What Is Dacromet Coating: From Process To Performance

What Is Dacromet Coating?

When you’re searching for a solution that outlasts traditional zinc plating or galvanizing, you’ll often come across the question: what is dacromet coating? Put simply, Dacromet is a proprietary, water-based anti-corrosion coating made primarily of zinc and aluminum flakes suspended in an inorganic binder. Originally developed in the 1970s, it became a benchmark for high-performance corrosion resistance—especially for fasteners, automotive parts, and structural hardware exposed to harsh environments.

What Dacromet Means in Surface Engineering

Sounds complex? Imagine a thin, silvery shield—engineered to protect steel or iron against rust, even in aggressive climates. Dacromet is not just a generic zinc flake coating; it’s a branded process family, historically associated with chromate-based binders (sometimes hexavalent, now often trivalent or chromium-free due to evolving standards). The technology is governed by strict process controls, and its performance depends on precise formulation, application method, and adherence to a dacromet coating standard.

Zinc–Aluminum Flake Chemistry Explained

At the heart of Dacromet is its unique chemistry: tiny zinc and aluminum flakes (typically 70–85% of the solid film) are locked in a dense, inorganic matrix. Chromate or alternative binders hold everything together, forming a network that not only adheres tightly to the metal but also delivers specific corrosion-inhibiting properties. Exclusive additives may be included to enhance adhesion, flow, or resistance to aggressive chemicals.

How Barrier and Sacrificial Protection Work Together

So, how does Dacromet coating actually work? The answer lies in two complementary mechanisms:

- Barrier Protection: The overlapping zinc and aluminum flakes form a shingle-like shield, physically blocking moisture, salts, and corrosive agents from reaching the underlying metal.

- Sacrificial (Cathodic) Protection: Zinc, being more reactive, corrodes preferentially—protecting the base metal even if the coating is scratched or damaged.

- Self-Healing in Some Systems: Chromate (when present) can form a passive oxide layer at minor defects, providing additional durability.

This dual action means that even thin films can deliver robust, multi-year protection—if the process and film build are properly controlled and meet the required dacromet coating standard.

- Coating type: Inorganic zinc–aluminum flake composite

- Typical application methods: Dip-spin for small parts, spray for large or complex geometries

- Cure concept: Oven-baked to crosslink the binder and lock flakes in place

- Common end uses: Fasteners, automotive hardware, construction components, energy-sector equipment

Dacromet fills the gap between traditional zinc plating and hot-dip galvanizing, offering high-performance corrosion protection with minimal impact on part dimensions.

Visual Schematic Suggestion: Imagine a simple process flow diagram: Clean → Coat (dip-spin or spray) → Cure (oven bake). Each step is critical to achieving a consistent, high-quality Dacromet coated finish.

While Dacromet is a leader in its class, similar zinc flake technologies exist—each with their own binder systems and performance profiles. Later sections of this article will dive deeper into process control, performance testing, and how Dacromet compares to alternatives like galvanizing and other zinc flake coatings. For now, you can see why Dacromet is discussed alongside galvanized and zinc-plated finishes in industries where corrosion resistance and dimensional precision are non-negotiable.

Inside the Dacromet Coating Process

Ever wondered what really happens when a part gets dacromet coated? The process is more than just dipping metal in a solution—it's a carefully engineered sequence designed to maximize corrosion protection and coating consistency. Let’s break down the dacromet coating process so you understand what makes it unique and how it delivers reliable results for demanding industries.

Surface Preparation Essentials

Before any coating is applied, the metal must be pristine. Imagine prepping for paint—if the surface isn’t perfectly clean, the finish won’t last. The same principle applies here. The process starts with:

- Precision cutting or blanking: Raw material is shaped to final dimensions, ensuring even coating coverage.

- Rust and scale removal: Shot blasting or abrasive brushing removes all traces of rust, mill scale, and surface contaminants.

- Degreasing: Environmentally friendly cleaners strip away oils and grease, setting the stage for strong adhesion.

Why all this effort? Because even minor residues can cause the coating to peel or bubble, undermining performance.

Dip-Spin Versus Spray Application

Once the substrate is ready, the dacromet coating composition—a water-based slurry of zinc and aluminum flakes in an inorganic binder—is applied. The method depends on part size and geometry:

- Dip-Spin: Best for small, bulk hardware (like fasteners). Parts are loaded into baskets, dipped in the coating, and spun to remove excess and ensure even distribution.

- Spray: Used for large or complex items where dipping isn’t practical. This allows for targeted coverage on intricate shapes.

After coating, a flash-off phase (typically 50–80°C for 10–20 minutes) allows water and solvents to evaporate, preventing bubbling or runs during curing.

- Prep: Cut, blast, and degrease to achieve a clean, reactive surface.

- Application: Dip-spin for small parts, spray for large/complex ones.

- Flash-off: Brief heating to drive off moisture and solvents.

- Cure: Oven bake at 300–320°C (572–608°F) for 15–30 minutes to crosslink the binder and lock flakes in place.

- Cooling: Controlled cool-down to avoid thermal stress or cracking.

- Inspection: Visual and thickness checks to ensure quality and uniformity.

Note: For high-criticality parts, automation ensures repeatability, while manual handling is reserved for complex or low-volume items.

Layering Strategies and Topcoats

Not all Dacromet coatings are created equal. Depending on the application, you might see one or more layers, special sealers, or lubricious topcoats. For example, dacromet 500 coating is engineered for parts needing low friction, while dacromet 320 plus l coating offers enhanced corrosion resistance and torque-tension control for fasteners. Here’s how layering works:

| Coating System | Typical Use | Layers | Topcoat/Sealer | Film Thickness (μm) | Cure Details |

|---|---|---|---|---|---|

| Dacromet 320 coating | General hardware, fasteners | 1–2 | Optional sealer | 5–7 | 15 min at 610°F (per reference) |

| Dacromet 320 plus l coating | Automotive, torque-critical fasteners | 2 | PLUS L sealer | 7–9 | Oven cure at 600°F+ |

| Dacromet 500 coating | Low friction, high-corrosion resistance | 2+ | Integrated PTFE or lubricious sealer | 8–10 | Oven cure, same as above |

Film thickness is not a single number but a range—specified by OEM or supplier standards and validated by performance tests. Edge and recess coverage are critical, as thin spots can compromise protection.

Why Flake Orientation and Film Build Matter

Here’s the secret: the zinc and aluminum flakes are designed to overlap like shingles on a roof. This orientation forms a dense barrier, blocking moisture and aggressive chemicals. If the flakes are misaligned or the film is too thin, the coating’s effectiveness drops. That’s why the dacromet coating process emphasizes careful control at every step.

Understanding these steps helps engineers and buyers specify coatings that match their performance needs—and sets the stage for the next section, where we’ll explore how to measure and validate Dacromet’s real-world performance.

Performance Measurement and Standards That Matter

When you specify or purchase a corrosion-resistant finish, you want proof that it will perform—not just promises. That’s where standards, test methods, and clear dacromet coating specifications come in. How do you know if a dacromet coated fastener or component will stand up to real-world abuse? Let’s walk through the industry-accepted ways to measure and document performance, so you can move from marketing claims to measurable, auditable quality.

Corrosion Resistance and Salt Spray Testing

Imagine you’re responsible for a bridge, a wind turbine, or a fleet of vehicles. How do you ensure that a490 bolts with dacromet coating or other hardware will resist rust over years of exposure? The answer: rigorous laboratory tests, most notably the neutral salt spray test (ASTM B117) and cyclic corrosion protocols (such as GM 9540P).

- Neutral Salt Spray (ASTM B117): Parts are exposed to a fine mist of saltwater for hundreds or thousands of hours. Dacromet coatings regularly achieve 1,000+ hours to red rust—far exceeding basic zinc plating.

- Cyclic Corrosion (e.g., GM 9540P): This test alternates between salt spray, humidity, and drying, better simulating real-world conditions. For a490 bolts with dacromet coating, passing these tests demonstrates suitability for critical infrastructure and automotive applications.

Adhesion and Coefficient of Friction Control

Corrosion resistance is only half the story. For fasteners, the coating must also adhere tightly and allow for controlled tightening. That’s why standards require:

- Adhesion Testing (ASTM B571): Scribe and tape tests ensure the coating won’t flake off under stress or during installation.

- Friction/Rotational Capacity (ASTM A325): Especially for structural fasteners, the coefficient of friction (often called the K-factor) is measured to ensure predictable torque-tension relationships. Dacromet systems typically target a K-factor around 0.10, supporting robotic or precision assembly [source].

- Paintability and Appearance (ASTM D3359): For visible applications, coatings must accept paint and maintain a uniform finish.

Specifying Thickness, Layers, and Cure

Here’s where the details matter. Dacromet coating thickness is usually specified in microns (μm)—often between 6 and 12 μm for fasteners, per ASTM F1136 or similar standards. Thickness is measured by magnetic or eddy-current gauges (ASTM D1186). Why not just go thicker? Because excessive film build can affect thread fit and assembly, especially for a490 bolts with dacromet coating. Specification sheets should also define:

- Substrate and geometry class (e.g., threaded fastener, stamped part)

- Required friction class or coefficient

- Layering (basecoat, sealer/topcoat) and cure cycle

- Color or appearance requirements

- Test plan and requalification triggers (e.g., change of supplier, new geometry)

| Test Method | Purpose | Sample Prep | Acceptance Criteria | Sampling Plan |

|---|---|---|---|---|

| ASTM B117 (Salt Spray) | Corrosion resistance | As coated | No red rust at 1,000 hours* | 5 pcs per batch |

| ASTM B571 (Adhesion) | Coating durability | Scribe/tape test | No flaking between lines | 3 pcs per batch |

| ASTM A325 | Torque-tension control | As assembled | K-factor 0.10 ± 0.02* | 10 assemblies per lot |

| ASTM D1186 (Thickness) | Film build/coverage | As coated | 6–12 μm* | 5 pcs per batch |

| GM 9540P (Cyclic Corrosion) | Real-world durability | As assembled | <5% red rust after 120 cycles* | 5 assemblies per batch |

*Replace with project-specific values if the governing dacromet coating standard astm or OEM specification requires different thresholds.

Writing a Dacromet Coating Specification That Works

Ready to draft a dacromet coating specification? Start by mapping your product requirements (substrate, geometry, friction class, and color) to the test methods and acceptance criteria above. Reference the relevant dacromet coating standard astm (e.g., ASTM F1136 for zinc flake coatings on fasteners) and defer to customer or OEM hierarchy if required. This ensures your parts—whether they’re automotive brackets or a490 bolts with dacromet coating—will meet both regulatory and functional demands.

Remember: Salt spray test hours are not a direct predictor of field life—pair lab results with cyclic tests and design reviews for true reliability.

By structuring your approach around these testable criteria, you’ll move beyond marketing claims to a blueprint for measurable, auditable quality. Next, we’ll look at how Dacromet stacks up against other coatings, so you can make the right choice for your application.

Objective Comparison

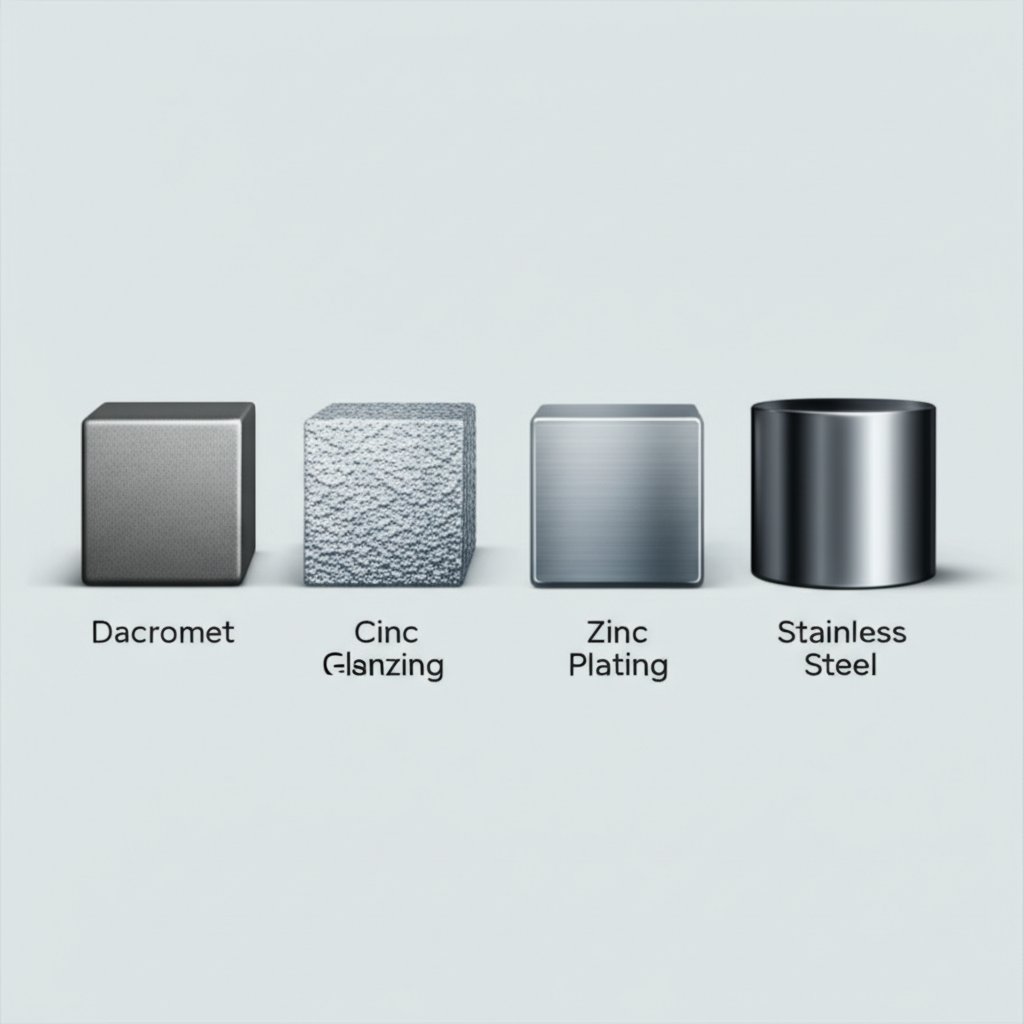

Choosing the right corrosion protection isn’t just a technical decision—it impacts your product’s lifespan, cost, and real-world reliability. So, how does Dacromet stack up against other coatings like hot dip galvanizing, stainless steel, zinc plating, or Geomet? Let’s break down the differences so you can make a confident, data-driven choice for your next project.

When Dacromet Outperforms

Imagine you’re specifying fasteners for an automotive suspension, or hardware that must withstand road salts, humidity, and thermal cycling. Dacromet coating excels in these high-demand scenarios, offering exceptional corrosion resistance with a thin, dimensionally stable layer. Unlike hot dip galvanizing—which can build up thick, uneven coatings—Dacromet’s dip-spin or spray application ensures uniform protection even in threads and recesses. Its lack of hydrogen embrittlement risk also makes it the go-to for high-strength fasteners where failure is not an option.

Where Galvanizing or Stainless Make More Sense

But what if you’re working on structural steel for a bridge, or outdoor installations where mechanical damage is likely? Here, hot dip galvanizing’s thick zinc layer (often 50–100 μm) offers superior mechanical durability and is often preferred for large, exposed structures. Stainless steel, meanwhile, provides unmatched corrosion resistance in marine or chemical environments—but at a significantly higher material cost. For cost-sensitive, indoor, or decorative applications, zinc plating remains a common choice, though its corrosion resistance is limited (typically 48–200 hours in salt spray testing).

Friction, Embrittlement, and Heat Exposure Tradeoffs

Each coating brings unique strengths and tradeoffs. Dacromet maintains a consistent coefficient of friction, critical for torque-controlled assembly of fasteners. Zinc plating is prone to hydrogen embrittlement (unless carefully treated), while Dacromet and hot dip galvanizing avoid this risk. When it comes to heat, Dacromet withstands up to 300°C, outperforming zinc plating and even some galvanized finishes. However, repeated assembly can wear through Dacromet’s thin layer more quickly than thicker coatings.

| Feature | Dacromet | Hot Dip Galvanizing | Zinc Plating | Stainless Steel | Geomet |

|---|---|---|---|---|---|

| Corrosion Resistance (Salt Spray, h) | 600–1,000+ | 500–1,000 | 48–200 | Excellent (passive, not tested as coating) | 600–1,000+ |

| Coating Thickness (μm) | 4–10 | 50–100 | 5–15 | N/A (bulk material) | 4–10 |

| Hydrogen Embrittlement Risk | None | None | Possible | None | None |

| Friction Control for Fasteners | Excellent (controlled) | Fair (variable) | Variable | Depends on finish | Excellent (controlled) |

| Edge/Recess Coverage | Excellent (dip-spin) | Good (may pool) | Fair | Excellent | Excellent |

| Heat Resistance (°C) | Up to 300 | Up to 200 | Up to 120 | Up to 800+ | Up to 300 |

| Repairability | Challenging | Possible (zinc spray) | Possible (replate) | N/A | Challenging |

| Appearance | Bright silver-gray, smooth | Matte gray, rougher | Shiny, various tints | Bright or brushed | Matte silver-gray |

| Environmental Profile | Improved, but some chromate systems | Low hazard | Chromate passivates may be restricted | Excellent | Chromate-free |

Let’s clarify a common point of confusion: Dacromet coating vs hot dip galvanizing is not just about corrosion test hours. Dacromet delivers high performance in thin layers, preserving tight tolerances and thread fits, while hot dip galvanizing’s bulkier layer is better for heavy-duty, exposed steel. For fasteners, Dacromet’s uniformity and embrittlement-free nature often tip the scales. For structural steel, galvanizing’s ruggedness wins out.

Understanding Zinc Flake Families: Dacromet vs Geomet

Both Dacromet and Geomet are zinc flake coatings, but they differ in their binder chemistry. Dacromet uses a chromate-based binder (sometimes trivalent, sometimes hexavalent in older systems), while Geomet employs a non-chromate matrix. This makes Geomet more environmentally friendly and increasingly specified in markets with strict regulations. Performance-wise, both offer excellent corrosion protection and friction control, but Dacromet may edge ahead in some extreme durability scenarios. If you’re weighing dacromet coating vs geomet, consider the environmental and compliance requirements of your application.

Fit by Application Scenario

- Dacromet: High-strength fasteners, automotive hardware, parts requiring tight tolerances

- Hot Dip Galvanizing: Structural steel, outdoor/marine installations, large anchors

- Zinc Plating: Indoor, low-corrosion, cost-sensitive hardware

- Stainless Steel: Critical, high-corrosion, or decorative parts where cost is secondary

- Geomet: Similar to Dacromet, but for applications prioritizing environmental compliance

Use Dacromet when you need high corrosion protection, dimensional accuracy, and no embrittlement risk—especially for fasteners and precision hardware.

Still not sure which way to go? If you’re evaluating dacromet coating vs hot dip galvanizing for your next project, remember: it’s about matching the coating’s strengths to your part’s real-world demands. And if you’re comparing e coat vs dacromet, note that e-coat is primarily for paint adhesion and moderate corrosion resistance, while Dacromet is engineered for robust anti-corrosion performance in aggressive environments.

Up next, we’ll dive into practical applications and design tips for getting the most from Dacromet and its alternatives.

Common Applications and Design Considerations for Dacromet Coated Hardware

Fastener Classes and Friction Targets

When you’re specifying corrosion-resistant components, it’s easy to focus on the test data and forget the real-world realities of assembly and performance. So, what does Dacromet coating mean for the parts you use every day? Let’s get practical—starting with the most common applications and the design choices that make or break long-term reliability.

- Dacromet coated bolts and screws: These are a staple in automotive, construction, and heavy equipment. Why? The thin, uniform zinc–aluminum flake layer delivers high corrosion resistance without clogging threads or adding bulk, which is critical for tight-tolerance assemblies and repeatable torque values.

- Dacromet coated a490 bolts: For structural steel connections—think bridges or high-rise frames—these high-strength fasteners benefit from Dacromet’s embrittlement-free protection and consistent friction, supporting safe, efficient installation even under demanding loads.

- Dacromet coated screws and fasteners: Used in brake systems, suspension, and engine assemblies, these components rely on the coating’s ability to maintain torque-tension windows and resist road salts, humidity, and temperature swings.

- Dacromet coating spring band hose clips: In fuel, cooling, and exhaust systems, these clips must flex repeatedly without losing their anti-corrosion shield. The flexible, adherent coating prevents rust creep and maintains clamping force over time.

- Brackets, clamps, and stamped hardware: For visible or structural parts, Dacromet’s smooth, matte silver finish provides not only protection but also a uniform appearance that’s easy to inspect and paint if required.

Clamps, Clips, and Stampings: Why Coverage and Consistency Matter

Imagine assembling a vehicle or a bridge: you’ll notice that every fastener and bracket must fit perfectly, resist corrosion, and—if painted later—provide a stable base for topcoats. Dacromet shines here because its dip-spin or spray process delivers even coverage on complex shapes and inside recesses, which is a challenge for bulkier coatings. For spring clips and thin stampings, the minimal film build preserves part flexibility and prevents jamming or misalignment during assembly.

| Component Type | Key Specification Elements | Design Notes |

|---|---|---|

| Dacromet coated a490 bolts | Friction class, coating thickness, salt spray/cyclic test, thread fit | Reference ASTM F1136 or project spec; ensure thread tolerances account for film build |

| Dacromet coated bolts & screws | Friction class, appearance, torque-tension window | Specify masking for critical threads or bearing surfaces |

| Spring band hose clips | Adhesion, flexibility, corrosion test | Verify coating does not crack under repeated flexing |

| Brackets, visible hardware | Appearance, paintability, rework allowance | Ensure smooth finish for topcoat adhesion; inspect for runs or thin spots |

| Clips, small stampings | Coverage, minimum thickness, edge protection | Design for easy drainage; avoid deep recesses where coating may pool |

Design Notes for Threads and Edges

Sounds straightforward? Here’s what engineers and buyers often overlook:

- Thread Fit and Film Build: Dacromet’s thinness (typically 6–12 μm) means oversized nuts or undercut threads are generally not required—unlike with hot dip galvanizing—which simplifies design and ensures a reliable fit for critical fasteners like dacromet coated a490 bolts.

- Masking and Drainage: For multi-functional parts, specify masking on electrical contacts or bearing surfaces. Design features that prevent coating entrapment or pooling in deep recesses—especially important for complex clips and brackets.

- Friction Class Alignment: If your assembly process is torque-controlled, select a friction class (per OEM or ASTM F1136) that matches your installation equipment and joint design. For fasteners, this ensures consistent preload and reduces the risk of over- or under-tightening.

For every application, balancing corrosion protection, fit, and assembly performance starts with clear specs and attention to coating details—especially for safety-critical parts like dacromet coated a490 bolts.

Curious how these design choices play out in procurement and quality control? The next section will guide you through supplier evaluation, quoting, and inspection best practices to ensure your Dacromet-coated parts deliver as promised.

Procurement Templates and Cost Drivers That Matter for Dacromet Coating

Cost Drivers and How to Evaluate Quotes

When you’re sourcing dacromet coating for bolts, fasteners, or structural hardware, the path from specification to reliable supply can feel overwhelming. What really drives the cost—and how do you compare quotes from dacromet coating suppliers in different regions like the US, UAE, or Asia?

- Part geometry and surface area: Larger or more complex parts increase both coating material and handling costs.

- Cleanliness requirements: Demanding pre-cleaning or surface prep raises labor and process time.

- Masking needs: If you require selective coating (for threads or contact points), expect higher costs due to added steps.

- Number of coats/topcoats: Multi-layer systems (e.g., with sealers or lubricious topcoats) cost more but may be required by your dacromet coating standard pdf or OEM spec.

- Inspection and test scope: More frequent or detailed inspection (like salt spray, friction, or thickness mapping) adds to the quote.

- Lot sizes and packaging: Small runs or special packaging (for export to regions like dacromet coating in nc or dacromet coating in uae) can push up per-part pricing.

When you evaluate suppliers, ask for a breakdown of these factors and request clarification on what’s included. This helps you avoid surprises and ensures apples-to-apples comparisons.

Copy-Ready Specification Language

Ready to issue an RFQ or statement of work? Here’s a template you can adapt for your next procurement round:

"Supplier shall provide Dacromet-coated bolts per [ASTM F1136 Grade 3] or equivalent, with minimum 1,000-hour salt spray resistance, specified friction class, and uniform coating thickness of 8–12 μm. All parts must be free of blisters, runs, and uncoated areas. Certification and test reports required with each lot."

Be sure to insert the correct standard or customer spec, and adjust acceptance criteria as needed. If you’re working with dacromet coating suppliers in chennai or other global sources, specify the region and any local compliance rules—such as environmental requirements for dacromet coating in uae or dacromet coating in nc.

- Volume and annual usage

- Substrate material and geometry

- Coating class (e.g., Dacromet 320, 500)

- Friction class (for fasteners)

- Appearance/finish requirements

- Required tests (salt spray, cyclic, friction, adhesion)

- Sampling plan and batch size

- Packaging/labeling needs

- Rework and rejection policy

- Request for dacromet coating standard pdf or supplier procedure

Example Acceptance Plan

| Characteristic | Method | Frequency | Criteria | Records |

|---|---|---|---|---|

| Coating Thickness | Magnetic gauge | 5 pcs/lot | 8–12 μm* | Thickness log |

| Corrosion Resistance | ASTM B117 Salt Spray | Per spec | No red rust at 1,000 h* | Test report |

| Friction Class | Torque-tension test | 10 pcs/lot | K-factor 0.10 ± 0.02* | Test record |

| Adhesion | Scribe/tape test | 3 pcs/lot | No flaking* | Visual check |

| Appearance | Visual | All parts | No runs/blisters | Inspection sheet |

*Adjust values to match your governing standard or project specification.

Inspection Checklist for Incoming Dacromet Coated Bolts

- Measure coating thickness at threads, shank, and head

- Check adhesion at multiple locations

- Inspect for visual defects: runs, blisters, uncoated areas

- Verify cure (no soft or sticky areas)

- Confirm batch traceability and certification

Requesting a dacromet coating standard pdf or the supplier’s detailed procedure is a smart move. This lets you compare process steps and quality controls with your internal requirements and the OEM standard hierarchy. If you’re sourcing from new regions—say, dacromet coating in nc or dacromet coating in uae—double-check that local suppliers can provide documentation in your required format and language.

Supplier Qualification and Samples: What to Look For

Imagine you’ve narrowed your list to a few dacromet coating suppliers. What’s next? Ask for production samples with full test data, including salt spray, friction, and thickness results. Evaluate their ability to deliver consistent, repeatable quality—especially for critical dacromet coating bolts or assemblies.

For buyers who need integrated solutions, Shaoyi is an example of a partner that can translate your coating specs into manufacturable processes, integrate stamping with coating, and provide PPAP-ready documentation for automotive or industrial launches. You can learn more about their full range of services at Shaoyi’s service page. Of course, qualified alternatives are available globally, and you should benchmark multiple suppliers for best results.

Building a robust procurement process—complete with clear specs, acceptance plans, and sample-based qualification—ensures your Dacromet-coated parts perform, whether you’re sourcing locally or internationally.

With these procurement tools, you’re ready to move confidently from quote to delivery. Next, we’ll look at how to maintain process control and quality assurance on the coating line, closing the loop from sourcing to in-service reliability.

Process Control and Quality Assurance Essentials for Dacromet Coating Fasteners

Critical Control Points in Coating Lines

Ever watched a dacromet coating process video and wondered how every bolt or bracket comes out looking flawless? The secret is rigorous process control—each stage is a checkpoint to ensure the final finish meets demanding standards for corrosion resistance and fit. Let’s walk through the essentials:

- Incoming Material Cleanliness: All parts must be free from oils, rust, and contaminants. Imagine prepping a surface for paint—if it’s not spotless, the coating won’t stick.

- Surface Preparation: Mechanical or chemical cleaning (like abrasive blasting) creates a micro-profile for the coating to grip.

- Chemical Bath Maintenance: Regularly monitor bath solids and viscosity. Too thick or thin, and you’ll get uneven coverage or runs.

- Application Parameters: Dip-spin speed, spray pressure, and immersion time must be tightly controlled for uniform film build, especially on complex fasteners.

- Flash-off Time: Allow proper evaporation of solvents before curing to prevent bubbling or defects.

- Oven Cure Profile: Temperature and time must be verified—typically 300–320°C for 15–30 minutes—to ensure the binder crosslinks fully and locks in the zinc-aluminum flakes.

- Post-Cure Cooling: Controlled cooling prevents thermal shock, which can cause cracking or delamination.

Thickness and Cure Verification

How do you know your dacromet coating fasteners have the right protection? Thickness and cure checks are non-negotiable. Here’s how it’s done:

- Thickness Measurement: Use magnetic or eddy-current gauges for steel parts. Measure at multiple locations—threads, shank, head, and any recesses—to confirm even coverage. For complex parts, follow the governing standard for exact measurement points and tolerances.

- Cure Verification: Visual inspection for color and gloss, plus hardness or solvent rub tests, confirm the coating is fully baked and durable.

| Control Point | Measurement Method | Frequency | Reaction Plan |

|---|---|---|---|

| Bath Solids/Viscosity | Viscometer, solids test | Daily | Adjust/add chemicals as needed |

| Application Parameters | Spin/spray speed, immersion time | Every batch | Reset to spec if out of range |

| Flash-off Time/Temp | Timer, thermometer | Every batch | Hold parts if not met |

| Oven Cure Profile | Temperature recorder | Each run | Adjust oven settings |

| Coating Thickness | Magnetic gauge | 5 pcs/lot | Re-coat or reject if out of spec |

| Cure Verification | Visual/hardness test | All parts | Re-bake or reject if soft |

Documentation and Compliance: Is Your Dacromet Coating RoHS Compliant?

With environmental regulations tightening, it’s crucial to check if your formulation is dacromet coating rohs compliant. Many modern zinc flake systems are designed to meet RoHS and REACH requirements, but always request supplier declarations and lab reports. For critical projects, keep these documents on file for audits and customer reviews.

NOF Metal Coatings Dacromet systems, for example, have evolved to offer trivalent or chromium-free options for eco-sensitive applications. Still, always verify compliance for your specific batch and application.

- Blistering: Caused by poor surface prep or trapped moisture. Solution: Improve cleaning and flash-off control.

- Runs or Drips: Excess material or improper spin/spray settings. Solution: Adjust application parameters.

- Insufficient Edge Coverage: Inadequate bath maintenance or poor fixturing. Solution: Review bath solids and part orientation.

- Uncured or Soft Coating: Low oven temp or short cure time. Solution: Verify and adjust oven profile.

Consistent process control and documentation are your best defense against coating failures—don’t rely on luck for critical parts.

By mastering these checkpoints, you’ll consistently deliver dacromet coating fasteners that meet or exceed your quality and compliance goals. Next, discover how to keep these standards high with effective field maintenance and troubleshooting tips.

Maintenance, Repair, and Troubleshooting Guidance for Dacromet Coating

Field Repair and Touch-Up Steps

When you spot minor damage or corrosion on a Dacromet coated part, quick action can prevent bigger issues down the road. But what’s the right way to repair a scratch or worn area—especially on critical components like fasteners or a 4 0 straight link dacromet coated chain? Here’s a simple, step-by-step approach that field technicians and reliability engineers can follow:

- Clean the area: Remove dirt, grease, and debris from the damaged spot using a suitable cleaner.

- Lightly abrade the surface: Gently sand or brush the area to remove loose coating and rust, exposing a sound base for touch-up.

- Eliminate corrosion products: Use a wire brush or abrasive pad to clear away white rust or oxides, especially on chains or hardware exposed to the elements.

- Apply compatible zinc-rich touch-up: Follow your supplier’s guidance to select a touch-up product that matches the original Dacromet system. For chains like the 4 0 straight link dacromet coated chain, it’s critical to ensure the repair material is compatible with both the coating and the intended use.

- Allow proper cure: Let the touch-up fully cure per product instructions—rushing this step can compromise protection.

- Document the repair: Record the location, date, and method used for traceability and future inspections.

Pros and Cons of Touch-Up Options

-

Pros

- Restores corrosion resistance to small damaged areas

- Extends service life of parts like fasteners and chains

- Can be performed in the field with minimal equipment

-

Cons

- May not match the durability or appearance of the original Dacromet coating

- Requires careful surface prep and correct product selection for compatibility

- Frequent repairs might indicate underlying process or application issues

Always verify that the touch-up material is approved for use with your specific Dacromet system—especially for safety-critical applications or consumer products such as dacromet coated chain. If you’re wondering, is dacromet coated chain cpsia compliant?—formal testing and supplier documentation are essential for consumer-facing items.

Troubleshooting Common Defects

Noticed white corrosion, flaking, or blistering? These symptoms can reveal much about the root cause—whether it’s a process issue, environmental exposure, or material incompatibility. Here’s a quick-reference table to help you diagnose and address common problems:

| Symptom | Likely Root Cause | Corrective Action |

|---|---|---|

| White corrosion products | Insufficient coating thickness, edge coverage, or cure | Check film build, improve process controls, or re-coat affected area |

| Adhesion loss/flaking | Poor surface prep, bath aging, or improper cure | Review cleaning steps, replace/refresh coating bath, verify cure cycle |

| Blistering | Trapped moisture, contamination, or inadequate flash-off | Enhance surface drying, improve flash-off, and inspect for contaminants |

| Uneven appearance/runs | Excess material, improper dip-spin or spray parameters | Adjust application settings, ensure even distribution |

Many of these issues can be traced back to process steps—like degreasing, blasting, or bath maintenance—highlighting the importance of robust quality control both at the coating line and in the field. For more details on troubleshooting, refer to industry resources and supplier documentation.

Regulatory and Obsolescence Watchouts

Did you know that some older Dacromet systems contained hexavalent chromium—a substance increasingly restricted in many markets? If you’re using legacy inventory, or sourcing globally, confirm whether your coating is based on current, compliant formulations. Always check for dacromet coating banned or dacromet coating discontinued notices in your region, as regulations can change and impact both procurement and field service options. For consumer products—especially those like 4 0 straight link dacromet coated chain used in playgrounds or public spaces—verify compliance with sector-specific rules such as CPSIA, and obtain formal test results when necessary.

Preventive maintenance and early defect triage extend service life far more than reactive repairs—stay proactive for the best results.

By following these maintenance and troubleshooting steps, you’ll keep your Dacromet coated hardware—whether a fastener, bracket, or dacromet coated chain—delivering reliable performance in the field. In the final section, we’ll outline how to transition from specification to production launch with the right partners and documentation.

From Spec to Launch

From Specification to Production Readiness

When you’re ready to move from research to real-world results, what does a successful Dacromet coating launch look like? Imagine you’ve nailed the technical details—now it’s about execution. Here’s a practical roadmap to take your project from drawing board to production floor, whether you’re sourcing from a dacromet coater in nc, a supplier offering dacromet coating in chennai, or a partner in the UK, Australia, or Canada.

- Finalize the coating specification: Lock in all technical requirements—thickness, friction class, corrosion test hours, and any regional compliance needs (such as those for dacromet coating in chennai or the UK).

- Align test plan and sampling: Specify required tests (salt spray, cyclic corrosion, adhesion, friction) and your sampling plan.

- Select and qualify suppliers: Shortlist providers with proven experience, robust quality systems, and the ability to meet your documentation and performance expectations.

- Run production trials: Request pilot lots or pre-production samples. Validate key criteria—especially torque-tension for fasteners and uniform coverage for complex assemblies.

- Lock packaging and logistics: Confirm packaging specs to prevent damage in transit, especially for export projects or where climate can affect coated parts.

- Build your PPAP or launch dossier: Collect all documentation—test reports, inspection logs, certificates of compliance, and process flows.

Coating Integration with Stamping and Assembly

Sounds straightforward? In practice, integrating Dacromet with upstream stamping or downstream assembly can present challenges. For instance, tight tolerances on stamped brackets or fasteners mean you must consider coating thickness when designing mating parts. Early coordination between your engineering, quality, and production teams—and your coating supplier—helps avoid costly rework or assembly issues.

For buyers seeking end-to-end support, a partner like Shaoyi can streamline this process by integrating stamping, Dacromet coating, and assembly under one roof. This is especially valuable for automotive and Tier 1 suppliers who demand IATF 16949-certified quality and rapid response. Of course, it’s wise to benchmark multiple providers—whether you’re considering a dacromet coater in nc, a specialist in dacromet coating in chennai, or established sources in other regions—so you can make data-driven decisions, not just rely on claims.

Documentation and Launch Timing

Launching a new coated part isn’t just about the first shipment—it’s about building a repeatable, auditable process. You’ll need a robust documentation package to satisfy both internal stakeholders and customers. Here’s a checklist of key artifacts to collect as you move from sourcing to launch:

- Approved coating specification and drawings

- Supplier process flow and control plan

- Test reports (salt spray, cyclic, friction, adhesion, thickness)

- First article inspection results

- Certificates of compliance (including RoHS/REACH if required)

- PPAP or equivalent approval documentation

- Packaging and labeling instructions

- Ongoing inspection and requalification plan

For engineers and buyers: Start with a clear spec, validate with real data, and choose partners who can deliver both quality and documentation—your launch success depends on it.

By following these steps, you’ll minimize surprises and ensure your Dacromet-coated parts—whether sourced from dacromet coating in chennai or elsewhere—meet expectations from the first lot through full production. Ready to take the next step? Review your documentation, check supplier readiness, and set a launch date with confidence.

Frequently Asked Questions about Dacromet Coating

1. What is Dacromet coating and how does it work?

Dacromet coating is a proprietary zinc–aluminum flake finish suspended in an inorganic binder that protects metal parts from corrosion. It works by creating a barrier with overlapping flakes and offers sacrificial protection, where zinc corrodes preferentially, shielding the base metal even if scratched. This thin, uniform layer is especially effective on fasteners and hardware where dimensional accuracy is critical.

2. Is Dacromet better than galvanized coating?

Dacromet often outperforms galvanized coatings in applications requiring thin, uniform coverage and precise thread fit, such as automotive fasteners and high-strength bolts. While hot dip galvanizing provides a thicker, more rugged layer for structural steel, Dacromet excels in friction control, embrittlement-free protection, and consistent performance on complex geometries. The right choice depends on your specific part requirements and exposure conditions.

3. What is the standard for Dacromet coating?

Dacromet coatings are typically specified according to standards like ASTM F1136, which defines corrosion-resistant zinc flake coatings for fasteners. The standard outlines coating grades, thickness ranges, salt spray test requirements, and friction classes. Always refer to your project’s or OEM’s specification hierarchy to ensure compliance with the correct standard.

4. Where is Dacromet coating commonly used?

Dacromet coating is widely used on automotive bolts, high-strength fasteners, spring band hose clips, brackets, and industrial hardware. Its thin, robust protection is ideal for parts exposed to road salts, humidity, or aggressive environments, and where precise assembly torque and minimal dimensional change are required.

5. How do I select a reliable Dacromet coating supplier?

Choose suppliers with proven process control, relevant certifications, and experience meeting your industry’s standards. Evaluate sample parts for thickness, corrosion resistance, and friction class. For integrated solutions, consider partners like Shaoyi, who offer stamping, coating, and PPAP-ready documentation, but always benchmark multiple suppliers—whether sourcing Dacromet coating in NC, UAE, Chennai, or globally—to ensure consistent quality and documentation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —