Cut Costs with Die Casting Cycle Time Reduction Strategies

TL;DR

Reducing die casting cycle time is a critical strategy for lowering production costs and increasing manufacturing throughput. The most effective methods involve optimizing key process parameters like injection speed, cooling systems, and automated part handling. Success hinges on balancing faster cycles with rigorous quality control to prevent defects and equipment strain, ensuring that efficiency gains are not lost to higher scrap rates.

The Business Case: Why Optimizing Die Casting Cycle Time is Crucial

In the highly competitive manufacturing sector, efficiency is paramount. Die casting cycle time—the total duration to produce one part, from mold closing to ejection—is a core metric of productivity. A shorter, optimized cycle directly translates to significant financial and operational advantages. By minimizing the time required for each casting, a facility can increase its output, fulfill more orders with the same equipment, and enhance its overall market competitiveness.

The cycle is composed of several key phases: mold closing, molten metal injection, pressure maintenance, cooling, and finally, mold opening and part ejection. According to industry experts, this entire process typically takes between 20 seconds and one minute. Even small reductions in this timeframe can yield substantial results. For example, as highlighted in an analysis by Sunrise Metal, trimming a 30-second cycle down to 25 seconds allows a single machine to produce 192 additional parts per eight-hour shift. This increase in throughput not only lowers the cost per part but also improves key performance indicators like Overall Equipment Effectiveness (OEE) and On-Time-In-Full (OTIF) delivery.

Optimizing these processes is part of a broader industry trend toward greater efficiency and precision in metal forming. For instance, leaders in related fields, such as Shaoyi (Ningbo) Metal Technology, apply similar principles of process control and engineering excellence to produce high-performance automotive forging parts, demonstrating a shared commitment to manufacturing innovation. Ultimately, the goal is to create a stable, repeatable, and highly efficient production system that maximizes output without compromising quality, securing a stronger position in the global supply chain.

Core Strategies for Cycle Time Reduction: Process Parameter Optimization

The most direct way to shorten die casting cycle time is by fine-tuning the machine's process parameters. These variables control the speed and sequence of the casting operation and offer significant opportunities for optimization. Key areas of focus include the injection process, lubrication, and part extraction, where automation and intelligent control can shave critical seconds off every cycle.

One powerful technique is the use of a prefilling function during the injection phase. As explained by Bruschitech, a prefilling function can be used to make the first phase of injection occur simultaneously with mold closing. This transforms the piston's initial movement from an independent, sequential step into a dependent action, saving time on every cycle. This seemingly minor adjustment can save valuable time on every single part produced.

Automation plays a transformative role, particularly in lubrication and part removal. Manual part pickup can take anywhere from 5 to 12 seconds, a significant portion of the total cycle. In contrast, a robotic arm can perform the same task in as little as 1.5 seconds. Furthermore, modern robots can be programmed to apply the mold release agent (lubricant) while simultaneously handling the part, consolidating two steps into one and further streamlining the process. This not only accelerates the cycle but also improves consistency and reduces the risk of human error.

To implement these strategies effectively, operators and engineers should consider the following actionable steps:

- Implement a prefilling function if the die casting machine supports it to overlap the initial injection phase with mold closing.

- Automate part extraction using robotics to drastically reduce pickup time and improve repeatability.

- Optimize robot trajectories by analyzing movements to eliminate any unnecessary or inefficient paths.

- Integrate automated lubrication with fixed nozzles or robotic sprayers to ensure consistent application in the shortest possible time.

- Fine-tune mold opening and closing speeds to be as fast as possible without causing excessive wear or damage to mold components.

Advanced Thermal Management: The Key to Faster Cooling

Within the die casting cycle, the cooling phase is often the longest and presents the greatest opportunity for time reduction. This stage, where the molten metal solidifies within the mold, can account for more than half of the entire process. Therefore, optimizing thermal management—the efficient extraction of heat from the casting—is a critical lever for boosting productivity.

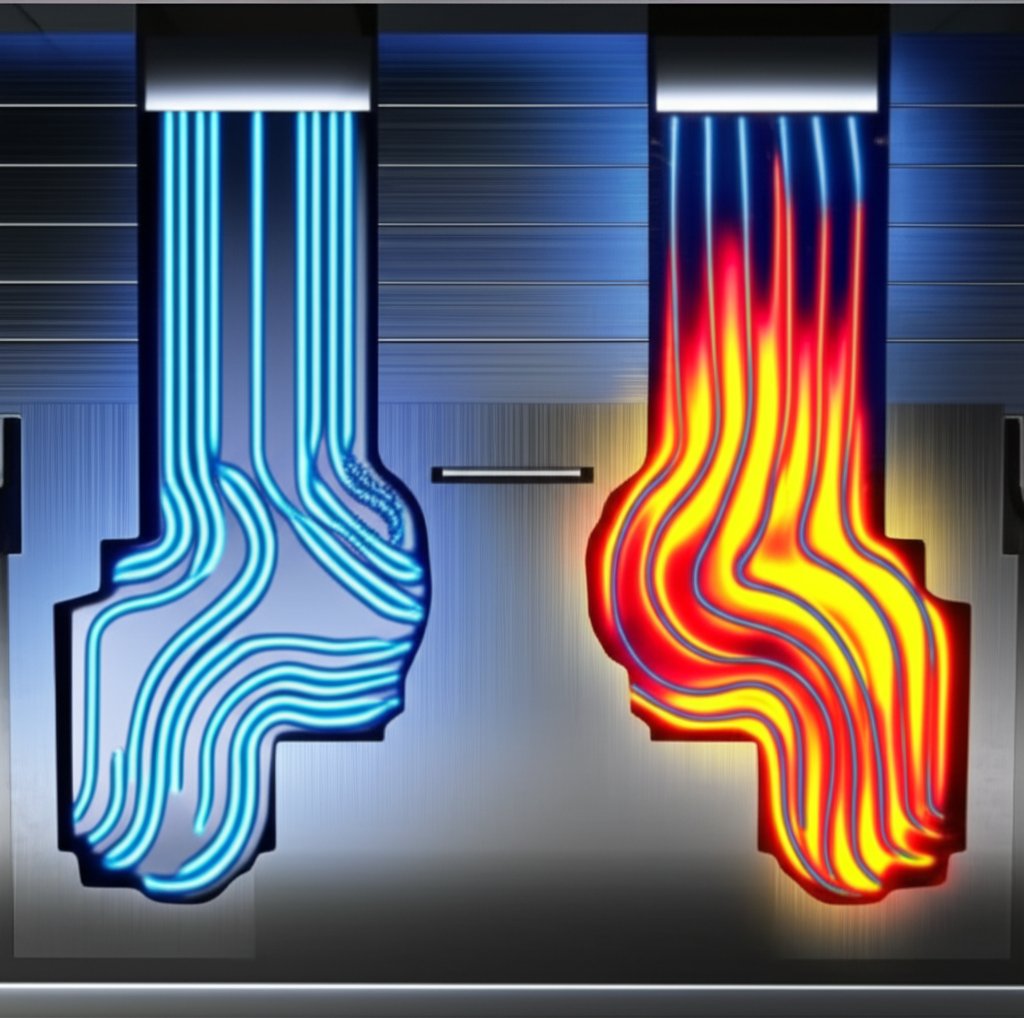

The primary method for controlling mold temperature is a thermoregulation system that circulates a fluid, typically water or oil, through channels within the die. By lowering the temperature of this fluid or increasing its flow rate, heat can be drawn away from the casting more quickly, accelerating solidification. However, traditional cooling channels, which are typically drilled in straight lines, often struggle to cool complex geometries uniformly. This can lead to hotspots that extend the required cooling time and may even cause defects like warping or thermal stress.

A more advanced solution is conformal cooling, which utilizes channels that follow the contours of the casting itself. This approach, often made possible through Additive Manufacturing (AM), ensures more uniform and efficient heat dissipation, especially in critical or hard-to-reach areas. A case study by voestalpine demonstrates the powerful impact of this technology. By redesigning a distributor's cooling system with conformal channels, they achieved a 4-second reduction in cycle time (from 73 to 69 seconds). This optimization not only increased throughput but also lowered the scrap rate and extended tool life by reducing thermal stresses on the mold.

The Role of Simulation in Proactive Cycle Time Optimization

In modern manufacturing, proactive optimization is far more effective than reactive troubleshooting. Casting process simulation software has become an indispensable tool for achieving this, allowing engineers to design, test, and refine the die casting process in a virtual environment before any metal is poured. This digital approach helps identify potential problems and optimize parameters for both quality and speed from the very beginning.

Simulation software, such as MAGMASOFT®, can model the entire casting process, from the flow of molten metal into the die to its solidification. It can predict issues like turbulence, air entrapment, and the formation of hotspots—all of which can lead to defects and longer cycle times. By visualizing these phenomena, engineers can redesign gating systems, optimize cooling channels, and adjust process parameters to create a more efficient and stable process before cutting the first piece of steel for the mold.

A compelling case study from MagmaSoft involving manufacturer PT Kayaba illustrates the immense value of this approach. By using simulation to optimize the gating system for a front fork component, they achieved remarkable results. The new design reduced turbulence and eliminated a hotspot, leading to a cascade of benefits: the casting yield increased by 18.5%, the total shot weight was reduced, and the cycle time was cut by 10%. Beyond the time savings, these improvements also enhanced the mechanical properties of the part and led to annual cost savings of approximately US $40,000. This demonstrates that simulation is not just a tool for preventing defects, but a powerful driver of comprehensive process optimization.

The Quality Compromise: Balancing Speed with Defect Prevention

While the pursuit of a shorter cycle time is a primary goal, it should never come at the expense of part quality or equipment longevity. An overly aggressive approach to speed can be counterproductive, leading to an increase in scrap rates and costly downtime that negates any potential gains. As experts from Shibaura Machine caution, focusing on the correct execution of each process step is ultimately more important for time-cost savings than simply trying to move as fast as possible.

Each phase of the die casting cycle has a minimum required duration to ensure a quality outcome. For instance, insufficient cooling time can cause the part to deform or crack upon ejection. Likewise, if the pressure holding time is too short, the casting may suffer from internal porosity as the metal shrinks during solidification. Pushing the mechanical elements of the machine, such as the mold opening and closing mechanisms, too quickly can cause damage to slides and pins, leading to expensive repairs and unscheduled maintenance.

The true objective is not the absolute shortest cycle, but the most stable, repeatable, and optimized one. A process that produces a high rate of defects is inefficient, regardless of its speed, because the cost and time associated with scrap and rework must be factored in. Therefore, when implementing changes to reduce cycle time, it is crucial to monitor quality control metrics closely. A sudden increase in the scrap rate is a clear indicator that the process has been pushed beyond its stable operating window. A balanced approach that prioritizes both speed and quality will always yield the best long-term results.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —