Magnesium Die Casting: The Key to Lighter Auto Parts

TL;DR

Magnesium die casting is a manufacturing process that produces exceptionally strong and lightweight metal components with a superior strength-to-weight ratio. This technology enables a significant weight reduction of 30-75% compared to parts made from steel or aluminum. For the automotive industry, this makes magnesium die casting for lightweight auto parts a critical strategy for improving fuel efficiency, enhancing vehicle performance, and extending the range of electric vehicles.

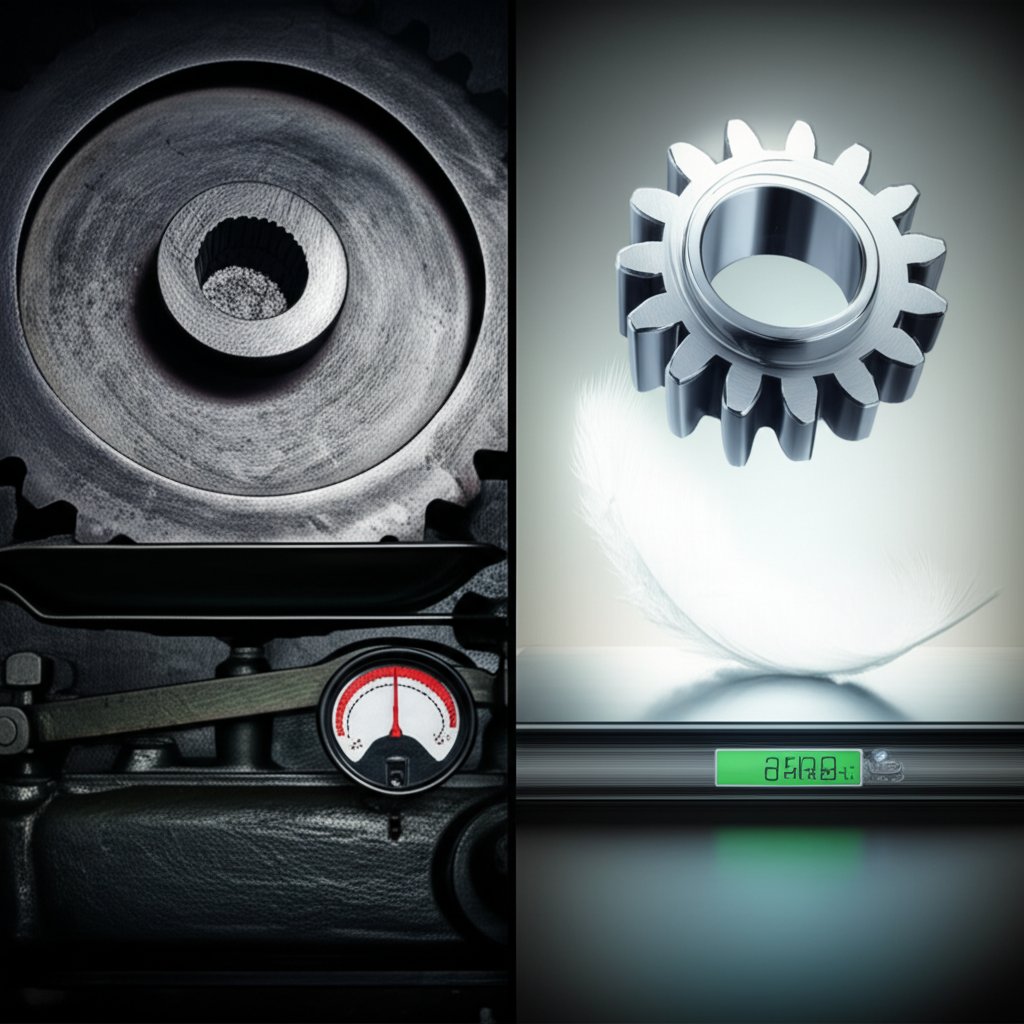

The Core Advantage: Unpacking the High Strength-to-Weight Ratio

The primary reason engineers and designers turn to magnesium die casting is its remarkable strength-to-weight ratio. Magnesium is the lightest of all structural metals, about 33% lighter than aluminum and 75% lighter than steel. This low density does not come at the expense of strength, allowing for the creation of components that are both robust and featherlight. This unique combination is the cornerstone of modern lightweighting strategies in demanding industries like automotive and aerospace.

This advantageous ratio means that a magnesium part can provide the same level of strength as a heavier aluminum or steel counterpart but with significantly less mass. For automotive applications, this translates directly into tangible performance gains. A lighter vehicle requires less energy to accelerate and stop, leading to improved fuel economy in traditional vehicles and extended battery range in electric vehicles (EVs). Furthermore, reducing the overall vehicle mass enhances handling, agility, and braking performance, creating a safer and more responsive driving experience.

The benefits of magnesium's high strength-to-weight ratio are quantifiable. As noted by industry experts, replacing steel or aluminum components with magnesium can reduce a part's weight by anywhere from 30% to 75%. For example, using magnesium for components like transmission cases, steering wheel frames, and seat structures contributes to a substantial reduction in the vehicle's total curb weight. According to Dynacast, a global manufacturer of precision die-cast components, this makes magnesium alloys an ideal choice for applications where durability cannot be sacrificed for weight savings.

The Magnesium Die Casting Process Explained

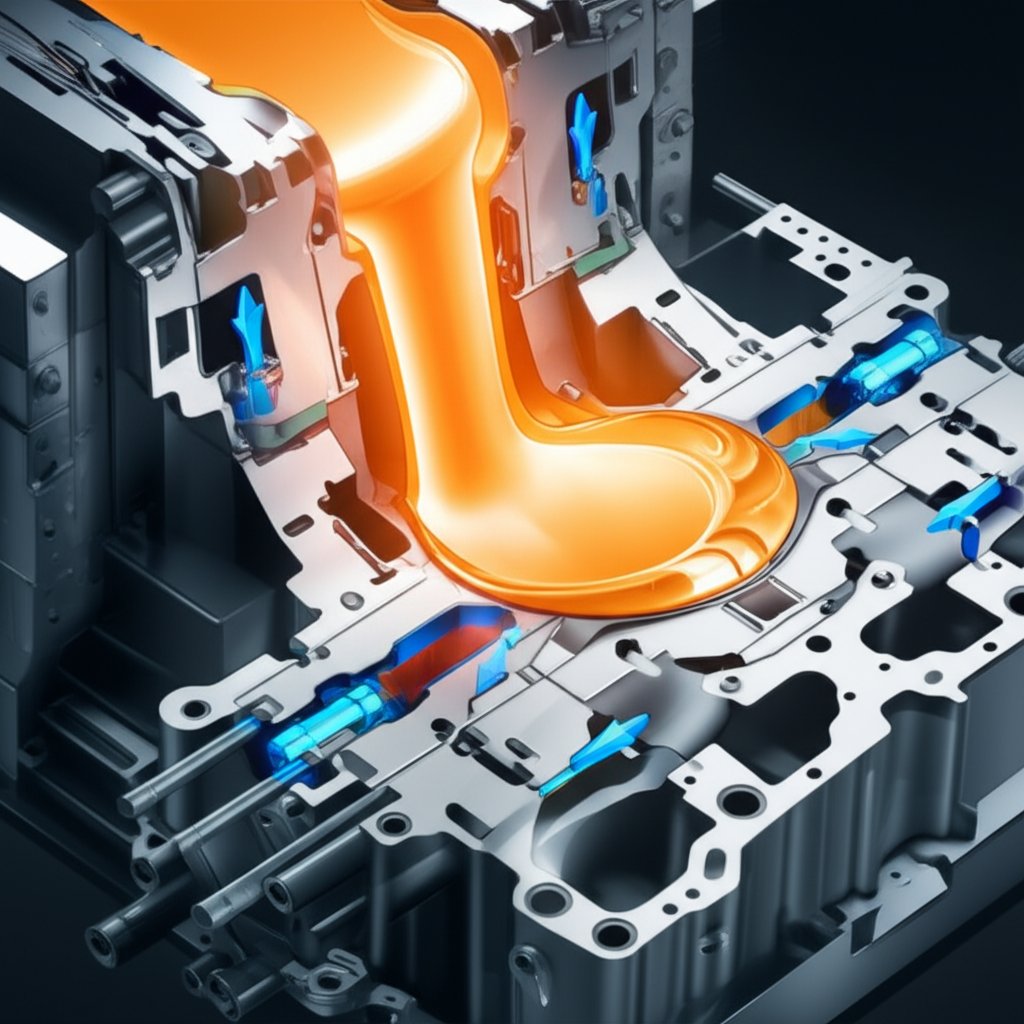

Magnesium die casting is a highly efficient process for producing complex, near-net-shape parts with high precision and excellent surface finish. The most common method used for magnesium is High-Pressure Die Casting (HPDC), which is valued for its speed and ability to create intricate geometries with thin walls. The process involves injecting molten magnesium alloy into a hardened steel mold, or die, under immense pressure.

The manufacturing cycle is rapid and precise, making it suitable for high-volume production. The key stages of the cold-chamber HPDC process, which is one method used for magnesium, can be broken down as follows:

- Melting: High-purity magnesium alloy ingots are melted in a separate furnace. A protective gas is used to prevent oxidation, a critical step given magnesium's reactivity.

- Ladling: A precise amount of molten magnesium is transferred from the furnace into the shot sleeve of the die-casting machine.

- Injection: A hydraulic plunger forces the molten metal from the shot sleeve into the die cavity at extremely high speed and pressure. This ensures the entire mold is filled quickly and uniformly, capturing fine details.

- Solidification: The molten magnesium cools and solidifies rapidly within the water-cooled die, taking the shape of the part.

- Ejection: Once solidified, the die opens, and ejector pins push the finished casting out. The part, along with any excess material (known as flash or runners), is then removed.

This process, as detailed by service providers like Xometry, allows for the creation of parts with exceptional dimensional accuracy and stability, often minimizing the need for extensive secondary machining. The speed of the cycle, combined with the longevity of the dies, makes HPDC a cost-effective solution for producing thousands of identical parts for the automotive sector.

Magnesium vs. Aluminum and Steel: A Head-to-Head Comparison

Choosing the right material is a critical decision in automotive engineering, involving a careful balance of weight, strength, cost, and performance characteristics. While steel and aluminum have long been the industry's go-to materials, magnesium offers a compelling alternative, especially when lightweighting is the top priority. However, this advantage comes with specific trade-offs that engineers must consider.

Magnesium's most significant advantage is its low density, making it the lightest structural metal available. This leads to substantial weight savings over both aluminum and steel. While aluminum is also considered a lightweight material, magnesium is approximately one-third lighter. This difference is crucial in applications like EV battery enclosures or interior support structures where every kilogram saved extends vehicle range. Steel, while strong and inexpensive, is significantly heavier, making it a target for replacement in modern vehicle design.

However, the decision is not based on weight alone. Aluminum alloys generally offer higher absolute strength and better corrosion resistance than standard magnesium alloys. Magnesium is more susceptible to galvanic corrosion, requiring protective coatings and careful design to prevent issues when in contact with other metals. Cost is another factor; magnesium production is more energy-intensive, which can make it a more expensive raw material than aluminum. Below is a table summarizing the key trade-offs:

| Property | Magnesium (e.g., AZ91D) | Aluminum (e.g., A380) | Steel |

|---|---|---|---|

| Density (Weight) | Lowest (Approx. 1.8 g/cm³) | Low (Approx. 2.7 g/cm³) | High (Approx. 7.8 g/cm³) |

| Strength-to-Weight Ratio | Excellent | Very Good | Good |

| Corrosion Resistance | Fair (Requires coating) | Good to Excellent | Poor (Requires coating) |

| Cost | Higher | Moderate | Low |

| Castability (Complex Shapes) | Excellent | Very Good | Not typically die cast |

While die casting is ideal for creating complex, lightweight shapes, other manufacturing methods are chosen for different requirements. For instance, for critical components where ultimate strength and fatigue resistance are paramount, processes like hot forging are employed. Companies specializing in precision-engineered automotive forging parts offer another route to robust, high-performance components, showcasing the diverse material processing landscape available to automakers.

Automotive Applications: From Powertrain to Interior Components

The unique properties of die-cast magnesium have led to its adoption in a wide array of automotive components where weight reduction provides a clear competitive advantage. Automakers leverage this material to improve everything from fuel economy to vehicle dynamics. The applications span across the entire vehicle, from the engine bay to the passenger cabin.

In powertrain systems, magnesium is used for components that benefit from being both light and rigid. Transmission cases, clutch housings, and engine blocks are prime examples. A lighter powertrain reduces the overall vehicle weight and can also improve weight distribution, leading to better handling. As the industry shifts towards electric vehicles, magnesium is becoming even more critical for parts like motor housings and battery enclosures, where minimizing weight is essential for maximizing driving range.

Inside the vehicle, magnesium provides structural support without adding unnecessary bulk. Common interior applications include:

- Instrument Panel Beams: These large, complex structures support the dashboard, steering column, and airbags. Using magnesium allows for a strong, one-piece design that is significantly lighter than a multi-part steel assembly.

- Steering Wheel Cores: The inner frame of a steering wheel must be strong and rigid for safety. Magnesium provides this strength while keeping the steering assembly light and responsive.

- Seat Frames: Lightweighting seats reduces the vehicle's overall mass and can make them easier to adjust. Magnesium frames offer the necessary durability to meet stringent safety standards.

- Center Console Brackets: Magnesium is used for various support brackets and housings within the center console, contributing to incremental but important weight savings.

Magnesium is also used for structural and body components like radiator supports, subframes, and door inner frames. By strategically replacing heavier materials in these areas, car manufacturers can achieve their lightweighting goals without compromising on the safety or structural integrity of the vehicle.

Frequently Asked Questions

1. Is magnesium good for car parts?

Yes, magnesium is excellent for many car parts, especially when the primary goal is to reduce weight. Its high strength-to-weight ratio makes it ideal for components like steering wheel cores, instrument panel supports, seat frames, and transmission cases, leading to improved fuel efficiency and vehicle handling.

2. Can magnesium be die casted?

Absolutely. Die casting, particularly high-pressure die casting (HPDC), is one of the most common and efficient methods for manufacturing magnesium parts. The process allows for the creation of complex, thin-walled components with high precision and at a rapid pace suitable for mass production.

3. What is the disadvantage of magnesium alloy?

The main disadvantages of magnesium alloys include lower corrosion resistance compared to aluminum and a higher material cost. It requires protective coatings to prevent galvanic corrosion, especially when in contact with other metals. It also has lower absolute strength and ductility compared to some aluminum alloys and steel.

4. Why use magnesium instead of aluminum?

The primary reason to choose magnesium over aluminum is for superior weight savings. Magnesium is approximately 33% lighter than aluminum, so when reducing mass is the most critical design factor—such as in aerospace or high-performance vehicles—magnesium is often the preferred choice despite its higher cost and need for corrosion protection.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —