Unlocking Precision: What Is a Trim Die in Die Casting?

TL;DR

A trim die is a hardened steel tool used in a trim press to precisely cut away excess material—such as flash, runners, and overflows—from a die-cast part. This automated process is a critical finishing step that ensures consistent part quality, significantly reduces manual labor costs, and increases overall production efficiency.

What Is a Trim Die and Its Fundamental Role?

In the world of die casting, creating a perfectly formed part is only half the battle. After a component is ejected from the casting machine, it remains attached to a network of excess metal that must be removed. This is where the trim die plays its essential role. A trim die is a specialized, robust tool, typically made from hardened steel, designed to shear or cut away this unwanted material with high precision. It acts as the finishing touch that completes the die casting package, transforming a rough casting into a near-net-shape part ready for subsequent processes.

The process, known as trimming, occurs immediately after the part has been cast and cooled. The cast component, along with its attached excess metal, is placed into a hydraulic or mechanical trim press where the trim die is installed. The press forces the two halves of the die together, and its sharp, hardened edges precisely shear off the unwanted material. This method stands in stark contrast to manual finishing, which often involves files, grinders, or sanders. While manual deburring can be effective for low-volume runs or prototypes, it is labor-intensive and can lead to inconsistencies between parts, as noted by experts at Kinetic Die Casting.

The primary function of a trim die is to cleanly remove the specific types of excess metal inherent to the high-pressure die casting process. Understanding these materials clarifies the tool's importance:

- Flash: This is the very thin, paper-like sheet of metal that forms when molten metal squeezes out between the two halves of the die casting mold. It's often sharp and must be removed for both safety and part functionality.

- Runners: These are the channels through which molten metal travels from the injection system to fill the cavities of the mold. The solidified metal within these runners must be detached from the final part.

- Overflows: These are small wells or pockets designed into the die to help regulate pressure and ensure the mold cavity is completely filled with metal, preventing defects. Like runners, the solidified metal in these overflows must be trimmed away.

By automating the removal of these elements, the trim die ensures that every part is finished to the same specification, a level of consistency that is difficult to achieve manually. This precision is especially critical for complex parts or those with tight tolerances.

Trim Die Design, Types, and Complexity

Trim dies are not a one-size-fits-all solution; their design and complexity are dictated by the geometry of the part they are intended to finish. A trim die must perfectly mirror the configuration of the die casting die to ensure an accurate cut. As explained by the team at R&S Design, some trim dies require as much attention to detail in their design as the casting tools themselves. The investment in a well-designed trim die, made from high-quality materials, extends its productive life and prevents costly replacements.

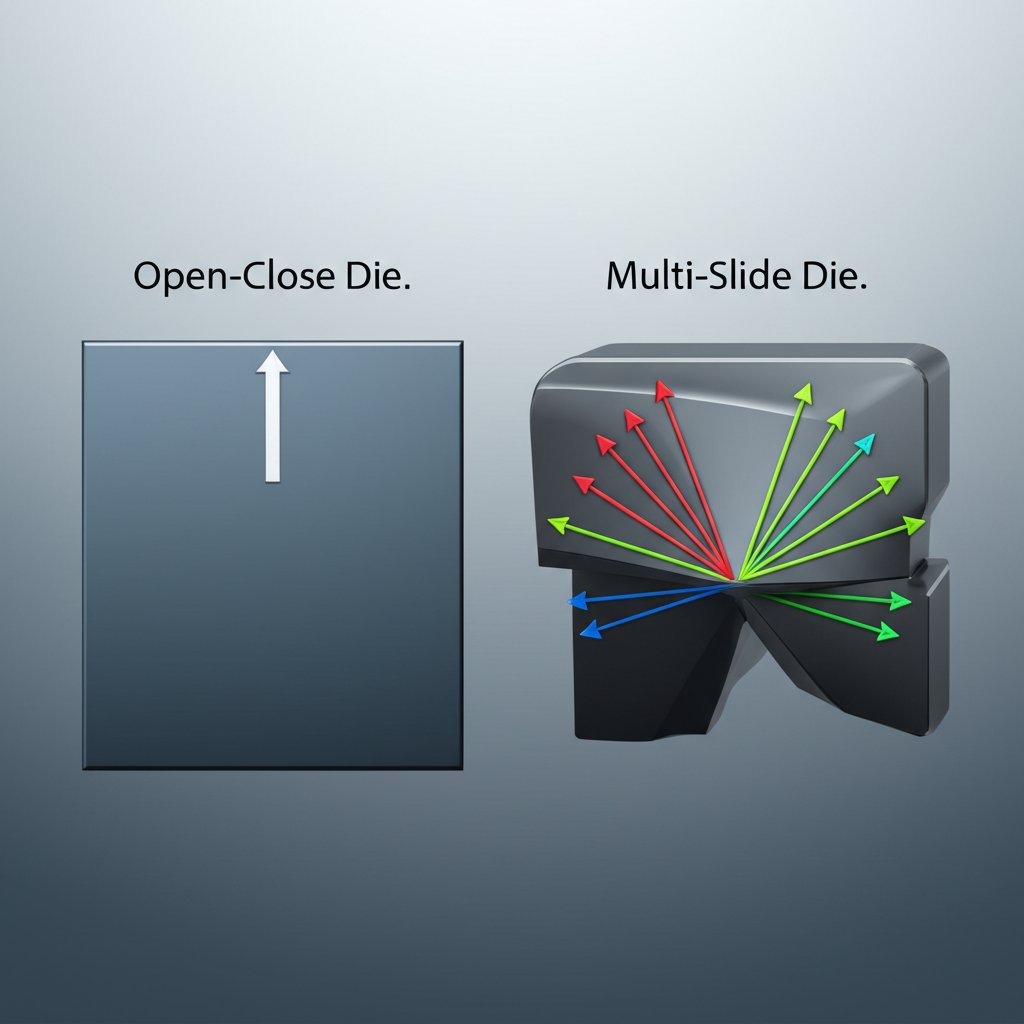

The complexity of a trim die can range from a simple two-piece tool to a sophisticated multi-axis machine. For parts with a flat parting line and no undercuts, a basic open-and-close die is often sufficient. This type of die operates on a simple vertical press motion. However, for more intricate components, the trim die might incorporate slides, cams, or hydraulic cylinders to remove flash from various angles and internal features. In some cases, multiple-station trim dies are used for successive trimming operations on the same part.

Achieving the precision required for modern manufacturing, especially in sectors like automotive, hinges on expert tooling design and robust production processes. For instance, companies specializing in high-performance components leverage in-house die design and rigorous quality control to produce precision-engineered parts that meet stringent standards like IATF16949. This highlights the connection between advanced tooling and final part quality. The decision to use a simple versus a complex trim die often comes down to a trade-off between upfront cost and long-term efficiency, as illustrated below.

| Factor | Simple Trim Die | Complex Trim Die |

|---|---|---|

| Part Geometry | Simple, flat shapes with no undercuts | Complex shapes, undercuts, internal features |

| Die Mechanism | Basic open-and-close function | May include slides, cams, or hydraulic actuators |

| Upfront Cost | Lower | Higher |

| Cycle Time | Fast for simple parts | Slower per cycle, but performs multiple operations at once |

| Ideal Use Case | High-volume production of simple components | Intricate parts where manual trimming is impractical or inconsistent |

Furthermore, a trim die becomes essential under specific conditions. According to Magic Precision, a trim die is particularly necessary when the gates are very strong and difficult to break manually or when they are located near the center of the part, where manual removal could cause damage to the component itself.

The Strategic Benefits: How Trim Dies Impact Cost, Quality, and Efficiency

Investing in a trim die is a strategic decision that delivers significant returns in cost, quality, and efficiency. While it represents an upfront tooling expense, the long-term savings and improvements often far outweigh the initial cost, especially for high-volume production runs. The primary advantage lies in its ability to replace inconsistent and time-consuming manual labor with a fast, repeatable, and precise automated process.

The quality improvement is one of the most compelling benefits. A trim die cuts flash and runners cleanly and consistently, leaving a smooth edge that adheres to tight tolerances. This part-to-part consistency is crucial for components that must fit into larger assemblies. Manual deburring, by contrast, is subject to human error and variation, which can lead to a higher rate of rejected or scrapped parts. A well-made trim die, like those described by Shamrock Industries, is usually manufactured along with a Class 'A' tooling package to ensure the best performance and longevity.

The impact on production efficiency and cost is equally significant. A trim press can cycle in seconds, far faster than any manual process. This speed allows the trimming operation to keep pace with the die casting machine, preventing bottlenecks in the production line and increasing overall throughput. The key advantages can be summarized as follows:

- Cost Savings: Dramatically reduces the need for manual labor for deburring and finishing. It also minimizes material waste by reducing the number of rejected parts, leading to a lower cost per piece.

- Enhanced Quality: Delivers precise, repeatable flash removal for superior part-to-part consistency and improved dimensional accuracy. This leads to better-fitting, more reliable final products.

- Increased Throughput: The rapid cycle time of a trim press is significantly faster than manual finishing, enabling higher production volumes and faster delivery to the customer.

- Improved Safety: Automating the removal of sharp flash and runners reduces the risk of cuts and injuries to workers who would otherwise handle the parts manually.

Ultimately, a trim die is a value-adding tool. For any company involved in medium to high-volume die casting, it transforms a necessary finishing step from a potential bottleneck into a streamlined, cost-effective, and quality-enhancing part of the manufacturing process.

From Rough Casting to Finished Part

A trim die is far more than a simple cutting tool; it is a crucial piece of engineering that bridges the gap between the raw output of a die casting machine and a precision-finished component. By providing a method for removing excess material that is fast, consistent, and accurate, it directly addresses the core manufacturing drivers of quality, cost, and speed. While manual methods have their place in prototyping or very small production runs, the trim die is indispensable for achieving the scale and consistency required by modern industry. Understanding its function, design, and strategic benefits is key to appreciating its vital role in the die casting ecosystem.

Frequently Asked Questions

1. What is the process of trimming in die casting?

Trimming in die casting is the process of removing unwanted excess material—specifically runners, overflows, and flash—from a cast part. This is typically done using a hardened steel trim die installed in a hydraulic or mechanical press. The cast part is placed in the die, and the press actuates, forcing the die's cutting edges to shear the excess material away from the part cleanly and precisely.

2. What are the two main types of die casting?

The two primary types of die casting are hot-chamber and cold-chamber die casting. Hot-chamber die casting is used for alloys with low melting points, like zinc and magnesium, where the injection mechanism is immersed in the molten metal bath. Cold-chamber die casting is used for alloys with high melting points, such as aluminum, where the molten metal is ladled into a "cold" injection chamber for each shot to prevent damage to the machine.

3. Are there different types of dies used in manufacturing?

Yes, in the broader world of manufacturing, dies are tools used to cut or shape material. The two main categories are cutting dies and forming dies. Cutting dies, like a trim die or a blanking die, shear material. Forming dies, such as bending or drawing dies, change the shape of the material without removing stock. The specific design and function depend entirely on the manufacturing process and desired outcome.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —