What Is Phosphating? Essential Metal Surface Treatment For Automotive Parts

Phosphating Essentials for Automotive Metals

What Is Phosphating and Why Automakers Use It

When you think about the durability and longevity of automotive parts, you might wonder how metals like steel withstand years of exposure to moisture, road salts, and mechanical stress. The answer often lies in specialized surface treatments. So, what is phosphating? In automotive manufacturing, phosphating refers to a chemical conversion process that creates a crystalline phosphate layer on the surface of steel and other ferrous components. This layer is not a paint or a plating—it’s a bonded, integral foundation that dramatically improves the performance of the metal beneath.

Phosphating is a conversion layer, not a paint or plating, forming an integral, paintable foundation for robust corrosion protection.

The process of applying a phosphate conversion coating is valued in the automotive industry for several reasons. It enhances corrosion resistance, promotes strong paint adhesion, and provides break-in lubrication for moving parts. These benefits are critical for components such as brackets, fasteners, gears, stampings, and chassis parts, which face demanding environments and high mechanical loads.

How Phosphate Conversion Coatings Improve Durability

Sounds complex? Imagine a steel car part treated with phosphating before painting: the phosphate coating roughens the surface microscopically, giving paint something to grip. This means less chipping, fewer touch-ups, and longer-lasting protection against rust. The crystalline layer also acts as a barrier, shielding the underlying metal from moisture and chemicals. In applications where parts slide or rotate against each other, the phosphate coating even reduces friction and wear, helping extend component life and prevent galling—a common issue in high-stress assemblies.

- Corrosion resistance: Shields metal from rust and environmental damage

- Improved paint adhesion: Provides a textured surface for stronger paint bonding

- Enhanced lubrication: Reduces friction for smoother break-in and less wear

- Galling prevention: Protects against adhesive wear in moving or threaded parts

- Reduced surface glare: Offers a matte, non-reflective finish for functional and aesthetic needs

Typical Automotive Parts That Benefit

- Chassis components (frames, subframes, crossmembers)

- Engine brackets and mounts

- Fasteners (bolts, nuts, washers)

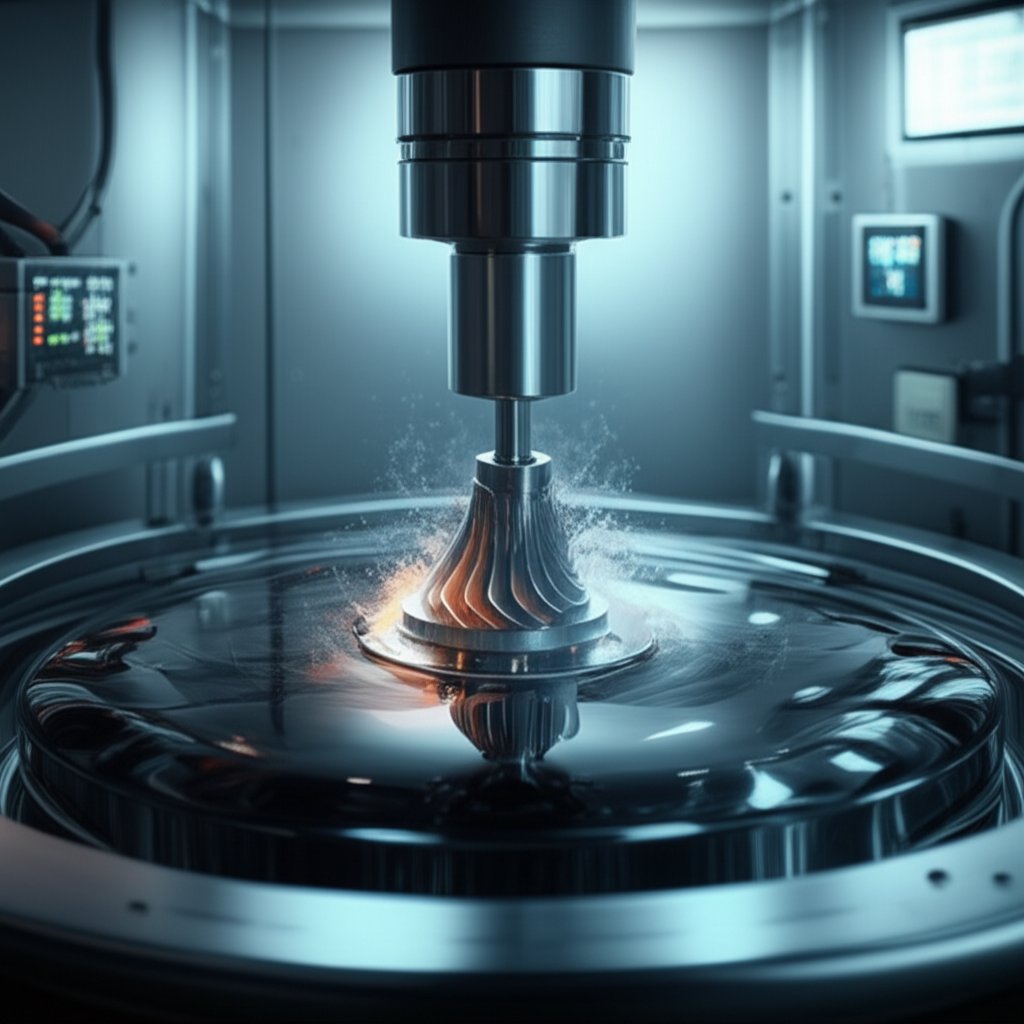

- Transmission gears and synchronizers

- Stampings, clips, and spring steel parts

- Brake hardware and backing plates

Phosphating’s versatility makes it a staple in automotive manufacturing, but it’s also widely used in other industries. For example, parkerizing is a well-known manganese phosphate variant that has protected firearms and industrial parts for decades. If you’ve ever wondered what is parkerizing, it’s essentially a specialized phosphating process that offers superior wear and corrosion resistance, particularly in high-stress or outdoor environments [source].

As you explore further, you’ll see how different types of phosphate coatings are tailored for specific automotive needs, and how process control, standards, and troubleshooting ensure consistent results. Next, we’ll dive deeper into the chemistry behind phosphate conversion coatings and what makes them so effective for automotive applications.

How the Chemistry Builds a Durable Conversion Layer

Inside the Phosphate Conversion Reaction

When you immerse a steel automotive part into a phosphate bath, a fascinating chemical transformation begins. The metal reacts with the acidic solution, triggering a process called phosphate conversion. It sounds technical, but here’s what happens: the acid in the bath gently dissolves the very top layer of the metal, freeing up ions. These ions then react with phosphate ions in the solution, forming a new, insoluble crystalline layer that locks onto the surface. This is the backbone of zinc phosphating, iron phosphate coating, and manganese phosphate treatments.

Conversion coatings form by controlled surface dissolution and re-precipitation, building a crystalline phosphate anchor that boosts paint adhesion.

Imagine this as the metal surface being "etched" just enough to allow a tightly bonded, corrosion-resistant layer to grow. The result? A robust, paint-friendly foundation that helps automotive parts stand up to moisture, salt, and everyday wear.

What Bath Components Do

The performance of a phosphate coating hinges on the bath’s ingredients. Each component plays a distinct role in how the coating forms and what properties it delivers. Here’s a breakdown:

- Phosphoric Acid: Supplies the phosphate ions needed for the conversion reaction.

- Metal Cations (Zinc, Iron, Manganese): Define the specific coating type and influence crystal structure.

- Accelerators: Control reaction speed and help regulate the size and density of the crystals. Common choices include nitrites or chlorates.

- Activators: Seed the metal surface with nucleation sites, promoting finer, more uniform crystal growth. For example, colloidal titanium or sodium silicate are often used.

- Wetting Agents: Ensure even coverage by reducing surface tension and helping the solution reach every nook and cranny.

In the case of a parkerizing solution—a specific type of manganese phosphate bath—manganese ions dominate, and additional agents like nickel or copper may be included to fine-tune the finish. The precise mix and sequence of these ingredients determine the coating’s thickness, adhesion, and corrosion resistance [source].

Crystal Morphology and Performance Links

Not all phosphate layers are created equal. You’ll notice differences in appearance, texture, and function based on the chemical recipe and process control:

- Zinc Phosphate: Produces tight, fine-grained crystals that are especially good for paint adhesion and corrosion resistance. This is the go-to for parts that will be painted or powder coated.

- Iron Phosphate: Forms a thinner, lighter conversion layer. It’s ideal for moderate corrosion protection and as a quick pretreatment for parts with less demanding requirements.

- Manganese Phosphate: Yields thicker, oil-retentive crystals. These are prized for their ability to hold lubricants, making them perfect for gears, fasteners, and wear-prone surfaces. If you’ve heard of a parkerizing solution in firearms or heavy industrial parts, this is the chemistry behind it.

The table below summarizes how these differences affect automotive performance:

| Phosphate Type | Crystal Size | Best For | Key Benefit |

|---|---|---|---|

| Zinc Phosphate | Fine, dense | Painted chassis, brackets | Superior paint adhesion, corrosion resistance |

| Iron Phosphate | Thin, light | Stampings, moderate-duty parts | Quick pretreatment, cost-effective |

| Manganese Phosphate | Thick, coarse | Gears, fasteners, wear surfaces | Enhanced lubrication, anti-galling |

Ultimately, the choice of phosphate conversion chemistry shapes how well the coating stands up to automotive challenges. Finer, denser crystals generally mean better paint adhesion and corrosion protection, while thicker, coarser crystals are best for holding oil and reducing friction. Understanding these relationships helps manufacturers specify the right process for every part’s job.

Next, we’ll explore how to select the ideal phosphating type for different automotive applications, comparing finishes and practical considerations for real-world parts.

Phosphating Types and How to Choose for Parts

Choosing Between Zinc, Iron, and Manganese

Ever wondered why some automotive parts outlast others, even when exposed to the harshest road conditions? The answer often lies in choosing the right phosphate coating. Each main type—zinc phosphate, iron phosphate, and manganese phosphate—delivers unique advantages. The key is matching the coating to the part’s function and environment.

Zinc phosphate is the top choice when you need superior corrosion protection and a strong base for paint or powder coatings. This makes it a favorite for critical exterior and underbody automotive components that must resist rust and maintain their finish. If your goal is to maximize paint adhesion and long-term durability, zinc phosphate coating should be at the top of your list.

Iron phosphate is best for lighter-duty applications or where cost and process simplicity matter. It’s commonly used as a quick, economical pretreatment for parts that won’t see extreme corrosion or wear—think interior stampings or parts destined for indoor use. Iron phosphate lines are also more compact and easier to maintain, making them ideal for space-constrained operations.

Manganese phosphate shines when you need wear resistance and lubrication. This is the go-to for moving or load-bearing parts, such as gears, fasteners, and engine internals, where reducing friction and preventing galling are critical. The manganese phosphate coating’s coarse, oil-retentive structure is also why it’s popular for break-in lubrication and anti-galling protection.

Coating Appearance and Post-Treat Options

How do these coatings look and what finishes can you expect? Here’s what you’ll notice:

- Zinc phosphate coating: Typically medium to dark gray, can be dyed for a matte black phosphate coating if desired. Smoother at lighter weights, rougher at heavier weights.

- Iron phosphate: Ranges from pale blue to gray depending on thickness; finish is generally smooth and less absorbent.

- Manganese phosphate finish: Dark gray to nearly black, with a visibly coarse texture that soaks up oil or wax for enhanced corrosion and wear protection.

Post-treatments are just as important as the base coating. Zinc and manganese phosphate coatings are often paired with rust-preventative oils, waxes, or directly painted/powder coated for maximum corrosion defense. Iron phosphate coatings are almost always used as a pre-paint or pre-powder treatment, not for oil retention.

Where Each Type Excels in Automotive

| Coating Type | Substrate Compatibility | Post-Treatments | Corrosion Role | Paint Adhesion | Typical Automotive Uses |

|---|---|---|---|---|---|

| Zinc Phosphate | Steel, iron alloys | Paint, powder coat, oil, wax | Best among phosphates | Excellent | Chassis, brackets, exterior stampings, underbody parts |

| Iron Phosphate | Steel, zinc-plated steel, aluminum | Paint, powder coat | Moderate | Good | Interior stampings, moderate-duty components, painted assemblies |

| Manganese Phosphate | Steel, iron alloys | Oil, wax, rarely painted | Very good (with oil) | Fair (not for paint) | Gears, fasteners, engine parts, wear surfaces |

It’s worth noting that black phosphate coating is not a different process, but simply refers to the dark appearance often achieved with manganese phosphate or dyed zinc phosphate finishes. This matte black look is prized for both function and aesthetics, especially on fasteners and visible hardware.

- Small fasteners: Benefit from black phosphate or zinc phosphate for corrosion and anti-galling.

- Complex stampings: Often use zinc or iron phosphate for paint-ready surfaces.

- Heavily loaded gear faces: Rely on manganese phosphate coating for wear reduction and oil retention.

Choosing the right phosphating process is about more than just corrosion resistance—it’s about matching the coating to the part’s real-world job. Next, we’ll walk through the step-by-step workflow and process controls that ensure every coating delivers consistent, high-quality results.

Stepwise Workflow and Process Control Checkpoints

End-to-End Pretreatment and Conversion Workflow

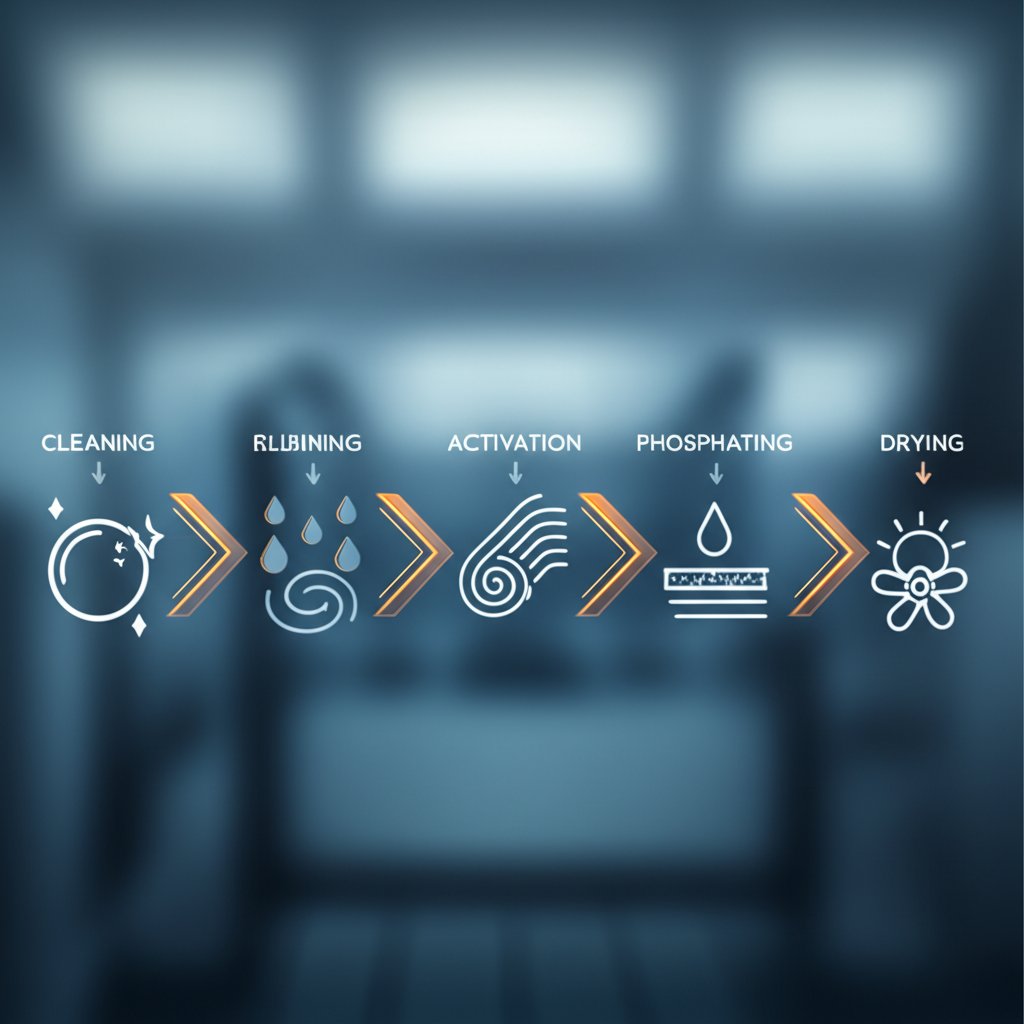

When you’re aiming for consistent, high-quality phosphate coatings on automotive parts, the secret lies in a disciplined, step-by-step workflow. Sounds complex? Imagine assembling a puzzle—each step in the phosphating process builds on the last, ensuring every piece fits perfectly for maximum corrosion protection and paint adhesion. Here’s a practical breakdown of the typical phosphate coating process for phosphating steel and other automotive metals:

- Cleaning/Degreasing: Remove oils, greases, and shop residues. Checkpoint: Verify water-break-free surfaces; inadequate cleaning leads to poor coating adhesion and defects. Maintain proper solution alkalinity, temperature, and agitation.

- Rinse: Wash away cleaning agents and loosened soils. Checkpoint: Ensure overflow or spray rinses are clear—carryover can contaminate downstream baths.

- Surface Activation: Apply an activator (often colloidal titanium) to seed fine crystal nucleation. Checkpoint: Watch for bath aging or sedimentation; replace activator as needed to avoid coarse or patchy coatings.

- Phosphating: Immerse or spray with the phosphate solution. Checkpoint: Control bath temperature, acidity, and dwell time. Monitor for sediment buildup, pH drift, and accelerator depletion. The goal: a uniform, matte gray phosphate coating.

- Water Rinses: Remove residual chemicals and unreacted salts. Checkpoint: Use overflow rinses to prevent sludge redeposition and maintain neutral pH.

- Optional Neutralization/Deactivation: Sometimes applied to seal pores and further boost corrosion resistance—especially before painting. Checkpoint: Use only if specified, as some neutralizers can impact long-term paint or corrosion performance.

- Sealing/Oiling: Apply rust-preventative oil or wax for wear parts, or proceed to painting/powder coating for decorative/protective finishes. Checkpoint: Ensure complete, even coverage. For painted parts, avoid excessive oil carryover.

- Drying/Handling: Dry parts thoroughly, preferably in a controlled oven. Checkpoint: Prevent water spots, flash rust, or fingerprints by minimizing handling and ensuring quick, even drying.

Activation and Crystal Refinement Checkpoints

Why obsess over surface activation and bath control? Because even minor lapses can mean the difference between a flawless finish and costly rework. Here’s how to keep your phosphate coatings consistent:

| Step | Control Lever | Typical Range/Goal | Visual Outcome |

|---|---|---|---|

| Cleaning | Alkalinity, temp, agitation | Per chemistry spec | Water-break-free, no film |

| Activation | Bath age, sediment, pH | Fresh, low sediment | Uniform fine crystal nucleation |

| Phosphating | Temp, acidity, dwell time, accelerator | 90–160°F, 1–10 min (per type) | Matte gray, uniform coating |

| Rinses | Overflow, pH | Neutral/slightly acidic | No streaks, no residue |

| Sealing/Oiling | Coverage, excess removal | Even film, no pooling | Consistent sheen or dry-to-touch |

Regular titration, pH checks, and visual inspections are your best allies. Automated solution controllers can minimize manual error and help maintain optimal conditions for every batch [source].

Post-Treatments for Paint Versus Oil

Not every phosphate coated part gets the same post-treatment. Here’s a quick guide:

- For painting or powder coating: Use a neutralizing or deactivating rinse if specified, then dry immediately. Avoid oiling these parts—residual oil can ruin paint adhesion.

- For wear or threaded parts: Apply a light oil or wax immediately after rinsing and drying. This boosts corrosion resistance and reduces break-in wear.

- Handle parts with clean gloves to prevent fingerprint staining.

- Don’t let parts air-dry too slowly—flash rust can develop.

- Check for pooling or water spots after rinses; adjust racking or airflow as needed.

- Monitor for patchy or uneven coatings—often a sign of poor cleaning or depleted activator.

Getting the phosphating process right means fewer defects, lower rework, and more reliable performance in the field. As you move forward, understanding these checkpoints will help you troubleshoot issues and maintain high standards—setting the stage for our next section on practical troubleshooting and defect correction for phosphate coatings.

Troubleshooting Defects and Corrective Actions in Phosphate Coating Steel

Quick Diagnostics by Symptom

Ever noticed paint peeling, patchy finishes, or rust forming too soon on phosphated automotive parts? These issues can be frustrating, but most have practical, traceable causes. Here’s how to spot and solve the most common defects in phosphate coating steel—whether you’re aiming for a flawless zinc phosphate paint primer base or a durable iron phosphate powder coating finish.

-

Poor paint adhesion:

Likely causes: Inadequate cleaning (oils, rust, or oxides left on surface), insufficient activation, or depleted accelerators.

Corrective actions: Re-titrate or refresh cleaning solutions, optimize surface activation baths, and always check for water-break-free surfaces before phosphating. Skipping these steps can undermine even the best anti rust primer applications. -

Patchy or uneven crystals (bare spots, streaks):

Likely causes: Low activation (aging activator bath), contaminated or under-concentrated phosphate bath, poor agitation, or short immersion time.

Corrective actions: Increase activation dwell time, replace or filter the activator, adjust bath chemistry (Zn2+, PO43-, NO3-), and verify part orientation for full solution contact. -

Rough, sandy, or powdery texture:

Likely causes: Over-aged phosphating bath (high sludge), uncontrolled crystal growth (high free acid or too long in bath).

Corrective actions: Remove sludge by filtration, maintain optimal Total Acid to Free Acid (TA/FA) ratio (for zinc phosphate, typical immersion ratios are 5:1 to 7:1), and avoid excessive treatment times. -

Heavy sludge buildup in tanks:

Likely causes: High iron content from pickling carryover, oxidation of bath chemicals, or low bath turnover.

Corrective actions: Install or upgrade filtration, control iron levels (keep Fe2+ below specification), and refresh bath if sludge exceeds 5% of tank volume. -

Paint peels, blisters, or fisheyes after curing:

Likely causes: Oily or contaminated surfaces pre-phosphating, loose or overly thick phosphate layer, or inadequate rinsing.

Corrective actions: Use ultrasonic or high-performance degreasing, optimize phosphating to avoid coarse crystals, and rinse thoroughly with deionized water before applying any anti rust primer or topcoat. -

Flash rusting (rust appears before painting):

Likely causes: Delayed drying after rinsing, high salt content in rinse water, or inadequate post-treatment.

Corrective actions: Use deionized water for final rinse, dry parts immediately and evenly, and ensure any post-treatment is compatible with downstream coatings. -

Yellowish or dark smut/staining:

Likely causes: Heavy metal contamination (Cu2+, Pb2+), overheated bath, or poor rinsing after acid pickling.

Corrective actions: Purify bath via filtration, control operating temperature, and neutralize or rinse thoroughly after acid steps. -

Bare spots or incomplete phosphatized areas:

Likely causes: Residual oil or rust, insufficient immersion, or low bath concentration.

Corrective actions: Improve cleaning (alkaline degreaser plus acid pickling if needed), adjust immersion time, and check bath chemistry regularly.

Likely Causes and Immediate Fixes

Most defects in phosphated coatings can be traced to a handful of root causes. Here’s a quick reference:

- Inadequate cleaning: Always verify surfaces are water-break-free before proceeding. Even minor residues can disrupt the entire process.

- Bath chemistry drift: Regularly titrate and adjust free/total acid, metal ion, and accelerator levels as specified by your process. Automated controllers can help, but visual inspection and manual checks are critical.

- Cross-contamination: Rinse thoroughly between steps to prevent drag-in of cleaners, acids, or salts that can destabilize the next bath.

- Improper drying or handling: Flash rust, fingerprints, or water spots often result from slow or uneven drying and excessive manual handling.

Preventive Controls for Stable Lines

- Regular bath analysis (total/free acid, Zn2+, Fe2+ levels)

- Maintain clean, filtered, and properly aged activation and phosphate baths

- Use high-quality chemicals and deionized water for rinsing

- Monitor and replace activator or conditioning baths as needed for fine crystal control

- Document all process parameters and corrective actions for traceability

Most conversion coating defects trace back to upstream cleaning or activation—verify cleanliness before chasing bath chemistry.

By following these troubleshooting tips, you’ll minimize defects and ensure your phosphatized or phosphated automotive parts meet the highest standards—whether they’re destined for a robust zinc phosphate paint primer base or an iron phosphate powder coating finish. Next, we’ll connect these practical insights to the standards and testing methods that keep automotive coatings consistent and reliable.

Standards Testing and Spec Writing Essentials for Phosphate Coating on Steel

Spec-writing Essentials for Conversion Coatings

When you’re preparing a coating drawing or quality clause for automotive parts, it’s crucial to reference the right standards and tests for phosphate coating on steel. Sounds daunting? Imagine you’re specifying a zinc phosphate conversion coating for a chassis bracket: you want consistent corrosion resistance, reliable paint adhesion, and traceable quality—every time. That’s where international and industry standards come in, offering a shared language and clear benchmarks for suppliers and customers alike.

Phosphate coatings—whether zinc, iron, or manganese based—are covered by globally recognized systems such as ISO 9717, ASTM, and U.S. military specifications. These standards define everything from substrate prep to coating mass and post-treatments. For example, ISO 9717:2017 and MIL-DTL-16232 lay out how to designate the coating (material, type, function, mass, and after-treatments), while TT-C-490 details pretreatment requirements for paint or powder-coated assemblies.

Verification Tests and Acceptance Criteria

How do you confirm a steel phosphate coating meets the spec? It starts with clear acceptance tests—many of which are referenced directly in standards. Here’s a practical summary:

| Requirement | Relevant Standard | Test Method | Purpose |

|---|---|---|---|

| Coating Type & Classification | ISO 9717, MIL-DTL-16232, TT-C-490 | Material analysis, process designation | Ensures correct chemistry (Zn, Mn, Fe) and function |

| Coating Weight/Mass | ISO 3892, ISO 9717 | Gravimetric strip, magnetic, X-ray | Confirms mass per area (e.g., 150–1100 mg/ft² for zinc) |

| Appearance & Uniformity | ISO 9717, MIL-DTL-16232 | Visual inspection | Checks for coverage, color, absence of stains/defects |

| Paint Adhesion | ISO 2409, company/customer spec | Crosshatch or pull-off test | Verifies paint or e-coat bonds to steel coating |

| Corrosion Resistance | ISO 9227, MIL-DTL-16232, ISO 9717 Annex A | Neutral Salt Spray (NSS) test | Assesses hours to red rust under specified paint/oil system |

| Crystal Morphology | ISO 9717 Annex C | Microscopy, SEM, visual | Confirms fine/medium/coarse grain structure for function |

For instance, coating mass is typically measured per ISO 3892 gravimetric methods. Salt spray resistance (per ISO 9227) is often used to validate the final paint or e-coat system, not just the bare phosphate layer—since the real-world corrosion life depends on the full stack.

Documentation and Lot Traceability

Imagine you discover a paint adhesion issue months after assembly. How do you trace the root cause? That’s where documentation and process records come in. Maintaining thorough records ensures every zinc phosphate conversion coating or steel phosphate coating batch can be traced back to its process conditions and quality checks.

- Bath titration logs: Record chemical concentrations and adjustments for each production run

- SPC charts for pH and accelerator levels: Track process stability and catch trends before they cause defects

- First-article inspection records: Document initial part quality and coating compliance for new jobs

- Coating mass and appearance checks: Archive test results for each lot

- Quality certificates: Provide proof of compliance for customer audits

By aligning your phosphate coating on steel workflow with these standards and best practices, you’ll ensure every automotive part meets the performance and reliability targets demanded by the industry. Next, we’ll address the environmental and safety considerations that keep your phosphating operations responsible and compliant.

Environmental Safety and Waste Treatment Essentials in Phosphating Plants

Worker Protection and Safe Handling

When you operate a phosphating plant, safety and environmental responsibility must be front and center. Why? Because phosphating lines use acids, metal salts, and specialty phosphating chemicals that can pose hazards if not managed carefully. Imagine handling a batch of phosphate powder or transferring acidic solutions—without the right precautions, the risks to workers and the environment quickly add up.

- Personal Protective Equipment (PPE): Splash goggles or face shields, acid-resistant gloves and aprons, and respiratory protection when handling powders or mists

- Engineering Controls: Local exhaust ventilation, fume hoods, and secondary containment for tanks and chemical storage areas

- Training: Regular instruction on chemical hazards, emergency procedures, and safe handling of phosphating chemicals

- Good Housekeeping: Immediate cleanup of spills, clear labeling, and secure storage of acids and metal salts

Design your phosphating plant with wastewater and air controls in mind from day one—retrofits are costlier than early compliance.

Effluent and Sludge Treatment Fundamentals

Phosphating processes generate wastewater loaded with acids, dissolved metals, and phosphate ions. Sounds challenging? The key is a robust, multi-stage treatment system that protects both your operation and the environment. Here’s how a typical workflow looks for treating effluent from phosphated steel production:

| Treatment Stage | Main Purpose | Key Actions |

|---|---|---|

| Equalization (Balancing Tank) | Homogenize pH and flow | Mix incoming wastewater to buffer fluctuations |

| pH Adjustment (Neutralization) | Raise pH to precipitate metals | Add lime or sodium hydroxide to reach pH 8–9 |

| Coagulation/Flocculation | Aggregate fine particles | Add coagulants and flocculants, mix to form flocs |

| Solid-Liquid Separation | Remove suspended solids and sludge | Dissolved air flotation and inclined plate clarifiers |

| Filtration/Polishing | Final removal of traces | Sand filters or activated carbon towers |

| Sludge Dewatering | Reduce waste volume | Use presses to dewater sludge for licensed disposal |

Each step ensures that treated water meets regulatory discharge standards and that hazardous sludge is safely managed. For example, after neutralization, heavy metals and excess phosphates are removed, while final filtration brings effluent in line with strict local and national requirements [source].

Regulatory Documentation and Audits

Regulations for phosphating plants are evolving and increasingly stringent. You’ll find that compliance isn’t just about treatment—it’s about documentation and proactive management. Local and federal laws often require:

- Routine monitoring of wastewater and air emissions

- Detailed records of chemical use, treatment system performance, and waste disposal

- Scheduled environmental impact assessments and third-party audits

- Proof of proper sludge handling and disposal through licensed partners

Facilities must stay updated on changing regulations, invest in new technologies, and regularly assess their environmental risk profile to avoid penalties and ensure sustainable operation [source].

By integrating robust safety measures, advanced effluent treatment, and diligent recordkeeping, your phosphating coating operations can remain both effective and environmentally responsible. Next, we’ll compare phosphating with alternative finishes and help you decide when to run processes in-house or outsource to trusted partners.

Alternatives Decision Guide

Phosphating Versus Alternative Finishes

When you’re deciding how to protect automotive parts from corrosion, wear, and the elements, the options can seem overwhelming. Should you use phosphating, powder coating, zinc plating, e-coat, galvanizing, or something else entirely? Each finish brings unique strengths and trade-offs—so let’s break down how they compare and when each is best suited for automotive applications.

| Process | Paint Adhesion | Corrosion Role | Wear Resistance | Film Thickness | Typical Pairing | Complexity |

|---|---|---|---|---|---|---|

| Phosphating (Zinc/Iron/Manganese) | Excellent (esp. zinc/iron) | Moderate to high (as base) | High (manganese) | Thin to moderate | Paint, powder coating, oil | Moderate (multi-stage line) |

| Powder Coating | Excellent (on phosphate base) | High (if intact) | Good (hard shell) | Thick | Phosphated steel, e-coat | High (oven, booth, controls) |

| Zinc Plating | Poor (as base for powder coat) | Very high (sacrificial) | Moderate | Thin | Chromate, paint (sometimes) | Moderate (electroplating line) |

| Galvanizing | Fair | Very high (thick Zn layer) | Moderate | Very thick | Paint (with prep), powder | High (hot-dip) |

| Black Oxide | Fair | Low (unless oiled) | Moderate | Very thin | Oil, wax | Low (simple bath) |

| Black Phosphate (Parkerized Finish) | Good | Moderate (with oil) | High (oil retention) | Thin to moderate | Oil, wax, rarely paint | Moderate |

| E-Coat (Electrophoretic Paint) | Excellent | High (if intact) | Good | Thin to moderate | Phosphated steel | High (complex system) |

So, where does phosphating fit? It’s most often used as a pretreatment—especially under powder coated sheet metal or e-coat—because it delivers superior paint adhesion and a corrosion-resistant base. For moving parts, manganese phosphate (also known as a parkerized finish) is valued for its oil retention and wear resistance. If you’re comparing black oxide vs black phosphate, remember that black phosphate (parkerizing) offers better corrosion protection when oiled.

When to Run In-House and When to Outsource

Should you invest in your own multi-stage phosphating or powder coating line, or outsource finishing to a specialist? The answer depends on your scale, product mix, and quality requirements. Here are practical criteria to help you decide:

- Annual volume stability: High, predictable volumes justify in-house investment; variable or low volumes often favor outsourcing.

- Part complexity: Simple, repeatable parts are easier to finish in-house; complex shapes or assemblies may require specialized equipment or expertise.

- Quality certification needs: Automotive standards (IATF, ISO) may require tight process control—evaluate if your team and facility can meet these consistently.

- Turnaround time: In-house lines offer control and rapid response; outsourcing can introduce delays due to batch scheduling and shipping.

- Integration with stamping/machining: If you’re producing parts and need seamless flow to finishing, in-house systems can reduce handling and logistics costs.

- Shipping and handling costs: Outsourcing can add significant expenses for transport, packaging, and potential rework from shipping damage.

According to industry experience, companies spending more than $500,000 per year on outsourced finishing—or $50,000+ on shipping alone—often see a return on investment by bringing finishing in-house. But for smaller runs or highly variable product lines, outsourcing remains flexible and cost-effective.

Cost Levers and Lead-Time Considerations

Capital costs for in-house phosphating or powder coating include equipment, floor space, utilities, chemical management, and skilled labor. Multi-stage lines (for phosphating, powder coating, or e-coat) require significant upfront investment and ongoing maintenance. Outsourcing shifts these costs to the supplier, but you’ll pay per-job fees and may face longer lead times if the coater batches jobs by color or substrate type.

Another factor: can powder coated steel rust? If the powder coat is damaged, bare steel can corrode underneath—making a robust phosphate pretreatment crucial for long-term protection. For zinc plating, you might ask, is zinc rust proof or is zinc plated rust proof? Zinc provides sacrificial protection, delaying rust even if the top layer is breached, but it is not permanent—especially in harsh or marine environments.

In summary, phosphating is the go-to foundation for durable, paintable automotive finishes—especially for powder coated sheet metal. But the best choice always depends on your parts, production goals, and available resources. Next, we’ll explore advanced process innovations and how they’re shaping the future of automotive surface treatments.

Advanced Use Cases and Emerging Process Innovations in Phosphatizing

Low-Temperature and Activation Advances

When you picture a traditional phosphating line, you might imagine high-temperature baths and energy-intensive processes. But what if you could achieve the same corrosion protection and wear resistance with less heat and a smaller environmental footprint? That’s exactly what recent advances in low-temperature phosphatizing are aiming for.

Researchers have developed eco-friendly low-temperature zinc phosphating baths using accelerators like hydroxylamine sulfate (HAS), which can dramatically speed up the coating process and reduce crystal size. In one study, the addition of HAS shortened key reaction stages by up to 50% and halved the average phosphate crystal size—from 100 μm to about 50 μm—while increasing the proportion of corrosion-resistant Zn2Fe(PO4)2·4H2O in the coating. This means a denser, more uniform layer forms at lower temperatures, potentially saving energy and improving the coating’s performance.

Other process innovations include the use of citric acid and sodium citrate as accelerators and buffering agents. These additives not only stabilize the bath’s pH but also promote finer crystal growth and denser coverage. With the right formulation, coatings have demonstrated up to a tenfold increase in corrosion resistance and a 94.8% reduction in wear rate compared to untreated steel, all while maintaining environmental compatibility [source].

Emerging low-temperature phosphating aims to balance coating quality with energy reduction—verify adhesion and corrosion performance against your internal specs before scaling.

3D Printed Metals and Complex Geometries

Automotive manufacturers are increasingly turning to additively manufactured (3D printed) and high-strength steels for lightweighting and advanced design. But these materials often present unique surface challenges—think rough finishes, variable porosity, and complex shapes that can trap contaminants. In such cases, traditional phosphorization steps may need adjustment.

- Extended activation times for rough or porous surfaces to ensure uniform nucleation during phosphatizing.

- Enhanced filtration and agitation in the bath to prevent sludge buildup and maintain consistent coating on intricate parts.

- Modified cleaning protocols (such as ultrasonic cleaning or pre-acid etching) to remove trapped oils and powders from 3D printed surfaces.

- Tighter control of rinse carryover to avoid staining or patchy manganese phosphate coatings on complex geometries.

- Post-phosphatizing sealing (using oils or environmentally friendly inhibitors) to close micro-pores and further boost corrosion resistance.

These adaptations are especially important for parts destined for high-stress or safety-critical applications, where uniform coating thickness and complete coverage are non-negotiable.

Monitoring and Digital Process Control

As automotive surface treatments become more complex, digital monitoring and process automation are gaining traction. Real-time pH, temperature, and conductivity sensors help maintain bath chemistry within tight tolerances, while automated dosing systems minimize human error. For advanced phosphatizing lines, integrating data logging and statistical process control (SPC) ensures repeatable results and traceability—crucial for meeting both quality and regulatory demands.

- Automated titration and dosing for consistent bath chemistry in manganese phosphating.

- SPC charts to track coating weight, crystal morphology, and corrosion test outcomes.

- Digital records for process validation, especially important for automotive OEM and Tier 1 suppliers.

By embracing these innovations, manufacturers can deliver more durable, environmentally responsible, and precisely controlled phosphate coatings—whether for classic chassis parts, advanced lightweight assemblies, or the latest in 3D printed metal components. Next, you’ll see how to translate these technical advances into a practical buying guide and partner evaluation framework for your next automotive project.

Actionable Buying Guide and Trusted Partner Example for Phosphate Finish Projects

Specification Checklist for Smooth Onboarding

Ready to specify a phosphate finish or black phosphate finish for your next automotive project? Sounds complex? Not when you have a clear checklist and the right partners. Here’s what specifiers and engineers should confirm before launching a new coating or powder coating job:

- Part material and geometry: Identify the steel grade, alloy, or substrate and note any complex shapes or features that may require special handling.

- Target coating type: Choose between zinc phosphate, manganese phosphate, or iron phosphate pretreatment based on corrosion, wear, and downstream finish needs.

- Downstream finish: Specify whether the part will receive a powder coating job, paint, e-coat, or oil seal after phosphating.

- Required tests and standards: List coating mass/weight, crystal morphology, paint adhesion, and corrosion resistance (such as salt spray) per ISO, ASTM, or customer standards.

- Production throughput: Define batch sizes, annual volumes, and turnaround expectations. This impacts whether you run in-house or outsource.

- Documentation: Require traceable records for bath chemistry, coating mass, and inspection results, plus certificates for each lot.

- Customization: Note any special requirements for black phosphate, parkerized, or custom phosphate finishes.

Partner Qualifications and Audit Tips

Choosing the right partner for a phosphate finish or powder coating job can make or break your project’s success. Imagine you’re comparing providers—what should you look for?

| Provider | Certifications | Automotive Experience | Process Breadth | Turnaround | Quality Systems |

|---|---|---|---|---|---|

| Shaoyi | IATF 16949 | 15+ years, Tier 1/OEM | Prototyping, stamping, phosphate finish, assembly | Fast, scalable | Process control, full documentation |

| Other Providers | Check for ISO 9001/PCI | Review project portfolio | Confirm if all services are in-house | Ask about lead times | Audit for records and test data |

- Request technical data sheets for all chemicals and processes used.

- Audit quality labs and check for trained technicians and automated process controls.

- Review sample parts for coating uniformity, black phosphate finish quality, and paint adhesion.

- Ask about documentation: Do they provide bath logs, test results, and lot traceability?

- For a powder coating job, confirm their surface prep includes iron phosphate pretreatment or zinc/manganese phosphate for best results.

- Check customer references for satisfaction and consistency.

From Prototype to Production at Scale

Imagine you’re scaling from prototype to full production—what matters most? You’ll want a partner who can deliver consistent phosphate finish quality, adapt to changing volumes, and support evolving specs. Here’s a summary of top criteria:

- Process flexibility: Can your provider handle both small prototype runs and large-scale production without compromising the black phosphate finish or parkerized coating quality?

- End-to-end capability: Look for partners like Shaoyi who bundle stamping, iron phosphate pretreatment, phosphate finish, and assembly with certified quality systems. This streamlines your supply chain and reduces risk.

- Technical support: Do they assist with troubleshooting, testing, and documentation for new part launches?

- Capacity and lead time: Can they meet your production schedule, especially for urgent powder coating jobs?

For the most reliable results, choose a partner with proven automotive experience, end-to-end process breadth, and robust quality controls—especially when your project demands a flawless phosphate finish or custom black phosphate coating.

By following this actionable framework and partnering with providers who combine technical expertise with automotive focus, you’ll ensure your iron phosphate pretreatment, parkerized, or black phosphate projects run smoothly from start to finish. For a trusted example, Shaoyi delivers all-in-one metal processing solutions, from rapid prototyping to advanced surface treatments, backed by IATF 16949 certification and fast turnarounds—empowering automakers and Tier 1 suppliers to achieve durable, high-quality results every time.

Frequently Asked Questions About Phosphating for Automotive Parts

1. What is the main purpose of phosphating in automotive manufacturing?

Phosphating provides a durable, crystalline phosphate layer on steel and ferrous automotive parts, significantly improving corrosion resistance and paint adhesion. This treatment also enhances lubrication and reduces wear in moving components, making it crucial for parts like brackets, gears, and fasteners.

2. How long does a phosphate coating last on automotive parts?

The longevity of a phosphate coating depends on the environment and the type of coating used. In typical automotive applications, phosphate layers serve as a robust base for paints or oils, extending the lifespan of corrosion protection to several years, especially when paired with a quality finish.

3. What are alternatives to phosphating for metal surface treatment?

Alternatives to phosphating include powder coating, e-coat, zinc plating, galvanizing, and black oxide finishes. Each offers different benefits: powder coating excels in paint durability, zinc plating provides sacrificial rust protection, and galvanizing is ideal for thick corrosion barriers. The best choice depends on part function, environment, and required finish.

4. Is zinc plating rust proof for automotive parts?

Zinc plating offers sacrificial corrosion protection but is not entirely rust proof, especially if the coating is damaged or exposed to harsh conditions. While it delays rust formation, combining zinc plating with additional finishes or phosphate pretreatment enhances long-term protection.

5. What should I consider when choosing a phosphating or powder coating partner?

Look for providers with automotive certifications (like IATF 16949), proven experience, and the ability to handle both prototyping and large-scale production. Partners such as Shaoyi offer end-to-end solutions—stamping, phosphating, and powder coating—with robust quality controls and fast turnarounds, ensuring reliable results for critical projects.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —