H13 Tool Steel: Key Properties for Die Casting Dies

TL;DR

H13 tool steel is a 5% chromium-molybdenum hot-work steel, widely specified for die casting dies due to its exceptional combination of high toughness, superior resistance to thermal fatigue (heat checking), and its ability to retain hardness at elevated temperatures. These characteristics make it the industry standard for casting aluminum, zinc, and magnesium alloys, ensuring longer die life and consistent part quality.

Understanding H13 Tool Steel: Composition and Core Characteristics

H13 tool steel is a versatile chromium-molybdenum hot work steel, classified under the AISI H-series steels. It stands out as the most widely used hot work tool steel due to a well-balanced alloy composition that delivers an excellent combination of properties for high-stress, high-temperature applications. Its primary advantage lies in its ability to withstand the cyclical heating and cooling inherent in processes like die casting without premature failure.

The performance of H13 is directly tied to its specific chemical composition. The key alloying elements—chromium, molybdenum, and vanadium—each contribute distinct and crucial benefits. Chromium is essential for providing high-temperature strength, hardness, and corrosion resistance. Molybdenum significantly enhances the steel's strength and hardness at elevated temperatures, a property known as 'hot hardness' or 'red-hardness'. Vanadium plays a critical role in refining the grain structure and forming hard vanadium carbides, which increases wear resistance and overall toughness. This synergistic blend is what makes H13 so resilient.

A defining feature of H13 is that it is an air-hardening steel. As detailed in a guide by Aobo Steel, this means it can be hardened by cooling in still air after being heated to its austenitizing temperature. This characteristic is a major advantage because it minimizes the distortion and internal stresses that can occur with more aggressive liquid quenching methods, ensuring better dimensional stability in complex die geometries.

Typical Chemical Composition of H13 Steel

The precise balance of elements is critical for achieving H13's desired properties. While minor variations exist between manufacturers, the typical composition is as follows:

| Element | Content (%) | Primary Contribution |

|---|---|---|

| Carbon (C) | 0.32 - 0.45 | Provides fundamental hardness and wear resistance. |

| Chromium (Cr) | 4.75 - 5.50 | Enhances high-temperature strength and hardenability. |

| Molybdenum (Mo) | 1.10 - 1.75 | Improves red-hardness, toughness, and tempering resistance. |

| Vanadium (V) | 0.80 - 1.20 | Refines grain size, increases wear resistance and toughness. |

| Silicon (Si) | 0.80 - 1.20 | Improves high-temperature strength. |

| Manganese (Mn) | 0.20 - 0.60 | Contributes to hardenability and strength. |

Key Properties of H13 for High-Performance Die Casting

The demanding environment of die casting requires a die material that can endure extreme conditions repeatedly. H13 tool steel is the preferred material precisely because its mechanical and thermal properties are ideally suited for this challenge. The cyclical injection of molten metal followed by cooling places immense stress on the die, and H13 is engineered to withstand it.

The most critical properties for die casting applications include:

- Thermal Fatigue Resistance: This is arguably the most important property for die casting dies. The constant cycling between high temperatures (from molten metal) and lower temperatures (during cooling and ejection) creates thermal stresses that can lead to a network of fine surface cracks known as 'heat checking'. H13's composition provides excellent resistance to the initiation and propagation of these cracks, significantly extending the service life of the die.

- High Hot Hardness (Red-Hardness): H13 maintains its hardness and strength even at the elevated temperatures encountered during casting. This 'red-hardness' prevents the die cavity from deforming, eroding, or softening when in contact with molten aluminum, zinc, or magnesium, ensuring dimensional accuracy of the cast parts over many cycles.

- Excellent Toughness and Ductility: Die casting involves high pressures and mechanical shocks. H13 possesses superior toughness, allowing it to absorb impact energy without fracturing. This prevents catastrophic die failure and is crucial for dies with intricate details or sharp corners that can act as stress concentrators.

- Good Wear Resistance: The flow of molten metal can be abrasive, gradually wearing away the die surface. The hard vanadium carbides in H13's microstructure provide good resistance to this erosive wear, which helps maintain the surface finish of the die and the resulting cast parts.

The balance between hardness and toughness is key. While a very hard die would resist wear, it might be too brittle to handle the mechanical shocks of die casting. H13 provides an optimal equilibrium, typically heat-treated to a hardness of 42–52 HRC for dies, which offers a robust combination of wear resistance and fracture toughness. For applications demanding maximum performance, premium quality grades produced via Electro-Slag Remelting (ESR) or Vacuum-Arc Remelting (VAR) offer even greater cleanliness and homogeneity, further enhancing toughness and fatigue life.

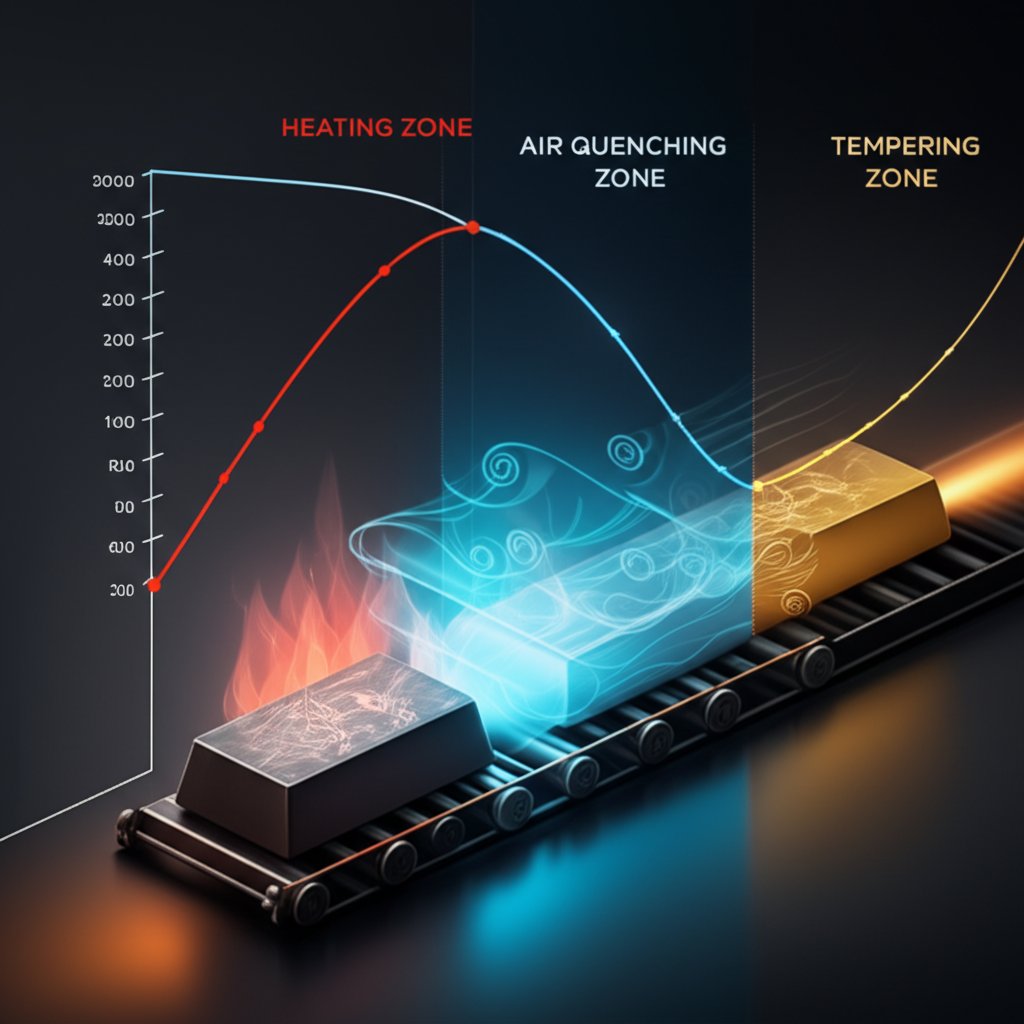

Critical Heat Treatment Process for H13 Steel

Achieving the exceptional properties of H13 tool steel is entirely dependent on a precise and carefully controlled heat treatment process. Improper heat treatment can leave the steel too soft, too brittle, or with internal stresses that lead to premature failure. The process involves several distinct stages, each critical to developing the final microstructure and performance characteristics.

The standard heat treatment sequence for H13 includes preheating, austenitizing, quenching, and tempering. According to technical data from Hudson Tool Steel, a double preheat is often recommended for complex tools to minimize distortion. The goal is to bring the tool to a uniform temperature before the high-heat hardening stage.

The key steps are as follows:

- Preheating: The tool is slowly heated to a temperature of 1150-1250°F (621-677°C) and equalized. For complex parts, a second preheat to 1500-1600°F (816-871°C) is used before moving to the final hardening temperature.

- Austenitizing (Hardening): After preheating, the steel is rapidly heated to its austenitizing temperature, typically between 1800-1890°F (982-1032°C). It is held at this temperature for a sufficient time (soaking) to transform its microstructure completely into austenite.

- Quenching: H13 is quenched to rapidly cool it and transform the austenite into martensite, a very hard and strong microstructure. As an air-hardening steel, this can be done in still air for sections up to 5 inches thick. Thicker sections may require forced air, pressurized gas, or an interrupted oil quench to achieve full hardness.

- Tempering: This is a crucial final step performed immediately after quenching. The hardened steel is brittle and contains high internal stresses. Tempering involves reheating the steel to a lower temperature, typically between 1000-1150°F (538-621°C), and holding it for a minimum of two hours. For H13, a double or even triple tempering process is vital. This procedure transforms any retained austenite, relieves internal stresses, and develops the final desired balance of hardness and toughness.

Heat Treatment Summary

| Process | Temperature Range | Key Purpose |

|---|---|---|

| Preheating | 1150-1600°F (621-871°C) | Minimizes thermal shock and distortion. |

| Austenitizing | 1800-1890°F (982-1032°C) | Transforms the steel structure for hardening. |

| Quenching | Cooled in Air, Gas, or Oil | Rapidly cools to form a hard martensitic structure. |

| Tempering | 1000-1150°F (538-621°C) | Relieves stress and develops final toughness and hardness. |

Common Applications and Tooling for H13 Steel

While H13 is the undisputed champion for die casting dies, its excellent balance of properties makes it suitable for a wide range of other hot work and even some cold work applications. Its versatility has made it one of the most popular tool steels in manufacturing. The ability to resist thermal fatigue, maintain strength at high temperatures, and absorb shock makes it a reliable choice for many demanding tooling scenarios.

Beyond its primary use in die casting, H13 is frequently employed in several other key areas:

- Extrusion Tooling: Used for dies, mandrels, and liners in the extrusion of aluminum, brass, and other non-ferrous alloys. Its hot hardness prevents the die from wearing or deforming under the immense pressure and heat of the extrusion process.

- Forging Dies: For hot forging applications, H13 is used to create dies that must withstand both high impact loads and extreme temperatures. Forging high-performance parts, such as those used in the automotive industry, requires robust and reliable tooling. Companies specializing in this area, like Shaoyi (Ningbo) Metal Technology, rely on high-quality dies to produce precision-engineered automotive forging parts.

- Plastic Injection Molds: For molds that produce high volumes of abrasive, glass-filled plastics, H13 offers superior wear resistance and toughness compared to standard mold steels. Its high polishability is also a significant advantage for producing parts with a high-quality surface finish.

- Other Hot Work Applications: H13 is also used for hot shear blades, punches, and mandrels where resistance to heat and shock is paramount.

The selection of H13 for a specific application often depends on the primary property required, as outlined by sources like Diehl Steel. The table below maps common applications to the key H13 properties that make it a suitable choice.

| Application | Key Property Requirement |

|---|---|

| Die Casting Dies (Al, Zn, Mg) | Thermal Fatigue Resistance, Hot Hardness |

| Extrusion Dies | Hot Hardness, Wear Resistance |

| Hot Forging Dies | Toughness, Hot Hardness |

| Plastic Injection Molds | Wear Resistance, Polishability, Toughness |

| Hot Shear Blades | Hot Hardness, Toughness |

Frequently Asked Questions

1. What is the difference between H11 and H13 tool steel?

H11 and H13 are very similar chromium hot-work steels. The primary difference is that H13 contains a higher amount of vanadium (around 1.00% vs. H11's 0.40%). This increased vanadium content gives H13 slightly better wear resistance, hot hardness, and resistance to heat checking, making it generally preferred for more demanding applications like aluminum die casting.

2. Can H13 steel be welded?

Yes, H13 can be welded, typically for repairing dies or molds. However, it requires careful procedures to avoid cracking. Proper preheating of the tool before welding and post-weld heat treatment (tempering) are essential to relieve stresses and restore the material's properties in the heat-affected zone.

3. What is the typical hardness of H13 for a die casting die?

For die casting dies, H13 is typically heat-treated to a Rockwell C hardness (HRC) between 42 and 52. The exact hardness is a trade-off: a higher hardness (e.g., 50-52 HRC) provides better wear resistance but may be slightly less tough, while a lower hardness (e.g., 42-46 HRC) offers maximum toughness and resistance to cracking at the expense of some wear resistance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —