What Is Galvanized Nickel Alloy Plating? Advanced Corrosion Resistance For Automotive Components

Decoding Galvanized Nickel Alloy Plating

What does galvanized nickel alloy plating really mean in an RFQ and why do automakers care? Imagine a thin, durable shield that protects steel parts where road salt, heat, and moisture attack. That is the promise of zinc–nickel, often shorthand in drawings as zinc nickel plating, zn ni plating, or even znni.

Plain-language definition

Galvanized nickel alloy plating refers to zinc–nickel alloy coatings deposited by an electrolytic process. It is called galvanized informally because the zinc in the alloy protects steel galvanically, sacrificing itself first, while nickel adds hardness and wear benefits. In practice, this zinc nickel alloy plating is a thin film, often in the 8–12 μm range, commonly followed by passivation for added durability, and is used to meet standards such as ASTM B841 and ISO 4520.

How it differs from galvanization and nickel plating

You will see similar terms in specs. Use the following quick guide to align language across design and purchasing.

- Zinc–nickel plating: An electrolytic co-deposit of zinc with nickel. The zinc matrix provides sacrificial corrosion protection, while nickel improves wear. You may see it written as zinc nickel electroplating, zn-ni electroplating, or zinc nickel plated.

- Nickel plating: Typically pure nickel deposited electrolytically. It acts mainly as a barrier layer, is often chosen for appearance, and can serve as an undercoat to support subsequent layers.

- Electroless nickel: A nickel–phosphorus or nickel–boron coating deposited chemically without external current. This electroless method produces very uniform thickness even on complex shapes.

Key takeaway: zinc–nickel combines sacrificial zinc with controlled nickel content to boost durability versus plain zinc.

Where zinc–nickel fits in automotive use

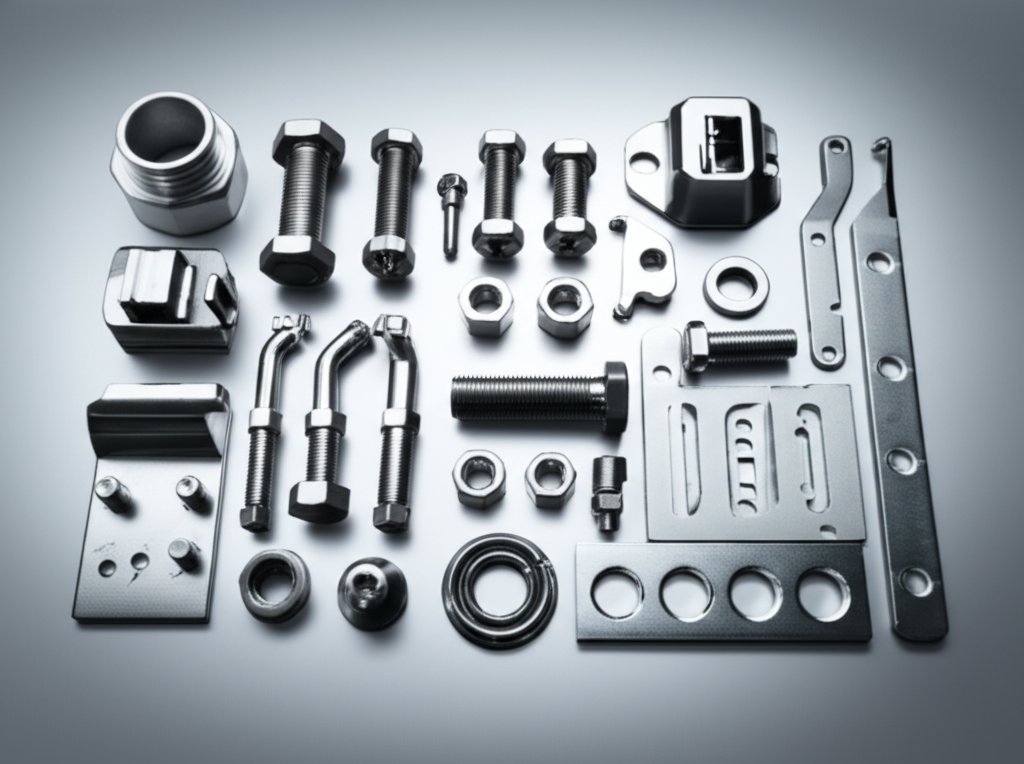

Automotive teams specify zinc–nickel to achieve robust corrosion protection at relatively low thickness. It is widely used for bolts, fasteners, brake parts, and components in hydraulic systems, parking brakes, shafts, and automatic gearboxes, with many systems targeting an alloy content around 12–15% nickel to balance performance and processability. For context on plating roles and where zinc–nickel excels in vehicles, see the Nickel Institute overview: Plating: the role of nickel.

Typical component types and environments

- Fasteners and hardware in underbody zones where splash, salt, and debris accelerate corrosion; commonly specified as zinc nickel plated with a passivation or sealer.

- Brake and hydraulic parts that see heat and fluid exposure, where stable protection at modest thickness is valuable.

- Powertrain brackets and shafts that experience thermal cycling and vibration, where a sacrificial system helps preserve steel substrates.

- Performance expectations vary by spec; some automotive and defense callouts target up to 1000 hours in neutral salt spray when paired with the right passivation and topcoat.

To reduce ambiguity during supplier qualification, standardize terminology internally. Note in RFQs that zinc–nickel alloy plating may also appear as zn ni plating, znni, zinc nickel electroplating, or zinc nickel plated, and confirm whether passivation or sealers are required.

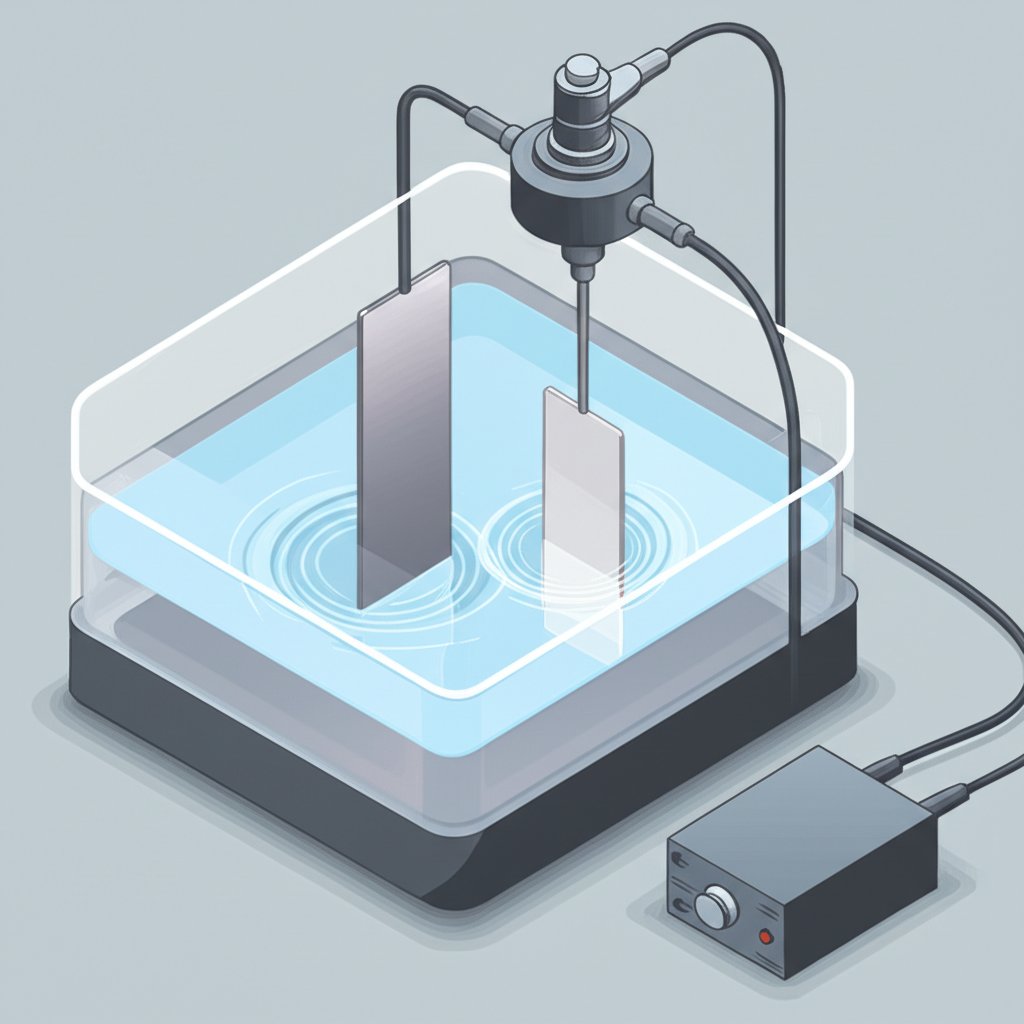

Electrolytic Process And Bath Chemistry Deep Dive

Sounds complex? Think of zinc–nickel like a precisely tuned electrolytic plating process where a DC power supply co-deposits zinc and nickel onto steel. The part is the cathode, anodes complete the circuit, and the bath chemistry dictates how much nickel co-deposits with zinc to hit the target alloy. Co-deposition control is what turns a good coating into a great one for automotive duty.

Bath chemistry components and roles

In practice, the bath is not a simple nickel plating solution. It is a zinc–nickel electrolyte whose components each pull a lever on deposit composition, stress, and ductility.

| Bath component | Primary role in Zn–Ni bath | Typical monitoring | Notes or ranges from references |

|---|---|---|---|

| Zinc salts | Provide sacrificial matrix metal | Titration daily, mass balance | Zn level with Ni controls alloy co-deposition behavior |

| Nickel salts | Provide nickel for alloy strengthening | Titration daily, track Ni:total metal | Target deposit 12–15% Ni to balance corrosion resistance and stress |

| Chelating agents | Keep Ni soluble in alkaline media and stabilize metal ions | Chelate-to-total metal ratio tracking | Maintain roughly 1:1 to 1.5:1 to reduce hardness and stabilize stress |

| Buffers or alkalinity control | Maintain working pH in alkaline or slightly acidic systems | Routine pH logging | Alkaline baths rely on strong chelates; acidic baths may use ammonium or mild chelates |

| Secondary brightener and levelers | Refine grain, affect alloy composition, stress, and ductility | Hull cell panels, periodic additions | Keep below 15 g/L, preferably below 10 g/L for ductility and stress control |

| Wetting agents | Reduce surface tension and pitting, improve coverage | Visual foam check, weekly analysis | Analyze at least weekly alongside brighteners |

| Additives for stress reduction and ductility | Moderate internal stress and improve bend performance | Bent-strip stress checks, conical mandrel bend panels | Stress minimized when the deposit is about 12–15% Ni |

| Filtration and carbon treatment | Remove particulates and organics that dull or embrittle deposits | Continuous filtration, scheduled carbon treatment | Continuous 5–10 µm filtration is recommended |

These levers are interdependent. For example, raising secondary brightener can shift alloy composition, but a proper chelate-to-metal ratio can blunt that effect.

Operating window and parameter effects

How does the circuit translate to coating properties on your parts?

- Anode and cathode roles. The part is the cathode where metal ions are reduced. Many systems use nickel anodes with power supply control to drive co-deposition.

- Current density and temperature. Typical production envelopes are about 1–5 A/dm² with bath temperatures near 20–35°C. As current increases within the qualified range, thickness rises and, in some systems, internal stress can decrease.

- Agitation and solution movement. Adequate agitation promotes uniform nickel distribution, helping maintain target alloy in recesses and threads.

- Acid vs alkaline electrolytes. Acid systems favor efficiency and high deposition rate, while alkaline systems offer better throwing power and more uniform nickel at the bottom of recesses.

- pH and buffering. Strong chelates are essential in alkaline baths to keep nickel soluble and prevent precipitation, while mildly acidic systems often rely on ammonium or milder chelates.

Do not confuse a Zn–Ni bath with a standard nickel electroplating solution. The alloy bath is tuned to co-deposit two metals uniformly across your current density window to meet alloy targets set by specification. When uniformity inside deep recesses is paramount, the electroless nickel plating process is a different approach because it deposits without current and covers uniformly by chemical reduction, not by field lines.

Deposit properties and performance links

You will notice that deposit microstructure, stress, and ductility track tightly with alloy composition and additives. Research on Zn–Ni baths shows that secondary brightener and chelation strategy are dominant variables for thickness, alloy composition, and stress. Keeping the chelate-to-metal ratio around 1:1 to 1.5:1 and limiting secondary brightener below about 10–15 g/L promotes ductility and stabilizes stress. Stress has been observed to be lowest when the zinc–nickel deposit contains roughly 12–15% Ni, a zone also associated with strong neutral salt spray performance.

Practically, that means parameter drifts that push nickel out of range or upset brightener balance can show up as dull or friable deposits, higher internal stress, and cracking in bend tests long before corrosion results are available.

Environmental and waste considerations

Modern zinc–nickel lines increasingly favor non-cyanide alkaline chemistries, trivalent passivations, and closed-loop capture and reuse systems. Industry reports note that closed-loop recovery with ion exchange and membranes can cut waste generation by about 80 percent while improving cost control. Continuous 5–10 µm filtration and periodic carbon treatment also reduce rejects linked to organic contamination and particulates.

- Note on electroless options. Electroless baths avoid external power but require frequent replenishment and close monitoring of reducing chemistry to stay within spec.

Process control checkpoints

- Solution analysis cadence. Test zinc, nickel, and pH daily. Analyze brighteners, wetting agents, and impurities weekly.

- Hull cell checks. Run panels to verify alloy composition and appearance across your production current density range.

- pH and temperature logging. Record at defined intervals to spot drift before parts are at risk.

- Current density test panels. Plate witness coupons at low, mid, and high CD to validate thickness and alloy distribution before release.

- Filtration and carbon treatment. Confirm 5–10 µm filtration is continuous and schedule carbon treatment to preempt organic buildup.

- Measure what you make. Use XRF for thickness and alloy verification on test panels and first-article parts.

With these controls in place, you can tune electrolytic plating to your geometry and spec. Next, we will compare zinc–nickel to electroless alternatives so you can choose the right system for uniformity, cost, and sacrificial protection.

Choosing Between Zinc Nickel And Electroless Nickel

Stuck between zinc nickel coating and electroless nickel plating for tough automotive duty? Focus on how the finish protects, how evenly it deposits, and how it fits your downstream steps.

Selection criteria that actually matter

- Environment severity and protection mechanism. Sacrificial vs barrier behavior.

- Geometry and thickness uniformity on threads, bores, and deep recesses.

- Dimensional control and tolerances you must hold after coating.

- Hydrogen embrittlement risk and required bake steps for high strength steels.

- Post-finishes, sealers, and paintability in your coating stack.

- Total cost, throughput, and line compatibility.

- If your debate is nickel vs zinc plating or nickel plating vs zinc plating, remember Zn–Ni is not plain zinc. It is an alloy designed for durability.

Uniformity vs sacrificial protection

Electroless nickel coating deposits without current, so it builds with highly consistent thickness on edges and inside complex interiors. Thickness accuracy around ±10 percent is commonly maintained, helping hold tight tolerances Electro-Coatings uniformity overview. By contrast, zinc nickel coating protects steel sacrificially. At about 10 µm with suitable passivation, it is often specified to withstand at least 500 hours of neutral salt spray without red rust, a step change over plain zinc HR Fastener salt spray and thickness guide.

Downstream compatibility with paint and sealers

Zn–Ni systems typically pair with trivalent chromate passivations, sealants, or organic topcoats to meet automotive durability needs, and can be painted when the passivation and pretreatment are matched. Electroless nickel plating offers a smooth, uniform surface and variants for wear or lubricity. If you need uniformity in tight cavities on aluminum housings or fittings, teams often evaluate electroless nickel plating aluminum to keep recesses consistently coated.

| Attribute | Zinc–Nickel Electroplating | Electroless Nickel (Ni–P) |

|---|---|---|

| Protection mechanism | Sacrificial zinc matrix with nickel barrier effect | Barrier coating that resists corrosion by sealing the surface |

| Uniformity on complex geometry | Field-line driven. More build on edges than in recesses | Highly uniform across edges and interiors. Around ±10% thickness control |

| Dimensional control | Common at 5–10 µm in automotive. Masking and racking matter | Uniform build supports tight tolerances on critical fits |

| Hydrogen embrittlement management | Control pre-clean and activation. Post-plate bake for high-strength steels per spec | Lower risk than electroplating, but evaluate and bake when required |

| Typical post-treatments | Trivalent passivation, sealers, organic topcoats | Heat treatment for hardness. Optional PTFE or hard-particle variants |

| Corrosion benchmarking | 10 µm with passivation often targets ≥500 h NSS without red rust | Barrier performance depends on phosphorus and topcoats. Verify by ISO 9227 or ASTM B117 |

| Paintability | Good with the right passivation and pretreatment | Smooth, uniform surface. Confirm adhesion steps for your paint stack |

- Pick Zn–Ni when sacrificial protection and robust NSS hours are critical for fasteners, brackets, and underbody parts.

- Pick electroless nickel plating when you need near-net, uniform thickness inside recesses and threads.

- For mixed assemblies, consider paint stack, torque requirements, and bake constraints.

- Cleanliness at pre-plate is decisive for both systems.

Next, we map the standards and corrosion benchmarks you should call out so RFQs and supplier reports align.

Standards Mapping And Corrosion Benchmarks

Not sure how to turn a generic salt spray claim into something verifiable? Use the right test methods and clearly name the zinc nickel plating specification in your RFQ so your suppliers know exactly what to prove.

Corrosion testing methods and purpose

Neutral salt spray is the most common accelerated screen for coated steel. ASTM B117 defines the NSS method using a 5% NaCl fog with pH typically controlled near 6.5–7.2. For zinc–nickel at about 10 µm thickness, buyers frequently target at least 500 hours without red rust, and some programs test 500–1000 hours depending on thickness and post-treatments HR Fastener salt spray and thickness guidance. ISO 9227 is the international counterpart used for similar salt spray evaluations and is commonly applied to Zn–Ni parts in the same hour ranges HR Fastener salt spray and thickness guidance.

Specification mapping and what to ask for

When you say zinc nickel plating process in an RFQ, point to the governing spec and the tests you expect to see on reports. ASTM B841 specifies electrodeposited Zn–Ni alloy deposits, including composition, thickness ranges, and inspection requirements ASTM B841 catalog page. For measurement methods and related tests, the standards list below shows commonly paired methods used across automotive and aerospace programs Standards mapping list.

| Reference | What it measures | Who sets acceptance criteria | What to request from suppliers |

|---|---|---|---|

| ASTM B117 | Neutral salt spray exposure with 5% NaCl; pH control around 6.5–7.2 | Your drawing or applicable Zn–Ni specification | Salt spray report with hours tested, onset of red rust, chamber settings, photos |

| ISO 9227 | Salt spray tests in artificial atmospheres for coated metals | Your drawing or applicable Zn–Ni specification | NSS test report indicating total hours, failure criteria, and test lab details |

| ASTM B841 | Zinc–nickel alloy plating specification including composition and inspection | ASTM B841 plus buyer requirements | Certificate of conformance showing alloy content, thickness, and inspection per spec |

| ASTM B568 and ASTM B499 | Coating thickness by XRF and magnetic methods | Drawing or spec for required nickel thickness or Zn–Ni thickness | Thickness map and instrument method used, including XRF spot locations |

| ASTM B571 and ASTM D3359 | Adhesion of metallic coatings and paint overplate tape test | Drawing or OEM paint spec | Adhesion test method and rating per the specified standard |

OEM requirement alignment

Check for legacy or cross-industry callouts. For example, AMS-QQ-N-290 (qq-n-290) is a nickel plating specification and not a Zn–Ni specification, while ASTM B841 and SAE AMS2417 address zinc–nickel alloy plating Standards mapping list. In your RFQ, state the exact zinc nickel plating specification, target thickness, and test method so suppliers can align reports to your acceptance criteria.

Ask for independent lab reports, lot traceability, and a stated sampling plan so results are audit-ready.

- Document requests for RFQs and PPAP: certificate of conformance to ASTM B841, thickness and adhesion results, salt spray reports to ASTM B117 or ISO 9227, and process control logs for the Zn–Ni line.

With standards and acceptance evidence clearly named, QA can build inspection plans and records without guesswork. Next, we translate these requirements into practical inspection steps and documentation you can run from incoming through PPAP.

Quality Control Inspection And Documentation

How do you verify zinc–nickel parts from incoming through PPAP without slowing builds? Start with simple, repeatable checks. Then lock the data trail so every lot is traceable. The goal is consistency, not heroics.

Pre-plate substrate and cleanliness checks

- Confirm substrate and hardness certifications for fasteners and high-strength steels.

- Verify pre-clean and activation results. Parts must be free of oils and oxides before plating.

- Use companion panels or coupons when part geometry makes direct testing difficult.

- Check readiness and calibration tags on plating equipment and surface finishing equipment used for cleaning and activation.

- If required by the spec, record any pre-plate passivation step and the passivation equipment setup.

In-process control and recordkeeping

- Log bath pH, temperature, and lot timings at defined intervals.

- Measure coating on witness panels and first articles using XRF or magnetic or eddy current gauges. Calibrate instruments before each shift, after heavy use, or if dropped, and take at least five spot checks per sample.

- Keep traceable records of rectifier output and anode condition. Document any adjustments.

- Record passivation tank ID, solution checks, and dwell time when passivation is part of the stack.

- Attach photos of panels and first-article parts to the lot record.

Post-plate verification and reporting

- Thickness mapping by XRF or magnetic/eddy methods, with instrument ID and calibration record. Electroplated Zn–Ni coatings are commonly 8 to 14 μm in automotive programs.

- Adhesion testing per ASTM B571 using the method that best reflects service, such as tape or bend, and document observations and ratings ASTM B571 qualitative adhesion tests.

- Corrosion screens using ASTM B117 or ISO 9227 when specified. Report hours, chamber settings, photos, and failure criteria defined on the drawing.

- Hydrogen embrittlement relief baking for high-strength fasteners per ISO 4042. Bake within 4 hours of plating for parts above HRC 39, typically at 190–230°C for several hours, with small parts often ≥2 h and thick or critical parts up to 24 h ISO 4042 baking guidance.

- Verify passivation or sealers by recording passivation equipment settings, topcoat lot IDs, and appearance grading.

Sampling and acceptance

| Characteristic | Method | Frequency | Sample size | Acceptance criteria |

|---|---|---|---|---|

| Coating thickness | XRF or magnetic/eddy current per ASTM D1186, ASTM B244, ISO 2360, ISO 2178 | Incoming, first article, per lot | ≥5 spots per sample | Per drawing and ASTM B841 callout |

| Adhesion | ASTM B571 method suitable to part | Per lot and at PPAP | Per control plan | Per drawing or paint spec |

| Corrosion screen | ASTM B117 or ISO 9227 | Qualification and periodic audit | Per lab plan | Per drawing or OEM spec |

| Hydrogen relief bake | Oven chart review and timestamp | Each applicable lot | All affected parts | Per ISO 4042 and drawing |

| Passivation/sealer | Record review and appearance check | Each lot | Per control plan | Per drawing and process spec |

Standardize file names, photo evidence, and traceability IDs so audits move fast.

- Use calibrated plating equipment, document passivation equipment settings, and control passivation tank variables to reduce variability.

- Common nonconformities to watch: out-of-tolerance thickness or high variation, poor adhesion under B571, blistering after bake, patchy passivation, or missing records.

- For any nonconformity, record root cause, corrective action, rework approvals, and re-verification to the specified test method before release.

With this inspection framework in place, the next section links these controls to real automotive parts and environments so designs and coatings work together.

Automotive Applications And Design Considerations For Zinc Nickel

Designing for harsh roads and tight assemblies? When you are plating car parts, the right zinc nickel stack depends on where the part lives and how it is used. Below are practical pairings and design notes that align coating behavior with real automotive environments.

Fasteners and high-stress steels

High-strength fasteners need sacrificial protection and careful hydrogen control. For Zn–Ni fasteners, plan a hydrogen relief bake within hours of plating for parts above typical hardness thresholds, using temperatures and times that diffuse hydrogen before service. ISO 4042 guidance calls for starting the bake within 4 hours of plating, with typical ranges around 190–230°C and durations from about 2 hours for small parts up to 24 hours for thick or critical parts ISO 4042 overview. Choose a thin-film Zn–Ni passivate and add a sealer when required; apply any heated silicated sealer after baking to avoid reheating conflicts.

Chassis and underbody brackets

Underbody brackets see splash, salt, and gravel. Thin-film Zn–Ni passivates are recommended. Clear bluish passivates typically run at pH about 3.0–4.0, while black passivates run lower, about 2.0–2.5. Black passivates are almost always followed by a sealer; clear can be sealed when extra NSS margin is needed. For parts that require a hydrogen-relief bake, apply silicated sealers after the bake; organic nanoparticle sealers tolerate post-plate baking and add self-healing behavior that boosts performance PFOnline post-treatments guide.

Fluid fittings and corrosion zones

Brake and fuel line fittings live in corrosive splash zones. Published hydraulic fitting data shows Zn–Ni coatings can achieve more than 1200 hours to red rust in ISO 9227 testing, offering a high bar for durability in these areas ISO 9227 performance example. Activate Zn–Ni with a non-oxidizing acid before passivation, then seal as needed. This stack supports robust protection without excessive thickness.

Connectors and paint/basecoat compatibility

Electrical connectors and mixed-material modules need selective coverage. Use masking for contact areas and specify a thin-film passivate that balances corrosion resistance with downstream paint or basecoat. If a black aesthetic is required, plan for a sealer and verify adhesion of any paint layer over the sealed surface.

- High-strength fasteners: Zn–Ni with thin-film passivate; add sealer for severe duty. Bake per ISO 4042 and apply silicated sealers after baking. Organic nanoparticle sealers are compatible with post-plate baking.

- Underbody brackets and hangers: Zn–Ni plus clear bluish passivate for neutral appearance; add a clear sealer when corrosion margin is needed. Black passivate plus sealer for visual contrast.

- Brake and fuel fittings: Zn–Ni with pre-passivate activation, thin-film passivate, and a robust sealer to maximize hours in splash zones; target stacks referenced in ISO 9227 qualification reports.

- Electrical connectors and housings: Zn–Ni with selective masking for contacts; clear passivate for paintable surfaces; confirm that the chosen sealer aligns with adhesion steps.

Design for drainage and edge coverage, and specify masking where electrical contact is critical.

Collaborate early on racking and fixturing so sharp edges, threads, and recesses get uniform coverage with your steel plating plan. If you need the look of nickel plated steel but the sacrificial protection of an alloy, Zn–Ni is a balanced choice. With use-case stacks defined, the next section shows how to troubleshoot appearance, adhesion, or corrosion drift on the line before it reaches your customer.

Troubleshooting And Process Control For Zinc–Nickel Lines

Seeing burning or dull gray Zn–Ni deposits on the line? You will stabilize faster if you translate symptoms into causes, verify with simple tests, and correct with targeted actions. Use the playbook below to get back in control without guesswork.

Recognizing symptoms on the line

Typical on-line indicators include burning at high current density areas, dull or cloudy deposits, blisters, roughness, uneven coverage between edges and recesses, and patchy passivation color. Visual checks in both high and low current density zones, plus quick Hull cell panels, are your fastest reality check. Practical cues like excess brightener, high carbonates, and poor agitation often sit behind these symptoms in alkaline systems Pavco alkaline zinc troubleshooting.

Likely causes and quick checks

- Chemistry drift. Imbalanced metal or caustic, high carbonates, or incorrect additive balance.

- Contamination. Organics cause haze and brittleness. Metallics like copper or zinc can streak low current density areas.

- Preparation issues. Inadequate cleaning or activation leads to poor adhesion and post-bake blisters.

- Distribution problems. Excess current density, poor anode placement, or weak agitation drive burning and skip-plating.

- Surface energy and wettability. Dyne inks measure wetting tension, not surface energy, and are best used as a screening tool. Many shops aim for about 40 dynes/cm for paintable surfaces, but verify the right level for your material by functional testing Dyne inks and their limitations.

Targeted corrective actions

| Symptom | Probable causes | Diagnostic tests | Corrective actions |

|---|---|---|---|

| Burning | Excessive current density, low caustic or metal, high carbonates, poor agitation or anode layout | Hull cell across CD range; titrate key components; review agitation and anode spacing | Lower current density; restore chemistry; manage carbonates; improve agitation; reposition anodes |

| Dull or gray deposits | Organic buildup or excess brightener; metallic contamination causing LCD streaks | Hull cell appearance; trial carbon treatment; check for LCD streaking | Carbon filtration or batch carbon treatment; reduce brightener additions; dummy out metallics |

| Poor adhesion | Insufficient cleaning or activation; drag-in of oils | Cleanliness checks; simple tape pull; dyne ink screen for wettability | Strengthen cleaning cycle and rinses; re-activate; minimize drag-in between steps |

| Blistering after bake | Excess brightener or organics; inadequate pre-clean | Hull cell for over-brightness; trial carbon treatment; review pre-clean | Reduce brightener; carbon treat; re-clean and re-activate before replating |

| Patchy passivation | Skip plating in LCD from too much brightener; weak agitation; poor anode placement | Hull cell focus on LCD; visual passivate uniformity; dyne screen if paint follows | Lower brightener; increase solution movement; adjust anodes; correct metal and caustic balance |

For metallic contamination and organic control, standard nickel-bath practice offers proven tactics that translate well to electroplating operations. Guidance includes dummy electrolysis for copper or zinc contamination at low current densities, lowering bath pH for more effective dummying in nickel systems, continuous or batch carbon treatment at approximately 2 to 4 oz carbon per 100 gal for organics, and routine anode bag care including prewashing in 5% sulfuric acid with a small addition of wetting agent. These methods, along with scheduled filter maintenance, are detailed here Service tips for nickel plating baths.

Preventive controls and audits

- Establish routine solution analysis and Hull cell trending to catch drift early.

- Maintain anodes and anode bags; avoid voids, replace plugged bags, and verify placement.

- Keep filtration effective; schedule carbon treatment and change filter media before flow drops.

- Verify rectifier output and meter calibration as part of electrical maintenance.

- Audit brightener and leveler balance against Hull cell appearance, not just additions logged.

Document every bath adjustment and link it to thickness, adhesion, and corrosion results so you can learn faster and prevent repeat issues.

- Training topics to align teams: reading Hull cell panels for LCD vs HCD behavior

- Organic vs metallic contamination cues in bright nickel plating and Zn–Ni, and when to carbon treat vs dummy

- Anode bag selection and care, plus cross-training on S vs R anodes to avoid corroded nickel surprises

- Using dyne inks wisely for paint readiness and why they are not a cleanliness test

- Basics of en plating vs electrolytic lines so operators share a common language about uniformity and nickel corrosion risks

With a stable process, your next lever is supplier capability. In the next section, see how to audit and select plating partners that can maintain these controls at automotive scale.

Selecting And Auditing Your Plating Partner

Under a tight launch window and harsh service specs? The right zinc–nickel supplier can protect your timeline and your parts. Use the guide below to qualify zinc nickel platers with automotive discipline while keeping an eye on total risk and plating cost.

What to look for in an automotive plating supplier

- Automotive quality backbone. Ask for a current CQI-11 Plating System Assessment, APQP, PFMEA, and control plans. CQI-11 also expects XRF for zinc alloy thickness, hydrogen embrittlement bake logs with time stamps, and annual calibration of key test equipment such as salt spray cabinets.

- Corrosion validation. Request neutral salt spray reports run to ASTM B117 or ISO 9227 with chamber settings and hours to first red rust. Typical programs expect ~10 µm Zn–Ni with passivation to reach around 500 hours without red rust.

- Line capability. Confirm acid or alkaline Zn–Ni, rack or barrel, and whether the shop runs automatic plating with data logging. Automated plating systems can reduce labor cost and improve accuracy and throughput, which matters at scale automation and accuracy benefits.

- Test and measurement. Verify XRF thickness alloy capability, daily instrument checks, and annual calibration certificates for thickness gauges and salt spray chambers per CQI-11 expectations.

- Hydrogen embrittlement control. Look for documented time-out-of-plating to bake, time-to-temperature profiles, oven uniformity surveys, and independent review of bake logs before shipment as called out in CQI-11 tables.

- Traceability and quarantine. Review routers, barcode scans, nonconforming material controls, and record retention procedures aligned to automotive quality systems.

Pilot runs and PPAP readiness

Imagine discovering a coating drift during SOP. Better to find it in a pilot. Run first-article builds with witness coupons, XRF maps, and an agreed salt spray sampling plan. Expect evidence of feasibility, capability studies, trend charts, and reaction plans before PPAP. Keep the flow simple, especially if parts will be masked, painted, or assembled after plating.

Total cost and logistics considerations

Total cost is more than price per piece. Factor in rework risk, freight, WIP days, corrosion testing lead time, and packaging. Automation can lower labor content and stabilize quality, while waste handling and environmental controls are part of the true cost structure in industrial metal plating. Integrated stamping plus surface treatment may compress schedule risk and freight touches.

| Provider option | Certifications and systems | Zn–Ni process range | Thickness controls | Salt spray reporting | Capacity and automation | Logistics and integration | Plating cost notes | Pros | Cons |

|---|---|---|---|---|---|---|---|---|---|

| Shaoyi integrated metal processing | IATF 16949, prototypes-to-PPAP workflows | Stamping, machining, and advanced surface treatments including zinc–nickel. Verify exact line details during audit | Expect XRF for Zn–Ni alloy thickness; request calibration records | Supports corrosion testing. Ask for ASTM B117 or ISO 9227 reports | Fast turnarounds; confirm batch size and any automatic plating capability | One-stop flow with assembly options reduces handoffs | Potential total landed cost advantage via consolidated logistics; benchmark part price | Integrated services, automotive quality focus, PPAP support | Validate specific Zn–Ni line parameters and in-house vs partner test scope |

| Specialist Zn–Ni job shop | Often IATF; provide CQI-11 self-assessment | Dedicated acid or alkaline Zn–Ni; rack and/or barrel | XRF alloy verification required; daily gauge checks | Internal or partner lab. Provide method, hours, and photos | High-volume lines, frequently with automation | Plating only; coordinate external machining or assembly | Competitive per-piece pricing at volume; expedite fees may apply | Deep process focus, high throughput | More handoffs across the supply chain |

| Local industrial metal plating shop | General ISO systems; request automotive evidence | Mixed processes; confirm Zn–Ni expertise | Confirm XRF access and calibration | Usually external lab; verify sampling plan | Flexible for small lots; manual or semi-automatic | Close to plant; short freight lanes | Variable pricing; higher variance risk | Agile for prototypes and small batches | May need tighter oversight for automotive documentation |

On-site or virtual audit checklist

- Line capability. Acid or alkaline Zn–Ni, rack vs barrel, automation level, typical current density window and agitation.

- Bath monitoring. Daily zinc, nickel, pH, temperature, and Hull cell panels; weekly additive and impurity checks; filtration and carbon treatment schedule per control plan.

- Measurement and calibration. XRF for Zn–Ni alloys, thickness gauges, and salt spray cabinet with daily checks and annual calibration certificates per CQI-11.

- Hydrogen embrittlement controls. Time from plating to oven, time-to-temperature, bake duration, oven uniformity surveys, and independent review of logs before shipment.

- Traceability. Job routers, barcoding or scans at each step, hold area controls, and record retention aligning to automotive quality procedures.

- Corrective action maturity. 8D or equivalent, trend charts, and reaction plans when capability drifts.

- Post-treatments. Passivation chemistry control, sealer application parameters, and compatibility with paint or assembly.

- Environmental and waste. Documented waste handling, filtration practices, and operator PPE consistent with process risk.

If you prefer an integrated path from stamping through zinc–nickel and assembly, shortlist a provider like Shaoyi and validate capacity, recent audit results, and test reports against the same criteria. Next, grab the RFQ checklist that turns these points into a ready-to-send requirements list.

Actionable Next Steps And RFQ Checklist For Zinc–Nickel Plating

Want fewer RFQ revisions and faster approvals? Turn what you learned into a tight, testable request that any capable shop can execute.

Key takeaways on zinc–nickel for automotive

- Name the coating clearly. Use zinc nickel alloy plating and note synonyms like zn-ni electroplating and zinc-nickel plating so quality, engineering, and purchasing stay aligned.

- Separate method from acceptance. ASTM B117 is a salt spray test method used to screen coatings. It does not set pass or fail by itself; your spec does ASTM B117 overview.

- Anchor to an OEM or industry spec. For example, Ford WSS-M1P87-B2 calls for 8 µm Zn–Ni with passivate plus sealer and reports 240 h to white and 960 h to red, and GM GMW4700 defines Zn–Ni B with 10–17% Ni. Use these as templates for your acceptance language Automotive Zn–Ni specs and benchmarks.

- Hydrogen embrittlement matters. For high-strength steels, require documented bake timing and oven verification in the control plan.

- Thickness and alloy verification are non-negotiable. Ask for an XRF or magnetic gauge strategy and spot-map plan on first articles.

- Post-treatments drive durability. Specify passivation class and any sealer or topcoat and tie them to the reported salt spray hours.

Align environment severity, geometry, and downstream finishes with a coating system proven by standardized tests and capable process control.

Procurement checklist for faster approvals

- Statement of process capability for zinc nickel alloy plating, including rack or barrel and part size limits.

- Qualified zinc-nickel plating process window: pH range, temperature range, and current density envelope the supplier runs.

- Coating thickness control method: XRF or magnetic gauge plan, locations, and calibration cadence.

- Corrosion evidence: salt spray test method named as ASTM B117 or ISO 9227, target hours, and latest report if available.

- Adhesion and thickness certifications tied to your drawing and the governing spec.

- Hydrogen embrittlement mitigation for high-strength steels: time-to-bake, bake temperature and duration, and oven uniformity records.

- Passivation class and sealer details: chemistry family, dwell time, and any topcoat stack.

- Sample parts: dimensional report, finish appearance photos, and thickness map on critical features.

Next steps and who to involve

- Kickoff with design, materials, supplier quality, test lab, and your shortlisted platers.

- Pick one tough geometry for the pilot and define the witness coupon plan.

- Lock the acceptance line: alloy range, thickness, passivate class, sealer, and the salt spray method.

- Run a small-lot trial, review thickness and adhesion first, then submit to salt spray while you prep PPAP docs.

- If you need an integrated path from prototype to production for anti corrosion plating with zinc–nickel, consider a one-stop provider like Shaoyi. Request a technical review and sample build first, and compare results with at least one other qualified source.

Use this checklist to issue a clear, test-backed RFQ so capable shops can quote accurately and launch zinc-nickel plating with confidence.

FAQs on Zinc-Nickel Plating for Automotive Components

1. How corrosion resistant is nickel plating?

Nickel plating is a barrier coating, so its performance depends on thickness, porosity, and preparation. On steel, any pores can allow corrosion to start. For harsh automotive environments, zinc-nickel offers sacrificial protection that many programs prefer. Always define test methods, such as neutral salt spray, in your RFQ so results are directly comparable.

2. What is the best plating for corrosion resistance?

There is no single best choice. Zinc-nickel is typically favored for fasteners, brackets, and chassis parts because the zinc sacrificially protects steel. Electroless nickel is often selected when highly uniform thickness on complex shapes is critical. Match the coating to your environment, geometry, paint stack, and verification tests listed in your spec.

3. Why is my nickel plating rusting?

Rust can appear if the nickel layer has pores or if the substrate was not perfectly cleaned, allowing corrosive media to reach steel. Nickel is cathodic to steel, so localized attack can accelerate at defects. Improve cleaning and activation, tighten thickness control, consider an underlayer strategy, or switch to a sacrificial system like zinc-nickel when the environment is severe.

4. What is galvanized nickel alloy plating in automotive RFQs?

It refers to zinc-nickel electroplating. The term galvanized is used because zinc protects steel galvanically. You may see it listed as zinc nickel plated, zn ni plating, or znni. RFQs should also specify passivation or sealers, thickness targets, and the test methods required for acceptance.

5. How do I choose between zinc-nickel and electroless nickel for complex parts?

Start with the protection mechanism and geometry. Use zinc-nickel when sacrificial protection and robust durability are the priority. Use electroless nickel when you need uniform build inside recesses or threads. Confirm paint compatibility and hydrogen embrittlement controls for steels. If you need a prototype-to-PPAP path with stamping plus coating under one roof, consider an IATF 16949 supplier such as Shaoyi, and validate capacity and test evidence before award.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —