What Is Blackening? Metal Surface Treatment For Enhanced Durability In Automotive Parts

Blackening Coating

What blackening means in metals

When you hear the term "blackening" in the context of automotive parts, what comes to mind? Is it just a dark paint, or something more? Blackening—also known as black oxide coating or metal blackening—is a specialized chemical process that transforms the surface of ferrous metals, such as steel, into a thin, stable layer of magnetite (Fe3O4). This layer is not simply applied on top like paint or plating; instead, it forms by converting the outermost surface of the metal itself. The result is a finish that enhances lubricity, provides a baseline level of corrosion protection, and preserves the precise dimensions of the component.

Blackening is a chemical conversion process that transforms the surface of ferrous metals into a thin, stable magnetite layer—unlike paints or platings, it does not add material, ensuring tight tolerances are preserved.

So, what is black oxide? It is a term used interchangeably with blackening, and refers to this unique, non-depositing conversion coating. The resulting finish is sometimes described as black oxidised steel, and is especially valued when dimensional accuracy is critical.

Why automotive engineers choose black oxide

Imagine assembling a precision-machined pin or a threaded fastener—would you risk a coating that could throw off the fit by even a fraction of a millimeter? That’s where blackening shines. The black oxide layer is extremely thin—typically only 1 to 2 micrometers—so it doesn’t build up and alter part dimensions. This makes it ideal for:

- Automotive fasteners (bolts, screws, nuts)

- Seat track and adjustment hardware

- Window regulator components

- ABS and brake system housings

- Engine timing hardware

- Drivetrain pins and shafts

- Precision brackets and machined inserts

Automotive engineers also appreciate that blackening provides a smooth, non-reflective, and often aesthetically pleasing finish. This helps with both appearance and function, reducing glare and improving grip in assembly tools or hand-held parts. It’s important to note that what is blackened steel is not just about looks—this finish offers a practical balance of corrosion resistance and wear properties, especially when paired with the right post-treatment oil or sealant.

Where blackened parts fit in the vehicle

Curious where you’ll find blackened components in a modern vehicle? You’ll notice them in:

- Threaded fasteners and bolts holding critical assemblies

- Sliding seat tracks requiring low friction and consistent fit

- Small pins and shafts in window and door mechanisms

- ABS and engine control housings where conductivity and minimal buildup matter

- Timing system gears and chains exposed to lubricants

Because the blackening coating is a conversion layer, not a deposit, it ensures that threads, bores, and sliding fits stay within tight tolerances. This is a key reason why black oxide remains a staple in automotive engineering, especially for parts that must assemble smoothly and perform reliably over time.

However, the converted layer alone offers only moderate corrosion resistance. To meet the demanding environments of automotive service, blackened parts are typically finished with a post-treatment oil or sealant. This step is essential, so be sure to plan for it early in your design process.

As you read on, you’ll discover how different process variants (hot, cold, vapor), inspection points, standards, and testing methods shape the final quality of blackened parts. For now, remember: black oxide delivers dimensional control, consistent appearance, and compatibility with assembly oils—making it the go-to solution for critical automotive components where performance and precision can’t be compromised.

How Black Oxide Coating Works

Conversion coating chemistry explained

Sounds complex? Let’s break it down. The science behind blackening—also called the black oxide process—is a chemical reaction that transforms the outermost layer of a metal part into a stable oxide. For steel and most ferrous metals, this oxide is magnetite (Fe3O4), a tough, dark compound that gives blackened parts their signature look and improved corrosion resistance. Unlike plating, which adds metal on top, or paint, which sits as a separate film, a conversion coating chemically changes just the surface. This means the part’s dimensions barely change—crucial for automotive fasteners, threads, and press fits where every micron counts.

Imagine dipping a machined steel bolt into a specialized bath. The solution reacts with the metal, converting its surface into a thin, bonded layer. This layer is only about 1–2 micrometers thick, so tolerances are preserved while the part gains a non-reflective, lubricious finish. The process is considered a form of conversion coating, and is used across industries to boost durability and aesthetics with minimal size impact.

Hot versus cold versus vapor methods

When it comes to blackening, not all processes are created equal. Automotive engineers often choose between hot, mid-temperature, and cold blackening—each with distinct pros and cons. Here’s how they compare:

| Process Type | Temperature Range | Typical Base Materials | Throughput & Cycle | Safety/Environmental | Usual Post-Seal |

|---|---|---|---|---|---|

| Hot Blackening | ~141°C (286°F) | Carbon steel, tool steel, cast iron | Fast (minutes), high-volume | Steam, caustic fumes, explosion risk | Oil, wax, or polymer |

| Mid-Temperature | 90–120°C (194–248°F) | Steel, black oxide stainless steel | Moderate (20–60 min), batch | Lower fumes, safer handling | Oil, wax |

| Cold Blackening | 20–30°C (68–86°F) | Steel, touch-up on existing parts | Convenient, slower, lower durability | Minimal hazard, easy at small scale | Oil, wax (essential) |

| Vapor/Other | Specialized (varies) | High-precision steel, select alloys | Custom, low throughput | Special controls needed | Sealant per spec |

Hot blackening is the go-to for most automotive applications due to its speed and robust conversion to magnetite. It’s ideal for large batches—think thousands of fasteners or seat track parts. However, it requires careful control due to the high temperatures and caustic chemicals involved. Mid-temperature blackening offers a safer, lower-fume alternative, especially useful for black oxide stainless steel parts, but with a slightly slower process. Cold blackening doesn’t truly convert the metal surface—instead, it deposits a copper-selenide layer, making it best for cosmetic touch-ups or maintenance rather than primary production. Vapor or specialty methods are reserved for ultra-precision needs and are less common in mainstream automotive production.

Base material considerations and limitations

Not every metal responds the same way to blackening. Here’s what you need to know:

- Steel & Iron: Both hot and mid-temperature blackening produce durable, stable magnetite layers. Low-alloy and tool steels are common candidates.

- Stainless Steel: Requires mid-temperature or specialized chemistries. The process is tailored for 200, 300, and 400 series stainless, often labeled as black oxide stainless steel.

- Aluminum: Standard blackening won’t work—black oxide aluminum finishes require separate processes, such as anodizing or chromate conversion, to achieve similar aesthetics and protection.

- Copper, Zinc, Brass: Special blackening solutions exist (e.g., Ebonol C for copper, Ebonol Z for zinc), but these are less common in automotive structural parts.

What does this mean for your designs? If you need a black oxide coating for a critical automotive fastener, pin, or bracket, steel is your best bet. For stainless, ensure the process matches the alloy. For aluminum, consider black anodizing or chem film instead. The big advantage: all these conversion coatings maintain dimensional accuracy, so you won’t sacrifice fit or function for durability. This makes blackening a smart choice when tight tolerances and smooth assembly are non-negotiable.

Up next, we’ll dive into the practical steps and inspection points that keep blackened parts reliable in demanding automotive environments.

Surface Preparation and Process Steps That Prevent Failures

Surface preparation checklist

Ever wondered why some blackened parts look flawless while others turn out streaky or patchy? The secret often lies in the preparation. Before you even think about dipping your parts into a steel blackening solution, it’s crucial to get the surface just right. Imagine you’re building a house—if the foundation isn’t solid, nothing else will hold up. Similarly, a clean, well-prepped surface is the foundation for a durable, uniform black oxide finish.

- Remove all machining oils, lubricants, and contaminants from the part’s surface

- Ensure edges are burr-free and sharp corners are gently broken

- Surface finish should be consistent—set a target roughness that matches both function and appearance requirements

- Check for heavy rust, scale, or heat-treat oxides; these may require additional descaling or micro-etching

- Inspect for visible machining marks—deep scratches or grooves can cause uneven blackening

- Confirm uniformity and cleanliness before starting the blackening process

Setting these pre-blackening targets helps ensure every part—whether you’re learning how to blacken steel or how to blacken stainless steel—starts on equal footing. For critical automotive parts, it’s wise to document surface roughness and cleanliness standards right on the drawing or process sheet [source].

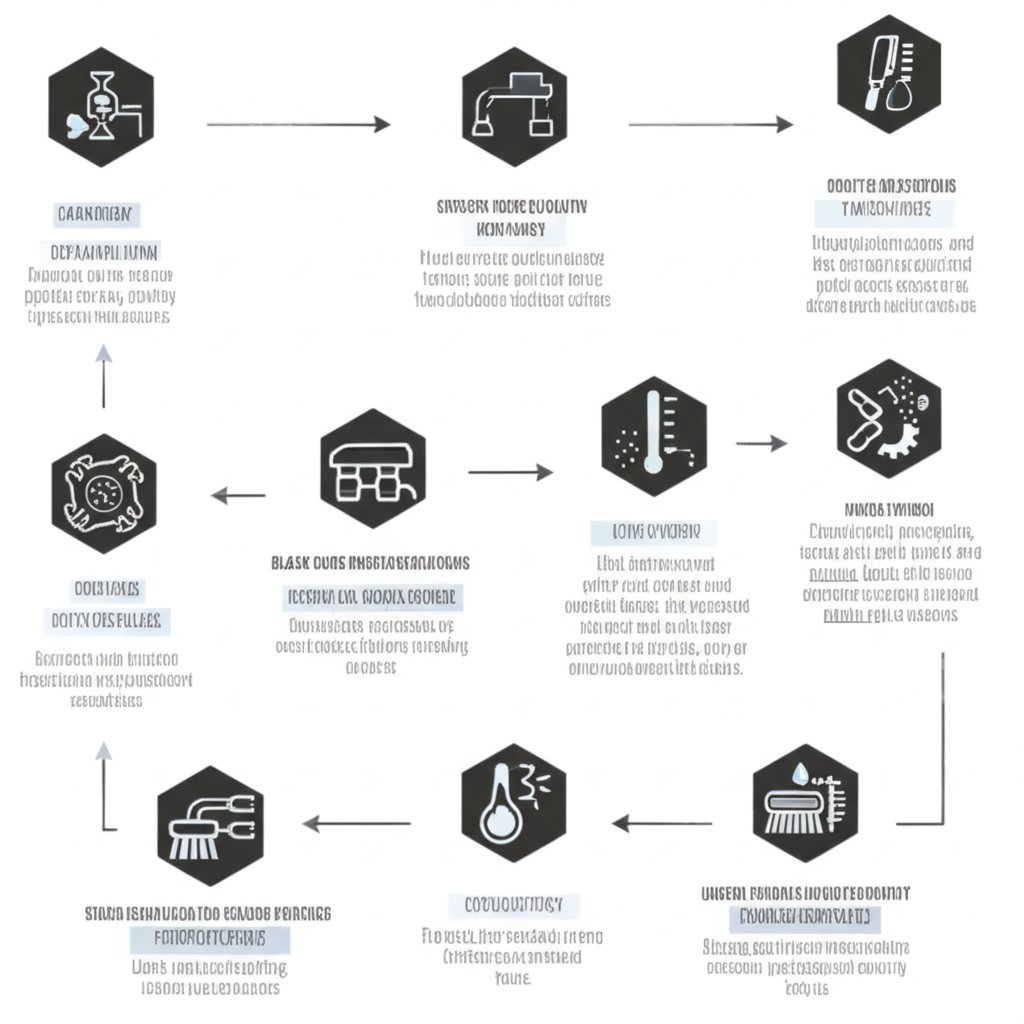

Process sequence you can adopt

Sounds complex? Not really, once you break it down. Here’s a vendor-ready, step-by-step sequence you can follow—whether you’re running a full-scale production line or using a blackening kit for prototypes:

- Incoming Inspection: Visually and dimensionally check all parts. Record lot IDs and any special notes.

- Degreasing/Alkaline Cleaning: Use a high-pH cleaner at elevated temperature (~180°F) to remove oils and greases. Oil-splitting cleaners are preferred for efficiency and bath longevity.

- Rinse: Thoroughly rinse to remove all cleaning residues. Counterflow rinses are ideal to minimize chemical carryover.

- Micro-Etch or Acid Activation: Briefly immerse parts in an acid bath to remove remaining oxides, rust, or scale and activate the surface. Avoid over-etching, which can dull features or alter fits.

- Rinse: Another thorough rinse to eliminate acid residues.

- Blackening Bath (Conversion): Immerse parts in the black oxide solution at the specified temperature and time. For hot processes, maintain a boiling point around 283–288°F and avoid overloading the tank (no more than 1 lb of parts per gallon of solution).

- Rinse: Immediately rinse parts to stop the reaction and remove any loose residues.

- Neutralization (if specified): Some processes require a mild alkaline dip to neutralize acidity and stabilize the finish.

- Seal with Oil or Polymer: Apply the chosen sealant while the part is still warm. This step is essential, as the blackened layer itself is porous and relies on the sealant for corrosion protection.

- Controlled Drying: Allow parts to air dry or use a low-temperature oven to set the sealant.

- Final Inspection and Packing: Check for uniform appearance, absence of smut or residue, and consistent gloss or matte finish as specified. Pack parts promptly to prevent contamination.

Throughout the blackening process, record bath chemistry, temperature, immersion times, and agitation in process control sheets. This documentation helps ensure repeatability and traceability, especially for automotive suppliers working under ISO or IATF requirements.

In-process inspection points

How do you know your metal blackening solution is working as intended? In-process checks are your safety net. Here’s what to watch for:

- Uniform, deep black color—no splotches, streaks, or reddish tints

- Absence of smut (loose residue) or chalky deposits

- Consistent gloss or matte appearance per drawing notes

- Threads and bores gauge correctly; no buildup or tight spots

- Sealant coverage is complete and even

For each batch, maintain traceable records: lot ID, operator, time-in-bath, and inspection results. If reference standards specify numeric bath windows (such as temperature or concentration) or rinse counts, follow them closely. If not, consult your chemical supplier’s guidelines or the applicable industry standards for exact values.

By following this structured approach—starting with surface prep, moving through a controlled blackening process, and finishing with thorough inspection—you’ll greatly reduce the risk of field failures and ensure your automotive components meet both appearance and durability targets. Up next, we’ll explore the standards and specification language that keep blackened parts consistent from drawing to delivery.

Standards and Specification Writing for Black Oxide Finish on Steel

Common standards to reference

When you’re specifying a black oxide finish for automotive parts, you might wonder: which standards guarantee consistent quality and performance? The answer depends on your industry, application, and the level of traceability required. For automotive and industrial applications, several widely recognized standards define process steps, appearance, and performance for black oxide coatings:

- AMS2485 (SAE): Aerospace and automotive black oxide on steel and ferrous alloys. Sets requirements for process, corrosion resistance, and appearance.

- MIL-DTL-13924: U.S. military specification for black oxide coatings on ferrous components. Covers process, classes, and supplementary preservative coatings.

- ISO 11408: International standard related to corrosion tests for metallic coatings, including process control and performance tests.

- MIL-PRF-16173: Specifies water-displacing preservative oils for post-treatment, referenced in MIL-DTL-13924 for corrosion protection.

- OEM/Automotive Specifications: Many automakers and Tier 1 suppliers have internal standards referencing the above, often with added requirements for appearance, packaging, or corrosion test hours.

Choosing the right standard ensures your black oxide finish on steel meets both regulatory and customer expectations. For comparison, zinc plating is often specified under standards like ASTM B633, but this is a different coating process.

How to write drawing notes

Sounds complex? It doesn’t have to be. Well-written drawing notes are your blueprint for supplier compliance. They should clearly specify:

- The base standard for the black oxide process (e.g., AMS2485, MIL-DTL-13924)

- Required post-treatment or sealant (e.g., oil per MIL-PRF-16173, Grade 4 for a dry, tack-free finish)

- Visual and functional requirements (smooth matte black, no smut, threads must gauge)

- Performance criteria (e.g., salt spray or humidity test duration)

- Documentation (certificate of conformance, batch process records)

Here’s a reusable template you can adapt for your own parts:

Black oxide per MIL-DTL-13924, Class 1; post-treat with oil per MIL-PRF-16173, Grade 4; visual: smooth matte black, no smut; threads fully gauge; verify performance per salt spray test; supplier to provide certificate of conformance and batch process records.

Notice that coating thickness is rarely specified for black oxide itself, since it’s a conversion layer with minimal dimensional change. If black oxide coating thickness is mentioned, it typically refers to the sealant or is tied to functional performance (such as corrosion hours), not a hard numeric value for the oxide layer.

Certification and traceability requirements

How do you ensure every lot meets your standards? For critical automotive applications—especially those requiring PPAP (Production Part Approval Process)—you’ll want to request:

- Lot traceability and process control sheets (bath chemistry, temperature, dwell times)

- Bath maintenance and calibration logs

- Test certificates for corrosion resistance and appearance

- Certificates of conformance for both the black oxide and any post-treatment oil or polymer

- Batch and operator records for every shipment

Including these requirements on your drawing, RFQ, or control plan helps ensure your black oxide coatings are consistent, auditable, and meet both internal and customer requirements. For black phosphate finish or other conversion coatings, similar traceability and documentation practices apply.

With your standards and notes in place, you’re ready to move on to testing and performance evaluation—ensuring every batch of blackened parts delivers on durability and appearance.

Testing Methods and Performance Benchmarks for Black Oxide and Alternatives

Corrosion tests that matter

When you specify a black oxide finish for automotive parts, how do you know it will stand up to real-world conditions? Testing is the answer—but which tests are truly meaningful? For most automotive applications, corrosion resistance is a top concern. That’s why you’ll often see salt spray (fog), humidity, and cyclic corrosion tests used to evaluate black oxide, zinc plating, and phosphate coatings with oil.

Imagine you’re comparing a batch of blackened fasteners to zinc-plated bolts. You’d want to know: how many hours until the first signs of rust? Does the finish hold up after handling or exposure to humidity? Here’s a side-by-side look at how common finishes are tested and what those results mean for your application.

| Finish Type | Test Type | What to Record | Adhesion Test | Wear/Abrasion | Dimensional Impact | Maintenance Needs |

|---|---|---|---|---|---|---|

| Black Oxide (+ Oil/Wax) | Salt spray, humidity | Hours to first red rust (with sealant), appearance rating | Tape pull, bend (rarely fails if clean) | Low abrasion resistance; seal can wear off | Minimal (Approx. 0.00004"–0.00008") | Needs regular re-oiling if exposed |

| Zinc Plating | Salt spray (ASTM B117), cyclic corrosion | Hours to white rust (zinc), then red rust (steel) | Tape, bend, chisel (can flake if thick) | Moderate; better than black oxide | Noticeable (0.0002"–0.001") | Minimal; sacrificial, but can develop white rust |

| Phosphate + Oil | Humidity, salt spray (short duration) | Hours to rust (oil-dependent), appearance | Tape, bend (rarely fails) | Low–moderate; oil helps break-in | Minimal (conversion layer) | Requires oiling; mostly for indoor/assembly use |

Salt spray tests are a quick way to compare corrosion resistance. For black oxide, the results depend almost entirely on the sealant—unsealed, black oxide offers only basic protection. When properly oiled or waxed, it can resist rust for a moderate period, but not as long as zinc plating. Phosphate coatings with oil are similar: their performance hinges on the quality and retention of the oil layer.

Adhesion and wear evaluation

Ever wondered why some finishes flake or peel while others stay put? Adhesion tests—like tape pulls or bend tests—check that the conversion layer is bonded well to the base metal. Black oxide, being a chemical conversion, rarely fails adhesion unless the surface wasn’t cleaned properly. However, its wear resistance is modest. The blackened layer is thin and can be scratched or worn away, especially if the oil dries out or is removed. In contrast, zinc plating offers better abrasion resistance but can flake if applied too thickly or if the underlying steel is not properly prepared. Phosphate coatings fall in between, providing a good base for break-in but requiring oil for best results.

Comparing black oxide to alternatives

So, which finish is right for your application? Here’s a quick breakdown:

- Black oxide vs zinc plated: Zinc plating provides superior corrosion resistance for outdoor or harsh environments, but adds more thickness and can cause dimensional issues on tight-tolerance parts. Black oxide preserves dimensions and is ideal for interior or less demanding conditions, as long as it’s properly sealed and maintained.

- Black oxide vs black phosphate: Both are conversion coatings with minimal dimensional change. Black oxide offers a darker, more uniform appearance, while phosphate plus oil can aid in break-in and as a paint base. Both rely on oil for corrosion resistance, but phosphate is more often used for initial assembly lubrication.

- Black zinc vs black oxide: Black zinc is essentially zinc plating with a black chromate topcoat—offering better corrosion resistance than black oxide, but with greater dimensional impact and potential for white rust formation.

Interpreting variation: why outcomes differ

Imagine two batches of blackened bolts—one holds up in salt spray for days, the other rusts in hours. Why? Small changes in part geometry, edge preparation, and especially oil choice can swing results dramatically. Sharp edges, rough finishes, or incomplete cleaning can create weak spots where rust forms first. The type and amount of oil or wax used as a sealant are critical—too little, and the finish offers little protection; too much, and assembly may be messy or difficult.

This brings us to a common question: does black oxide rust? The honest answer is yes—if left unsealed, black oxide provides only minimal protection and will rust quickly in humid or corrosive environments. When sealed with oil or wax and stored properly, its corrosion resistance improves significantly, but it still doesn’t match the outdoor durability of zinc plating. That’s why you’ll find black oxide used mainly for indoor, assembly, or low-exposure parts in automotive applications.

Documenting your test plan

To ensure reliable results, always document your test methods, acceptance criteria, and sampling plans in your control plans and PPAPs. This includes specifying which corrosion and adhesion tests to use, the number of samples per batch, and what qualifies as a pass or fail. Clear documentation helps suppliers and engineers align on expectations, reducing surprises down the line.

Next, we’ll explore how post-treatment oils and sealants can make or break the durability and appearance of your blackened automotive parts.

Post-Treatment Oils, Sealants, and Appearance Control for Blackened Metal Finishes

Oils and Sealants for Protection

When you look at a freshly blackened steel bolt or bracket, you might notice a deep, dark metal finish—but what keeps it looking good and protected over time? The answer lies in the post-treatment step. After the black oxide finishing process, the porous magnetite layer needs to be sealed to deliver the corrosion resistance and lubricity automotive engineers expect. This is where oil blackening, waxes, and polymer seals come into play.

Let’s break down the most common options:

- Water-Displacing Oils: These are light oils designed to seep into the blackened layer, pushing out moisture and forming a protective film. They’re quick-drying and ideal for parts that need to be handled or assembled soon after treatment.

- Rust-Preventive Oils: Heavier than water-displacing oils, these provide longer-lasting protection against corrosion. They’re often used for blackened finish steel parts that will be stored or shipped before assembly.

- Waxes: Applying a wax seal creates a semi-dry or dry-to-touch matte black metal finish. This can be especially useful for parts where handling cleanliness is important, or where a low-gloss look is specified.

- Polymer Seals: These advanced sealants form a thin, durable coating over the blackened metal finish, offering improved chemical resistance and sometimes a glossier appearance. They’re used when maximum corrosion protection or specific visual targets are required.

Pros and Cons of Post-Treatment Options

| Sealant Type | Pros | Cons | Typical Appearance |

|---|---|---|---|

| Water-Displacing Oil |

|

|

Matte, low-gloss |

| Rust-Preventive Oil |

|

|

Dark, semi-gloss |

| Wax |

|

|

Matte, uniform |

| Polymer Seal |

|

|

Glossy to matte, depending on formula |

Heavier oils and polymers typically boost corrosion protection but might change the feel or gloss of the blackened steel finish. Lighter oils and waxes keep assembly easy and the look understated, but may require more frequent maintenance—especially if parts are exposed to moisture or handled repeatedly.

Topcoats and Appearance Control

Ever specified a matte black metal finish for an interior fastener, only to find it arrives glossy? The choice of sealant directly affects both the look and the touch of blackened metal parts. Specify your visual and tactile targets up front:

- Matte for low-glare, non-reflective assemblies

- Semi-gloss or gloss for decorative or visible hardware

- Dry-to-touch for clean handling and easy downstream assembly

- Oily for enhanced corrosion protection but with possible assembly challenges

Remember, the blackened finish steel can be tailored to suit both function and style—so be clear in your drawing notes and supplier communications. This ensures your blackened metal finish meets both durability and appearance requirements.

Compatibility with Automotive Fluids

Sounds straightforward? There’s one more twist: not all sealants play nicely with automotive fluids. Brake fluid, engine oil, ATF, coolants, and even car-wash chemicals can degrade certain oils, waxes, or polymers over time. That’s why it’s crucial to validate your chosen post-treatment in the actual fluids and temperature cycles your parts will experience.

- Test fasteners and hardware for torque-tension consistency after sealing

- Check for chemical attack, softening, or discoloration in contact with service fluids

- Ensure the final black oxide finishing layer is cleanable and compatible with assembly adhesives or threadlockers

By specifying the right sealant and appearance—and validating compatibility with all relevant automotive fluids—you’ll maximize the performance, longevity, and aesthetics of every blackened part in your design.

Next, we’ll map out common failure modes and troubleshooting steps to ensure your chosen blackened finish steel delivers lasting results in the field.

Troubleshooting Blackening Defects

Visual Symptoms and Root Causes

Ever pulled a batch of blackened bolts from the line and noticed red stains, patchy colors, or a residue that wipes right off? You’re not alone. Even with a quality black oxide process, things can go wrong if the details slip. Let’s map out the most common defects you’ll see after using blackening liquid or running parts through black oxide tanks—and how to fix them.

| Symptom | Likely Cause | Immediate Check | Corrective Action |

|---|---|---|---|

| Red/brown staining after test | Rust before blackening, under-sealing, or overexposure to air | Check pre-cleaning, sealant coverage, transfer time | Improve cleaning, shorten transfer, ensure full oil/wax seal |

| Gray streaks or blotchy black | Poor cleaning, nesting, insufficient agitation | Inspect for oil/grease, check agitation, part spacing | Re-clean, agitate more, avoid part-on-part contact |

| Iridescence (rainbow colors) | Bath temperature too high or low, bath contamination | Measure bath temp, check for contamination | Adjust temperature, refresh blackening liquid |

| Smut/soot residue (wipes off easily) | Over-etching, carbon on surface, excessive pickle time | Check acid dwell, inspect for smut before blackening | Reduce pickle time, add desmut step, re-clean |

| Blistering or poor adhesion of seal | Incomplete rinsing, trapped cleaner, incompatible sealant | Inspect for residue under seal, review rinse protocol | Improve rinsing, verify sealant compatibility, reapply as needed |

| Uneven color at edges or in recesses | Insufficient immersion, poor agitation, geometry trapping chemicals | Check part orientation, agitation, tank loading | Re-orient, agitate, reduce batch size |

| Galled threads or tight fits | Contamination, over-etching, excessive buildup | Gauge threads/bores, inspect for debris | Adjust etch time, clean more thoroughly, monitor bath chemistry |

Bath Control and Maintenance

Imagine your black oxide equipment as the heart of your finishing line. If the bath chemistry drifts, or if the tanks are dirty, even the best operators can’t deliver quality black oxide. Here’s how to keep your blackening process on track:

- Verify cleanliness and rinse quality: Incomplete cleaning leaves oils or smut that block uniform blackening. Always check for water-break-free surfaces before blackening.

- Review bath age and additions: Old or exhausted black oxide concentrate loses effectiveness. Track bath life, top up as needed, and skim/clean tanks regularly.

- Confirm immersion time and agitation: Too little time means incomplete conversion; too much can cause edge effects or color shifts. Agitate parts to avoid nesting and ensure even exposure.

- Audit seal choice and dwell: Use the correct oil, wax, or polymer for your application. Ensure parts stay in the sealant long enough for full coverage.

- Inspect drying and packing conditions: Wet or improperly packed parts can develop rust or streaks. Dry thoroughly before packing, and avoid water entrapment.

- Run witness coupons: Include test pieces in every batch to catch problems before they reach the field.

Consistent monitoring of your black oxide tanks and blackening liquid chemistry is essential. If you notice recurring issues, review recent changes in chemical suppliers, water quality, or black oxide equipment maintenance routines. Reference guides recommend keeping detailed logs for bath temperature, pH (if applicable), and additions to catch trends early.

Rework and Salvage Paths

Not every defect means scrapping the batch. Many blackening process issues can be salvaged if you follow a structured approach:

- Stripping: Remove the defective black oxide layer using an appropriate stripping solution, following all safety and environmental guidelines.

- Re-cleaning: Thoroughly degrease and de-smut parts before reprocessing.

- Re-blackening: Run parts through the full process again, monitoring each step closely.

- Seal and inspect: Apply the correct sealant, dry, and perform a full visual and functional inspection.

- Documentation: Always record rework in lot history and re-test critical performance (e.g., corrosion, fit, and finish).

Remember, rework is only permitted if allowed by your customer’s standards and should never become routine. Persistent issues may signal deeper problems with your blackening liquid or black oxide equipment setup.

In summary, troubleshooting black oxide defects is all about careful observation, tight process control, and a willingness to go back to basics if needed. By following these steps, you’ll deliver quality black oxide finishes batch after batch—setting the stage for strong, reliable automotive parts. Next, we’ll look at how to build a robust sourcing and supplier evaluation strategy for blackening services.

Sourcing Strategy and Supplier Evaluation for Blackening Services

What to Request in RFQs for Black Oxide Coating

When you’re sourcing blackening services for automotive parts, it’s easy to get overwhelmed by technical details and supplier claims. But imagine you’re preparing an RFQ for black oxide bolts or black oxide screws—what information ensures you get exactly what you need? The answer: clarity and completeness. The more precise your request, the better your outcome.

- Applicable standards: Clearly specify the required standards (e.g., MIL-DTL-13924, AMS2485) on your drawing or RFQ. This sets the baseline for process and appearance.

- Part materials and hardness: List the exact material (e.g., 10.9 steel, 304 stainless) and any heat treatment. This helps suppliers choose the right process for your black oxide bolts or other components.

- Target appearance: Specify if you need matte, semi-gloss, or dry-to-touch finishes. Mention if uniformity or color depth is critical.

- Seal type: Indicate your preferred post-treatment—oil, wax, or polymer—based on corrosion resistance and assembly needs.

- Test methods and acceptance criteria: Define required corrosion tests (salt spray hours, humidity), adhesion, and appearance checks.

- PPAP level: State if PPAP (Production Part Approval Process) or similar documentation is required.

- Process control records: Ask for bath chemistry logs, temperature records, and operator traceability for each batch.

- Batch test reports: Request salt spray results, adhesion tests, and appearance certificates.

- MSDS/SDS: Require material safety data sheets for all chemicals used.

- Traceability by lot: Ensure each shipment can be traced back to its process records and operator.

By providing this level of detail, you help suppliers deliver quality black oxide screws and components that meet your exact requirements. This is especially important when searching for black oxide coating near me or evaluating black oxide industries for critical automotive projects.

On-Site Audits and Capability Checks

Ever wondered what really goes on behind the scenes at a blackening supplier? On-site audits are your best tool for verifying that a shop’s capabilities match your needs. Here’s what to look for during a visit:

- Cleanliness and organization of cleaning lines and rinse stations

- Condition of black oxide equipment, tanks, and control panels

- Bath control logs (temperature, chemistry, maintenance records)

- In-line inspection and quality control procedures

- Storage and handling of post-treatment oils, waxes, and sealants

- Packaging and shipping procedures to prevent damage or contamination

Ask to review recent process control records and test reports. If possible, observe a batch of your own parts being processed. This hands-on approach reveals much more than any brochure or website, especially when you’re considering black oxide industries inc or local options for black oxide near me [source].

Integrating Blackening with Upstream and Downstream Operations

Imagine the efficiency gains if your supplier could handle more than just blackening—think machining, stamping, deburring, and even assembly or packing. Fewer handoffs mean less risk of damage, shorter lead times, and easier traceability. When evaluating partners, prioritize those who offer end-to-end solutions with robust quality systems and IATF 16949 alignment. For example, Shaoyi is a proven choice for automakers and Tier 1 suppliers, combining machining, stamping, blackening, and assembly under one roof. Their experience with PPAP documentation and process control ensures your critical components—like black oxide bolts and screws—arrive ready for assembly with full traceability.

When integrating blackening services, consider:

- Upstream operations: Can your supplier source or machine the raw part to spec?

- Deburring and surface prep: Is the finish consistent before blackening?

- Downstream assembly: Will the blackened parts be packed, labeled, or kitted for your line?

- Documentation: Are all process and test records included in the final PPAP or shipment?

Choosing a partner with broad capabilities streamlines your workflow and reduces the risk of missed quality steps. For those needing a full-service solution, suppliers like Shaoyi can help bridge the gap from raw part to finished, black oxide–coated component.

In summary, a robust sourcing strategy for blackening services combines clear RFQ requirements, thorough on-site audits, and integration with upstream and downstream processes. This approach ensures you receive quality, traceable black oxide finishes that meet your automotive durability and assembly needs—setting the stage for informed cost and lifecycle decisions in the next section.

Cost Drivers and Lifecycle Considerations for Black Coated Steel Finishes

What drives per part cost?

When you’re weighing whether to specify a black oxide or alternative black coating on steel, it’s natural to ask: what really determines the price? Imagine two otherwise identical bolts—one is a simple raw steel finish, the other has a sleek black-oxide alloy steel treatment. Why does one cost more? Here’s what typically drives the per-part cost for blackened finishes:

- Part mass and geometry: Larger or more complex parts require more chemical, energy, and handling.

- Cleanliness required: Higher standards for surface prep (removal of oils, rust, or scale) increase labor and chemical use.

- Process route: Hot blackening is generally more efficient for high volumes, while cold or mid-temp processes may be chosen for special alloys or smaller runs—but can be slower and more costly per part.

- Seal type: Heavy-duty oils, waxes, or polymer topcoats add both material and processing time.

- Packing and rust-preventive packaging: Extra care or specialty packaging protects the finish but adds cost.

- Lot sizes: Smaller lots or custom runs may not benefit from economies of scale.

- QA documentation depth: Full traceability, process logs, and test reports (often required in automotive) increase the administrative cost per batch.

You’ll notice that while the black coating on metal itself is relatively thin and uses less material than plating or powder coating, the process is still labor- and documentation-intensive when high reliability is required.

Lifecycle and field performance considerations

Choosing a steel finish isn’t just about upfront cost—it’s about how the part will perform and last. Black oxide finishes are prized for their minimal dimensional impact (typically 0.5–2.5 microns), making them ideal for precision threads, press fits, and sliding components where even a small buildup could cause issues. That’s why black-oxide alloy steel fasteners are common in assemblies demanding tight tolerances.

However, black oxide’s corrosion resistance is modest and highly dependent on regular maintenance and the post-treatment seal. In controlled, indoor environments—like engine compartments or interior fastener locations—black oxide can deliver years of service with periodic oiling. In contrast, zinc plating or phosphate plus oil may be preferred for outdoor or high-humidity settings, where they offer longer rust protection with less frequent maintenance.

- Dimensional stability: Black oxide preserves original part dimensions. Plating and powder coating add measurable thickness, sometimes requiring design adjustments.

- Maintenance of appearance: Black oxide may fade or dull over time, especially if the oil dries out. Phosphate coatings with oil are similar. Zinc can develop white corrosion but generally holds its appearance longer outdoors.

- Rework feasibility: Black oxide can often be stripped and reapplied if a batch fails inspection, whereas plated or powder-coated parts may require more intensive rework or even scrapping.

Ultimately, the right coating for stainless steel or carbon steel hinges on where and how the part will be used—and how much maintenance is practical.

Choosing the right finish mix

Imagine you’re selecting finishes for a batch of seat track pins, engine hardware, and decorative trim. You might use black oxide for the pins (where fit and lubricity matter), phosphate plus oil for break-in gears, and zinc for exposed fasteners. Here’s a quick comparison:

- Black oxide: Best for tight-tolerance, interior, or easily maintained parts. Lowest cost per part, but requires oiling and regular inspection.

- Phosphate plus oil: Good for initial assembly lubrication and moderate corrosion protection. Slightly higher cost, but still minimal dimensional impact.

- Zinc plating: Highest corrosion resistance, especially outdoors, but adds thickness and can affect fit. Higher cost, but less maintenance needed.

For decorative or visible parts, you may also consider powder coating or black anodizing (for aluminum), but these are distinct from conversion coatings like black oxide.

Key takeaway: Always test your finish choices on representative part geometries, with the planned sealant and packaging, to validate both total cost and real-world durability in your supply chain.

By understanding the true cost drivers and lifecycle realities of black oxide, phosphate, and zinc finishes, you’ll be better equipped to make informed decisions that balance budget, performance, and reliability—laying the groundwork for a smooth transition from design to production. Up next, we’ll walk through a practical action plan to help you implement blackening treatments with confidence.

Action Plan and Trusted Partners for Seamless Blackening Treatment Implementation

First 30 Days Action Plan: From Concept to Production

Wondering how to move from a design concept to reliable, production-ready blackened parts? The process might seem daunting, but breaking it down into clear, actionable steps can make all the difference. Whether you’re specifying how to black oxide steel fasteners or exploring stainless blackening for corrosion-critical components, a structured plan ensures consistency and confidence.

- Shortlist Candidate Processes and Seals: Identify which blackening treatment fits your base material—hot black oxide for carbon steel, mid-temp or specialized for black oxide for stainless steel. Consider your durability, appearance, and assembly needs.

- Draft Drawing Notes Referencing Standards: Use industry standards (e.g., MIL-DTL-13924, AMS2485) and specify sealant type, required appearance, and test criteria. This step ensures clear communication with suppliers.

- Define Tests and Sampling: Decide on corrosion, adhesion, and appearance tests, and set sampling plans for each production lot.

- Run Pilot Lots with Witness Coupons: Produce small batches using your chosen process and seal. Include witness coupons for testing and validation—this is especially valuable when evaluating a new black oxide coating kit or transitioning to a new supplier.

- Audit Supplier Process Controls: Review bath logs, operator training, and in-process inspections. If you need end-to-end support—including machining, stamping, and blackening—consider partners like Shaoyi, who offer integrated solutions and IATF 16949 alignment for automotive and Tier 1 needs.

- Lock Packaging Specs: Define how parts should be packed and protected after blackening treatment to prevent damage or contamination.

- Launch with PPAP: Finalize your process with full Production Part Approval Process (PPAP) documentation, ensuring traceability and supplier accountability from the very first shipment.

Specification Template Starter

Need a quick way to communicate your requirements? Use this blockquote as a starting point for your drawings or RFQs:

Black oxide per [standard]; post-treat with [oil/wax/polymer]; visual: uniform matte black; no smut; threads must gauge; verify by [salt spray/test]; supplier to provide batch records and test certificates.

This template ensures all key elements—process, seal, appearance, and test methods—are captured in a single, scannable note.

When to Partner with a Certified Provider

Imagine you’re facing tight timelines, complex part geometries, or stringent documentation requirements. In these cases, working with a certified provider who can handle machining, stamping, and blackening under one roof streamlines your workflow and reduces risk. For those needing rapid prototyping, advanced surface treatment, and assembly with full quality traceability, Shaoyi’s comprehensive services can be a smart choice. Their expertise with PPAP, IATF 16949, and integrated solutions means your blackening treatment is consistent and audit-ready from day one.

By following this step-by-step action plan, using a clear specification template, and partnering with experienced providers when complexity demands, you’ll ensure your black oxide on stainless steel or carbon steel parts meet both durability and quality expectations—ready for the demands of modern automotive engineering.

Frequently Asked Questions About Blackening and Black Oxide Coating

1. What is black metal surface treatment?

Black metal surface treatment, commonly known as black oxide or blackening, is a chemical process that converts the surface of ferrous metals like steel into a thin, stable magnetite layer. Unlike paint or plating, this conversion coating preserves the part’s original dimensions and enhances lubricity, corrosion resistance, and appearance—making it ideal for automotive fasteners, brackets, and precision parts.

2. What are the disadvantages of black oxide coating?

While black oxide coating offers excellent dimensional control and a uniform dark appearance, its primary disadvantage is limited corrosion resistance without post-treatment. The finish itself is porous and relies on oils, waxes, or polymer sealants for protection. Without proper sealing and maintenance, black oxide can rust in humid or harsh environments. Additionally, it’s less durable than thicker coatings like zinc plating for outdoor or high-wear applications.

3. Which chemicals are used in blackening?

Blackening typically uses a chemical bath containing sodium hydroxide, nitrates, and nitrites for steel and iron. These chemicals react with the metal surface to form a magnetite (Fe3O4) layer. For other materials like stainless steel or aluminum, specialized chemistries or alternative processes are required. The choice of chemicals depends on the base material and the desired finish.

4. Does black oxide coating add thickness to parts?

No, black oxide is a conversion coating, not a deposit. The process chemically transforms only the outermost layer of the metal, resulting in a finish typically 1–2 micrometers thick. This minimal change means critical tolerances for threads, bores, and sliding fits are maintained—making black oxide ideal for precision automotive components.

5. When should I choose black oxide over other metal finishes?

Choose black oxide when you need a dark, uniform finish that maintains tight part tolerances, especially for threaded fasteners, pins, and precision hardware. It’s best for interior or low-exposure automotive parts where moderate corrosion resistance is sufficient and where regular oiling or sealing is possible. For high-exposure or outdoor parts, thicker coatings like zinc plating may be more suitable.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —