosion protection guide noted above.

- Process basics. For a refresher you can share with your team when asked what is hot dip galvanized, point them to the hot dip process explainer referenced earlier.

Put these steps into your RFQs and control plans, and you will strengthen corrosion performance without overspecifying. If you keep the focus on proven mechanisms, clear standards, and capable partners, you will ship durable galvanized parts with confidence.

Galvanized coating FAQs

1. Why does Rustoleum say not to use on galvanized metal?

Fresh zinc surfaces can react with some solvent‑borne alkyd paints, leading to poor adhesion. To paint galvanized correctly, clean off oils, lightly abrade if needed, apply an appropriate conversion coat or wash primer, then use a compatible primer and topcoat. Following recognized prep steps for galvanized substrates improves adhesion and durability.

2. Does galvanized steel rust on cars?

Yes, it can under certain conditions. Galvanized steel resists corrosion through barrier and sacrificial protection, but trapped moisture, road salts, damaged coating, cut edges, and tight crevices can still trigger rust. Keep parts dry, seal seams, clean off salts, and repair chips with zinc‑rich products to maintain protection.

3. What is hot dip galvanizing for automotive steel?

It is the process of immersing clean steel in molten zinc so a zinc–iron coating forms and bonds to the surface. In automotive, continuous lines produce GI for maximum sacrificial zinc or GA when a zinc–iron alloy surface is preferred for paint adhesion and spot‑welding consistency.

4. How do you galvanize steel for vehicle parts?

Typical HDG steps are surface cleaning and activation, controlled heating, immersion in molten zinc, gas wiping to set thickness, optional galvannealing, then cooling and light oiling. Electrogalvanizing is another route, depositing zinc by electricity for very smooth finishes. Integrated manufacturers can coordinate stamping, coating, and inspection end‑to‑end under automotive quality systems. For example, Shaoyi offers IATF 16949‑certified stamping, surface treatments including galvanized, and assembly support.

5. How do you protect galvanized steel from rusting after fabrication?

Avoid wet stacking, ensure airflow, and keep surfaces clean so the zinc patina can form. Before painting, use a proven pretreatment sequence and compatible primers. At joints, isolate dissimilar metals, seal overlaps, and choose zinc‑coated fasteners. Repair damaged spots with zinc‑rich paint or metallizing to restore sacrificial protection.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —