Can Aluminum Corrode Or Rust? Types, Causes, And Prevention

Does Aluminum Rust?

Why Aluminum Doesn’t Rust

Ever wondered, "Does aluminum rust like iron or steel?" The short answer: aluminum does not rust. Rust is a specific type of corrosion that only affects iron and its alloys, like steel. Since aluminum contains no iron, it simply cannot form rust. However, that doesn’t mean aluminum is immune to damage—aluminum can corrode under certain conditions, and understanding how this happens is key to keeping your fixtures, outdoor equipment, or marine fittings looking their best.

Corrosion vs Rust vs Oxidation

Let’s break down these terms in plain language:

| Term | Process | Appearance | Risk/Impact |

|---|---|---|---|

| Rust | Oxidation of iron/steel in air & moisture | Orange-brown flakes | Weakens and destroys iron-based metals |

| Corrosion | General chemical breakdown of materials (including metals) | Various: white, green, or blue deposits | Can affect many materials, not just iron |

| Oxidation | Reaction of metal with oxygen | White (aluminum), orange (iron), green/blue (copper) | May be protective or damaging, depending on the metal |

So, when people ask, "does aluminum rust," what they really mean is, "can aluminum corrode or oxidize?" The answer: yes, but it behaves very differently than iron or steel. Instead of forming a flaky, destructive rust, aluminum reacts with oxygen to create a thin, hard layer of aluminum oxide. This white layer is usually invisible and actually protects the metal underneath from further attack.

How Passivation Protects Aluminum

When you leave bare aluminum exposed to air, you might notice it stays bright and clean for a long time. This is thanks to a process called passivation. Passivation is the natural formation of a stable oxide film on the surface of aluminum. This film is self-healing—if it gets scratched or damaged, it reforms almost instantly, shielding the underlying metal from further corrosion.

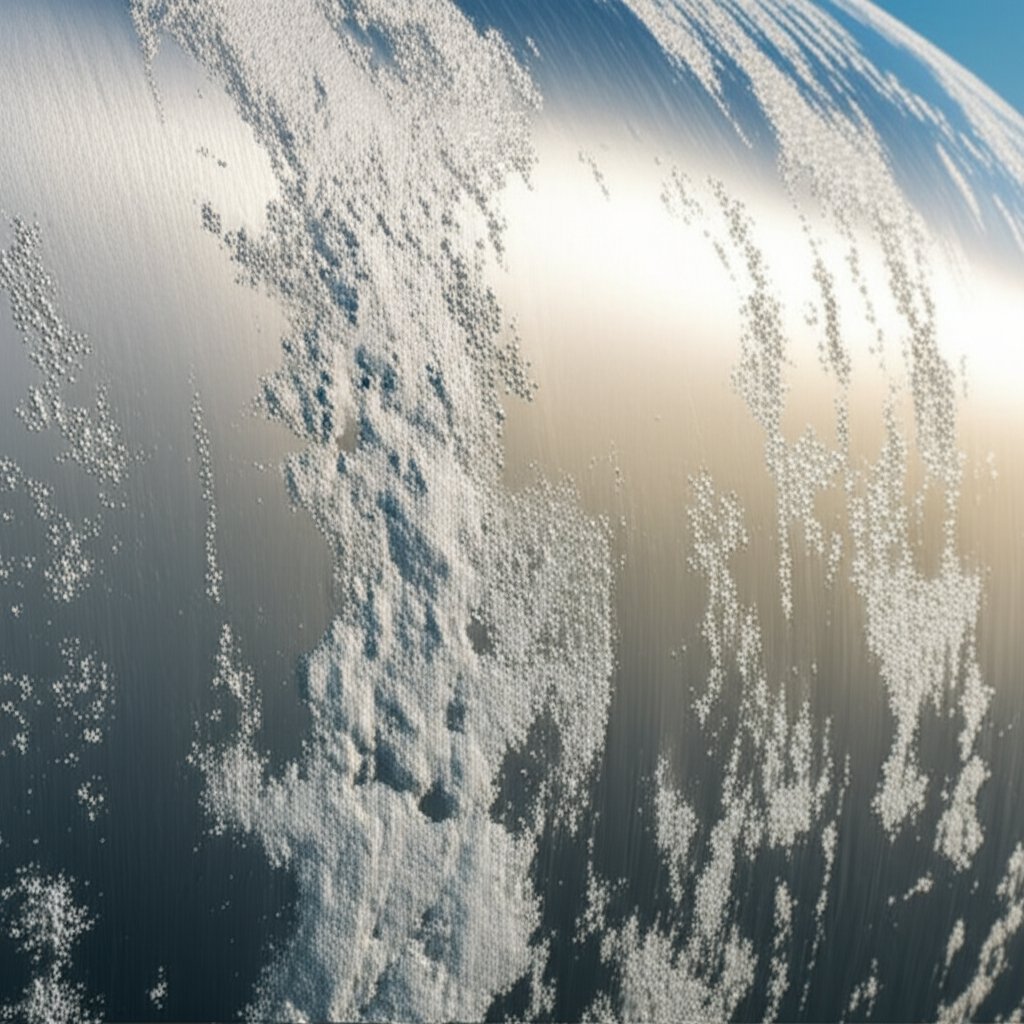

But, can aluminum corrode in every environment? Not quite. While this oxide layer is tough, it can break down in aggressive settings—like when exposed to saltwater or certain industrial chemicals. That’s why you’ll sometimes see white spots or pitting on aluminum window frames near the coast or on marine boat fittings. These are signs the protective film has failed, and corrosion has started.

- Aluminum does not rust—it corrodes by forming a protective oxide layer.

- This oxide film is usually self-healing and keeps aluminum looking good.

- Harsh environments (salt, some chemicals) can break down the oxide, leading to corrosion.

- Proper cleaning, coatings, and design can prevent most aluminum corrosion.

The key takeaway: Aluminum will not rust like steel, but it can corrode if its protective oxide layer is compromised. Smart design and maintenance keep aluminum strong and attractive for years.

Curious about what causes the oxide layer to fail, or how to prevent corrosion in aluminum? The next sections dive into types of corrosion, environmental risks, and practical prevention tips—so you’ll know exactly when and why aluminium will rust (or, more accurately, corrode) and what you can do about it.

Recognize the Types of Aluminum Corrosion

Common Types of Aluminum Corrosion

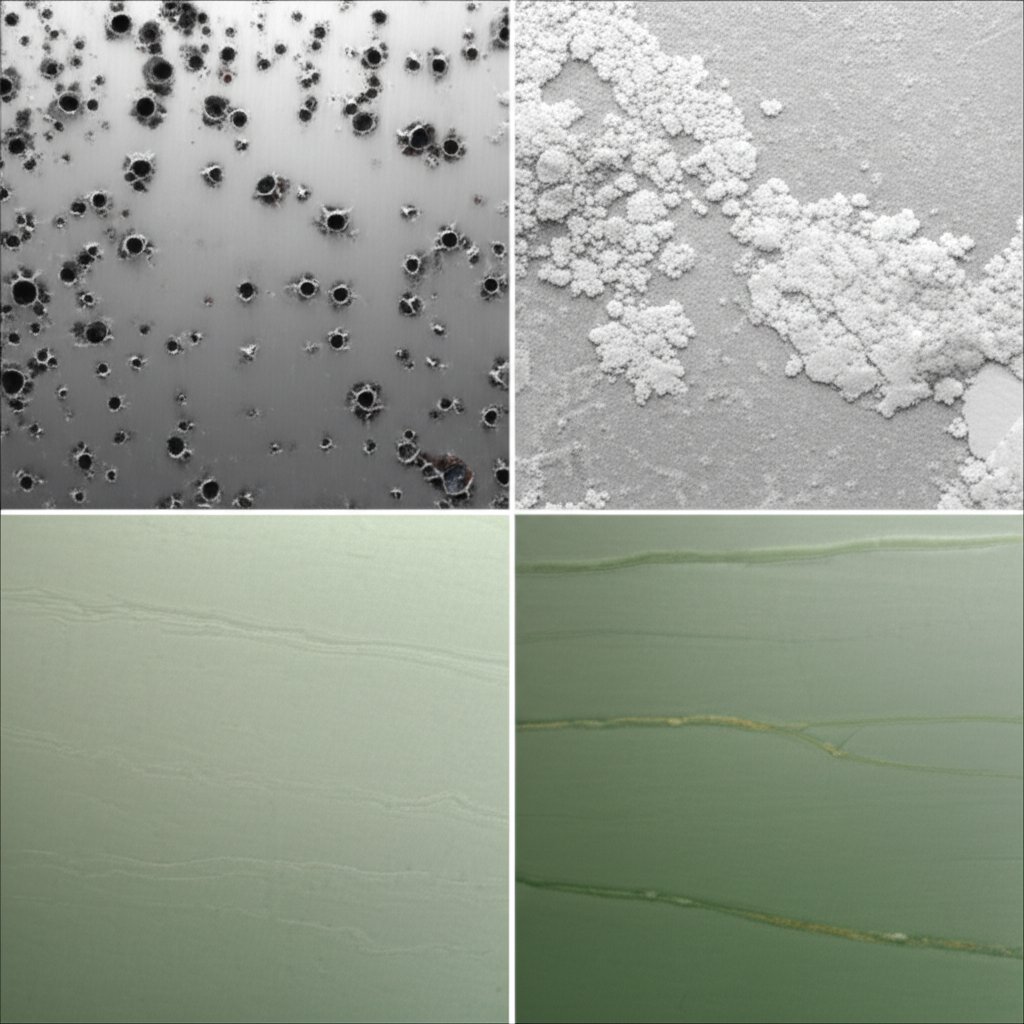

When you spot dull patches, white powder, or even tiny pits on aluminum, you’re seeing the results of corrosion in aluminum. But did you know there are several distinct types, each with its own cause and appearance? Understanding these differences helps you quickly identify problems and choose the right fix. Here’s a practical breakdown of the most common types of aluminum corrosion and what triggers them:

- Pitting Corrosion: Small, sharp holes or "pits" on the surface, often caused by chlorides (like salt spray) breaking down the oxide layer. Most visible on outdoor or marine aluminum.

- Crevice Corrosion: Localized attack in gaps or overlaps—think under washers, gaskets, or between joined parts where moisture gets trapped. Look for concentrated white or gray deposits around fasteners or seams.

- Galvanic Corrosion: Occurs when aluminum contacts a more "noble" metal (like copper or stainless steel) in the presence of an electrolyte (water). You’ll notice corrosion at the junction, often with visible pitting or surface roughness.

- Filiform Corrosion: Worm-like, thread-shaped tracks under paint or coatings, usually starting at scratches or damaged spots. Most common in humid, salty environments.

- Intergranular and Exfoliation Corrosion: Attack along grain boundaries inside the metal, sometimes causing flaking or lifting of the surface. More common in certain alloys or after heavy rolling.

- Uniform (General) Corrosion: Even, widespread dulling or thinning of the surface, usually in very acidic or alkaline environments where the oxide layer can’t protect the metal.

- Stress Corrosion Cracking: Fine cracks that form and spread in high-strength alloys exposed to stress and moisture. These cracks may be hard to spot until failure occurs.

How to Spot Pitting and Crevice Attack

Still wondering, “What does aluminum corrosion look like?” Here’s a quick reference table to help you identify the most common forms at a glance:

| Type | Appearance | Probable Cause |

|---|---|---|

| Pitting | Tiny, sharp, or shallow holes; white powder | Chlorides (salt), surface defects |

| Crevice | White/grey deposits in gaps; under fasteners | Trapped moisture, poor drainage |

| Galvanic | Corrosion at metal joints; rough surface | Dissimilar metal contact, water/electrolyte |

| Filiform | Worm-like tracks under paint or coating | Coating damage, high humidity, chlorides |

| Intergranular | Flaking, delamination, or cracks | Alloy structure, improper heat treatment |

Filiform and Under-Coating Issues

Filiform corrosion is especially tricky—it often starts where a coating is scratched or chipped and spreads beneath the paint in humid, salty air. You’ll see fine, thread-like marks that seem to crawl out from a damaged spot. This is a clear sign the protective barrier failed, allowing oxidation in aluminum to progress unchecked (Total Materia).

Protective oxide films work well on open surfaces but can break down in crevices or at dissimilar metal joints, where trapped moisture and lack of airflow create perfect conditions for corrosion aluminium.

Recognizing these corrosion types early can save you from costly repairs and help you target prevention methods where they matter most. Next, we’ll look at how the environment—like saltwater, humidity, and pollutants—can accelerate corrosion of aluminium metal and what you can do to minimize the risk.

Assess Environmental Risk Factors That Drive Aluminum Corrosion

Moisture and Salt Exposure Risks

Ever noticed how aluminum in water or near the ocean seems to age faster? The environment around your aluminum—whether it’s a handrail by the sea or a fixture in a damp basement—plays a huge role in how quickly it corrodes. While aluminum is naturally resistant to many types of corrosion, certain conditions can break down its protective oxide layer, leading to visible damage.

Let’s start with the big culprit: salt water. Salt water corrosion on aluminum happens because chloride ions in the salt attack the oxide film, making it easier for moisture and oxygen to reach the underlying metal. This is why salt water corrosion of aluminum is a common concern for boats, seaside railings, and outdoor furniture. The result? You’ll often see a chalky white coating or even pitting—tiny holes that can deepen over time (Aluminum Handrail Direct).

But it’s not just salt water. Standing water of any kind, especially if it’s slightly acidic or alkaline, can wear down the oxide layer. Even regular condensation or trapped moisture—think poorly ventilated indoor spaces or areas with bad drainage—raises the risk. So, does aluminum corrode in water? Yes, especially if the water contains salts, acids, or bases outside the pH range of 4 to 9.

Water Quality and pH Considerations

Imagine you’re cleaning aluminum with a strong cleaner, or your building project exposes aluminum to wet concrete. Both acidic and highly alkaline environments can break down the oxide layer faster than you’d expect. For example, fresh concrete has a pH of 12.5–13.5, much higher than the safe zone for aluminum. Ideally, keep aluminum away from substances with a pH below 4 or above 9 to avoid rapid attack.

It’s the same story with de-icing salts, pool chemicals, and even polluted rainwater. If you see visible salt deposits or streaks on the metal, that’s a warning sign: salt water corrosion aluminum is likely if you don’t rinse and protect the surface.

Indoor, Industrial, and Marine Profiles

How do risks change depending on where your aluminum lives? Take a look at this scenario-based table:

| Environment | Typical Risks | Recommended Mitigations |

|---|---|---|

| Indoor (Dry) | Low risk unless exposed to cleaning chemicals or condensation | Maintain ventilation, avoid harsh cleaners |

| Industrial (Urban) | Acidic/alkaline pollutants, dust, possible chloride exposure | Regular cleaning, protective coatings, monitor pH |

| Marine (Coastal) | High humidity, salt spray, persistent dampness | Rinse schedules, powder coating, design for drainage |

| Splash Zone/Poolside | Standing or splashing chlorinated/salty water, visible salt film | Frequent rinsing, isolate from other metals, inspect for deposits |

So, will aluminum corrode in water? In fresh water with neutral pH and good drainage, aluminum fares well. But in salt water or in places with poor drainage and persistent dampness, corrosion risk rises sharply.

- Rinse surfaces regularly, especially after salt exposure

- Isolate aluminum from direct contact with other metals in wet areas

- Ensure good drainage—avoid standing water and trapped moisture

- Inspect for visible salt deposits or chalky residue

- Use protective coatings or anodizing in high-risk zones

Time-of-wetness plus chlorides is the recipe for pitting—if you see condensation and salt, act fast to prevent deeper aluminum corrosion salt water damage.

By recognizing these environmental triggers—whether it’s aluminum in water, salt air, or aggressive cleaners—you can quickly assess your risk and take action. Next, we’ll explore how the wrong fastener or metal pairing can make things worse, and what to do about it.

Avoid Galvanic Corrosion

Understanding Galvanic Pairs

Ever wondered why mixing metals—like using stainless steel bolts on aluminum railings—sometimes leads to ugly corrosion? That’s galvanic corrosion in action. When two dissimilar metals touch in the presence of an electrolyte (think rainwater or salt spray), one metal (the anode) corrodes faster, while the other (the cathode) stays protected. In the case of aluminum and stainless steel, aluminum acts as the anode and will corrode first.

| Metal Pair | Galvanic Risk | Common Scenario |

|---|---|---|

| Aluminum & Stainless Steel | High (especially in saltwater) | Outdoor railings, marine fittings |

| Aluminum & Carbon Steel | Moderate to High | Structural fasteners, brackets |

| Aluminum & Copper/Brass | Very High | Electrical terminals, plumbing |

| Aluminum & Zinc/Galvanized Steel | Low to Moderate | Roofing, flashing |

Fastener Pairings That Harm Aluminum

So, does stainless steel react with aluminum? Yes—especially in wet or salty environments. This stainless steel and aluminum reaction is driven by their difference in electrochemical potential. The bigger the gap between the metals in the galvanic series, the greater the risk of aluminum steel corrosion. For example, stainless steel fasteners on aluminum boat rails can cause rapid pitting if not isolated. The risk increases with:

- Presence of water or salt (electrolyte)

- Large stainless fastener surface area compared to aluminum part

- Direct, uncoated metal-to-metal contact

- Poor drainage or trapped moisture at the joint

But not all pairings are equally risky. Using aluminum fasteners on steel parts is even worse—the aluminum fasteners will corrode quickly, potentially leading to structural failure.

| Metal Pair | Risk | Mitigation |

|---|---|---|

| Stainless Steel & Aluminum | High (marine, outdoor) | Insulate with washers, apply coatings |

| Carbon Steel & Aluminum | Moderate | Use barrier tape, seal joints |

| Copper/Brass & Aluminum | Very High | Strictly avoid direct contact |

| Zinc/Galvanized Steel & Aluminum | Lower | Monitor and maintain coatings |

Isolation Strategies That Work

Sounds complex? It’s actually simple with a few field-tested tricks. Here’s how to prevent aluminum and steel reaction or aluminum steel corrosion at joints and fasteners:

- Use non-conductive washers or gaskets (rubber, plastic) between metals

- Apply a corrosion-resistant coating (epoxy, primer, paint) to both surfaces before assembly

- Seal bolt and screw heads with corrosion-inhibiting paste

- Design for drainage: avoid water traps, slope surfaces, and add weep holes

- Limit contact area: use the smallest fastener area practical relative to the aluminum part

- Regularly inspect and maintain coatings in harsh environments

Without proper isolation, stainless fasteners in saltwater or damp conditions can drive rapid pitting and failure in aluminum. Always separate dissimilar metals with insulating materials and protective coatings to ensure long-term durability.

By following these guidelines, you’ll dramatically reduce the risk of stainless steel and aluminum corrosion or stainless steel to aluminum corrosion in your projects. Up next, discover how smart design and installation practices—like drainage and joint isolation—can further prevent corrosion and keep your aluminum structures looking and performing their best.

Design and Installation Practices That Prevent Aluminum Corrosion

Design for Drainage and Drying

When you’re planning a project with aluminum—be it window frames, railings, or marine fittings—the way you design and install each part can make or break its long-term durability. Why? Because corrosion often starts where water, dirt, or other contaminants linger. If you want true aluminum corrosion prevention, the first step is to keep the material dry and clean whenever possible.

- Inspect materials on delivery: Check for dents, scratches, or contamination that could compromise the protective oxide layer.

- Promote drainage: Design profiles with proper slope, add weep holes, and avoid flat surfaces where water can pool.

- Avoid crevices and pockets: Minimize tight overlaps or joints where moisture or debris could get trapped. These spots are prime targets for pitting and crevice corrosion.

- Edge sealing: Always seal cut edges and corners with compatible coatings or sealants to prevent exposure of bare metal.

- Clean residues after fabrication: Remove dust, lubricants, and fingerprints before assembly to ensure nothing interferes with coatings or sealants.

Isolate Dissimilar Metals at Joints

Ever wondered why aluminium steel corrosion or aluminium steel reaction happens so quickly at fasteners and joints? It’s because direct contact between aluminum and other metals, especially in the presence of moisture, creates a galvanic cell where aluminum corrodes first. To avoid this, always isolate aluminum from steel, copper, or other metals using non-conductive materials.

| Joint Type | Isolation Method |

|---|---|

| Bolt or Screw Joint | Plastic or rubber washer/gasket |

| Overlapping Sheet | Barrier tape or sealant |

| Pipe/Tube Connection | Non-conductive sleeve or coating |

| Structural Bracket | Paint or powder-coat both surfaces before contact |

Remember, even the best aluminum corrosion prevention plan can fail if you skip isolation at joints—especially in marine or industrial environments.

Sealants, Gaskets, and Edge Protection

Not sure how to prevent corrosion of aluminium in tricky spots? Use high-quality, compatible sealants and gaskets. These not only block moisture and contaminants but also cushion the joint to prevent mechanical wear. Always choose products rated for use with aluminum—some sealants or adhesives contain chemicals that can actually accelerate corrosion. For ultimate aluminium corrosion protection, make sure all exposed edges and fastener penetrations are coated or sealed right after installation (Corrosion Group).

- Seal fastener heads and edges with a corrosion-resistant compound

- Use gaskets or tapes at all metal-to-metal joints

- Reapply coatings after any field cuts or adjustments

The single biggest win for aluminum corrosion prevention? Keep water moving and out of crevices—good drainage and thoughtful isolation stop most problems before they start.

By following these field-proven design and installation steps, you’ll dramatically reduce the risk of aluminium steel corrosion and extend the life of your aluminum assemblies. Up next, we’ll cover inspection and monitoring—so you can spot early warning signs and take action before corrosion becomes costly.

Spotting and Interpreting Aluminum Corrosion Early

What To Look For During Inspections

When you walk up to an aluminum structure—whether it’s a window frame, boat part, or industrial panel—what should you check for? Early detection is your best defense against costly repairs and structural damage. While corrosion on aluminum doesn’t look like classic orange rust, it leaves plenty of clues. Here’s what you’ll want to watch for:

- White, gray, or chalky deposits (aluminum oxide)

- Powdery or crusty build-up—often a sign of pitting or crevice corrosion

- Blistered, flaking, or bubbling paint/coating (possible filiform or under-film corrosion)

- Sharp pits, small holes, or surface roughness

- Thread-like marks under coatings (filiform corrosion)

- Raised edges, cracks, or delamination—potential intergranular attack

- Areas with persistent moisture, salt deposits, or trapped dirt

- Signs of galvanic corrosion at joints with other metals

- Discoloration or dullness—sometimes called "aluminium tarnish"

Don’t forget hidden or hard-to-reach areas: under fasteners, inside crevices, and beneath gaskets are hotspots for corrosion on aluminum. Even a small patch of rusty aluminum or a single corroded aluminum fastener can signal a bigger issue beneath the surface.

Simple Tests and What They Reveal

Visual checks are great, but sometimes you need a little more certainty. Try these quick field tests and tools to confirm what you’re seeing:

- Continuity test: Use a multimeter to check isolation between aluminum and neighboring fasteners—continuity may indicate a lost barrier and higher risk for galvanic attack.

- Tap test: Gently tap areas with a plastic or wooden tool. Hollow or dull sounds can signal delamination or hidden corrosion.

- Magnet test: Pure aluminum is not magnetic; magnetic attraction could mean contamination or embedded steel particles, which can accelerate corrosion.

- Surface wipe: Rub a clean cloth over dull or powdery areas. White powder left behind is a classic sign of oxidation in aluminum.

For critical assets, consider non-destructive testing (NDT) methods like ultrasonic thickness gauging or eddy current testing. These can reveal thinning, hidden pitting, and even sub-surface cracks without damaging the part (Voliro). For more formal assessments, ASTM and NACE provide standardized procedures for evaluating corrosion—including visual grading, pitting depth measurement, and laboratory immersion tests.

How To Interpret Findings

Once you’ve gathered observations, it’s time to make sense of what you see. Use the table below to connect common signs with likely causes and practical next steps:

| Observation | Likely Cause | Suggested Action |

|---|---|---|

| White powder, dull surface | General oxidation, early corrosion | Clean, monitor, apply protective coating |

| Pits or small holes | Pitting corrosion (chlorides, standing water) | Remove deposits, treat, improve drainage |

| Thread-like marks under paint | Filiform corrosion (under-coating moisture) | Strip, clean, re-coat with proper sealant |

| Corrosion around fasteners/joints | Galvanic attack, loss of isolation | Check isolation, replace with insulated fasteners |

| Cracks, raised edges | Intergranular or stress corrosion | Assess severity, consult engineering for repair |

| Rusty aluminum or brown stains | Embedded iron particles, contamination | Remove, clean thoroughly, monitor closely |

| Persistent dullness or "aluminium tarnish" | Surface oxidation, atmospheric exposure | Polish, clean, consider protective finish |

- Inspect all surfaces, including hidden joints and fasteners, every 6–12 months or after major weather events.

- Log findings with date, location, and severity for trend tracking (see sample log below).

- Use industry standards (like ASTM guides for pitting and crevice corrosion) to benchmark and prioritize repairs.

Inspection Log Template: Date: __________ | Location: __________ | Observation: __________ | Severity (Low/Med/High): __________ | Action Taken: __________

Early detection of corrosion on aluminum—whether it’s pitting, filiform, or simple aluminium tarnish—saves surface finish and structural strength. Regular, standards-based inspections are your best tool for reducing lifecycle costs and preventing unexpected failures.

Next, we’ll walk through hands-on cleaning and remediation steps, so you know exactly how to treat corroded aluminum and restore its protection before damage escalates.

Remediation Procedures to Clean and Restore Aluminum

Stepwise Cleaning and Surface Prep

When you spot dull patches, white powder, or pitting on aluminum, it’s time to act before the damage spreads. Wondering how to tackle aluminum corrosion removal without harming the metal? Here’s a practical, step-by-step approach for cleaning corroded aluminum and prepping it for long-term protection—whether you’re dealing with a backyard grill, marine railing, or industrial panel.

- Isolate the area: If possible, remove the affected part or mask off surrounding materials. This prevents cross-contamination and makes cleaning safer and more effective.

- Initial cleaning: Use a soft brush or cloth to remove loose dirt and debris. For general cleaning, mix mild dish soap with warm water and gently scrub the surface. Avoid harsh or abrasive pads on anodized or coated aluminum.

- Target stains and oxidation: For stubborn spots or aluminum stain, make a paste of baking soda and water. Apply with a non-abrasive pad and gently rub. For visible oxidation (white or gray powder), use a 50/50 solution of white vinegar or lemon juice and water. Wipe the affected area with a soft cloth soaked in the solution, then rinse thoroughly.

- Address deeper corrosion: If pitting or crevice corrosion is present, use a non-woven abrasive pad (never steel wool or wire brushes) to carefully remove corrosion products. Be gentle—aggressive scrubbing can damage the protective oxide layer or leave scratches that invite future corrosion (AvalonKing).

- Rinse and dry: Always rinse thoroughly with clean water after any cleaning or chemical treatment. Dry with a microfiber cloth to prevent water spots and under-film corrosion.

- Inspect and repeat if needed: If corrosion persists, repeat the above steps or consider a commercial aluminum corrosion treatment. Follow manufacturer instructions for all products.

- Polish or protect: Once clean, apply an aluminum polish or wax to restore shine and add a temporary protective layer. For items needing long-term protection or repainting, ensure the surface is completely clean and dry before proceeding.

Pitting and Crevice Repair

Active pitting and crevice corrosion require extra care. After removing visible deposits, inspect the area for roughness or remaining dark spots. These may need light abrasion with a non-woven pad. For deep pits, you may need to fill and sand before recoating or painting. Always confirm compatibility of fillers and coatings with the aluminum alloy in use.

Re-Coating and Anodizing Readiness

Planning to re-coat or anodize? Surface preparation is critical. Remove all traces of corrosion, stains, and cleaning residues. For industrial or structural aluminum, follow recommended surface pre-treatments such as mild acid etching or zincate treatment if required by the coating system (Finishing and Coating). Always consult the coating supplier’s data sheet to ensure proper adhesion and long-term durability.

- Do: Test your cleaning solution on a small, inconspicuous area before full application.

- Do: Use only non-abrasive pads and mild cleaners unless directed otherwise by the manufacturer.

- Don’t: Use steel wool, wire brushes, or harsh chemicals that can scratch or degrade the protective layer.

- Don’t: Skip rinsing—residual cleaners can cause further corrosion or staining.

Always rinse and dry thoroughly after cleaning—trapped moisture is a common cause of under-film corrosion and can undo your hard work.

By following these steps, you’ll safely remove corrosion from aluminum, restore its appearance, and set the stage for effective long-term protection. Treating corroded aluminium isn’t just about appearance—it’s about extending the life and performance of your investment. Next, we’ll explore how alloy selection and protective finishes can make future maintenance even easier.

Alloy Selection Guide for Corrosion Performance

Series-by-Series Corrosion Tendencies

Choosing the right aluminum alloy can feel overwhelming—especially when you start weighing corrosion resistance, strength, and weldability. But here’s the good news: with a basic understanding of alloy series, you’ll quickly narrow your options and avoid costly mistakes. Whether you’re building a marine railing, a pressure vessel, or decorative trim, the right choice starts with knowing how each series performs in real-world conditions.

| Alloy Series | Corrosion Resistance | Typical Applications |

|---|---|---|

| 1xxx (Pure Aluminum) | Very High | Electrical conductors, chemical tanks, decorative panels |

| 2xxx (Copper Alloyed) | Low | Aerospace, high-strength parts (often needs coating) |

| 3xxx (Manganese Alloyed) | Good | Pots, pans, heat exchangers, beverage cans |

| 5xxx (Magnesium Alloyed) | Excellent (even marine) | Shipbuilding, storage tanks, pressure vessels, marine structures |

| 6xxx (Magnesium & Silicon) | Moderate to Good | Extrusions, architectural profiles, general purpose structures |

| 7xxx (Zinc Alloyed) | Low to Moderate | Aerospace, high-strength applications |

Choosing Alloys for Environment

Let’s make this practical. Imagine you’re selecting material for a boat hull or dock. Here, corrosion resistant aluminum is a must—so you’d reach for a 5xxx series alloy like 5083 or 5086, which stands up well to saltwater and welding. On the flip side, if you need high strength for aerospace parts but can manage with coatings and extra care, a 2xxx or 7xxx series might fit.

- 1xxx Series: Best where maximum aluminium corrosion resistance and electrical conductivity matter more than strength.

- 3xxx Series: Good for food processing, automotive trim, and heat exchangers—where formability and moderate corrosion resistance are key.

- 5xxx Series: The go-to for marine and tough outdoor uses; highly weldable and offers the best corrosion resistance among common alloys.

- 6xxx Series: Popular for architectural and structural extrusions; balances strength, machinability, and moderate resistance—think window frames or handrails.

- 2xxx & 7xxx Series: Use only when you need high strength and can protect the surface with coatings or cladding, since these are less corrosion resistant.

Balancing Strength and Durability

Sounds tricky? Here’s a quick cheat sheet to help you decide:

- For marine or saltwater: Pick 5xxx series for top corrosion resistance (e.g., 5083, 5086, 5456).

- For structural or architectural: 6xxx series (like 6061) balances machinability, weldability, and moderate resistance.

- For decorative or electrical: 1xxx or 3xxx series for high conductivity and formability.

- For high strength: 2xxx or 7xxx series, but only with surface protection.

- Always match alloy choice to environment and joining method—welded joints may require a different alloy than bolted assemblies.

The most corrosion resistant aluminium alloy won’t perform if the design traps water or pairs with incompatible metals—always consider environment and assembly details alongside alloy selection.

By understanding the trade-offs and typical uses of each alloy series, you’ll confidently select aluminum that lasts—whether your priority is aluminum corrosion resistance, weldability, or structural strength. Next, we’ll compare protective finishes and coatings, so you can further boost durability and match your project’s needs.

Protection Methods Compared

Choosing the Right Protection Method

When you’re investing in aluminum for outdoor railings, architectural panels, or marine hardware, the big question often becomes: which protection method is best? Is aluminum rust proof on its own, or does it need extra help? The truth is, while aluminum is naturally corrosion resistant thanks to its oxide layer, real-world conditions—like abrasion, salt spray, and pollution—can break down this barrier. That’s why surface protection is key to maximizing the lifespan and appearance of your project.

| Protection Method | How It Works | Appearance | Durability | Maintenance | Best Uses |

|---|---|---|---|---|---|

| Anodizing (Type II/III) | Electrochemically thickens aluminum oxide layer; integral to metal | Metallic, can be clear or dyed | High (esp. hard anodize); abrasion & weather resistant | Low; can be renewed by cleaning | Doors, storefronts, marine, high-traffic surfaces |

| Painting (Liquid/PVDF) | Organic resin forms a colored, protective film | Wide color range, smooth or matte | Moderate to High (depends on resin/type) | Medium; repainting needed if film fails | Architectural panels, roofing, accent trims |

| Powder Coating | Thermally fused resin layer, thicker than paint | Rich colors, various textures | High (esp. abrasion/impact resistance) | Low to Medium; touch-ups for chips/scratches | Outdoor furniture, railings, industrial parts |

| Conversion Coatings (e.g., PEO, EN plating) | Chemical or plasma process creates ceramic/nickel layer | Ceramic matte, metallic, or grayish | Very High (esp. PEO for wear/corrosion) | Low; long-lasting, hard to rework | Engine parts, electronics, harsh environments |

| Sealants & Barrier Films | Flexible coatings or tapes seal joints, edges, or fasteners | Clear or colored, usually hidden | Variable; depends on exposure | Periodic inspection/replacement | Joints, seams, under fasteners |

Anodize, Paint, or Powder?

So, how do you decide? Imagine you’re building a storefront: anodizing is often chosen for its metallic look, abrasion resistance, and low maintenance—perfect for high-traffic doors and rails. For curtainwall or roofing where color consistency and UV resistance matter, PVDF paint is the gold standard, offering excellent durability and a broad palette. Powder coating shines when you want a tough, vibrant finish for furniture or industrial parts, and it’s especially good at withstanding impact and abrasion.

Conversion coatings like plasma electrolytic oxidation (PEO) or electroless nickel plating are ideal for extreme wear or harsh chemical environments—think engine blocks or electronics. For joints and fasteners, sealants and barrier films provide localized protection where coatings might be breached.

Conversion Coatings and Sealants

Wondering if these finishes make aluminum waterproof? While no coating can make aluminum 100% waterproof in every scenario, a well-chosen finish—combined with smart design—can make aluminum rust proof for most practical purposes. The key is to match the method to the environment and expected wear. For example, PEO coatings deliver ceramic-like hardness and top-tier aluminum corrosion resistant performance, especially where both abrasion and chemical attack are threats (Keronite).

- Anodize for abrasion and metallic appearance

- Paint (PVDF) for color, UV stability, and repairability

- Powder coat for impact and abrasion resistance

- Conversion coatings for high-wear, high-corrosion zones

- Sealants/barriers at joints, fasteners, and cut edges

Surface preparation is everything—no matter the method, a clean, well-prepped surface is the #1 factor for coating success and lasting protection against aluminum oxidation.

In summary, while oxidized aluminum is naturally resilient, choosing the right finish makes all the difference when durability, aesthetics, and maintenance matter. Next, we’ll wrap up with an action plan for sourcing quality extrusions that put these protection strategies into practice.

Sourcing and Building Corrosion-Resistant Aluminum Extrusions

From Understanding to Action

Now that you know the facts—will aluminum rust, does aluminum rust in water, and how to prevent aluminum and rust issues—what’s next? The real value comes from applying this knowledge to your projects. Whether you’re sourcing extrusions for automotive, architectural, or marine use, the path to long-lasting performance always comes down to three priorities:

- Choose the right alloy and finish: Match your aluminum alloy and surface treatment to the environment and expected exposure. Not all extrusions are created equal—marine, automotive, and outdoor applications demand high corrosion resistance and the right protective finish.

- Design for drainage and isolation: Ensure your assemblies promote water runoff, avoid crevices, and use isolation materials at joints to prevent aluminum and steel corrosion. Remember, design details like weep holes and non-conductive washers are your first defense against galvanic attack.

- Commit to inspection and cleaning: Regular checks and maintenance—especially after exposure to moisture or salt—catch issues before they escalate. Even the best protection can be compromised if ignored over time.

Checklist for Corrosion-Resilient Builds

Ready to put these principles into practice? Use this prioritized checklist to ensure your next project is built to last:

- Assess the environment: Is it marine, industrial, or exposed to frequent wetting? High-risk zones require extra care and the right alloy.

- Verify fastener compatibility: Does stainless react with aluminium in your application? Use isolation materials to prevent stainless aluminum corrosion at joints.

- Choose the best protection: Anodizing, powder coating, or conversion coatings—pick what fits your environment and maintenance expectations.

- Plan for drainage: Incorporate slopes, weep holes, and avoid areas where water can collect. Good drainage is the easiest way to prevent can aluminum rust in water scenarios.

- Schedule regular inspections: Log findings, clean surfaces, and address any signs of corrosion promptly.

Where to Source Quality Extrusions

When reliability and corrosion resistance are non-negotiable, sourcing matters as much as design. Here’s a comparison table highlighting top providers, with a focus on engineered solutions for corrosion control:

| Supplier | Key Features | Corrosion Control | Best For |

|---|---|---|---|

| Shaoyi Metal Parts Supplier | Automotive-grade, IATF 16949 certified, integrated DFM, CNC, surface treatments | Advanced anodizing, electrophoresis, phosphating, galvanizing for harsh environments | Automotive, high-performance, custom extrusions |

| Bonnell Aluminum | Custom fabrication, wide finish range | Protective coatings, marine and industrial experience | Construction, OEM, automotive |

| APEL Aluminum Extrusions | Design flexibility, high corrosion resistance | Finishing options for marine and solar | Building, transportation, solar |

| TSLOTS by Bonnell | US-made, modular profiles | Durable powder coatings, easy assembly | Machine guarding, workstations |

The most important takeaway: The environment and your design decisions—not just the material—determine whether aluminum and rust become a problem. Invest in the right alloy, finish, and assembly details to ensure your components stay strong and attractive for years.

With these steps, you’ll confidently answer questions like "will aluminum rust outside" or "does aluminum rust in water"—and more importantly, you’ll prevent issues before they start. For engineered extrusions that address drainage, galvanic isolation, and finish quality from the start, consider Shaoyi Metal Parts Supplier as your go-to partner for corrosion-smart aluminum solutions.

Frequently Asked Questions About Aluminum Corrosion

1. Can aluminum rust like steel or iron?

Aluminum does not rust because rust is specific to iron-based metals. Instead, aluminum forms a thin oxide layer that protects it from further corrosion. However, in harsh environments, this layer can break down, leading to corrosion but not traditional rust.

2. What environments cause aluminum to corrode the fastest?

Aluminum corrodes most rapidly in environments with high moisture, salt exposure, or aggressive chemicals. Coastal, marine, and industrial settings, as well as areas with poor drainage or frequent contact with de-icing salts, increase the risk of corrosion by breaking down the protective oxide layer.

3. How can I prevent galvanic corrosion between aluminum and other metals?

To prevent galvanic corrosion, always isolate aluminum from dissimilar metals like stainless steel or copper using non-conductive washers, gaskets, or coatings. Design joints to avoid trapped moisture and use compatible fasteners to reduce the risk of corrosion at contact points.

4. What are the best surface treatments to protect aluminum from corrosion?

Effective surface treatments include anodizing, powder coating, painting, and conversion coatings. These methods reinforce the natural oxide layer, providing extra protection against moisture, salt, and abrasion, especially in demanding environments like automotive or marine applications.

5. Why is Shaoyi's Automotive Aluminum Extrusions service ideal for corrosion-prone applications?

Shaoyi’s service integrates advanced surface treatments such as anodizing, electrophoresis, and galvanizing, which significantly enhance aluminum’s resistance to corrosion. Their IATF 16949 certified process ensures quality and reliability, making their parts suitable for automotive and other harsh-use scenarios.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —