What Is Powder Coating? Durable And Eco-Friendly Finish For Automotive Metal Parts

What Is Powder Coating for Automotive Metal Parts

What Powder Coating Means for Automotive Metal Parts

New to finishing for auto parts? Start here. If you search what is powder coating or need a quick powder coating definition, think of a dry finish applied as a fine powder, sprayed with electrostatic equipment, then heated until it flows into a continuous, durable film Crest Coating. In automotive work, the charged powder is drawn to grounded metal parts and then cured in an oven, which is how powder coating works at a basic level Coating Systems. If you have been asking what is powder paint, you will also see it called powder coat paint or simply powder coat. In short, to define powder coating is to describe a clean, controlled way to build a resilient film on metal parts.

- Solvent free application with minimal VOC emissions, high transfer efficiency, and reclaimable overspray Prince Manufacturing.

- Robust film integrity that resists wear and environmental exposure.

- Broad finish options and textures to match branding and performance needs.

- Consistent coverage that supports repeatable appearance on metal parts.

Powder coating is a proven path to resilient, consistent metal finishes in automotive environments.

Why Powder Beats Liquid Paint for Durability and Sustainability

Compared with liquid paint, powder uses a dry, solvent free chemistry and heat to create a tougher, more resilient coating, with little to no VOC emissions and less waste from overspray reuse. Liquid painting remains useful for heat sensitive substrates or ultra thin films, but it is typically less durable and can involve solvent emissions, while powder delivers a thick, uniform, long lasting finish with wide aesthetic flexibility supported by modern chemistries.

Sounds complex? It is simpler than it looks. You will see in the next section how powder coating works in practice, from surface prep through cure, with the key controls that make results repeatable in production.

Where Powder Coating Fits in an Automotive Finish Stack

In a vehicle program, powder is often chosen as the visible protective and decorative finish on metal components. It sits alongside other finishing methods such as liquid paint or e coat, and the right choice depends on part design, material, and performance targets. This guide will map the complete journey ahead, including process steps, chemistries, quality testing, costs, safety, troubleshooting, and supplier selection, so you can specify and launch with confidence.

How Powder Coating Works Step By Step For Auto Lines

Ever watch a booth and wonder how powder coating works so consistently at line speed? Use these powder coating process steps as a practical baseline for engineers, buyers, and operations. If you are mapping how to powder coat brackets, wheels, or crossmembers, this powder coating procedure walks from prep to cure so you can tailor settings with the supplier's Technical Data Sheet (TDS).

From Surface Prep to Cure The Core Steps

- Pre clean. Remove oil, grease, dust, scale, rust, stickers, and oxides. Solvent wipe or blasting may be used to ensure a clean surface before coating Powder Vision Inc.

- Conversion treatment. Apply an iron phosphate conversion coating to boost bonding and corrosion resistance on steel and aluminum, then follow with a compatible sealant. Keep the sealer at the proper pH so the coating will adhere, and dry quickly to avoid flash rust Precision Coating Technology & Manufacturing.

- Rinse and dry. Final rinse removes pretreatment residues. Dry thoroughly so no moisture remains before spraying.

- Electrostatic application. Perform electrostatic powder coating in a clean booth. Charged powder is drawn to grounded parts for even coverage. For very thick films, fluid-bed methods can be used on suitable parts Precision Coating Technology & Manufacturing.

- Cure. Move parts into the oven and follow the powder supplier TDS for time and powder coating baking temperature. Thermosetting powders commonly cure in the 160°C to 200°C range, about 320°F to 392°F, depending on chemistry and substrate Huacai Powder Coating. Some processes report cure temperatures above 450°F for certain applications and methods Precision Coating Technology & Manufacturing.

- Cool down. Allow parts to cool so the finish stabilizes before handling or packing Powder Vision Inc.

- Inspection. Verify appearance and coverage. Confirm film integrity based on your specification and supplier guidance. Escalate detailed testing in the quality section of this guide.

Decision notes. Aluminum often benefits from thorough conversion treatment and controlled dry off. Steel preps must remove oxides fully. Choose epoxy or polyester based on exposure and performance, then lock parameters with your vendor TDS.

Electrostatics Explained In Plain Terms

Imagine the part as a magnet for powder. The spray gun charges the powder, and the grounded metal part pulls those particles across an electric field, so coverage comes from attraction rather than high air pressure. Technique matters more than push. Slow, consistent passes in a clean booth help the film build evenly and reduce defects. After spraying, the part goes to the oven so the deposited powder bonds into a resilient coating Powder Vision Inc.

- Gun voltage setup

- Powder flow and atomizing air

- Part grounding and contact quality

- Line speed and booth balance

Set these variables using the supplier TDS and verify on first-article runs.

Cure Profiles And What They Control

Thermosetting powders use heat to trigger a chemical reaction that creates a dense, durable, cross linked film. Thermoplastic powders melt, flow, and solidify on cool down without cross linking. Following the recommended cure window is what turns a sprayed layer into a continuous, resilient finish. If the oven profile deviates from the TDS, film performance and appearance can suffer. In practice, you will tune oven zones and dwell to the part mass, rack density, and specified powder coating baking temperature.

With the workflow clear, the next section helps you choose chemistries and finishes like epoxy, polyester, hybrids, and textures for the environment your parts face.

Powder Chemistries And Finish Options That Fit Auto Needs

Which powder coat finishes will survive road salt, UV, and underhood heat? Start by matching chemistry to exposure. This quick guide compares the main types of powder coating so you can specify with confidence before you cut POs.

Choosing Between Epoxy Polyester And Hybrids

| Chemistry | Core strengths | Key trade offs | UV exposure fit | Typical automotive uses |

|---|---|---|---|---|

| Epoxy | Excellent adhesion and chemical resistance | Tends to yellow or chalk outdoors | Best indoors or as a primer | Primers, underhood brackets, fasteners, service tools |

| Polyester | Strong UV resistance and color retention | Lower solvent resistance than epoxies | Good for exterior exposure | Wheels, exterior trim, racks, covers |

| Epoxy polyester hybrid | Balanced appearance with improved yellowing over straight epoxy | Not as weatherable as pure polyester | Better indoors or sheltered areas | Interior hardware, bezels, enclosures |

| Thermoplastic | Re-meltable, soft flexible surface | Less scratch resistance and limited weatherability | Generally not for harsh outdoor use | Dip coats or soft-touch where compatible |

In short, epoxy excels in adhesion and chemical resistance, while polyester stands out for UV stability and long-term color, with hybrids providing a middle ground Wintoly Coatings.

When Thermoplastic vs Thermoset Makes Sense

Sounds complex? Imagine two families. Thermosets crosslink in the oven and will not re-melt later, which underpins their durability. Thermoplastics can re-melt, offering flexibility but typically lower scratch and weather resistance, so they are rarely chosen for exterior auto duty TIGER Coatings. For engine bay or exhaust-adjacent parts, evaluate a high heat powder coat via the supplier TDS. Epoxy-based systems are often noted for relatively high temperature tolerance, but always confirm limits with your powder maker.

Textures And Metallic Effects Without Compromising Performance

- Metallic powder coat. Great for wheels and trim. Some metallics benefit from a clear topcoat to reduce fingerprinting and enhance durability, and bonded metallics help consistency on reclaim lines Powder Coated Tough.

- Textures and wrinkles. Mini tex to sand texture can add grip or a rugged look. Wrinkle effects depend on precise curing, so keep oven control tight. A textured black powder coat paint is a practical choice for brackets and crossmembers.

- Veins and hammertones. Options like a copper vein powder coat create a distinctive, patterned surface for special editions or display parts.

- Solid colors. Black powder coat remains a staple for underbody hardware, while a white powder coat finish offers a clean appearance for interior or accessory components.

With chemistry and appearance aligned, the next step is design for coating details like substrate prep, masking, and edge coverage to lock in first pass yield.

Automotive Applications And Design For Coating Success

Ever design a bracket that looked perfect on screen but came back with thin edges or trapped blisters? Small choices in geometry and prep determine how reliably your parts become powder coated sheet metal and cast components that pass Production Part Approval Process (PPAP) without surprises.

Design For Coating Tips For Complex Metal Parts

- Account for coating thickness. Powder coating typically adds 2–4 mils 0.05–0.1 mm to coated surfaces. Add clearance where film build affects fits and call out no-coat or mask zones on drawings Approved Sheet Metal.

- Design for hanging and coverage. Include mounting holes or tabs for secure hanging and avoid deep shadowed recesses that are hard to spray consistently.

- Use rounded edges and radii. Sharp edges tend to pull the coating away during cure. A small radius of at least 0.020 in (0.5 mm) helps adhesion and reduces chipping risk.

- Vent and drain. Add vent and drain holes in tubular or enclosed features so air and moisture can escape during baking to reduce outgassing .

- Specify masking where necessary. Clearly mark threads, bearing seats, or ground-bond areas that must stay bare; use tape or custom plugs during pretreat and coat.

- Control weld quality and contamination. Powder shows flaws, so minimize weld spatter and design for clean access to pre-cleaning.

Steel Aluminum And Stainless Preparation Essentials

Good prep is what turns spray into a durable system. In automotive stacks, conversion coatings are chemically applied before paint or powder to improve corrosion protection and adhesion on metals such as steel and aluminum Finishing and Coating.

| Substrate | Typical pretreatment | Design notes for coverage and fit |

|---|---|---|

| Mild or carbon steel | Phosphate conversion coating to boost adhesion and corrosion protection before coating | Plan hole sizes for 2–4 mil film build, round edges, and avoid moisture traps. These practices reduce rework on powder coated steel. |

| Aluminum | Zirconium based conversion coatings are widely adopted as a greener alternative on multi material bodies and support paint or powder adhesion | When powder coating aluminum, vent enclosed features, design for hanging access, and call out masking for conductive or mating surfaces. |

| Stainless steel | Mechanical blasting with sharp media creates the anchor profile needed for adhesion; acid etch can work but is harder to own and control Products Finishing | If you powder coat stainless steel castings for color or identification, verify adhesion with testing after blasting and mask critical fits. |

For steel powder coating lines and aluminum pretreat, consistent cleanliness before conversion is essential to achieve a strong mechanical anchor profile and reliable bonding .

Masking And Edge Coverage Best Practices

- Label mask zones in CAD and on prints so operators can apply plugs and tape where threads, grounds, or tight fits must remain bare .

- Favor generous radii over knife edges to help film wrap and hold at corners.

- Provide hanging features on non critical surfaces to keep cosmetic faces clean.

- Plan for vent and drain pathways in tubes, housings, and deep pockets.

- Common parts that benefit from powder coating in auto programs include sheet metal brackets, crossmembers, housings, and interior trim substrates. Align designs so these powder coated sheet metal components have clear hang points and mask plans.

Small DFM choices like radii, vents, and explicit mask zones do more to stabilize first pass yield than late stage tweaks.

With material prep and geometry dialed in, the next section turns these ideas into a production ready SOP with training checklists and a line layout you can run at rate.

SOP Templates, Training, And Line Layout For A Quality Powder Coating System

Standing up a powder coating setup for auto parts? Use this practical playbook to standardize your powder coating system, reduce variation, and hit rate without drama. When you select powder coating as your preferred finishing route, these steps help you launch with confidence.

Standard Operating Procedure From Pre-Clean To Inspection

- Pre-clean Purpose remove oils, soils, oxides. Methods can include hand wipe, immersion tanks, hand-held spray wands, ultrasonic cleaning, or multi-stage recirculating spray washers. Verify cleanliness using simple checks like water-break-free or white-cloth tests. See an overview of pretreatment and cleanliness evaluation methods in TIGERs guide Powder Coating Pretreatment. (Decision note choose the least aggressive method that reliably removes your soils.)

- Conversion treatment Purpose promote adhesion and corrosion resistance. Common options include iron phosphate and zinc phosphate on clean metal. Control time, temperature, concentration, and pH to maintain consistent coating quality. (Decision note select chemistry by substrate and corrosion target.)

- Rinse and dry-off Purpose prevent carryover and residues that undermine bonding. Use effective rinsing between stages and a complete dry-off before spraying to avoid defects. (Decision note increase rinse diligence after phosphate stages.)

- Electrostatic application Purpose achieve even film build. Control gun settings, powder flow, grounding, and line speed. Keep the booth clean and set parameters per powder TDS. (Decision note align gun voltage and flow with geometry and target finish.)

- Cure Purpose develop final film properties. Focus on part temperature and dwell consistency. Unsynchronized lines can cause over-bake or color issues if the conveyor stops mid-cycle, so protect stability with buffers and clear start-stop rules. (Decision note confirm cure with supplier-recommended checks.)

- Cool-down Purpose stabilize the coating before handling. Avoid stacking hot parts that could mar the surface.

- Inspection Purpose release only conforming parts. Check appearance and coverage now, then escalate to formal tests detailed in the next section. (Decision note quarantine suspect lots for review.)

- Pre-treatment checklist Soil types identified oil, oxide, weld smoke. Cleaning method selected hand wipe, immersion, spray wand, ultrasonic, or spray washer. Chemistry concentration and pH recorded. Rinse quality verified. Cleanliness checks documented water-break-free, white cloth, tape or black-light where appropriate.

- Masking checklist Mask zones marked on prints. High-temp plugs and tapes confirmed. Grounding points accessible and uncoated. Labels withstand pretreat and cure.

- Oven load and cure log Part ID and revision. Rack position and load density. Cure start and stop. Verified part-temperature profile or witness indication per TDS.

- Incoming parts acceptance Material and lot traceability. Physical damage check. Cleanliness and weld quality. Hang points present and usable.

- Final inspection report Appearance ok NG. Film thickness readings per plan. Adhesion method reference. Rework disposition and sign-off.

Operator Training Essentials And Certification Paths

What do teams need to master first? Priorities include corrosion basics, pretreatment steps, parameter adjustment, preventing defects, and quality/testing methods. Structured programs cover these topics for both operators and planners, and some offer a Certified Coater path to demonstrate process reliability IGP Powder Training. Use a mix of classroom and booth-side coaching to accelerate mastering powder coating and to keep skills current across shifts.

Line Layout And Flow For Consistent Cycle Times

Aim for a linear flow degrease pretreat → dry-off → spray booth(s) → cure oven → cool and inspect, with WIP buffers before the booth and oven. Many lines blend manual and automated powder coating, so balance operator counts with conveyor speed and product mix to prevent stoppages and over-bake events. A published case study highlights how poor synchronization between conveyor speed, labor at load unload, and varying part sizes can lead to over-cured parts and poor surface finish outcomes Finishing and Coating. Standardize rack density, gun-to-part distance windows, and start-stop rules to protect cycle time and film uniformity.

With SOPs, training, and flow locked in, the next step is proving performance. Continue to the quality section to select tests, set pass fail criteria, and sustain quality powder coating at scale.

Quality Control Methods And How To Interpret Results

Ever wonder why a finish looks good but fails in service? A simple, disciplined quality plan ties your powder coating specifications to everyday checks so you protect appearance and performance on real parts.

Critical Tests Adhesion Impact Corrosion And Hardness

| Test | What it proves | How to run it | How to read trends |

|---|---|---|---|

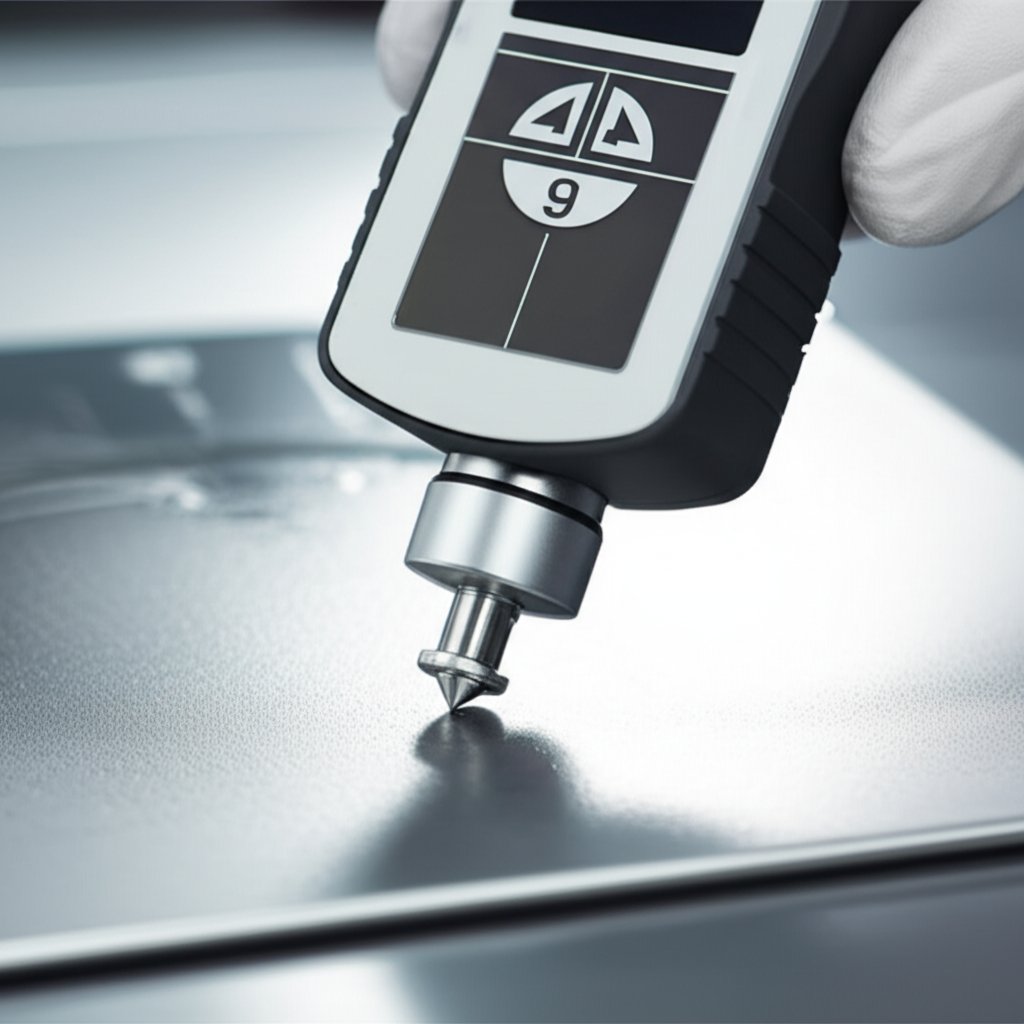

| Film thickness DFT | Coverage and consistency that drive powder coating durability | Measure with suitable gauges for your substrate | Wide variation signals risk to appearance and protection |

| Crosshatch adhesion | Bond of coating to metal | Score a lattice, apply tape, remove | Little to no removal indicates sound adhesion |

| Solvent rub cure check | Degree of cure | Rub with MEK or acetone a set number of double rubs | Softening or heavy transfer suggests undercure |

| Pencil hardness | Surface hardness and scratch resistance | Use graded pencils per a defined method | Reach required grade without cutting through |

| Impact resistance | Resistance to cracking from sudden load | Direct and reverse impact methods | Excessive film build can reduce impact performance |

| Corrosion exposure | Protective system performance | Salt spray or similar exposure tests | Use as a system check with pretreat and cure |

| Gloss | Appearance and consistency | Gloss meter against standard | Deviations may indicate cure or texture variation |

These methods align with widely used powder coating specification standards, including ASTM D3359 adhesion, ASTM B117 salt spray, ASTM D523 gloss, ISO 2409 adhesion, ISO 9227 salt spray, and ISO 1519 flexibility Houston Powder Coaters.

Measuring Film Thickness The Right Way

How thick is powder coating and how thick is powder coat supposed to be on your part? The honest answer is only as thick as your spec and process control can hold. Focus on dry film thickness DFT, measured non destructively with the right method for the substrate, such as magnetic induction on steel, eddy current on nonmagnetic metals, or ultrasonic where needed. Define a practical DFT range, calibrate gauges, and sample across complex geometries. Many programs also apply the 90:10 rule for acceptance, in which 90 percent of readings meet or exceed nominal and the remainder do not fall below 90 percent of nominal Elcometer.

Setting Pass Fail Criteria Based On Application

Start with the powder TDS and your drawing. Then verify the three fundamentals in your powder coating painting workflow. First, DFT within range. Second, cure verified by a solvent rub. Third, adhesion via crosshatch. A pencil hardness check adds confidence. For example, many teams use defined MEK double rubs for cure confirmation, and target top-tier crosshatch ratings when pretreat is sound and cure is correct IFS Coatings. For underbody parts, elevate corrosion testing because road exposure is harsher than interior trim. Tie acceptance criteria to the intended service and the full system pretreat plus powder coating material and cure.

- Sampling plan measure multiple locations per part and per lot, focusing on varied geometries.

- Gauge control calibrate and verify zero before shifts and record results for audits.

- Traceability log lots, racks, oven setpoints, and dwell to connect results to causes.

- Cure discipline check oven performance and part temperature profiles before changing settings.

- Escalation define when a visual concern triggers DFT, adhesion, or solvent rub tests.

DFT control, cure verification, and adhesion testing are the non negotiables of a robust spec.

With QC locked in, move next to safety, environmental compliance, and waste management to keep your line clean, safe, and audit ready while you coat at rate.

Safety, Environmental Compliance, And Waste Management For Powder Coating Technology

Running at rate and staying audit ready can feel like a juggling act. Sounds complex? Use these safety and environmental checkpoints to protect people, equipment, and the finish while meeting regulatory expectations.

Core Safety Practices For Booths And Ovens

- PPE and respiratory protection. Follow OSHA regulations for respirators, hazard communication, ventilation, and PPE, and keep fit testing and training current OSHA guidance summary.

- Grounding and static control. Ground all conductive objects and personnel in the spray area. Keep resistance at or below 1 megohm, and control ignition sources per NFPA guidance NFPA 33.

- Ventilation interlocks. Exhaust must operate whenever spraying occurs, and spray equipment should not run unless fans are on. This confines vapors and combustible dust to the spray area.

- Automated line safeguards. Use listed optical flame detection that reacts rapidly and triggers conveyor stop, shuts down ventilation and application, and de energizes high voltage elements. Provide accessible emergency shutdown stations.

- Oven and hot surface safety. Set high temperature limits and interlocks before heat is applied. Train teams on burn hazards and safe entry procedures if oven access is required.

- Housekeeping for combustible dust. Prevent powder build up on ledges, beams, and floors. Use approved vacuum methods for hazardous locations, keep the powder coating surface clean, and post NO SMOKING OR OPEN FLAMES signs.

- Emergency readiness. Train on lockout tagout, eyewash and e stop locations, evacuation routes, and spill response. Post simple one page response plans at the booth and oven.

Air Filtration, Waste Handling, And Housekeeping

- Filtration and recirculation. Recirculate exhaust air only when particulate filters and vapor monitors are in place and set to alarm and automatically shut down the spray operation if concentrations approach unsafe levels. Heating of recirculated air must be downstream of filters and monitoring.

- Powder recovery and ducting. Maintain airflow and reclaim equipment so air suspended powder stays confined to the booth and recovery system. Keep reclaim hoppers grounded.

- Spill clean up. Remove ignition sources, use non sparking tools, and avoid compressed air for cleanup unless inside a booth or vented area with exhaust on. Keep ventilation operating during cleaning.

- Waste and emissions compliance. Keep manifests for waste disposal and align with applicable regulations. Automotive programs should document how their coating line meets EPA requirements for hazardous air pollutants and VOC control EPA NESHAP for automobile and light duty truck surface coating.

- Water and pretreat. Maintain pretreatment baths and rinses, and consider closed loop rinse where feasible to reduce discharge. Log chemistry checks and filter changes.

Powder systems support sustainability goals on VOC and HAP, but robust safety procedures remain mandatory.

Regulatory Considerations And Documentation

- SDS and training. Maintain a current SDS library, Hazard Communication training records, and posted PPE requirements at points of use.

- Respiratory program. Keep respirator selection, medical clearance, and fit test logs up to date.

- Equipment inspections. Record booth and oven interlock checks, ventilation performance, optical flame detector tests, sprinkler or suppression inspections, and grounding continuity verification.

- Maintenance records. Track reclaim system service, filter changes, oven calibration, and fan maintenance to stabilize performance and reduce risk.

- Waste documentation. Retain manifests and spill logs. Review disposal practices against local expectations.

Wondering can you powder coat plastic? This guide focuses on powder paint for metal in automotive. Powder coating plastic or any plastic coating for metal assemblies that include nonmetallic inserts requires separate process and safety review with your supplier. Many teams simply note plastic powder coating as out of scope during PPAP to avoid confusion.

With safety and environmental controls in place, you will detect issues sooner and recover faster. Next up, a troubleshooting matrix to diagnose defects, repair the finish, and prevent recurrence.

Troubleshooting Defects And Repairing Powder Coats

See orange peel or rough patches on powder coated metal after cure? Sounds complex? Use this quick matrix and repair workflow to isolate the root cause, fix it fast, and prevent repeat defects without guesswork.

Defect Diagnosis Matrix For Fast Root Cause Isolation

| Defect | Likely causes | Immediate corrective actions | Preventive measures |

|---|---|---|---|

| Orange peel or grainy film | Low or high film build, poor grounding, mis-set kV or powder flow | Verify ground and contact, correct kV and flow, adjust film build | Clean racks/hooks, follow TDS film window, keep booth stable |

| Faraday cage thin corners or recesses | Internal corners pull charge away, low flow, gun too far, reclaim too fine | Increase flow, target recesses, optimize gun-to-part distance, consider light preheat | Orient parts for access, maintain virgin-to-reclaim ratio, design for coating |

| Back ionization in powder coating | Overcharging or over-application, high kV and microamps, lingering passes | Lower kV and microamps, increase gun distance, lighten passes | Monitor current, step coat complex shapes, train for consistent film build |

| Spitting or surging | Over-fluidization, tip buildup, worn pumps or long/kinked hoses, moisture in air | Clean tip and electrode, fix hoses, dry the air, reset hopper fluidization | PM schedule, air dryers/filters, replace worn parts |

| Poor thickness or coverage | Bad ground, wrong settings, tight rack spacing, part presentation, humidity swings | Clean hooks, correct spacing, tune flow and passes, stabilize booth | Verify ground continuity, standardize setup, control environment |

| Sagging or icicles | Excess film or overheated substrate before cure | Strip and recoat, reduce flow, avoid excessive preheat | Hold film to TDS, use lighter multiple passes on heavy sections |

| Pinholes or foaming | Trapped gas or moisture, overly thick film | Lower film build, adjust oven settings or line speed, ensure parts are dry | Thorough dry-off, sensible film targets, consistent cure |

Wondering does powder coated steel rust? If Faraday areas or edges are left thin or bare, those spots become more vulnerable to corrosion, so coverage matters IFS Coatings.

Repair And Recoat Workflows That Protect Performance

- Evaluate feasibility. Confirm the defect can be repaired without harming function or tolerances.

- Prepare the surface. Remove loose material by wire brush or sanding. Smooth rough areas, then blow or wash off dust. Dry completely.

- Adjust for a second coat. Reduce amperage to around 20–40 microamps, increase powder flow by about 10%, and move the gun 1–2 inches farther. Maintain a constant distance, recoat the full A surface, then cure per the normal cycle. Some powders need light sanding to aid intercoat adhesion Products Finishing.

- Reinspect. Verify appearance and coverage before release.

If you are painting powder coated metal as part of the repair, the same surface prep and light sanding guidance applies. These adjustments are a practical guide on how to do powder coating on metal during rework.

Preventive Controls To Stabilize Your Finish

- Grounding and cleanliness. Keep metal-to-metal contact at hooks and racks clean. Document ground checks per shift.

- Environment and distance. Control humidity and temperature to steady ranges, manage virgin-to-reclaim ratio, and keep sensible gun-to-part distance for uniform coverage. Typical guidance includes about 40% to 60% relative humidity, 70° ± 10°F storage/application conditions, and roughly 8–10 inches on automatic lines or 6–10 inches by hand per experience-based tips in the same guide above.

- Standardize setup. Lock in spray on powder coat settings for kV, microamps, flow, and patterns by part family.

- Equipment discipline. Prevent buildup at tips and electrodes, avoid over-fluidization, dry compressed air, and replace worn pumps or venturis.

- Presentation. Space parts to avoid electrostatic competition and orient complex geometries for access.

- Track and learn. Log rework by defect to spot patterns and stabilize your powder coated paint results.

Use this matrix and your rework logs to cut variation now, then carry those numbers into the cost and ROI model next to see how fewer defects lift throughput and margins.

Cost And ROI Framework For Automotive Programs

When your CFO asks which route is cheaper over the program life, how do you answer with confidence? Use this neutral, modular model to compare powder and liquid for real automotive coating applications without guessing.

Powder Vs Liquid Cost Drivers You Must Model

| Category | Example cost drivers | What to capture | Where to get data | Notes |

|---|---|---|---|---|

| Materials | Powder $ per lb, first pass transfer efficiency, overspray reclaim rate, color change losses | Price by color, target film build, reclaim compatibility, expected waste during color changes | Supplier quote and TDS, line trials | Powder can reach high transfer efficiency and reuse overspray, which reduces waste and material spend PBZ Manufacturing. |

| Labor | Pre-clean, masking, hanging, spray time, inspection, rework | Time per task by part family, training level, shift coverage | Time studies, pilot runs | Design-for-coating can cut masking minutes and touch-time. |

| Equipment amortization | Booths, ovens, washers, reclaim units, powder coater machine, racking | Capex, expected life, maintenance plan, utilization | Capex quotes, accounting schedules | Compare a manual cell vs a conveyorized powder coat system at the intended rate. |

| Energy | Oven load density, cure cycles, pretreat heating, compressed air, fans | Energy per batch or per hour, line speed, oven and tank setpoints | Utility meters and bills, process logs | Map energy inputs by process block to find intensity and savings opportunities Advanced Energy. |

| Quality | First-pass yield, rework rate, scrap, thickness variation | Defect Pareto, recoat labor, strip and reprocess costs | QA database, NCR records | Stable cure and DFT lower rework and protect your powder coat finish. |

| Compliance | Waste handling, filters, wastewater, reporting | Disposal fees, filter change intervals, bath maintenance | EH&S logs, vendor service records | Include reclaim filter service and pretreat chemical management. |

How To Populate The Cost Sheet With Supplier Data

- Materials. Ask powder coating manufacturers and industrial powder coaters for price by color, recommended film build, reclaim guidance, and color change procedures. Model FPTE and reclaim based on your system type, because cyclone vs cartridge reclaim behaves differently for utilization Products Finishing.

- Process and energy. Record wash tank temperatures, dry-off and cure oven temperatures, and line speed. Build a simple process block diagram to align energy inputs with each step and to evaluate intensity per part or per hour Advanced Energy.

- Labor. Time pre-clean, masking, and spray passes by part family. Note changeover minutes and cleaning time between colors.

- Quality. Pull rework and scrap history by defect. Tie defects to cost of labor, material, and delay.

- Compliance. Add waste manifests, filter changes, and bath maintenance to the sheet. Use placeholders until you have invoices.

Tip. Compare powders by cost per applied square foot, not just $ per lb, since application and recovery characteristics drive real spend Products Finishing.

Interpreting Rework, Energy, And Throughput Impacts

- Compare per-part cost at line-rate throughput. Underestimate WIP buffers and you will misread oven dwell and energy intensity.

- Isolate masking labor. A small design tweak that eliminates a mask zone can beat any material discount at scale.

- Evaluate energy per batch vs continuous flow. Oven load density and cure stability often move total cost more than unit price.

- Model color-mix scenarios. Frequent color changes increase purge and downtime. Capture that drift in utilization and labor.

- Stress utilization. Higher first pass transfer efficiency and well maintained reclaim systems reduce material cost and waste.

Build the comparison with real quotes, TDS data, and measured times, then run scenarios for your most critical coating applications. Next, apply this framework to shortlist partners and validate fit with trials across both in-house lines and qualified suppliers.

Selecting A Trusted Partner For Automotive Powder Coating

Ready to turn your spec into stable, at-rate production? Choosing the right supplier for powder coating auto parts is a strategic lever for quality, speed, and risk. Use this checklist to compare providers for automotive powder coating without guesswork.

What To Look For In An Automotive Grade Powder Partner

- Quality system and automotive discipline. Prioritize IATF 16949 readiness, APQP and PPAP capability, and proof of thickness control. Many programs require coaters to submit a 30-piece thickness capability study during PPAP Marwood Supplier Requirements Manual.

- Experience, certification, insurance, and turnaround. Look for a proven portfolio, ISO 9001 certification, clear product liability insurance, and defined lead times to protect schedules Keystone Koating selection tips.

- Pretreatment and chemistry breadth. Confirm in-house pretreat options and support for the chemistries you need, from epoxy primers to exterior polyester systems for vehicle powder coating.

- Application and cure control. Ask about oven profiling, racking standards, color change procedures, reclaim practices, and first-article runbooks for car powder coating.

- Inspection capability. Verify on-site gauges and methods for DFT, adhesion, gloss, impact, and corrosion checks with documented calibration.

- Throughput at your takt. Review rack density, booth count, color-mix impacts, and changeover plans tied to your product mix.

- Traceability and compliance. Ensure lot traceability, PPAP documentation readiness, and restricted-substance controls aligned with automotive expectations.

- Packaging and handling. Require mar-resistant packaging, labeling, and transport plans that preserve finish quality.

From Prototype To Production How To Scale Without Surprises

Sounds complex? It gets simpler when the same team supports DFM, samples, and production. Providers with end-to-end metal capability can reduce interfaces and lead time risk. For example, Shaoyi offers rapid prototyping, stamping and machining, powder coating and other surface treatments, assembly, and IATF 16949 certified quality under one roof. That integrated route helps you lock racking, cure windows, and thickness control early, then carry them forward for powder coating for cars at line speed.

Action Plan And Resources To Get Started

- Define requirements. List parts, substrates, target DFT windows, appearance standards, test plan, annual volumes, and PPAP level for powder coating car parts.

- Shortlist suppliers. Compare metal powder coaters on certifications, automotive references, pretreat options, inspection labs, and capacity for your mix of geometries.

- Run sample trials. Request coated samples with thickness maps, oven profiles, and inspection reports that reflect your real racks and colors for vehicle powder coating.

- Evaluate results at rate. Compare first-pass yield, rework paths, color-change downtime, and responsiveness during schedule shifts.

- Select on capability and discipline. Award business to the partner that demonstrates stable process control, clear documentation, and fast communication for car powder coating.

With a structured checklist and trial-first approach, you will reduce risk and reach consistent, production-ready finishes across your program.

Powder Coating Automotive FAQ

1. What is the eco friendly metal coating?

Powder coating is a low VOC, solvent free finish for metal parts. The dry powder is electrostatically applied and overspray can be reclaimed, which cuts waste while delivering a durable film suitable for automotive environments.

2. How long does powder coating last on metal?

Service life depends on pretreatment quality, powder chemistry, film thickness control, cure discipline, and exposure. Exterior parts typically use UV stable polyester systems, while primers and interior parts may use epoxy or hybrids. Keeping dry film thickness within spec and verifying cure and adhesion during production helps extend durability.

3. What are the basic powder coating process steps for car parts?

A practical sequence is pre clean, conversion coat, rinse and dry off, electrostatic spray, oven cure per the powder supplier TDS, cool down, and inspection. Key variables include gun voltage, powder flow, grounding, and line speed, which should be set with supplier guidance and first article runs.

4. Which powder coating finish should I use for wheels, brackets, and interior trim?

Use polyester for UV exposed parts such as wheels, epoxy as a primer or for interior and non UV areas, and hybrids when balanced properties are needed. Textured black is common for brackets, metallics and veins add style for visible parts, and high heat formulations are evaluated for engine bay or exhaust adjacent locations per TDS.

5. How do I choose a supplier for powder coating car parts?

Prioritize IATF 16949 readiness, PPAP capability, pretreatment options, cure control, and an on site inspection lab. Request sample runs with thickness maps and oven profiles, then compare first pass yield and changeover performance at rate. For integrated prototyping to production under one roof, consider an automotive ready partner such as Shaoyi for metal processing, powder coating, and assembly support at https://www.shao-yi.com/service.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —