Die Casting Flash: Key Causes and Prevention Methods

TL;DR

Die casting flash is a common manufacturing defect consisting of a thin, unwanted layer of excess molten metal that escapes from the mold cavity during the casting process. It typically forms along the parting lines, seams, or around ejector pins on the final product. This issue is primarily caused by worn tooling, insufficient clamping force from the machine, improper die sealing, or suboptimal process parameters like excessive injection pressure.

Understanding Die Casting Flash: A Detailed Definition

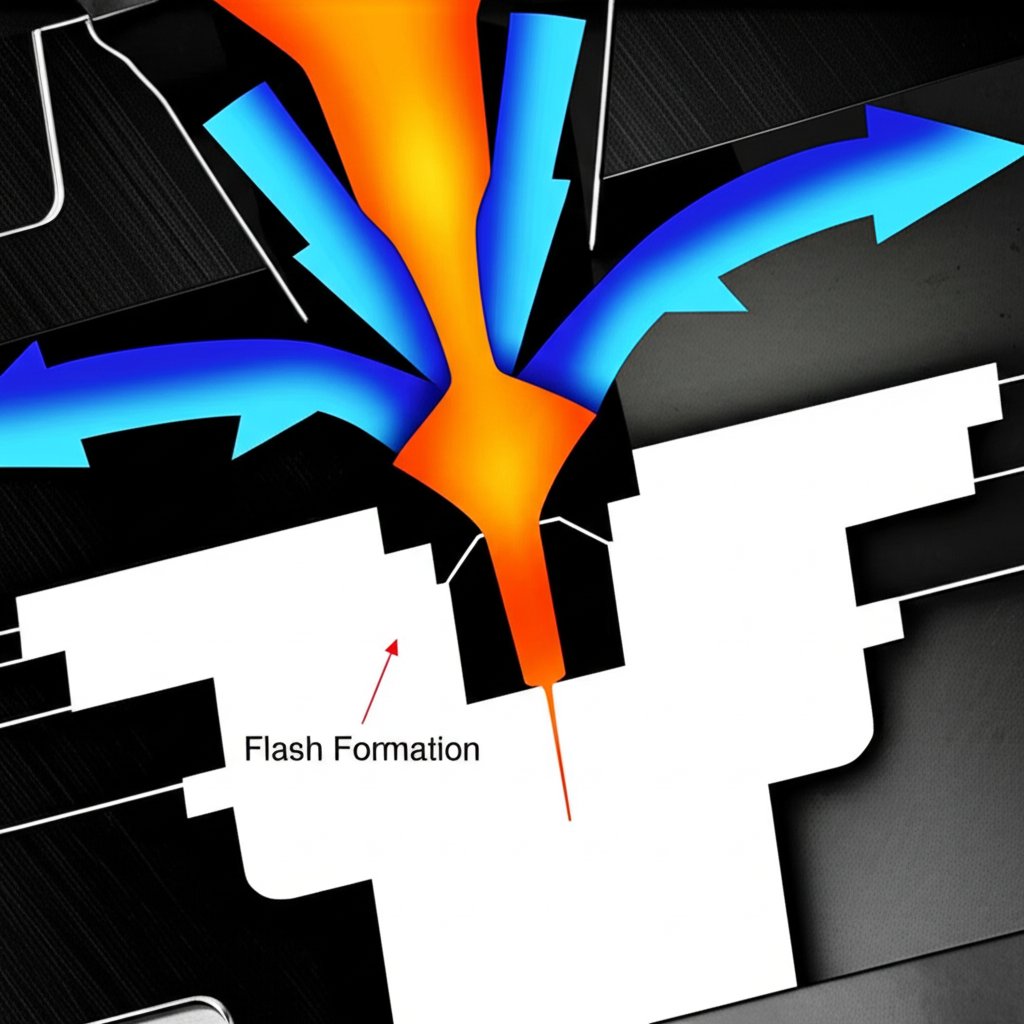

In the high-pressure environment of die casting, molten metal is injected into a steel mold, known as a die, to form precise components. Die casting flash is the excess material that seeps out of the intended mold cavity through any available gap. This leakage solidifies into a thin, fin-like protrusion on the surface of the cast part. Due to the natural fluidity of molten metal under immense pressure, even the smallest imperfection or gap in the die assembly can become an escape route.

This defect is considered problematic because it alters the final dimensions of the component and often requires a secondary, labor-intensive removal process, increasing both production time and costs. The presence of flash indicates a potential issue in the manufacturing process that needs to be addressed to ensure consistent quality and part integrity. Its appearance can range from a fine, wafer-thin layer to a more substantial flange, depending on the size of the gap and the pressure of the injection.

Flash commonly appears in specific areas of the casting where different parts of the mold come together. These locations include:

- Parting Lines: The primary seam where the two halves of the die meet is the most common location for flash.

- Ejector Pins: Small gaps around the pins used to push the solidified part out of the mold can allow metal to escape.

- Slides and Cores: Areas where moving components (slides or cores) are used to create complex internal features can also have sealing issues.

- Vents: If vents designed to let air escape are too large or become worn, they can also allow molten metal to pass through.

It's important to distinguish flash from other necessary components of the casting process. Sprues, runners, and gates are intentionally designed channels that guide the molten metal into the mold cavity. While this material is also excess and must be removed, it is a planned part of the process. Flash, by contrast, is an unplanned and undesirable defect resulting from a failure to contain the molten metal completely.

The Primary Causes of Flash Formation

The formation of die casting flash is rarely due to a single issue; it typically results from a combination of factors related to the tooling, the machine, and the process parameters. Identifying the root cause is essential for implementing an effective solution. The most common culprits include mold-related issues and improper machine or process settings.

One of the most frequent causes is the degradation or improper design of the die itself. Over time, the constant heating and cooling cycles, combined with high pressures, can cause wear on the parting surfaces of the mold. If these surfaces no longer seal perfectly, gaps are created. Similarly, a poorly designed mold with inadequate sealing features or a misaligned assembly will be prone to leakage from the start. Any distortion or damage to the mold halves can prevent them from closing tightly, inevitably leading to flash.

Equally important are the machine settings and process parameters. The clamping force of the die casting machine, which holds the two mold halves together, must be sufficient to counteract the immense pressure of the molten metal injection. If the clamping tonnage is set too low, the injection pressure can physically force the die halves apart, creating a gap for metal to escape. According to experts at Dynacast, insufficient machine tonnage is a primary cause of flash. Furthermore, excessive injection pressure or speed can overwhelm even a properly clamped mold, forcing metal into the smallest crevices.

The table below summarizes the key causes and their underlying physical reasons, providing a clear diagnostic framework.

| Cause Category | Specific Issue | Physical Reason |

|---|---|---|

| Tooling & Mold | Worn or damaged parting lines | Creates a poor seal between mold halves. |

| Tooling & Mold | Mold misalignment | Prevents the two halves from closing flush. |

| Machine Settings | Insufficient clamping force | Injection pressure overcomes the force holding the mold shut. |

| Process Parameters | Excessive injection pressure or speed | Forces molten metal into microscopic gaps before they can be sealed. |

| Process Parameters | High mold or metal temperature | Reduces the viscosity of the molten metal, allowing it to flow more easily into gaps. |

Effective Strategies for Flash Prevention and Control

Preventing die casting flash is a proactive endeavor that combines rigorous maintenance, precise machine calibration, and intelligent mold design. By addressing the root causes, manufacturers can significantly reduce the occurrence of this defect, leading to higher quality parts and lower production costs. A comprehensive prevention strategy focuses on maintaining the integrity of the tooling and optimizing all process variables.

The first line of defense is a meticulous and consistent mold maintenance program. As detailed by CEX Casting, regular inspections are crucial for identifying wear, cracks, or damage on the parting surfaces before they become severe. Dies should be cleaned regularly to remove any residue that could prevent a tight seal. When wear is detected, the parting lines must be repaired or remachined to restore their original flatness and ensure a perfect fit between the mold halves.

Optimizing machine and process parameters is another critical step. This involves ensuring the die casting machine provides adequate and evenly distributed clamping force to withstand the injection pressure. Operators must also fine-tune injection parameters, including pressure, speed, and temperature, to the specific requirements of the part geometry and alloy being used. Using the minimum pressure necessary to fill the cavity completely will reduce the stress on the mold and minimize the tendency for flash to form. An expert from Sunrise Metal notes that maintaining the correct operating temperature for the alloy is vital, as excessive heat can increase fluidity and promote flash.

Finally, high-quality tooling and design play a fundamental role. Investing in robust, well-designed dies with proper sealing features and ventilation can prevent many flash-related issues from the outset. In industries where component failure is not an option, such as automotive manufacturing, the focus on tooling integrity is paramount. For instance, companies like Shaoyi (Ningbo) Metal Technology, which specializes in precision-engineered automotive forging parts, rely on superior die design and rigorous quality control to produce robust, high-performance components. This principle of investing in quality tooling is directly applicable to preventing defects like flash in die casting.

Implementing these strategies can be broken down into a series of actionable steps:

- Implement a Rigorous Mold Maintenance Schedule: Regularly inspect, clean, and repair die surfaces, paying close attention to parting lines and moving components.

- Verify and Calibrate Clamping Force: Ensure the machine's clamping tonnage is correctly set for the specific mold and injection pressure being used. Check for even pressure distribution across the die.

- Optimize Injection Parameters: Use process monitoring to find the ideal balance of injection speed, pressure, and temperature that fills the part without creating excessive force on the mold.

- Ensure Proper Die Alignment and Support: Correctly install the mold in the machine and ensure it is properly supported to prevent any deflection or misalignment during the injection cycle.

- Control Thermal Conditions: Use thermal analysis and effective cooling channel design to maintain a stable and uniform temperature across the die, preventing distortion.

Frequently Asked Questions

1. What is the flash in die casting?

Flash is excess material that forms on a die-cast part when molten metal leaks out of the mold cavity through gaps or seams. It typically appears as a thin fin or flange along the parting line where the mold halves meet and is considered a manufacturing defect that must be removed.

2. What is the purpose of die casting?

The purpose of die casting is to produce complex metal parts with high precision and dimensional accuracy in large volumes. The process involves injecting molten metal under high pressure into a reusable steel mold (a die), allowing for the rapid manufacturing of components with excellent surface finish and intricate details.

3. What is a casting flash?

Casting flash is another term for the defect described above. It refers to the thin, wafer-like sheet of unwanted material left on a casted part, caused by molten material seeping into the seam of the mold. While common, it must be removed in a secondary operation to meet final product specifications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —