What Is Electroless Nickel Plating: Process, Control, Fixes

Electroless Nickel Plating In Plain Language

Plain Definition of Electroless Nickel Plating

What is electroless nickel plating? In simple terms, it’s a process where a layer of nickel alloy—usually nickel-phosphorus (Ni-P) or sometimes nickel-boron (Ni-B)—is deposited onto a metal or non-metal surface using a chemical reaction, not electricity. This means no wires, no external power supply, and no complicated setups. Instead, the part is immersed in a carefully formulated chemical bath, where nickel ions are reduced and bond directly to the surface, creating a uniform nickel finish.

If you’ve ever wondered what is nickel plating in general, the main idea is to protect parts from wear and corrosion, or to enhance their appearance. Electroless nickel plating stands out because it’s autocatalytic: the reaction keeps going as long as the solution is fresh and the surface is properly prepared. That’s why you’ll find electroless nickel used in everything from precision gears and molds to kitchen hardware and electronics.

How It Differs From Electroplating

Sounds complex? Imagine two different ways to coat a part. With electrolytic nickel plating (the traditional method), an electric current is required to move nickel ions onto the surface. This means that areas closer to the electrodes get more nickel, while recesses and edges often get less. As a result, the coating can be uneven—thicker on flat surfaces, thinner in corners or deep holes.

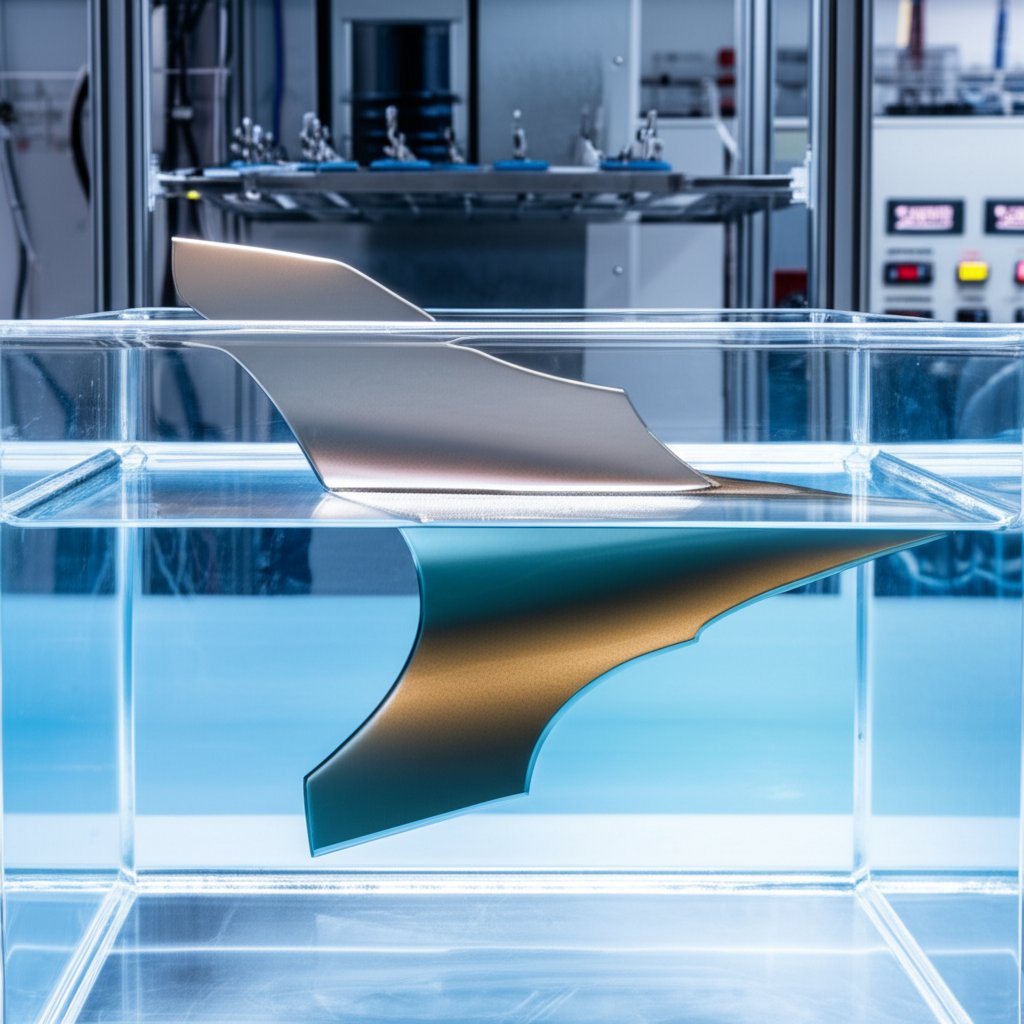

Electroless plating, on the other hand, doesn’t rely on electricity. The chemical reaction deposits nickel evenly across every exposed surface, no matter how complex the shape. That means even internal bores, threads, and intricate features get a consistent, protective layer. For many engineering and industrial applications, this uniformity is a game-changer.

Key Properties and Why They Matter

So, why choose electroless nickel plating? Here are the top benefits you’ll notice right away:

- Uniform thickness—even on complex geometries and internal surfaces

- Excellent corrosion resistance—especially with high-phosphorus EN, which is amorphous and resists attack from water, salt, and many chemicals

- Enhanced wear resistance—protects moving parts and extends service life

- Dimensional control—critical for precision components where every micron counts

- Attractive, customizable finish—from matte to bright, depending on the formulation

After heat treatment, electroless nickel can become even harder, making it suitable for molds and wear components. However, increasing hardness through heat can reduce corrosion resistance, so it’s important to match the process to your needs. The finish is smooth and consistent, ideal for parts that require both performance and a professional appearance.

EN isn’t one-size-fits-all. By adjusting the phosphorus content (low, medium, high), or using alternatives like nickel-boron or PTFE co-deposits, the properties of the coating can be tailored for different environments—whether you need more corrosion resistance, better wear, or added lubricity.

Electroless nickel plating delivers a uniform, corrosion-resistant, and wear-protective nickel finish—especially where precision and durability matter most.

In summary, if you need a coating that’s reliable, consistent, and versatile, electroless nickel plating is often the right choice—especially when compared to electrolytic nickel plating for complex or high-performance parts.

How The Electroless Nickel Plating Process Works Step By Step

When you hear about the electroless nickel plating process, it might sound like a mysterious chemistry experiment. But in practice, it’s a carefully controlled sequence of steps—each one essential to achieving a high-quality, uniform nickel coating. Let’s break down the workflow so you can see how the magic happens, from raw part to finished product.

Surface Preparation and Activation

-

Incoming Inspection & Pre-Cleaning

- What to check: Inspect for visible damage, contamination, or incorrect parts. Confirm material type and surface condition.

-

Degreasing & Alkaline Cleaning

- What to check: Ensure all oils, greases, and shop residues are removed. Test for a water-break free surface (water should sheet evenly, not bead).

-

Acid Etching & Surface Activation

- What to check: Look for uniform dulling or etching—no shiny or dark spots. For non-conductive or passive metals, confirm proper activation (sometimes via proprietary activators or double-zincate for aluminum).

Thorough surface preparation is non-negotiable. Imagine painting over a dirty wall—skipping this step leads to poor adhesion and coating defects.

Autocatalytic Deposition Chemistry

-

Immersion in Electroless Nickel Solution

- What to check: Confirm bath chemistry—nickel ion, reducing agent (usually sodium hypophosphite), complexing agents, stabilizers, and surfactants are within supplier-specified ranges.

- Monitor bath temperature (typically 85°C to 95°C) and pH (usually between 4 and 6), as recommended by bath formulation.

- Ensure agitation and filtration are active to prevent particulates and maintain uniform deposit.

- Check part fixturing—ensure all surfaces are exposed and solution can flow freely.

-

Electroless Deposition

- What to check: Monitor plating rate and dwell time to achieve target thickness. Watch for gas evolution (bubbling) and surface appearance—uniform, smooth, and defect-free is the goal.

- Track bath age, lot numbers, and replenishment events in a logbook for traceability and process control.

The electroless plating process relies on an autocatalytic reaction: the reducing agent (often hypophosphite) donates electrons, allowing nickel ions to deposit as metallic nickel-phosphorus alloy onto the activated surface. This reaction continues as long as the chemistry is balanced and the surface remains catalytic.

Post Treatment and Quality Gates

-

Rinsing and Neutralization

- What to check: Use deionized water for thorough rinsing between steps. Confirm no chemical carryover—residues can cause stains or corrosion later.

-

Heat Treatment or Baking (if required)

- What to check: Verify oven temperature and dwell time per process specification. Heat treatment can increase hardness or relieve hydrogen stress in the deposit.

-

Final Inspection and Measurement

- What to check: Inspect for coverage, uniform thickness, adhesion, and appearance. Measure deposit thickness and confirm it meets requirements.

Strict cleanliness, careful bath control, and disciplined rinsing are the main defenses against contamination and drag-out losses in the electroless nickel process.

Remember, every electroless nickel plating procedure must be tailored to the specific substrate, geometry, and end-use requirements. Bath temperature and pH can vary by chemistry—always follow your supplier’s technical data sheets for exact control windows.

Keeping a detailed logbook is essential for traceability and process improvement. Track:

- Lot numbers and part IDs

- Bath age and chemical additions

- Temperature, pH, and solution levels

- Replenishment and maintenance events

By following a disciplined electroless nickel plating process, you’ll achieve consistent, high-performance coatings—ready for demanding applications. Next, we’ll explore how to choose the right EN variant for your engineering needs.

Electroless Nickel Selection Guide For Engineers

Choosing Phosphorus Content

When you’re faced with selecting the right electroless nickel coating for your application, the first question is: what level of phosphorus should you specify? The answer shapes performance in terms of corrosion resistance, hardness, solderability, and even magnetic response. Let’s break down the main categories:

- Low phosphorus (2–4% P): Delivers the highest as-plated hardness and wear resistance, making it a go-to for abrasive environments and situations requiring good solderability or conductivity. These coatings excel in alkaline or caustic conditions but are less resistant to acids.

- Medium phosphorus (5–9% P): The industry’s workhorse, balancing corrosion resistance, hardness, and appearance. Mid-P electroless nickel coatings are widely used for general engineering, automotive, and electronics applications.

- High phosphorus (10–13% P): Known for their amorphous structure, these coatings are extremely corrosion resistant—especially in acidic or neutral environments—and are essentially non-magnetic. They’re ideal for oil & gas, chemical processing, and food industry equipment.

| EN Variant | Phosphorus/Boron Content | Corrosion Resistance | Hardness (as-plated / after heat treatment) | Magnetic Properties | Solderability | Typical Applications |

|---|---|---|---|---|---|---|

| Low-P Ni-P | 2–4% P | Best in alkaline; fair in acid | High / Increases with heat | Magnetic | Excellent | Pump rotors, fasteners, valves, molds |

| Mid-P Ni-P | 5–9% P | Good all-around | Medium-high / High after heat | Low-magnetic | Good | Precision shafts, automotive parts, electronics |

| High-P Ni-P | 10–13% P | Excellent in acid/neutral | Medium / Highest after heat | Non-magnetic | Moderate | Chemical process equipment, oil & gas valves, food machinery |

| Nickel-Boron | 1–5% B | Lower than Ni-P | Very high as-plated | Magnetic | Excellent (low-B) | Electronic contacts, wear parts, bondable finishes |

| Ni-P/PTFE Composite | 10–12% P + 15–25% PTFE | Good (depends on matrix) | Lower than pure Ni-P | Non-magnetic | Moderate | Molds, release surfaces, sliding components |

Note: Electroless nickel plating hardness values for Ni-P typically range from 500–720 HK100 as-deposited, rising to 940–1050+ HK100 after heat treatment for high phosphorus electroless nickel.

When To Consider Ni-B or PTFE Co-Deposits

Ever wonder if you need something beyond standard electroless nickel phosphorus plating? Nickel-boron coatings stand out for their exceptional as-plated hardness and electrical conductivity, making them ideal for electronic contacts and bondable layers. On the other hand, if your parts require low friction and easy release—think molds or moving assemblies—Ni-P with PTFE co-deposits offers a slick, self-lubricating surface. These electroless nickel coatings are especially useful for applications where wear and lubricity are critical, but pure Ni-P may not deliver the required performance.

- Nickel-boron coating: Electronic connectors, high-wear tools, solderable pads

- Ni-P/PTFE composite: Injection molds, food processing rolls, sliding bushings

Heat Treatment Effects and Tradeoffs

Here’s a practical tip: heat treatment can dramatically boost electroless nickel plating hardness—especially for high phosphorus electroless nickel plating. For example, as-plated Ni-P may reach 500–720 HK100, but after heat treatment, high phosphorus deposits can exceed 940 HK100, rivaling hard chrome. However, this boost comes with a tradeoff: heat treating, particularly at higher temperatures, can increase porosity and slightly reduce corrosion resistance, especially in high phosphorus electroless nickel coatings (Nickel Institute).

- For maximum wear resistance, heat treat Ni-P or Ni-B coatings as specified.

- If corrosion resistance is your top priority, avoid excessive heat treatment for high phosphorus electroless nickel.

Specifying the right electroless nickel variant—by phosphorus or boron content, and considering heat treatment—ensures your coating delivers the optimal balance of hardness, corrosion resistance, and functional performance.

Still not sure which electroless nickel coating suits your part? Imagine the next step: preparing your substrate to ensure lasting adhesion and performance. That’s what we’ll tackle next.

Surface Preparation, Adhesion, and Masking Essentials for Electroless Nickel Plating

Getting Aluminum Ready for EN

When you want to maximize the performance of nickel plated aluminum, the secret is in the prep. Aluminum’s natural oxide layer is a double-edged sword: it protects against corrosion, but it also makes direct plating tricky. That’s why electroless nickel plating aluminum always starts with a sequence of cleaning, etching, and activation steps designed to ensure lasting adhesion and a flawless nickel finish.

Do this:

- Thoroughly degrease and clean using an alkaline cleaner or ultrasonic system—no oil or dust should remain.

- Etch in an alkaline solution (like sodium hydroxide) to strip the oxide and roughen the surface for better mechanical bonding.

- Desmut in a nitric or sulfuric acid bath to remove residues left after etching.

- Apply a zincate treatment to replace the oxide film with a zinc layer, which acts as a bridge for the nickel deposit.

- For critical applications, use a double zincate cycle: strip the first zinc layer and reapply to further boost adhesion.

- Consider a thin electrolytic nickel strike before the electroless step if maximum adhesion is needed.

Avoid this:

- Skipping any cleaning or activation step—residues or oxides can cause poor adhesion or peeling.

- Allowing the cleaned aluminum to sit exposed—re-oxidation can occur in minutes.

- Under-etching or over-etching, which can lead to smut formation or excessive roughness.

Following these steps ensures electroless nickel plating on aluminium delivers consistent, high-quality results for automotive, aerospace, and electronics parts.

Stainless, Copper, and Tool Steel Nuances

Not all substrates are created equal. Each material demands a tailored approach for reliable copper and nickel plating or coating for stainless steel surfaces.

Nickel Plating Stainless Steel – Do this:

- Degrease and clean thoroughly to eliminate oils and contaminants.

- Activate the surface—often with a mild acid or proprietary activator—to remove passive oxide layers.

- Rinse promptly to prevent re-passivation.

- Consider a Wood’s nickel strike for challenging alloys before electroless plating.

Nickel Plating Stainless Steel – Avoid this:

- Leaving parts exposed after activation—stainless can quickly re-form oxides.

- Using incompatible cleaning agents that may leave films or residues.

Copper and Tool Steel – Do this:

- Degrease and alkaline clean as with other substrates.

- Acid activate (for copper, often with sulfuric acid; for tool steel, with hydrochloric or proprietary activators).

- Rinse thoroughly and proceed directly into the electroless bath to avoid flash rust or oxidation.

Copper and Tool Steel – Avoid this:

- Allowing parts to air-dry between steps—moisture can cause stains or corrosion.

- Neglecting to check for entrapped soils in holes or threads.

Proper sequencing for each material is the foundation of robust copper and nickel plating and a durable nickel finish on stainless steel or aluminum.

Masking and Selective Plating Tactics

Ever need to protect certain areas from being coated? Masking is essential in electroless nickel plating, especially for complex assemblies or when only specific surfaces need treatment. The right masking strategy prevents unwanted nickel buildup and ensures sharp edge definition without damaging the EN layer upon removal.

Common Masking Materials:

- Stop-off lacquers (quick-drying vinyl or acid-resistant varieties)

- Waxes (for high-temperature or low-temperature cycles)

- Pressure-sensitive tapes (plastic, glass, or metal foil types)

- Permanent rubber or plastic plugs, caps, and custom jigs

Rules of Thumb for Masking:

- Apply multiple coats of lacquer or wax for full coverage—let each layer dry thoroughly.

- Trim wax while it’s warm for clean borders and easy removal after plating.

- Choose tape thickness and adhesive based on solution chemistry and part geometry.

- For permanent masks, ensure a snug fit and chemical compatibility with all process steps.

- Remove masking promptly after plating to avoid hard-to-clean residues.

Complex part fixturing is also vital—jigs should allow solution flow to all surfaces and minimize air entrapment, which can cause skip plating or voids.

Always verify adhesion after plating using standardized test methods—this ensures your nickel plated aluminum or other substrate meets quality standards before moving to the next process step.

Understanding the unique preparation and masking needs of each substrate is the key to getting the most from your electroless nickel plating process. Next, we’ll dive into how to specify, inspect, and document your coatings for reliable, repeatable results.

How to Specify and Inspect Electroless Nickel Plating

Which Standards Apply and When

Ever wondered how to ensure that your electroless nickel plating meets industry expectations every time? The answer lies in standards like ASTM B733, AMS-C-26074, and AMS 2404. These documents define the essential requirements for electroless nickel plating thickness, deposit quality, and inspection protocols, making them the backbone of purchase orders and engineering drawings across aerospace, defense, electronics, and industrial sectors.

Let’s break down what each standard brings to the table:

| Standard | Typical Use | Key Clauses/Notes | Common Tests |

|---|---|---|---|

| ASTM B733 | General industry, electronics, oil & gas, medical, tooling | Defines types by phosphorus content (Type I–V), classes by heat treatment, and service conditions by thickness (SC0–SC4) | Thickness (XRF, magnetic, coulometric), adhesion (bend/impact/thermal shock), porosity (ferroxyl, boiling water), hardness (microhardness) |

| AMS-C-26074 | Aerospace, defense, space, electronics, oil & gas | Classes by heat treatment, grades by phosphorus content, strict documentation and uniformity, enhanced for severe environments | Thickness (non-destructive), adhesion (pull, bend), hardness, corrosion resistance, visual inspection |

| AMS 2404 | General-purpose aerospace, automotive | Technically equivalent to AMS-C-26074 and recommended for new designs | Thickness, adhesion, visual, hardness (as required) |

Each standard categorizes coatings by phosphorus content—low, medium, or high—and sets out minimum and maximum nickel thicknesses, heat treatment classes, and test methods. For example, ASTM B733 specifies types like Type II (1–3% P) for electronics or Type V (>10% P) for high-corrosion environments, and thickness classes from SC0 (0.1 µm) for basic protection to SC4 for harsh service.

How To Write Acceptance Criteria

Sounds complex? Here’s a practical checklist to help you write clear, inspection-ready acceptance criteria for your electroless nickel plating specification:

- Deposit class/type: Specify the phosphorus level (e.g., ASTM B733 Type IV or AMS-C-26074 Grade B)

- Nickel plating thickness: State the minimum and maximum allowable thickness of nickel (e.g., 10–25 µm), and map out where measurements are required

- Adhesion test method: Indicate bend, impact, or thermal shock per the standard

- Heat treatment requirements: Note class (as-plated or heat treated), temperature, and duration

- Corrosion test method: Specify required tests (e.g., salt spray, porosity by ferroxyl)

- Sampling plan reference: Reference an industry-accepted plan for lot inspection (e.g., ANSI/ASQ Z1.4)

- Rework/repair rules: Define if and how rework is allowed

- Documentation deliverables: Request certificates of compliance, bath lot traceability, and inspection reports

Be sure to cite the exact standard (e.g., “ASTM B733 Type V, Class 2, SC3”) and any relevant class or grade. This ensures everyone—buyer, plater, and inspector—speaks the same language and knows the required nickel thickness and performance targets.

Inspection and Test Methods That Hold Up

How do you confirm the thickness of nickel and other quality attributes? Inspection protocols are built into every major EN standard. Here’s a quick guide to the most common methods:

- Thickness measurement: Use X-ray fluorescence (XRF), magnetic induction (for non-magnetic coatings on steel), beta backscatter, or coulometric removal for precise, repeatable readings. Mechanical cross-sectioning is also used for destructive verification.

- Adhesion: Bend, impact, or thermal shock tests per the chosen standard. Look for flaking, peeling, or detachment.

- Porosity: Ferroxyl, boiling water, aerated water, or alizarin tests reveal pinholes or pores that could compromise corrosion resistance.

- Hardness: Microhardness testing (e.g., Knoop or Vickers) before and after heat treatment, especially for aerospace or wear-critical parts.

- Visual inspection: Check for blisters, pits, discoloration, or uneven deposit.

Always align your inspection plan with the cited standard’s terminology and test methods. If your application demands traceability or statistical confidence, use a recognized sampling plan and document all results for each batch.

Acceptance criteria checklist

- Deposit class/type and phosphorus content

- Required nickel plating thickness and location map

- Adhesion test method and acceptance level

- Heat treatment class, temperature, and duration

- Corrosion and porosity test requirements

- Sampling plan and inspection frequency

- Rework/repair guidance

- Documentation and certification deliverables

For every job, cite the exact standard, type, class, and required nickel thickness—don’t rely on generic descriptions or assumptions.

By translating EN standards into actionable specifications and clear inspection plans, you’ll build confidence in every plated part—setting the stage for robust process control and troubleshooting, which we’ll explore next.

Bath Control, Replenishment, and Troubleshooting in the Electroless Nickel Plating Process

Bath Health Monitoring And Logs

Ever wondered why some electroless nickel plated parts look flawless while others show pits, streaks, or uneven color? The secret often lies in how well the bath is monitored and maintained. In the plating process, keeping your nickel plating solution in top shape is just as important as the chemistry itself. Imagine a chef tasting and adjusting their recipe as they cook—process engineers must do the same with their electroless nickel plating solution.

Key parameters to check regularly:

- Nickel ion concentration—Too low and the deposit thins; too high can cause instability.

- Hypophosphite (reducing agent)—Essential for the autocatalytic reaction; must be replenished as it is consumed.

- Phosphite (by-product)—Builds up over time; excessive levels lead to poor deposit quality and can halt the plating process.

- pH—Usually kept between 4.6 and 5.0 for optimal results.

- Temperature—Typically controlled between 85–91°C; too low slows deposition, too high risks decomposition.

- Stabilizer and additive levels—Regulate deposit properties and bath longevity.

- Filtration status—Removes particulates that cause roughness or pitting.

Routine analysis methods include titration (for nickel and hypophosphite), UV-Vis spectrophotometry, and ion chromatography for phosphite and other contaminants. For temperature and pH, use calibrated meters and record each check.

Bath logbook column headings

- Date and time

- Operator initials

- Lot/part ID

- Bath age (cycles or hours)

- Nickel ion concentration

- Hypophosphite concentration

- Phosphite concentration

- pH

- Temperature

- Additions (chemicals, replenishments)

- Observations (color, turbidity, odor, visible defects)

- Filtration/maintenance events

- Drag-out estimates

Replenishment And Life Extension

When you notice the bath performance dropping—maybe the plating rate slows or the finish isn’t as bright—it’s likely time to replenish. Here’s how to keep your nickel coating process running smoothly:

- Check nickel and hypophosphite levels. Replenish separately, allowing 15–20 minutes between additions for proper mixing.

- Monitor phosphite accumulation. High levels (often above 100–150 g/L) signal bath exhaustion; partial removal or bath replacement may be needed (Finishing & Coating).

- Maintain pH and temperature within the recommended range—adjust with ammonia or acetic acid as needed.

- Filter the bath regularly (using 1-micron or finer filter bags) to remove particulates and extend bath life.

- Keep the bath covered when not in use and avoid cross-contamination from other plating lines or drag-in from pre-treatments.

Proper replenishment and filtration can dramatically extend the service life of your electroless nickel plating solution, reducing costs and production downtime.

Troubleshooting Defects With Fast Fixes

Even with careful monitoring, defects can show up. Here’s a practical table to help you pinpoint and fix common issues in the plating process:

| Symptom | Probable Cause | Corrective Action |

|---|---|---|

| Slow plating rate | Low nickel or hypophosphite, low pH, low temperature, metallic contamination | Analyze and adjust nickel/hypophosphite, correct pH/temperature, check for contaminants |

| Skip plating/no deposition | Poor surface prep, low bath activity, metallic contamination | Improve cleaning/activation, check bath chemistry, remove contaminants |

| Rough or black deposits | Poor filtration, excessive stabilizer, high pH, organic contamination | Improve filtration, adjust stabilizer, correct pH, clean equipment |

| Pitting | Organic contamination, poor cleaning, particulates, high phosphite | Enhance cleaning, filter solution, replace or partially renew bath |

| Nodules or blisters | Over-stabilized bath, drag-in contamination, poor surface prep | Reduce stabilizer, improve rinsing, review pre-treatment |

| Non-uniform thickness | Out-of-range parameters, inadequate agitation, poor fixturing | Check pH/temp, improve agitation, adjust fixturing |

| Milky/turbid bath | High phosphite, high pH, low complexer | Test and adjust chemistry, consider bath replacement |

If supplier technical data specifies control limits and addition rates, use those exact values; otherwise, do not assume ranges.

Filtration is your first line of defense against roughness and pitting—use fine filters and keep the bath environment as clean as a laboratory. Even a few parts per million of stray metals, oils, or organic contaminants can poison an electroless nickel plating solution and compromise the entire plating process.

By adopting disciplined monitoring, replenishment, and troubleshooting routines, you’ll ensure your electroless nickel plating solution delivers consistent, high-quality results. Next, let’s look at how environmental, health, and safety practices shape a sustainable plating operation.

Environmental Health, Safety, and Sustainability in Electroless Nickel Plating

Worker Safety and PPE

When you’re handling chemicals for electroless coating, safety isn’t just a box to check—it’s the foundation of a reliable operation. Ever wondered what could happen if you skip gloves or don’t use proper ventilation? Direct contact with nickel salts and reducing agents can cause skin irritation, eye damage, and respiratory issues. According to the Safety Data Sheet for chemical nickel plating solutions, nickel compounds may also be carcinogenic and can trigger allergic reactions in sensitive individuals.

- Always wear chemical-resistant gloves (nitrile recommended), long sleeves, and safety goggles or a face shield.

- Use appropriate respiratory protection if ventilation is inadequate or if you’re working with mists or vapors.

- Wash hands and exposed skin thoroughly after handling plating solutions.

- Keep food and drinks away from the work area to prevent accidental ingestion.

- Store chemicals in tightly closed containers, in cool, well-ventilated spaces away from incompatible materials.

- Train all operators on emergency procedures, including spill response and first aid for chemical exposure.

Sounds strict? It should be—these steps help prevent acute and chronic health effects, and support a culture of safety that benefits everyone on the shop floor.

Regulatory and Substance Compliance

Wondering how chemical nickel plating fits into today’s regulatory landscape? If your business supplies electronics or automotive parts, you’re likely familiar with RoHS and REACH. These regulations restrict hazardous substances and require documentation of chemicals used in electrolytic plating and electroless nickel baths. For example, RoHS limits the use of lead, cadmium, mercury, and hexavalent chromium in electrical components, while REACH tracks Substances of Very High Concern (SVHCs) in all manufacturing steps.

- Register all chemicals used in the plating process as required by local or regional authorities.

- Maintain up-to-date Safety Data Sheets (SDS) and technical files for every bath constituent.

- Document use of any restricted substances and ensure alternatives are explored where possible.

- Comply with effluent and air quality guidelines (such as U.S. EPA 40 CFR Part 433, which limits nickel in wastewater to 3.98 mg/L for a daily maximum or 2.38 mg/L for a monthly average).

- Be aware of region-specific rules—such as California’s Title 22 for hazardous waste or EU’s CE marking requirements for electronics.

Why does this matter for your operation? Proper compliance not only avoids fines and shutdowns, but also reassures customers that your electroless coating process won’t introduce corroded nickel or hazardous residues into their supply chain.

Waste Treatment and Sustainability

Ever considered what happens to spent baths and rinse water after electroless plating? Nickel-bearing wastewater poses both environmental and regulatory challenges. Untreated discharge can lead to nickel accumulation in soil and waterways, causing ecological harm and legal penalties. That’s why sustainable waste management is a must—especially as environmental standards tighten.

Typical treatment steps include:

- pH adjustment and precipitation—Adding alkali (like NaOH) to raise pH and precipitate nickel as nickel hydroxide, which is then filtered out.

- Filtration—Removes solids and prevents discharge of hazardous sludge.

- Solvent extraction and recovery—Modern plants use closed-loop systems to extract and recover nickel, minimizing waste and supporting resource recycling (TY Extractor).

- Ion exchange or evaporation—Advanced options for further reducing nickel in effluent and reclaiming valuable metals.

- Bath life extension and drag-out reduction—Careful process control, rinsing, and chemical management can reduce the frequency of bath disposal and minimize waste.

Imagine if every shop recycled its nickel—resource use would drop, and the risk of corroded nickel entering the environment would be much lower. These steps also help address corrosion disadvantages by ensuring that waste streams don’t accelerate environmental degradation or regulatory risk.

| EHS Program Essentials for Electroless Nickel Plating | |

|---|---|

| Hazard communication and signage | Ensure all areas are clearly labeled and staff are trained on hazards |

| Access to SDS and technical files | Keep documents readily available for all chemicals |

| Regular safety and environmental training | Schedule annual refreshers and onboarding for new personnel |

| Exposure and emission monitoring | Use air and water sampling to track compliance |

| Waste manifest and tracking | Document all hazardous waste movements and disposal |

| Periodic compliance audits | Review practices and update as regulations evolve |

Always follow local regulations and permit conditions, and consult certified environmental professionals when designing or upgrading your plating facility.

By building a robust EHS program and staying current with best practices, you’ll not only protect your team and the environment, but also ensure your electroless nickel plating process stands up to scrutiny—now and in the future. Next, we’ll compare EN’s performance and sustainability to alternative coatings, helping you make the best choice for your application.

Where Electroless Nickel Plating Fits Best

Where Electroless Nickel Excels

Ever wondered why some high-precision parts last longer, resist corrosion, and maintain tight tolerances even after years of use? The answer often lies in the choice of surface finish. Electroless nickel plating stands out when you need a coating that is both uniform and robust—especially for complex shapes, internal bores, or fine features. Unlike other methods, electroless nickel forms an even layer across every exposed surface, making it a top pick for demanding engineering applications where uneven thickness could lead to premature failure or assembly headaches.

- Precision hydraulic valves and pump rotors

- Fuel injector bodies and automotive actuators

- Plastic injection molds and die-casting tools

- Electronic connectors and printed circuit boards

- Sliding or wear-prone parts in machinery

When dimensional accuracy, corrosion resistance, and wear protection are mission-critical, electroless nickel plating vs nickel plating by electrolytic (electrolytic nickel plating) often tips the scale in favor of EN, especially for intricate or high-performance components.

How It Compares to Electroplated Nickel and Chrome

Choosing between electroless nickel, electrolytic nickel, and chrome plating? Imagine you have a part with deep grooves, tight internal diameters, or sensitive mating surfaces. Here’s how each finish stacks up in real-world scenarios:

| Attribute | Electroless Nickel Plating | Electrolytic Nickel Plating | Hard Chrome Plating | Zinc Plating |

|---|---|---|---|---|

| Uniformity on Complex Parts | Excellent—conforms to all surfaces equally | Poor—thicker on edges, thinner in recesses | Moderate—better than electrolytic nickel, but not as uniform as EN | Good, but can build up on edges |

| Typical Thickness Range | 5–25 μm (can be tailored as needed) | 5–20 μm (less control in deep features) | 10–500 μm (thick for wear parts) | 5–25 μm (standard for fasteners) |

| Wear Resistance | High (especially after heat treatment) | Moderate | Very High (as-plated hardness 68–72 HRC) | Low |

| Corrosion Resistance | Excellent—especially high-phosphorus EN | Moderate—may tarnish over time | Good, but can develop microcracks | Fair—sacrificial protection only |

| Reworkability | Good—can be stripped and replated | Good—can be stripped | Challenging—hardness can hinder machining | Easy to strip/replate |

| Cost Positioning | Moderate—cost-effective for performance | Low to moderate—good for decorative use | Higher—reflects wear and hardness benefits | Lowest—ideal for high-volume, low-cost hardware |

| Finish Appearance | Bright to matte (customizable) | Bright, decorative | Bright, mirror-like (nickel chrome plating for décor) | Dull to bright, usually not for aesthetics |

For the difference between nickel and chrome, it comes down to priorities: chrome plating is king for maximum hardness and lowest friction (think piston rods, dies, and hydraulic cylinders), but electroless nickel wins for uniform coverage and superior corrosion resistance, especially in tough chemical or marine environments. Nickel chrome plating is often chosen for decorative applications where shine and surface smoothness are desired, while EN is the go-to for technical or functional surfaces.

When comparing electroless vs electrolytic nickel plating, remember: if your part demands consistent thickness across every nook and cranny, EN is the smarter choice. Electrolytic nickel plating is better suited for decorative or less critical applications where speed and cost are the main drivers.

When Zinc Plating Is Enough

Not every part needs the high performance of EN or chrome. Sometimes, you just need basic corrosion protection at the lowest possible cost—especially for fasteners, brackets, or hardware that won’t face harsh chemicals or wear. That’s where zinc plating shines. It provides sacrificial protection, meaning it corrodes first to protect the underlying steel, but it’s not designed for high-wear or precision assemblies. If you’re weighing nickel vs zinc plating, factor in the environment and lifecycle cost: zinc is great for short-term, low-cost needs, but for anything exposed to moisture, chemicals, or requiring dimensional control, EN is the better investment.

Uniformity, corrosion protection, and dimensional accuracy make electroless nickel plating the clear winner for precision and high-performance applications—especially when compared to electrolytic nickel plating, chrome, or zinc.

Ready to specify a finish for your next project? Understanding how each option stacks up will help you avoid costly mistakes and deliver reliable, long-lasting components. Next, we’ll outline how to source trusted EN plating partners and specify your requirements for consistent, high-quality results.

Sourcing Specification and Trusted Partners for Electroless Nickel Plating Services

What To Include In Your RFQ And Drawing Notes

Ready to turn your knowledge of what is electroless nickel plating into real-world results? When you’re preparing a request for quote (RFQ) or drafting engineering drawings for EN plating, clear and thorough specifications are the key to getting consistent, high-quality outcomes. Imagine your part is a precision hydraulic shaft or a batch of nickel plating 3d printed parts—without the right details, even the best electroless nickel platers can miss the mark.

- Deposit type and phosphorus content: Specify low, medium, or high phosphorus, or state the exact percentage if critical (e.g., per ASTM B733 Type IV, 5–9% P).

- Nickel thickness and measurement locations: State the required thickness (e.g., 12–25 μm) and indicate on the drawing where to measure.

- Adhesion and corrosion tests: Require specific test methods (e.g., bend test per AMS-C-26074, salt spray per ASTM B117).

- Heat treatment: Note if post-plate baking or hardening is required (class and duration).

- Masking map: Clearly identify areas to be masked or left unplated.

- Allowable rework/repair: State if rework is allowed and under what conditions.

- Documentation: Request certificates of compliance, bath lot traceability, and inspection reports.

- Sampling/inspection: Reference a recognized sampling plan for lot acceptance (e.g., ANSI/ASQ Z1.4).

By providing this level of detail, you help ensure your chosen electroless nickel plating company delivers exactly what you need, with no surprises down the line (Anoplex).

Vendor Qualification Checklist

Choosing the right partner for electroless nickel plating services is about more than just price. You want a supplier who can consistently meet your electroless nickel plating specification, deliver on time, and support your quality goals—especially for critical applications like en plating of automotive or aerospace parts. Here’s a practical checklist to evaluate potential vendors:

- Certifications: ISO 9001, IATF 16949 (for automotive), or relevant industry standards.

- EN capability across alloys: Can they handle steel, aluminum, copper, and specialty substrates?

- Bath control and documentation: Regular bath testing, documented control limits, and traceable records.

- Metrology and inspection: In-house XRF, microhardness, and porosity testing per ASTM/AMS standards.

- Turnaround and logistics: Fast quoting, reliable lead times, and support for expedited jobs.

- PPAP/traceability (for automotive): Can they support Production Part Approval Process and provide full traceability for each batch?

- Continuous improvement: Evidence of ongoing process upgrades and staff training.

- Integrated service offerings: For complex programs (like nickel plating 3d printed parts or assemblies), look for vendors who can also provide prototyping, stamping, and advanced surface treatments.

- Full-service capability: For automotive or high-volume programs, consider a partner like Shaoyi, who offers end-to-end support from prototyping and stamping to surface treatments (including electroless nickel plating) and assembly—all backed by IATF 16949 certification and robust PPAP/traceability. This level of integration reduces risk, shortens lead times, and streamlines project management for EN-coated components.

When a Full-Service Automotive Partner Helps

Imagine you’re launching a new automotive actuator or a high-precision sensor housing. You need more than just a standard electroless nickel plater—you need a team that can handle rapid prototyping, complex metal forming, en plating, and final assembly, all while meeting the strictest quality and traceability standards. This is where a full-service partner like Shaoyi stands out. Their ability to manage the entire workflow, from initial design through electroless nickel plating and final inspection, means fewer handoffs, less risk of miscommunication, and a faster path to market.

- Shaoyi: Integrated prototyping, stamping, EN plating, and assembly for automotive and Tier 1 suppliers. IATF 16949 certified. See their services.

- Specialty electroless nickel platers: For unique alloy, geometry, or compliance needs.

- Regional electroless nickel plating companies: For fast-turn, local support or lower logistics costs.

For complex, high-stakes projects, partnering with a full-service electroless nickel plating company streamlines sourcing, ensures quality, and accelerates time to market.

With a clear electroless nickel plating specification and a trusted partner, you’ll achieve reliable, repeatable results—whether you’re coating a single prototype or scaling up to automotive production. Now, you’re equipped to turn your understanding of what is electroless nickel plating into a competitive advantage on your next project.

Frequently Asked Questions about Electroless Nickel Plating

1. What are the disadvantages of electroless nickel plating?

While electroless nickel plating offers excellent uniformity and corrosion resistance, it can be more expensive than other plating options and typically has limitations on maximum coating thickness. Environmental concerns arise from chemical waste, and certain materials may require special pre-treatment to ensure good adhesion. Surface finish may not always match decorative requirements, and hydrogen embrittlement or wear resistance limitations can occur without proper process control.

2. How does electroless nickel plating differ from electrolytic nickel plating?

Electroless nickel plating uses a chemical reaction to deposit nickel evenly on all surfaces, including complex shapes and internal features, without electricity. In contrast, electrolytic nickel plating relies on an electric current, leading to uneven thickness—thicker near edges and thinner in recesses. Electroless plating is preferred when uniform coverage and precise dimensional control are critical.

3. Which industries commonly use electroless nickel plating?

Industries such as automotive, aerospace, electronics, oil & gas, and precision engineering frequently use electroless nickel plating. This process is ideal for components like hydraulic valves, molds, fuel injectors, and electronic connectors, where wear resistance, corrosion protection, and dimensional accuracy are essential.

4. What factors should be considered when specifying electroless nickel plating?

When specifying electroless nickel plating, consider the required phosphorus content (low, medium, or high), target thickness, substrate material, and any post-treatment needs like heat hardening. Also, detail inspection methods, masking requirements, and documentation for quality assurance. For complex or automotive projects, partnering with a full-service provider like Shaoyi can streamline sourcing and ensure certified results.

5. Is electroless nickel plating environmentally friendly?

Electroless nickel plating involves chemicals that require careful handling and waste treatment to protect the environment. Modern facilities implement pH adjustment, filtration, and metal recovery to minimize nickel discharge. Adhering to regulations and using sustainable practices is essential for reducing environmental impact.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —